Polyurethane structural adhesive as well as preparation method and application thereof

A structural adhesive, polyurethane technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of low bonding strength, and achieve the effects of fast curing rate, simple preparation method and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

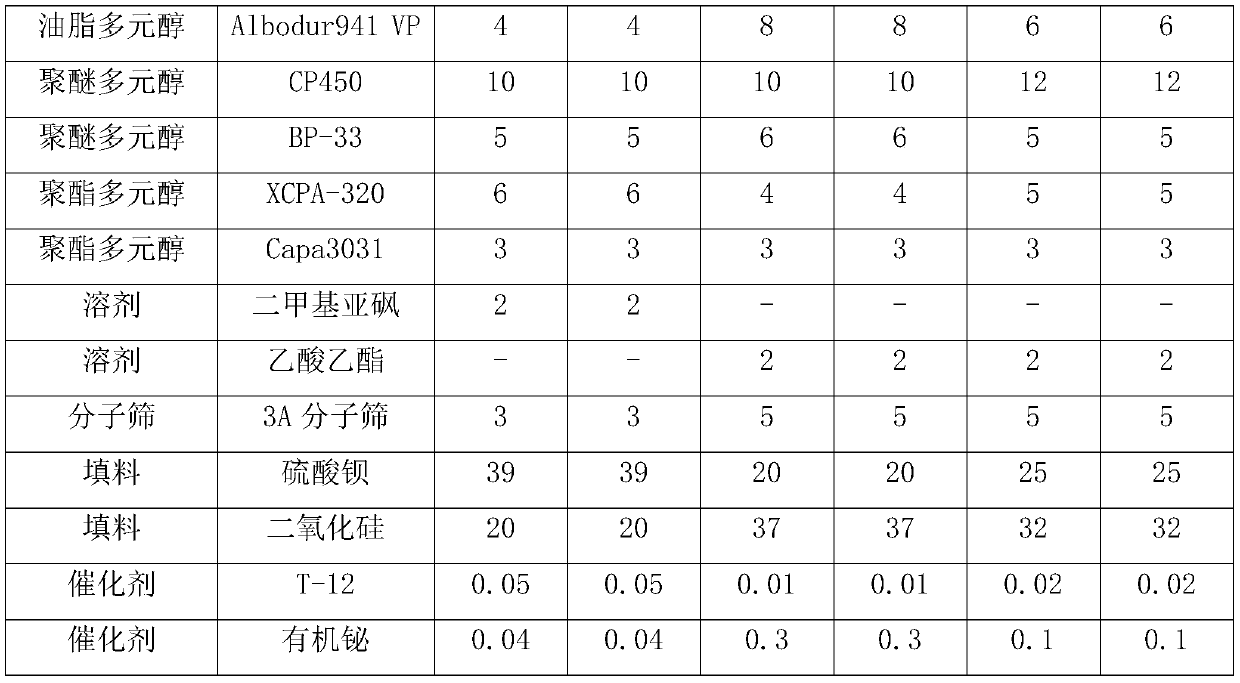

Embodiment 1

[0046] A polyurethane structural adhesive, comprising A component and B component, wherein the B component is a curing agent, and the A component includes the following raw materials: grease polyol, polyether polyol, polyester polyol, Solvent, molecular sieve, filler, catalyst; Wherein, described grease polyol is common castor oil (8kg) and hydrogenated modified castor oil Albodur941 VP (4kg) of Nanjing Jinhaiwei Chemical Industry Co., Ltd.; Described polyether polyol is CP450 (10kg) and BP-33 (5kg); Described polyester polyol is XCPA-320 (6kg) and Capa3031 (3kg), and described solvent is dimethyl sulfoxide (2kg), ethyl acetate (0kg); The filler is barium sulfate (57kg), silicon dioxide (2kg), and the catalyst is one or more of organometallic catalysts or tertiary amine catalysts, specifically the model of the American Air Chemical Company is T-12 Dibutyltin dilaurate product (0.05kg) and organic bismuth catalyst (0.04kg) of Changzhou Kairui Chemical Technology Co., Ltd. are u...

Embodiment 2

[0053] Compared with Example 1, except in the B component, the polymethylene polyphenyl polyisocyanate is Suprasec 2211 (0kg) and B1011 (30kg), and the preparation method of the polyurethane prepolymer (30kg) Yes: Weigh 0129M (20kg) and WANNATE 1635 (50kg), add common castor oil (15kg) and mix evenly, then add vacuum refined polyol 3MCPG (5kg) and CP450 (10kg) while stirring. Vacuumize the prepolymerization reaction, measure the isocyanate group content to reach the end point, then add phosphoric acid (0.02kg) and mix evenly after cooling down to obtain the polyurethane prepolymer. The vacuum refining conditions are: control the vacuum degree from -0.095 to -0.098MPa, The temperature is 105°C to 110°C, and the vacuum degree of the prepolymerization reaction is -0.090 to -0.098MPa. The inorganic powder is nano-active calcium (28kg) and silicon dioxide (2kg), and the molecular sieve is 3A molecular sieve (10kg), and the others are the same as in Example 1.

Embodiment 3

[0055] A polyurethane structural adhesive, comprising A component and B component, wherein the B component is a curing agent, and the A component includes the following raw materials: grease polyol, polyether polyol, polyester polyol, Solvent, molecular sieve, filler, catalyst; Wherein, described grease polyol is common castor oil (5kg) and hydrogenated modified castor oil Albodur941 VP (8kg) of Nanjing Jinhaiwei Chemical Industry Co., Ltd.; Described polyether polyol is CP450 (10kg) and BP-33 (6kg); Described polyester polyol is XCPA-320 (4kg) and Capa3031 (3kg), and described solvent is dimethyl sulfoxide (0kg), ethyl acetate (2kg); The filler is barium sulfate (55kg), silicon dioxide (2kg), and the catalyst is one or more of organometallic catalysts or tertiary amine catalysts, specifically the model of the American Air Chemical Company is T-12 Dibutyltin dilaurate product (0.05kg) and organic bismuth catalyst (0.04kg) of Changzhou Kairui Chemical Technology Co., Ltd. are u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com