A kind of reducer gearbox end cover and preparation method thereof

A gear box and reducer technology, applied in belt/chain/gear, mechanical equipment, transmission parts, etc., can solve the problems of poor heat resistance, poor corrosion resistance, poor shock absorption, etc., to achieve good heat resistance, improve The effect of improving heat resistance and overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

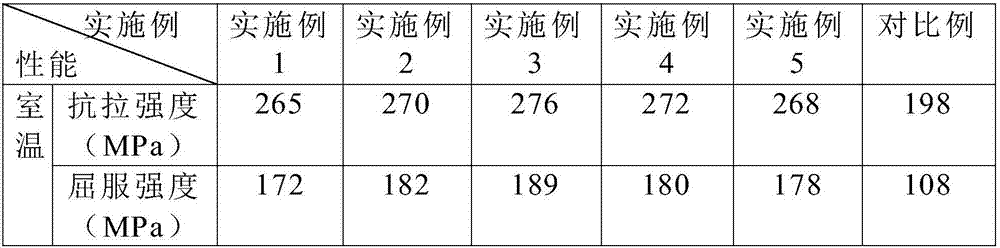

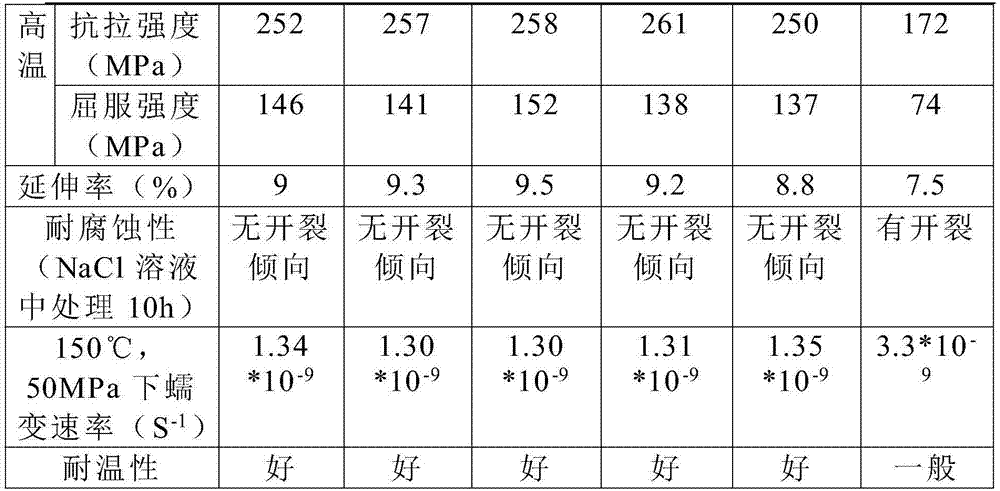

Examples

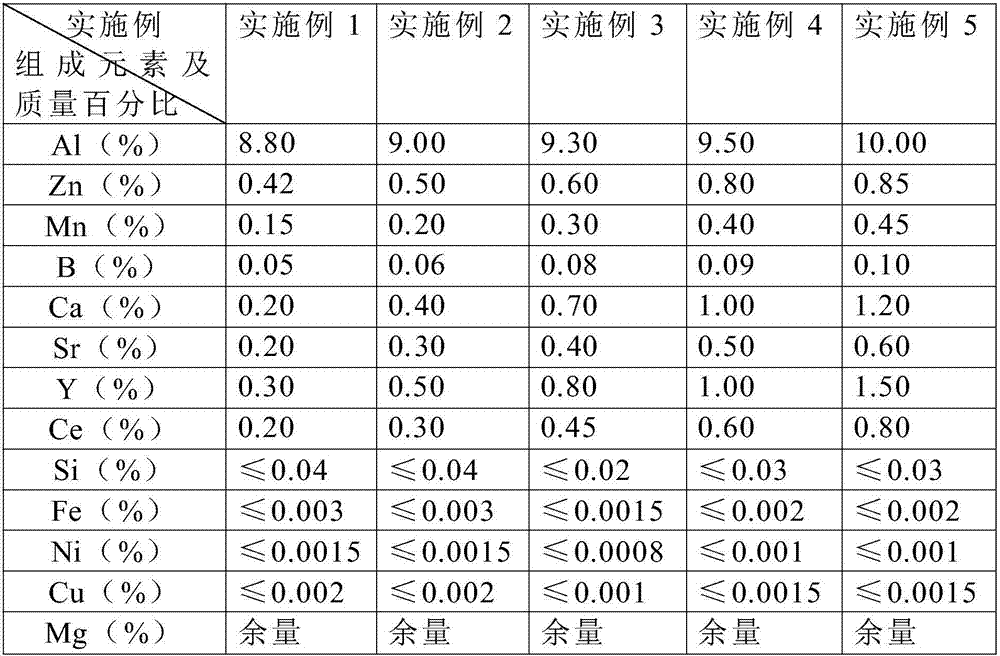

Embodiment 1

[0031] Pre-melting treatment: prepare the charge according to the composition and mass percentage of the end cover of the reducer gear box described in Example 1 in Table 1, preheat the charge to 150°C for later use, and then preheat the crucible at 500°C to dark It is red for later use; among them, the zinc in the charge is electrolytic zinc, the mixed rare earths are Y-rich mixed rare earths and Ce-rich mixed rare earths, the master alloy is an aluminum-manganese alloy with a manganese content of 12%-20%, and a boron content of 8%-12% Aluminum-boron alloys, magnesium-calcium alloys with a calcium content of 15%-20%, and aluminum-strontium alloys with a strontium content of 16%-25%;

[0032] Melting & Refining: In SF 6 +CO 2 Under the protection of mixed gas (SF 6 The volume fraction accounts for 0.2% of the mixed gas), the magnesium ingot in the charge is first added to the crucible, and it is completely melted at 680°C, and then the aluminum ingot, zinc, mixed rare earth ...

Embodiment 2

