Patents

Literature

181results about How to "Suppress unevenness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

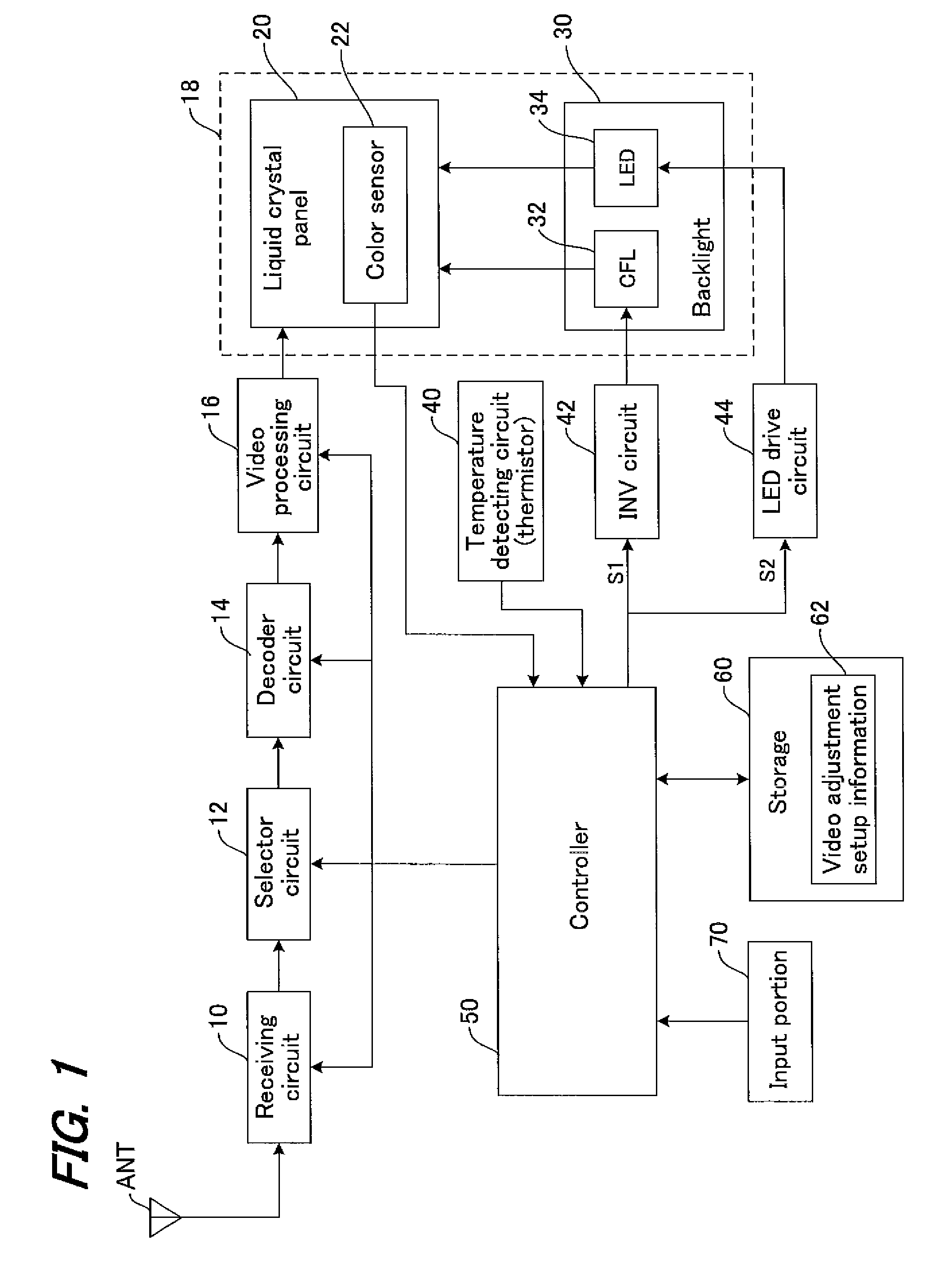

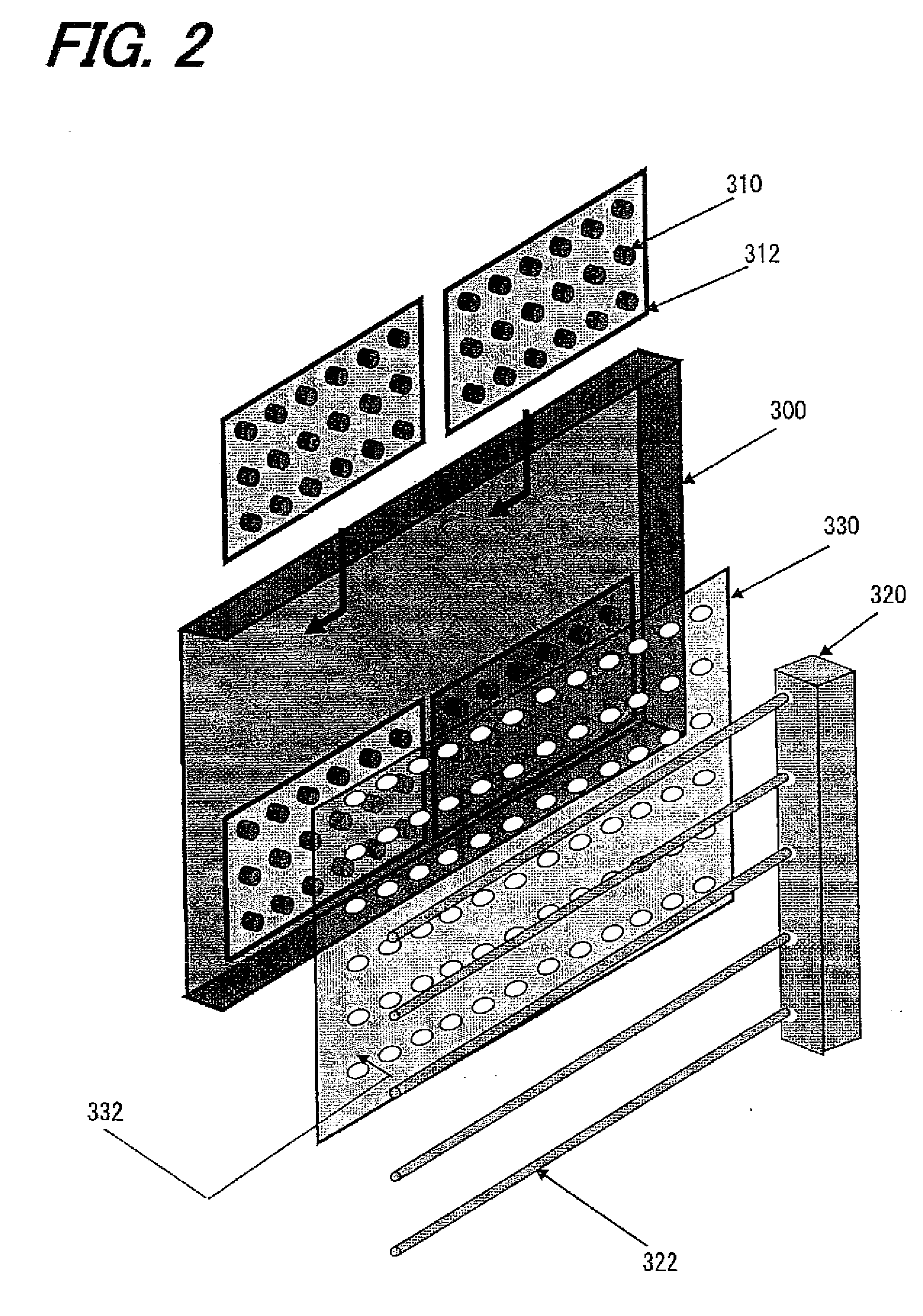

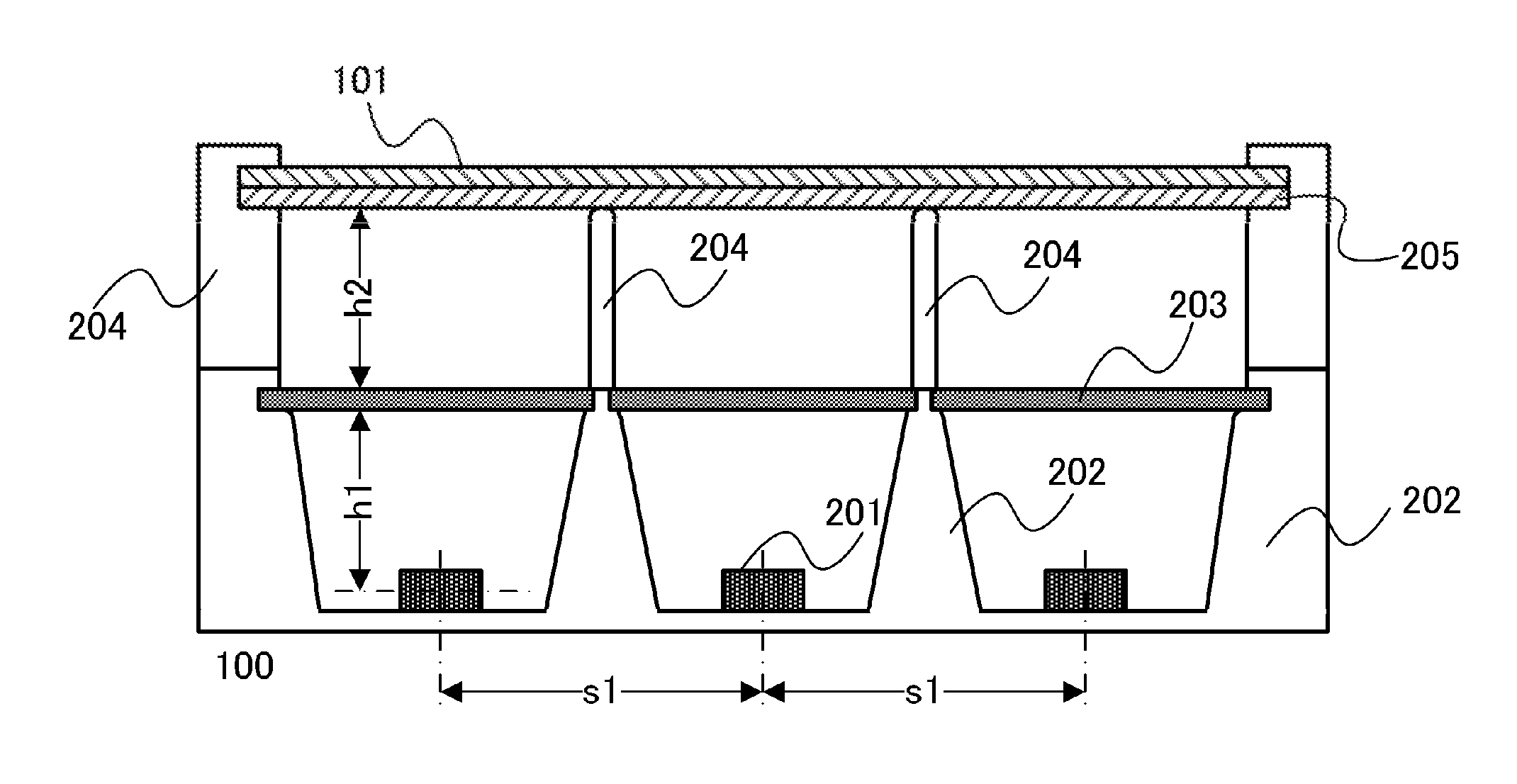

