Manufacturing method of wear-proof coating

A wear-resistant coating and wear-resistant material technology, applied in the field of preparation of wear-resistant coatings, can solve the problems of poor surface precision, low bonding strength between wear-resistant metal coatings and substrates, etc., so as to improve wear resistance and improve bonding Strength, the effect of improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

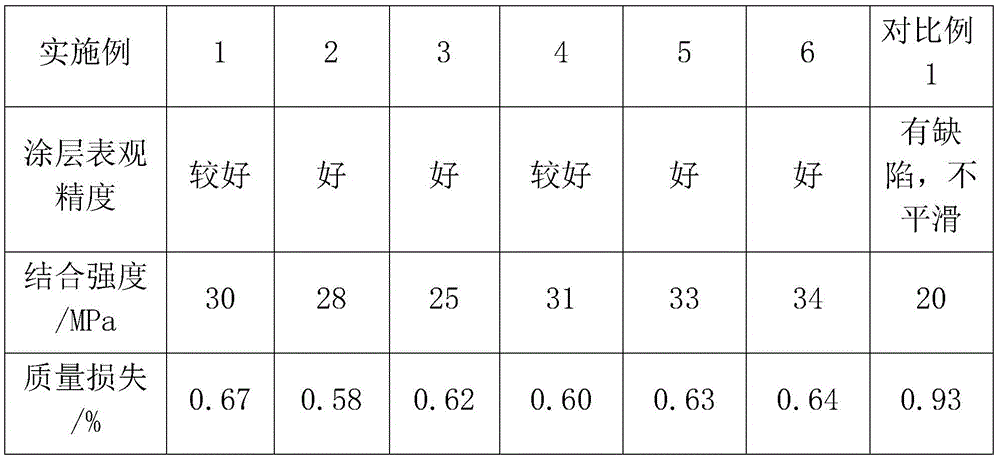

Examples

Embodiment 1

[0022] This embodiment provides a method for preparing a wear-resistant coating, comprising the following steps:

[0023] Step A: corrode and derust the surface of the steel plate, roughen it by sand blasting, and design a reaction combustion chamber;

[0024] Step B: spraying nickel-chromium alloy on the surface of the roughened steel plate;

[0025] Step C: pressing iron oxide powder and aluminum powder with a mass ratio of 2.9:1 into blocks, and placing them on the above-mentioned sprayed steel plate, and then putting them into the combustion chamber together;

[0026] Step D: preheating the steel plate, and then igniting to initiate a self-propagating high-temperature synthesis reaction;

[0027] Step E: Spray the wear-resistant alloy on the surface of the product by thermal spraying process.

[0028] Composite materials with good bonding strength and wear resistance requirements can be prepared by the above method.

Embodiment 2

[0030] This embodiment provides a method for preparing a wear-resistant coating, comprising the following steps:

[0031] Step A: corrode and derust the surface of the steel plate, roughen it by sand blasting, and design a reaction combustion chamber;

[0032] Step B: Spraying and spraying aluminum bronze on the surface of the roughened steel plate;

[0033] Step C: pressing iron oxide powder and aluminum powder with a mass ratio of 2.9:1 into blocks, and placing them on the above-mentioned sprayed steel plate, and then putting them into the combustion chamber together;

[0034] Step D: preheating the steel plate, and then igniting it to initiate a self-propagating reaction;

[0035] Step E: Spray nickel-chromium alloy on the surface of the product by thermal spraying process.

[0036] Composite materials with good bonding strength and wear resistance requirements can be prepared by the above method.

Embodiment 3

[0038] This embodiment provides a method for preparing a wear-resistant coating, comprising the following steps:

[0039] Step A: corrode and derust the surface of the steel plate, roughen it by sand blasting, and design a reaction combustion chamber;

[0040] Step B: Spraying FeNiCrBSi on the surface of the roughened steel plate;

[0041]Step C: pressing iron oxide powder and aluminum powder with a mass ratio of 2.9:1 into blocks, and placing them on the above-mentioned sprayed steel plate, and then putting them into the combustion chamber together;

[0042] Step D: preheating the steel plate, and then igniting to initiate a self-propagating high-temperature synthesis reaction;

[0043] Step E: Spray wear-resistant ceramics on the surface of the product through a thermal spraying process.

[0044] Composite materials with good bonding strength and wear resistance requirements can be prepared by the above method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com