Method for preparing copper-aluminum-copper compound board

A composite plate, composite plate technology, applied in the direction of chemical instruments and methods, metal rolling, manufacturing tools, etc., can solve the problems such as the bonding strength of the easily oxidized copper/aluminum interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

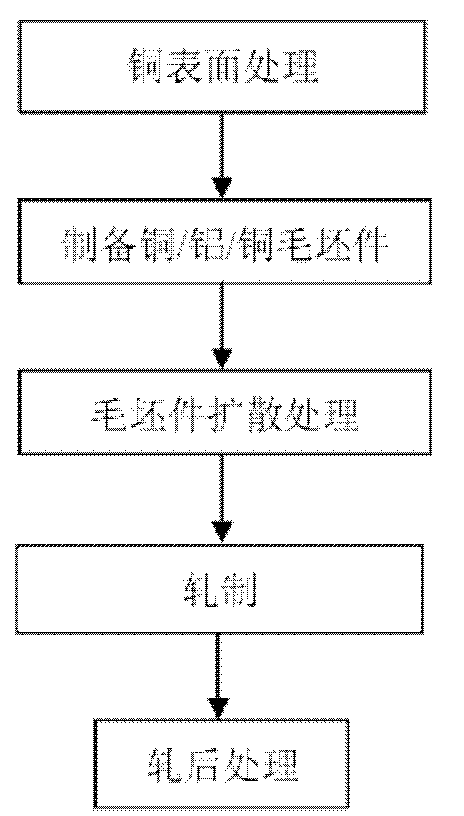

[0020] Such as figure 1 As shown, this embodiment includes the following steps:

[0021] Step 1: Copper surface treatment

[0022] Divide 0.8×50×150mm 3 The annealed HNi65-5 nickel brass is soaked in 10-20% sulfuric acid solution for 4 minutes to remove the oxide film on the surface, then rinse the surface with water and dry it. Sand the surface with a rolling brush.

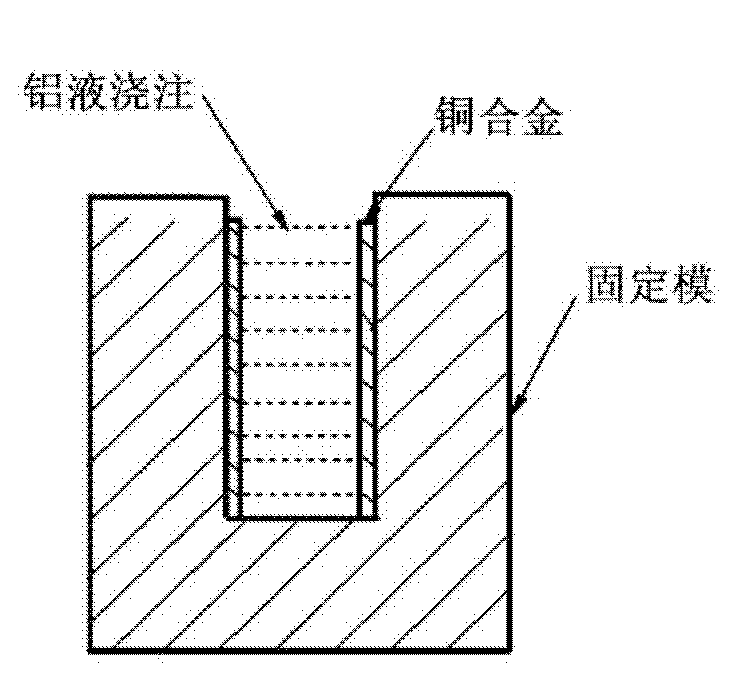

[0023] Step 2: Preparation of copper-aluminum-copper three-layer board blank

[0024] Prepare a simple fixed mold, as attached figure 2 . Fix the polished nickel-brass alloy on two parallel surfaces of the fixed mold, and the distance between the copper alloys is 3 mm. Polish the surface of 1050 industrial pure aluminum, put it into a ceramic crucible, put it into a well-type heat treatment test furnace, and melt it at 760 °C. Cast the molten aluminum into a fixed mold at room temperature, and take out the copper-aluminum-copper three-layer blank after cooling. The prepared blank is placed in an atmosph...

Embodiment 2

[0030] Such as figure 1 As shown, this embodiment includes the following steps:

[0031] Step 1: Copper surface treatment

[0032] 2×50×150mm 3 The annealed HNi65-5 nickel brass is soaked in 10-20% sulfuric acid solution for 4 minutes to remove the oxide film on the surface, then rinse the surface with water and dry it. Sand the surface with a rolling brush.

[0033] Step 2: Preparation of copper-aluminum-copper three-layer board blank

[0034] Prepare a simple fixed mold, as attached figure 2 . Fix the polished nickel-brass alloy on two parallel surfaces of the fixed mold, and the distance between the copper alloys is 20 mm. Polish the surface of 1050 industrial pure aluminum, put it into a ceramic crucible, put it into a well-type heat treatment test furnace, and melt it at 760 °C. Cast the molten aluminum into a fixed mold at room temperature, and take out the copper-aluminum-copper three-layer blank after cooling. The prepared blank is placed in an atmosphere-prot...

Embodiment 3

[0040] Such as figure 1 As shown, this embodiment includes the following steps:

[0041] Step 1: Copper surface treatment

[0042] 1.5×50×150mm 3 The annealed HNi65-5 nickel brass is soaked in 10-20% sulfuric acid solution for 4 minutes to remove the oxide film on the surface, then rinse the surface with water and dry it. Sand the surface with a rolling brush.

[0043] Step 2: Preparation of copper-aluminum-copper three-layer board blank

[0044] Prepare a simple fixed mold, as attached figure 2 . Fix the polished nickel-brass alloy on two parallel surfaces of the fixed mold, and the distance between the copper alloys is 13 mm. Polish the surface of 1050 industrial pure aluminum, put it into a ceramic crucible, put it into a well-type heat treatment test furnace, and melt it at 760 °C. Cast the molten aluminum into a fixed mold at room temperature, and take out the copper-aluminum-copper three-layer blank after cooling. The prepared blank is placed in an atmosphere-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com