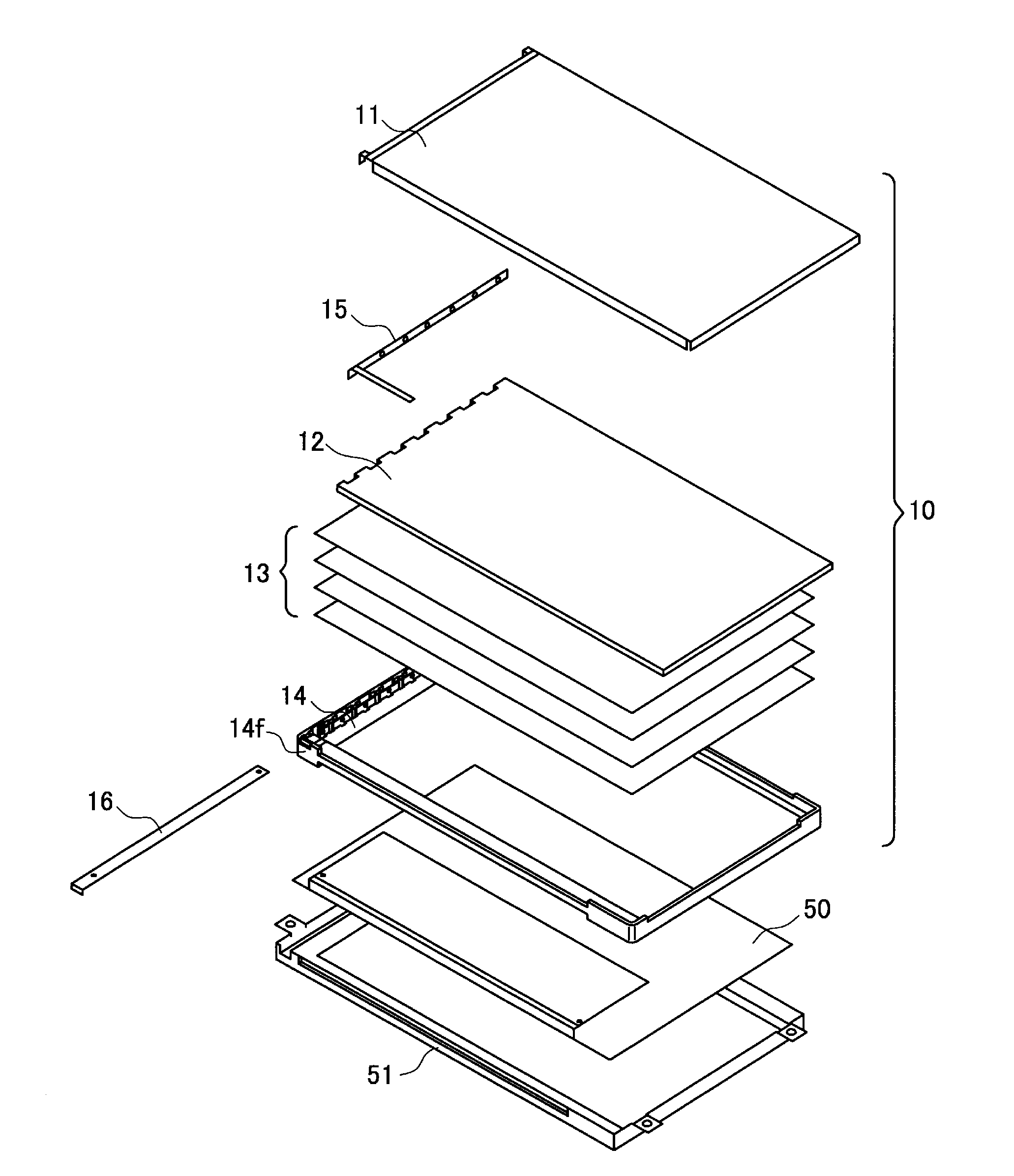

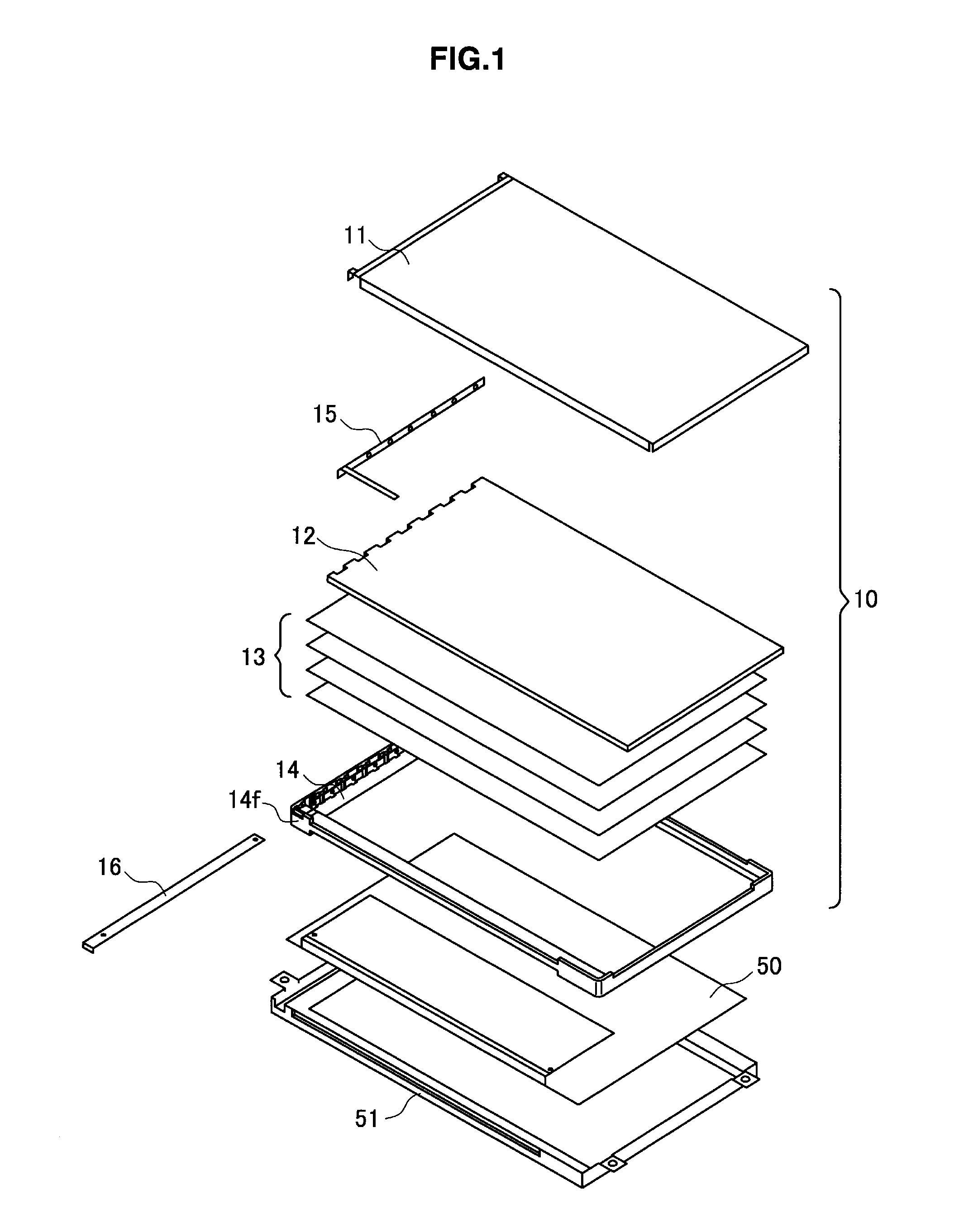

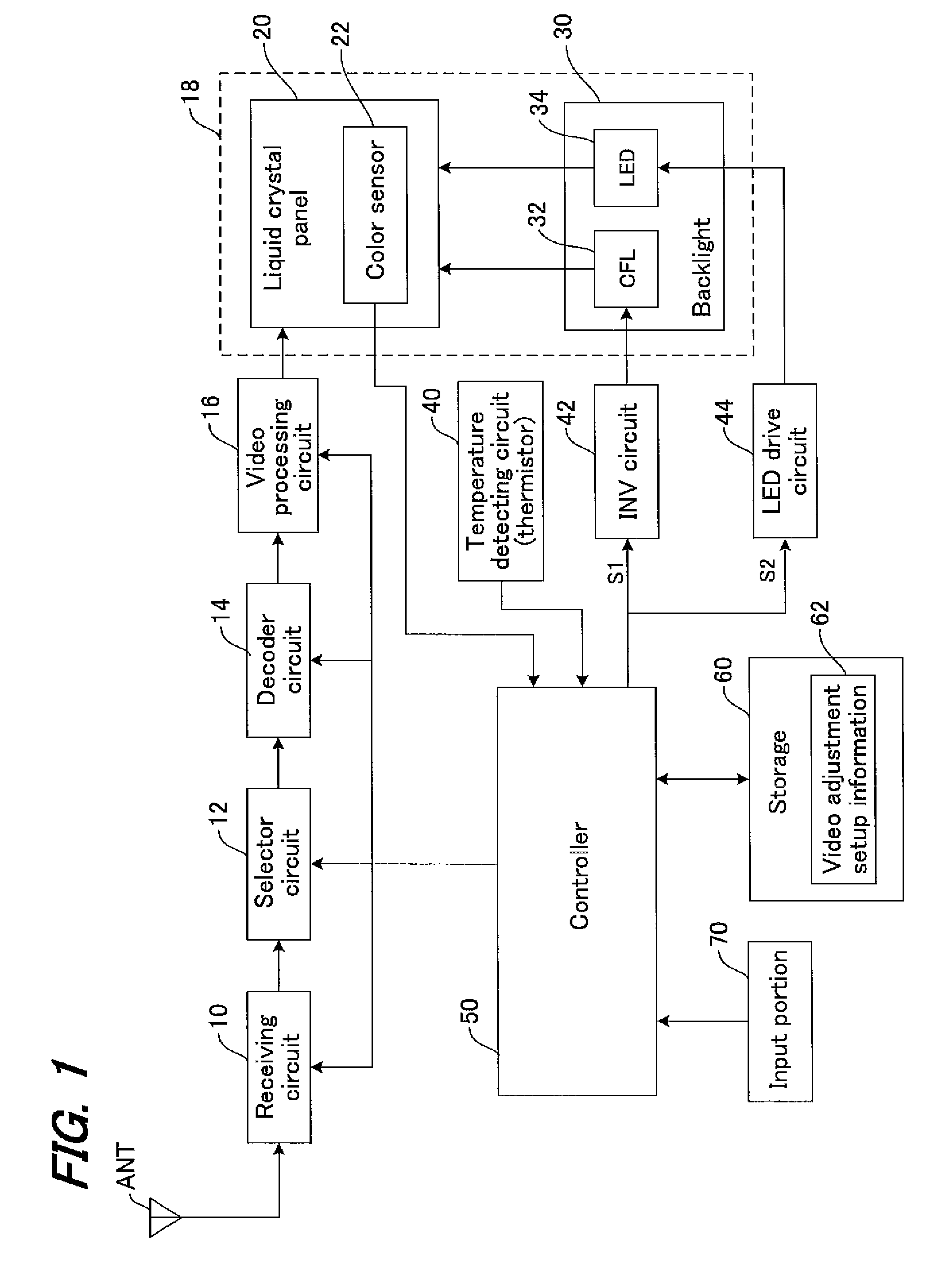

Liquid crystal display device and video display device using the same

ActiveUS20100073582A1Suppress light unevennessSuppress unevennessTelevision system detailsColor television detailsLiquid-crystal displayLight guide

