Method for preparing cross-linking waterborne adhesive for lithium ion batteries

A lithium-ion battery, water-based binder technology, applied in the directions of adhesives, secondary batteries, battery electrodes, etc., can solve the problems of low bonding strength, lack of elasticity, etc., and achieves simple preparation method, low cost, and wide sources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Solubility Experiment of GA-PAA Crosslinked with Hydroxyl-containing Small Molecules

[0044] (1) Firstly, 1g of GA-PAA (molecular weight: 400,000-1,000,000) was dissolved in 10ml of deionized water (DI-Water) in advance, and fully stirred under an argon atmosphere for 0.5-2.5 hours to drive off oxygen to obtain uniformity and good dispersibility solution; the stirring speed is 100-500 rpm;

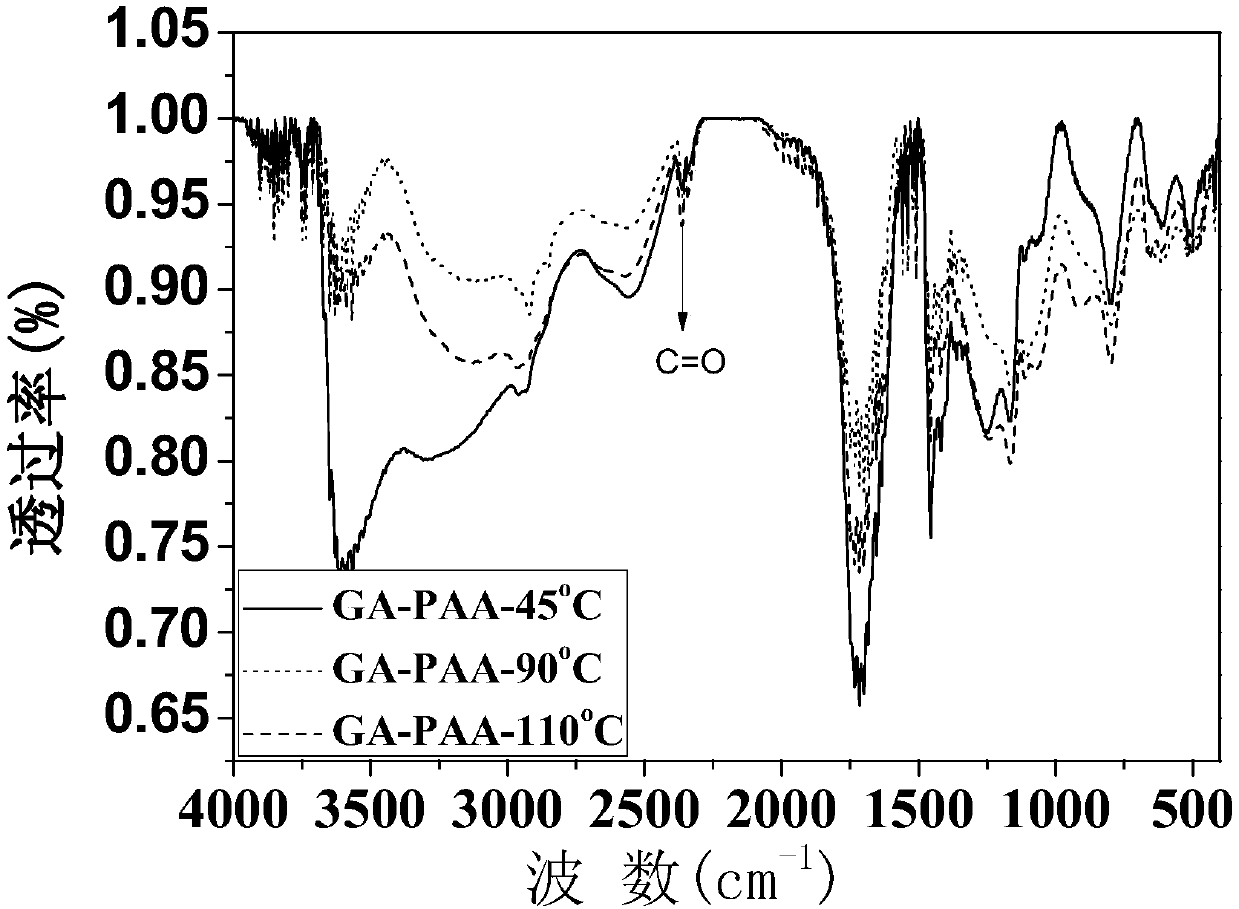

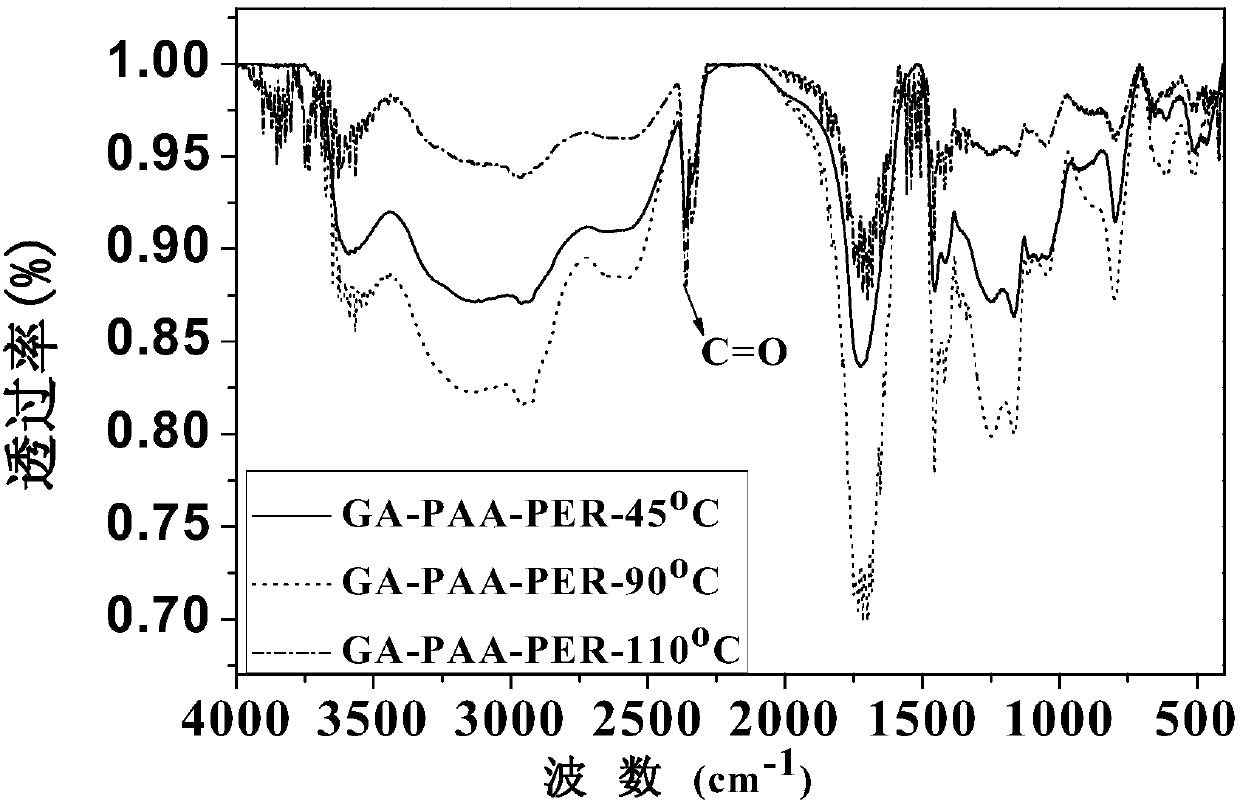

[0045] (2) Add one or more of ethylene glycol, glycerol, and pentaerythritol (OH:GA-PAA=1:10 molar ratio) to the solution obtained in step (1), and stir fully to obtain a mixed solution; vacuum temperature Esterification reaction at 45°C, 90°C, and 110°C for 1-24h, then dissolve in a certain quality of water respectively, and observe the dissolution status.

