Novel corrosion resistant antiwear metallic material

A metal material and corrosion-resistant technology, applied in the field of new corrosion-resistant and wear-resistant metal materials, can solve the problems of low wear resistance, high cost of duplex steel, low hardness of duplex stainless steel, etc., and achieve comprehensive corrosion resistance and wear resistance. Increases, reduces production costs, and improves the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The new type of corrosion-resistant and wear-resistant metal material is smelted in an intermediate frequency furnace. The process steps are: (1) After the detected content of scrap steel, pig iron and various ferroalloys are proportioned according to the content of the product, they are heated and smelted in sequence; (2) The temperature rises To 1520°C-1580°C, out of the furnace; (3) Resin sand molding, pouring temperature 1400°C-1450°C; (4) After the casting is cooled, remove the riser, flash, drape, etc.; (5) The casting is in the heat treatment furnace Machining is carried out after annealing treatment; (6) The casting is heated to 1000°C at a certain speed in the heat treatment furnace for air cooling treatment. The metallographic structure of the obtained novel corrosion-resistant and wear-resistant metal material is A+F+alloy carbide, and the hardness range is HRC25-32.

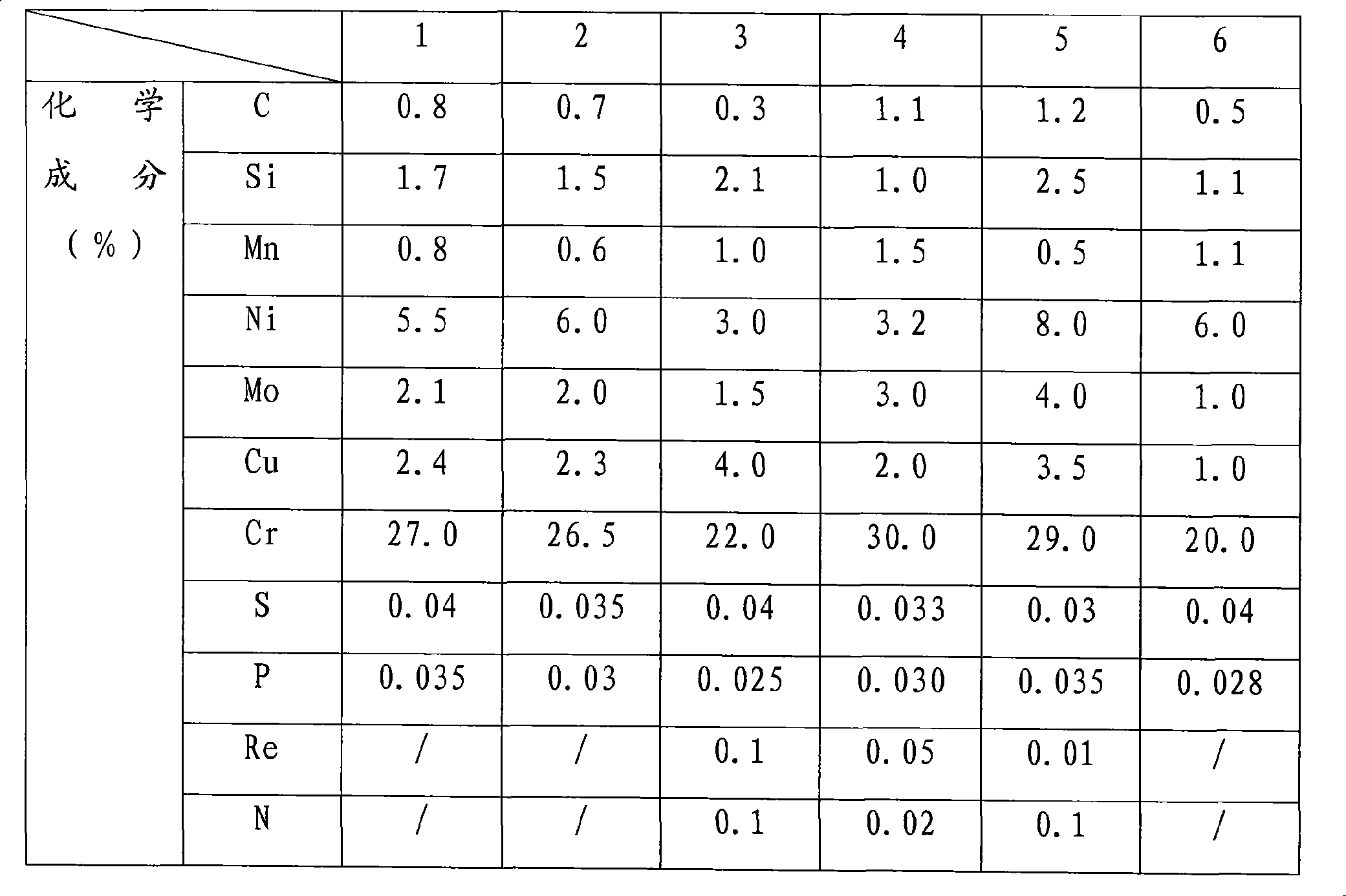

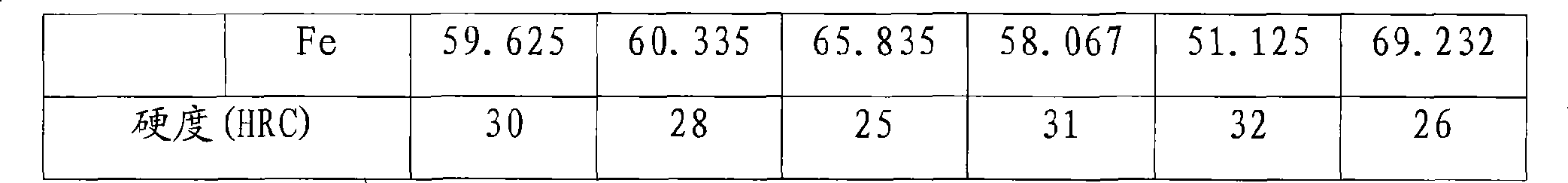

[0019] The chemical composition and hardness results of Examples 1-6 are shown in Table 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com