Electrochemical cell

An electrochemical and battery technology, applied in the field of electrochemical batteries, can solve the problems of negative electrode mechanical damage, charge and discharge efficiency reduction, etc., and achieve the effects of preventing foreign matter concentration, high reliability, excellent charge and discharge efficiency and cycle life characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0094] The positive electrode 30 can be prepared by currently known preparation methods.

[0095] For example, as the preparation method of the positive electrode 30, it can be enumerated that the positive electrode active material is mixed with the positive electrode conductive aid and / or the positive electrode binder as needed to form a positive electrode mixture, and the positive electrode mixture is press-molded into an arbitrary shape such as a film. Methods. For example, the positive electrode 30 can be formed by mixing an arbitrary solvent with a positive electrode mixture to prepare a slurry, coating it on a current collector, and performing compression molding after drying.

[0096] The positive electrode current collector 31 is not particularly limited, and conventionally known positive electrode current collectors can be used. For example, as the positive electrode current collector 31 , an aluminum foil made of aluminum alloy or pure aluminum may be mentioned.

...

Embodiment 1

[0150] In Example 1, first, as an electrochemical cell, prepare as figure 1 (a)~(c) The laminate type nonaqueous electrolyte secondary battery shown. It should be noted that, in this embodiment, SiO is used as the negative electrode active material to prepare a non-aqueous electrolyte secondary battery.

[0151] First, SiO powder as the negative electrode active material, graphite as the conductive agent, and polyvinylidene fluoride as the binder were mixed (45:40:15 by mass ratio), and then dispersed in N-methyl -Preparation of negative electrode mixture slurry in 2-pyrrolidone.

[0152] Next, the negative electrode mixture slurry is evenly coated on both sides of a copper foil with a thickness of 20 μm, and after drying, it is compressed and molded with a roll press to prepare a negative electrode sheet (a negative electrode sheet in which a negative electrode is laminated on a negative electrode current collector. body). The thickness of the negative electrode sheet wa...

Embodiment 2~5

[0163] [Reference example 1~9]

[0164] In Examples 2 to 5 and Reference Examples 1 to 9, for the preparation conditions of the battery in Example 1, the coating thickness of the negative electrode mixture slurry was changed, SiO as the negative electrode active material, graphite as the conductive agent, Changes in the storage state (storage container, storage place, storage period) of polyvinylidene fluoride as a binder or their mixture, or changes in the environment where the mixing is performed, prepare negative electrodes.

[0165] Next, the same measurement as above was performed using transmission X-ray analysis and fluorescent X-ray analysis, thereby confirming negative electrodes having various numbers of foreign substances.

[0166] Then, using these negative electrodes, batteries were assembled in the same manner as in Example 1 above, and the capacity retention rate was measured by the same method.