Embodiment 2

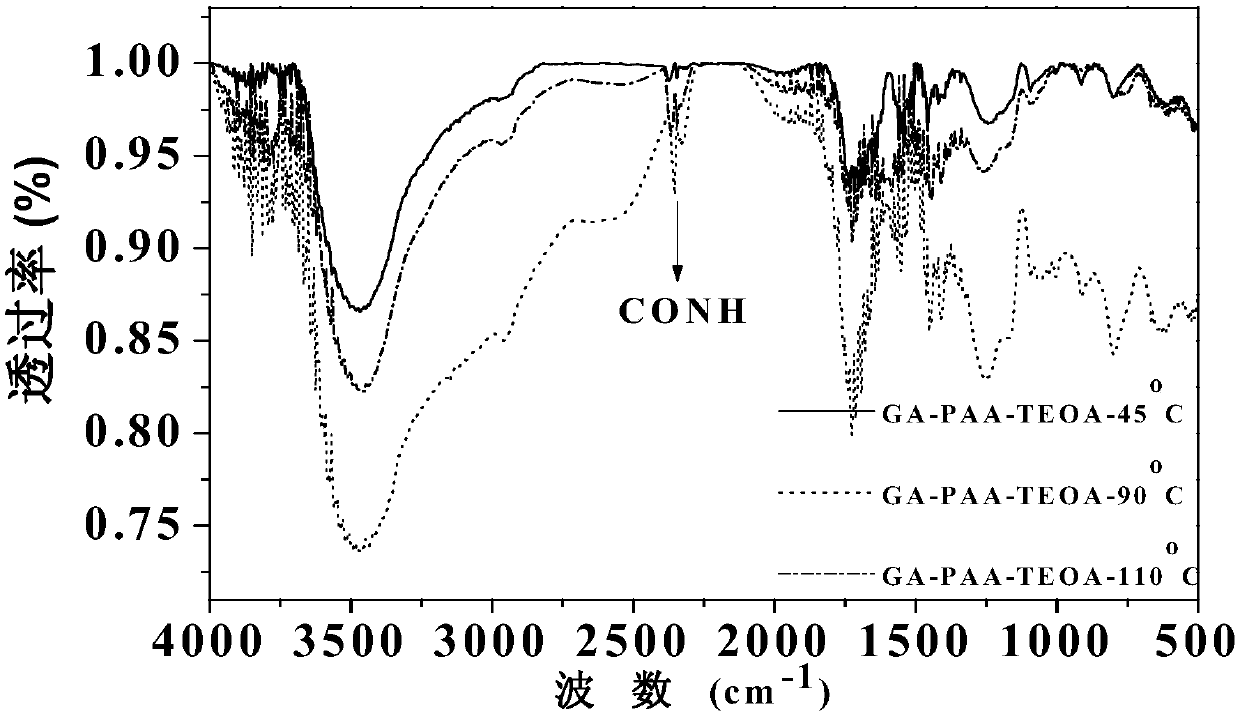

[0047] Referring to Example 1, the difference lies in step (2): add triethanolamine and other amine group-containing small molecule cross-linking agents into the solution obtained in step (1), undergo amidation reactions at different temperatures, and observe its dissolution.

Embodiment 3

[0049] Referring to Example 1, the difference lies in step (2): adding a hexamethoxymethylmelamine (HMMM) crosslinking agent into the solution obtained in step (1), and performing esterification treatment at different temperatures. Observe its dissolution.

[0050] It can be seen from Examples 1-3 that GA-PAA can be completely dissolved at 45-90°, and cross-linking and swelling will occur when heated above 110°. When pentaerythritol (PER), triethanolamine (TEOA) or hexamethoxymethylmelamine (HMMM) is added to the GA-PAA system, it can be completely dissolved by heating at 45°, and cross-linking will occur when the temperature rises to 90° or above swelling phenomenon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength value | aaaaa | aaaaa |

| Peel strength value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com