[0036] Pre-melting treatment: Prepare the charge according to the composition and mass percentage of the end cover of the reducer gear box described in Example 2 in Table 1, preheat the charge to 170°C for later use, and then preheat the crucible to dark at 520°C It is red for later use; among them, the zinc in the charge is electrolytic zinc, the mixed rare earths are Y-rich mixed rare earths and Ce-rich mixed rare earths, the master alloy is an aluminum-manganese alloy with a manganese content of 12%-20%, and a boron content of 8%-12% Aluminum-boron alloys, magnesium-calcium alloys with a calcium content of 15%-20%, and aluminum-strontium alloys with a strontium content of 16%-25%;

[0037] Melting & Refining: In SF 6 +CO 2 Under the protection of mixed gas (SF 6 The volume fraction accounts for 0.35% of the mixed gas), the magnesium ingot in the charge is first added to the crucible, and it is completely melted at 685°C, and then the aluminum ingot, zinc, mixed rare earth...

Embodiment 3

[0041] Pre-melting treatment: according to the composition and mass percentage of the end cover of the reducer gear box described in Example 3 in Table 1, prepare the charge, preheat the charge to 160°C for later use, and then preheat the crucible at 550°C to dark It is red for later use; among them, the zinc in the charge is electrolytic zinc, the mixed rare earths are Y-rich mixed rare earths and Ce-rich mixed rare earths, the master alloy is an aluminum-manganese alloy with a manganese content of 12%-20%, and a boron content of 8%-12% Aluminum-boron alloys, magnesium-calcium alloys with a calcium content of 15%-20%, and aluminum-strontium alloys with a strontium content of 16%-25%;

[0042] Melting & Refining: In SF 6 +CO 2 Under the protection of mixed gas (SF 6 The volume fraction accounts for 0.3% of the mixed gas), the magnesium ingot in the charge is first added to the crucible, and it is completely melted at 680°C, and then the aluminum ingot, zinc, mixed rare earth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com