Bonding reinforced modified material and application thereof in wet joint concrete of steel-concrete composite bridge deck

A modified material and concrete technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of low bond strength of wet joint concrete, large early tension and shrinkage creep, unsuitable early strength, etc., to achieve Reduce crack sensitivity, enhance toughness and interface resistance to crack propagation, and improve volume stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

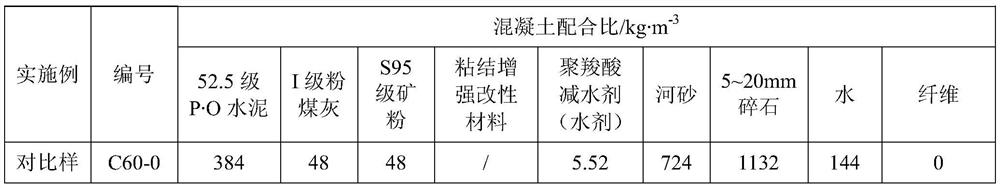

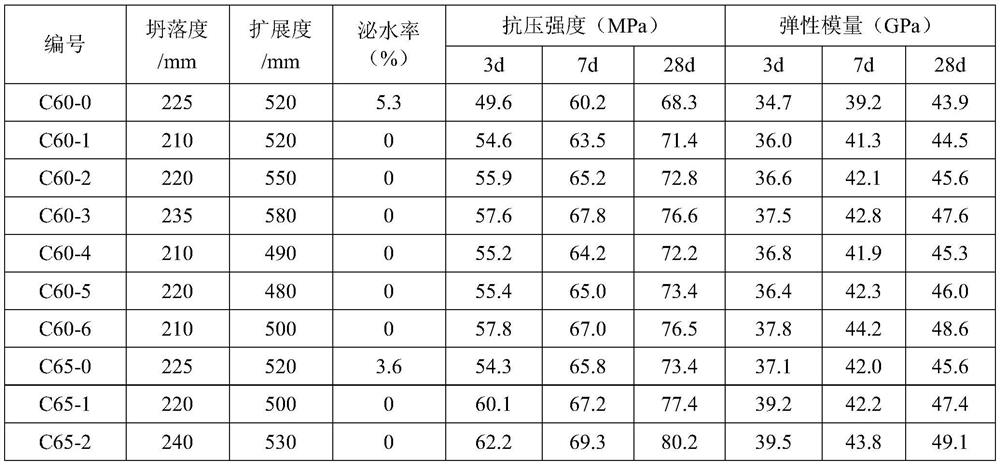

Embodiment 1

[0042] A bonding reinforcement modified material for steel-concrete composite bridge deck wet joint concrete, which is composed of the following components by mass percentage: expansion component 64.0%, silica fume 27.0%, early strength group 1.5%, thickening and toughening component 3.5%, water-reducing component 2.23%, shrinkage-reducing component 1.3%, viscosity-increasing and water-retaining component 0.15%, defoamer 0.32%.

[0043] In this example, the expansion component is ZY-I concrete expansion agent, the expansion source is calcium sulfoaluminate, the 7d limit expansion rate in water is 0.031%, and the 21d limit expansion rate in water is 0.004%. Other performance indicators meet the technical requirements of "Concrete Expansive Agent" GB / T 23439-2017; the specific surface area of silica fume (BET method) is 20.4m 2 / g, SiO 2 The content is 87.9%, the 7d activity index is 110%, and other performance indicators meet the requirements of "Silicon Fume for Mortar and ...

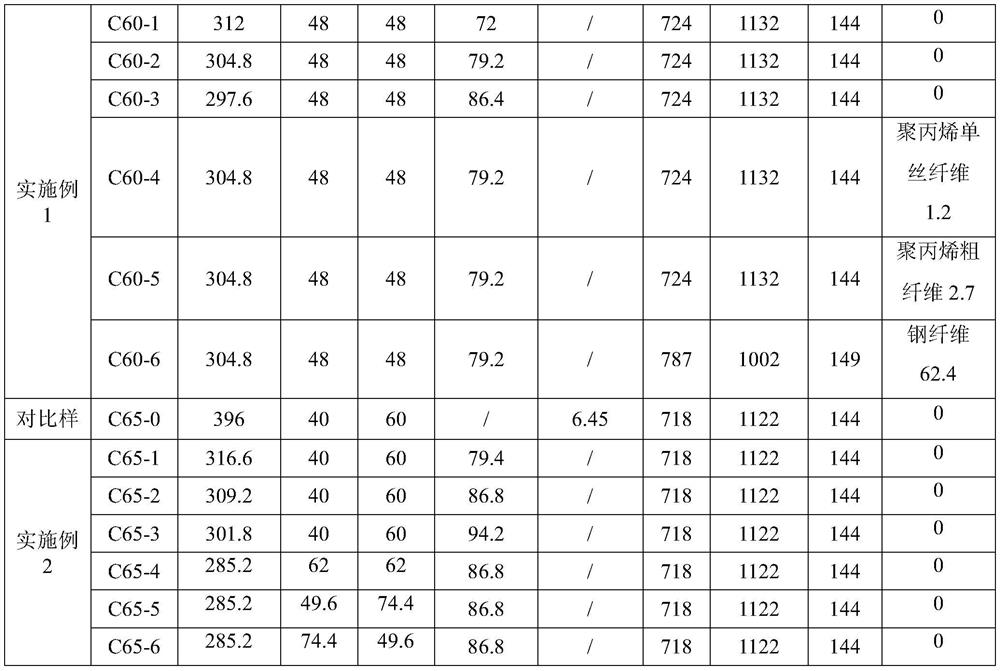

Embodiment 2

[0045] A bonding reinforcement modified material for steel-concrete composite bridge deck wet joint concrete, which is composed of the following components by mass percentage: expansion component 62.0%, silica fume 28.5%, early strength group 1.8%, viscosity-increasing and toughening component 3.8%, water-reducing component 2.5%, shrink-reducing component 1.0%, viscosity-increasing and water-retaining component 0.15%, defoamer 0.25%.

[0046] In this example, the expansion component is UEA-I concrete expansion agent, the expansion source is calcium sulfoaluminate, the 7d limit expansion rate in water is 0.031%, and the 21d limit expansion rate in water is -0.006% after 7 days in water , and other performance indicators meet the technical requirements of "Concrete Expansive Agent" GB / T 23439-2017; the specific surface area of silica fume (BET method) is 20.4m 2 / g, SiO 2 The content is 87.9%, the 7d activity index is 110%, and other performance indicators meet the requiremen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com