Solar ultra-white float photo-thermal glass and manufacturing method thereof

A manufacturing method and solar technology, applied in the field of glass, can solve problems such as low transmittance, and achieve the effect of high transmittance and high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

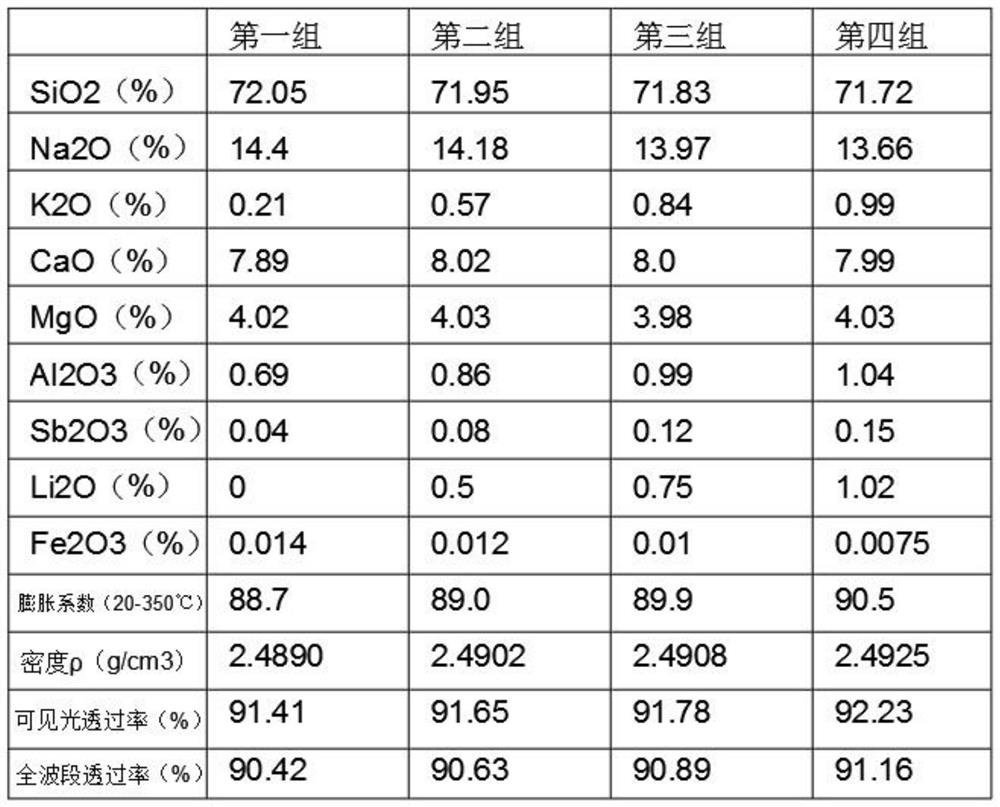

[0061] The proportions of the first group of selected components are as follows:

[0062] SiO2: 72.05wt%

[0063] Na2O: 14.4wt%

[0064] K2O: 0.21wt%

[0065] CaO: 7.98wt%

[0066] MgO: 4.02wt%

[0067] Al2O3: 0.69wt%

[0068] Sb2O3: 0.04wt%

[0069] Li2O: 0wt%

[0070] Fe2O3: 0.014wt%

[0071] The proportions of the components selected in the second group are as follows: SiO2: 71.95wt%

[0072] Na2O: 14.18wt%

[0073] K2O: 0.57wt%

[0074] CaO: 8.02wt%

[0075] MgO: 4.03wt%

[0076] Al2O3: 0.86wt%

[0077] Sb2O3: 0.08wt%

[0078] Li2O: 0.5wt%

[0079] Fe2O3: 0.012wt%

[0080] The third group selected the proportion of each component as follows: SiO2: 71.83wt%

[0081] Na2O: 13.97wt%

[0082] K2O: 0.84wt%

[0083] CaO: 8.0wt%

[0084] MgO: 3.98wt%

[0085] Al2O3: 0.99wt%

[0086] Sb2O3: 0.12wt%

[0087] Li2O: 0.75wt%

[0088] Fe2O3: 0.01wt%

[0089] The fourth group selects the proportions of each component as follows:

[0090] SiO2: 71.72wt%

[0091]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com