Manufacturing method of copper-aluminum composite board

A copper-aluminum clad plate and manufacturing method technology, applied in the direction of roll speed control, temperature control, metal rolling, etc., can solve the problems of low copper-aluminum bonding strength, danger, complicated process, etc., to avoid surface oxidation and increase surface activity. energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

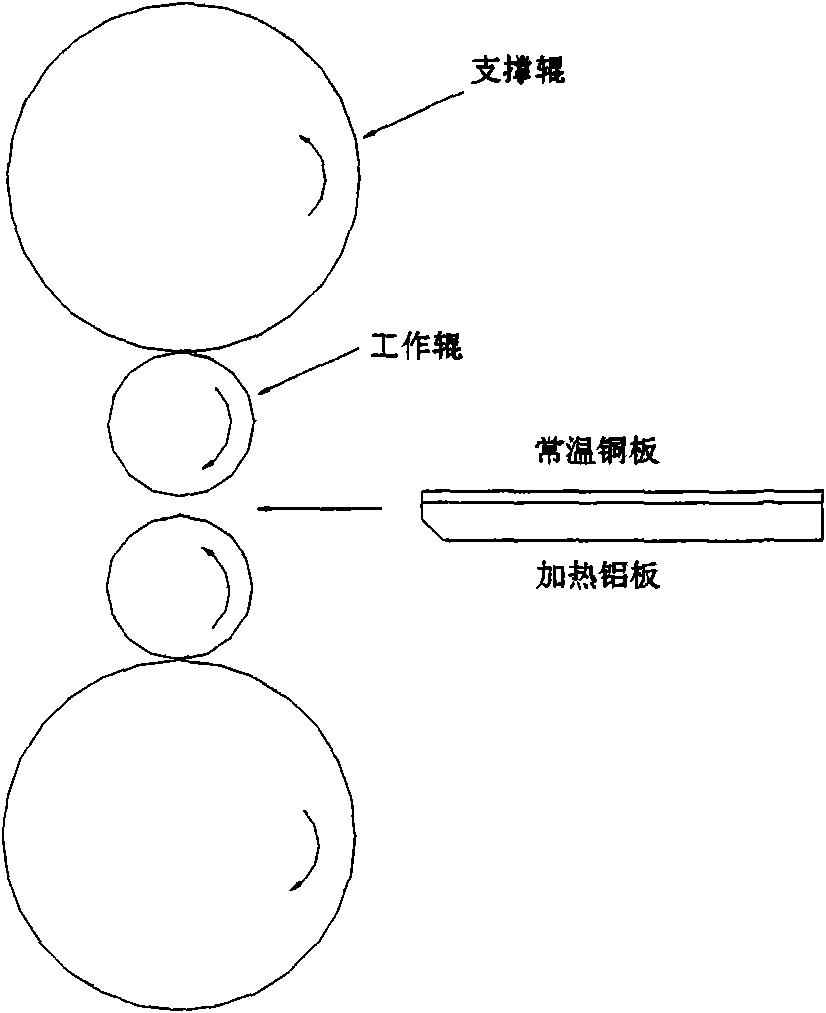

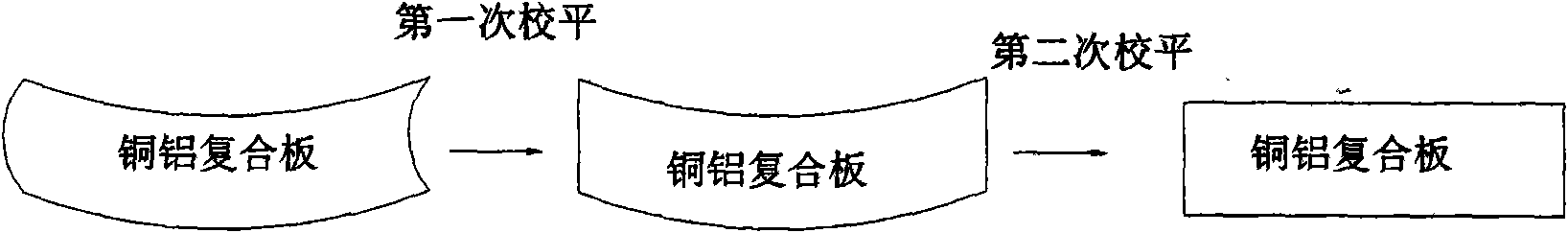

[0017] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0018] The invention discloses a method for manufacturing a copper-aluminum composite panel. The method comprises the following steps:

[0019] Step 1, pre-processing;

[0020] Hang the soft pure copper plate of δ0.7×430×360 on the pre-treatment line for degreasing and degreasing treatment; including: degreasing tank-hot water tank-cold water tank-neutralization tank-cold water tank-drying tunnel Dry process processing.

[0021] Put the soft pure aluminum plate of δ3.0×430×360 into a box furnace, heat it to 350-420 degrees, and carry out degreasing treatment for half an hour.

[0022] Raw materials used in this embodiment: industrial pure copper plate (soft state) with Cu≥99.9%, industrial pure plate (soft state) with Al≥99.6%. According to the different thickness of the required product, the thickness of the raw material is selected: copper Cu is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com