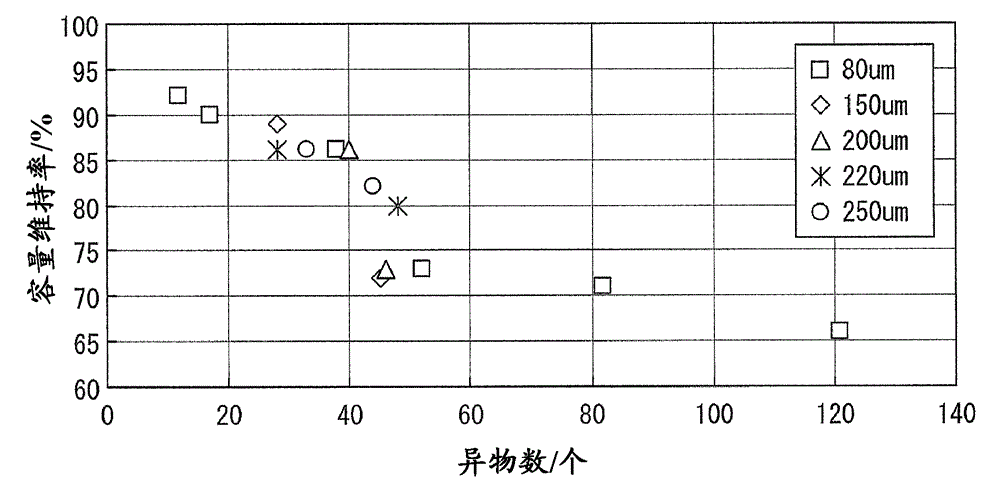

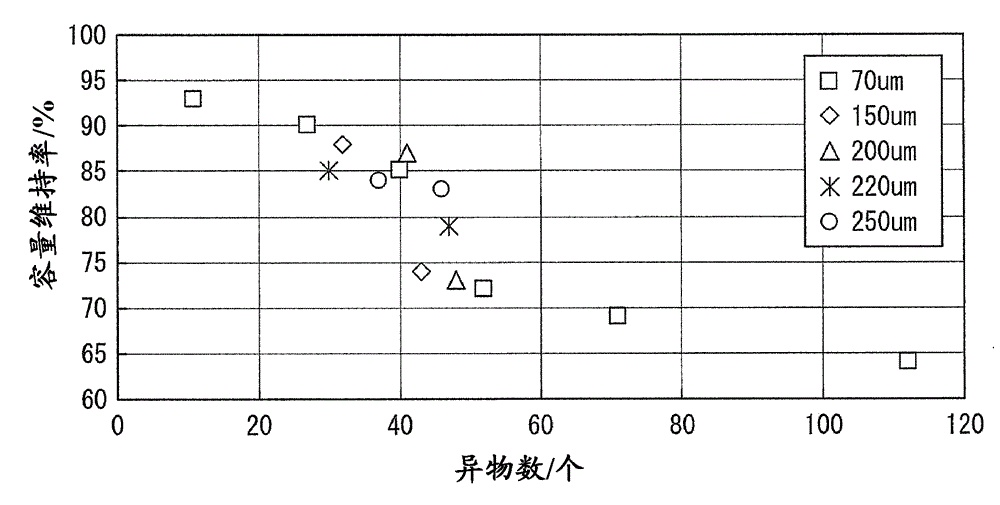

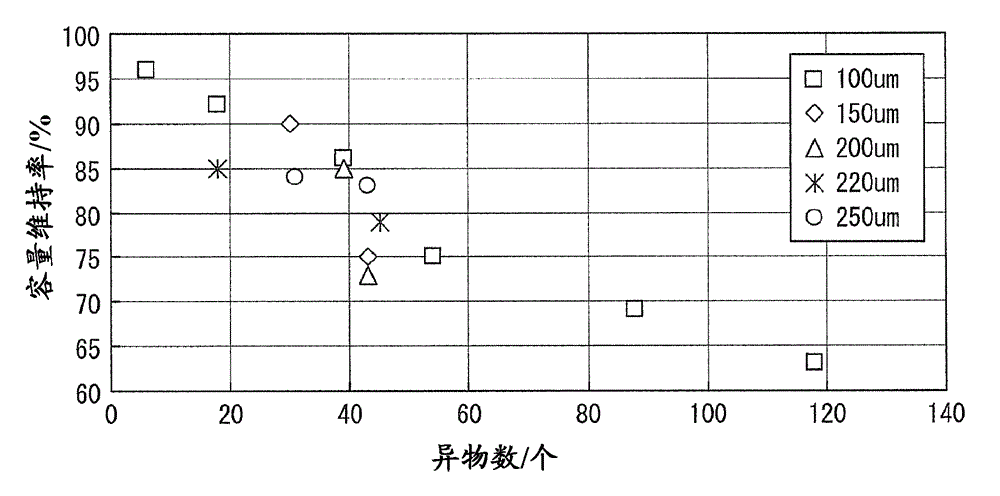

[0167] Including Example 1, the thickness, number of foreign mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com