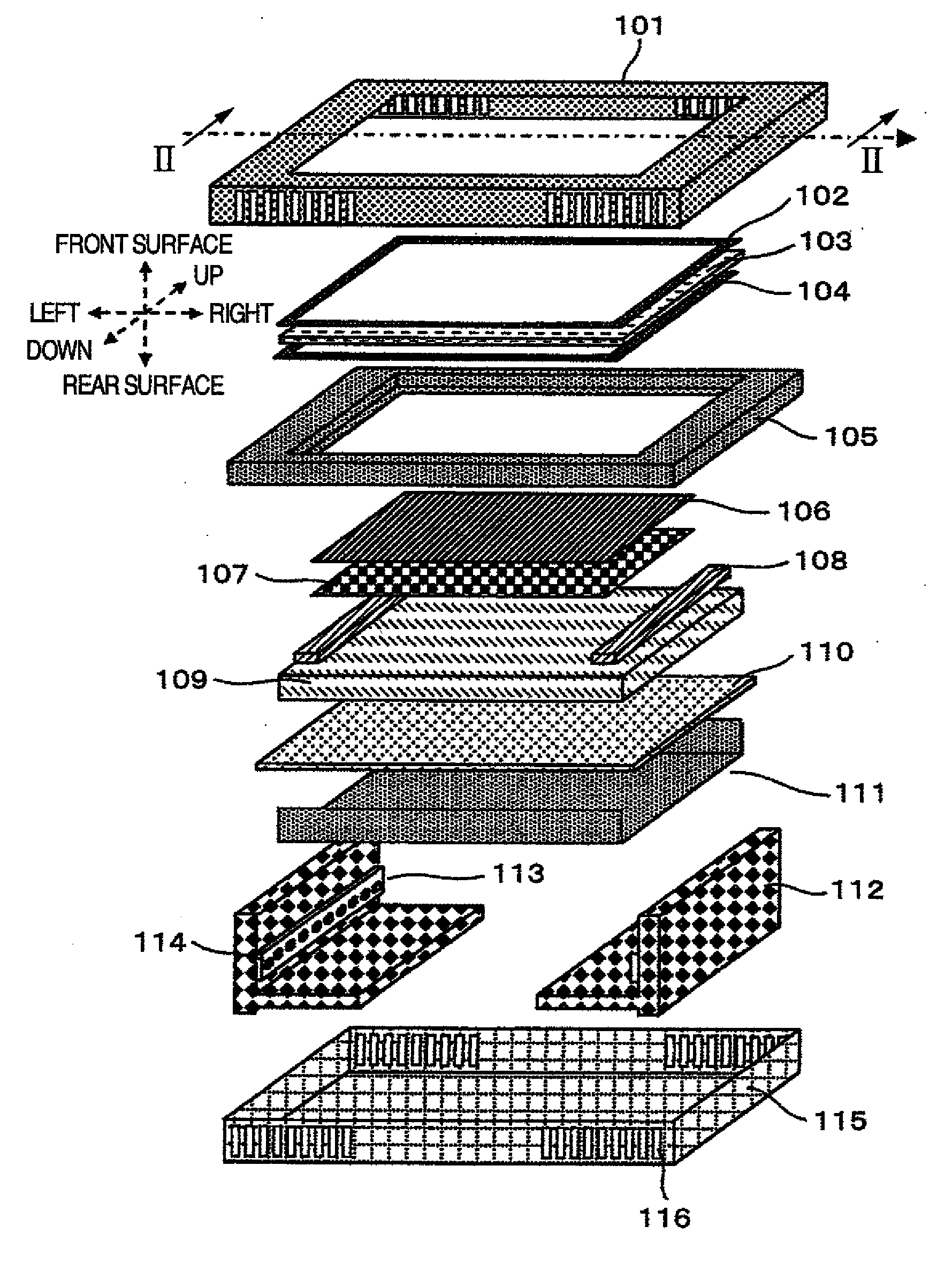

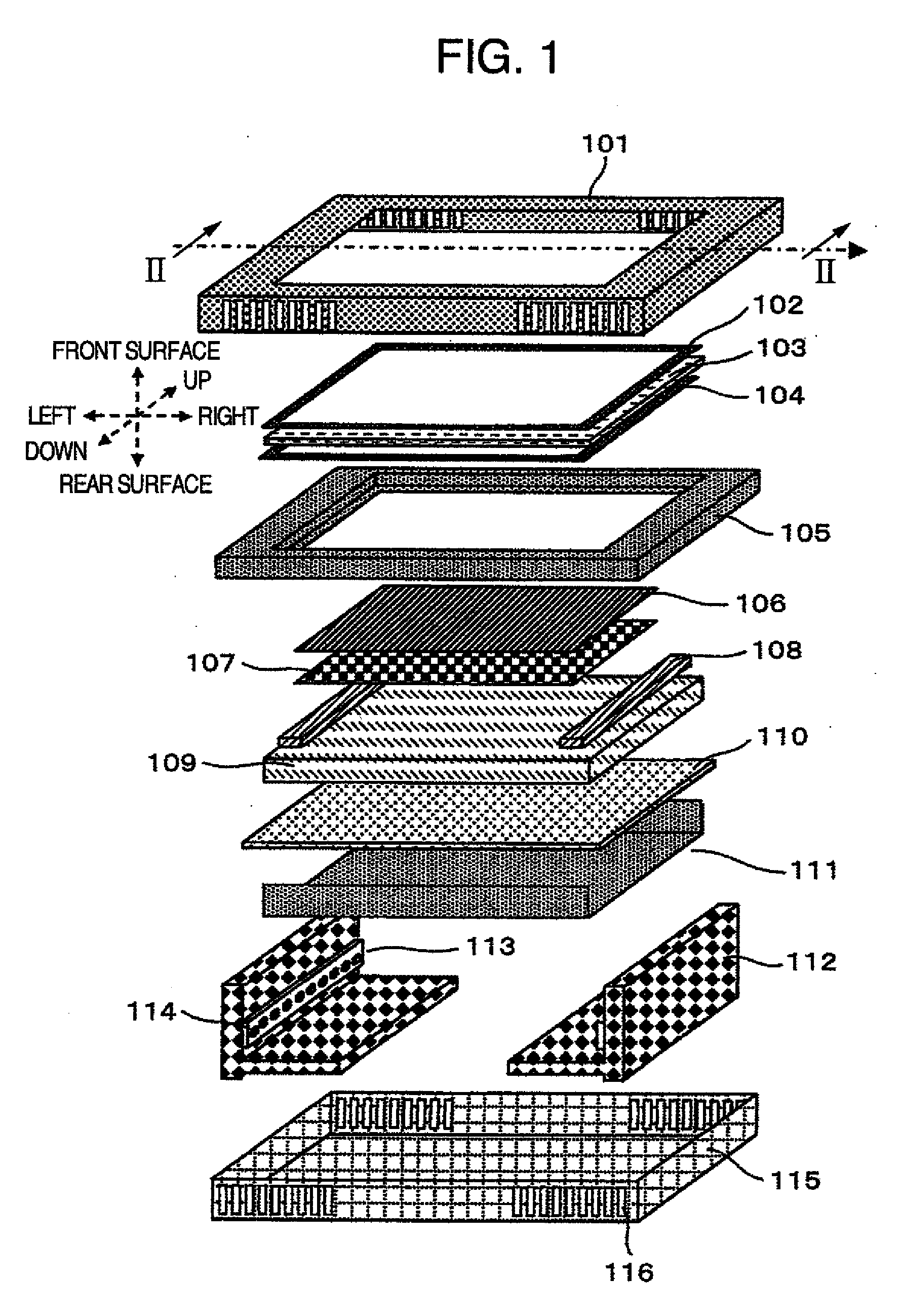

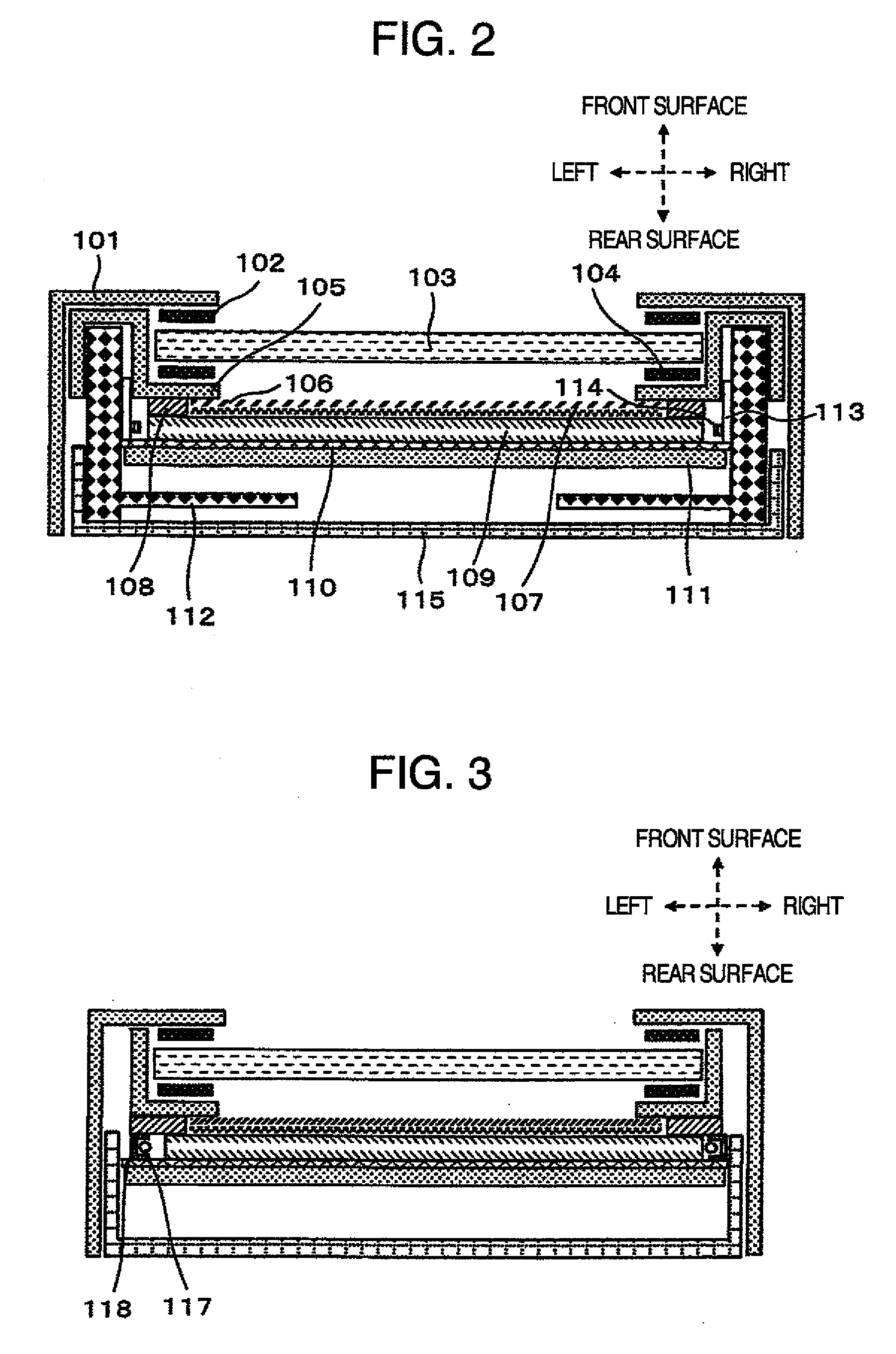

In a liquid crystal display device and a video display device using the same, for suppressing light unevenness at the end of a display region, the video display device is provided with a liquid crystal display device and a housing configured to support the liquid crystal display device, wherein the liquid crystal display device includes a liquid crystal panel, a first frame and a liquid crystal support member which interpose the liquid crystal panel therebetween, a light guide plate which is disposed at the liquid crystal support member on a side opposite to a side where the liquid crystal panel is disposed, and a light source which is disposed at a side surface of the light guide plate, and wherein a cushion member is disposed between the liquid crystal support member and the light guide plate.

Owner:MAXELL HLDG LTD

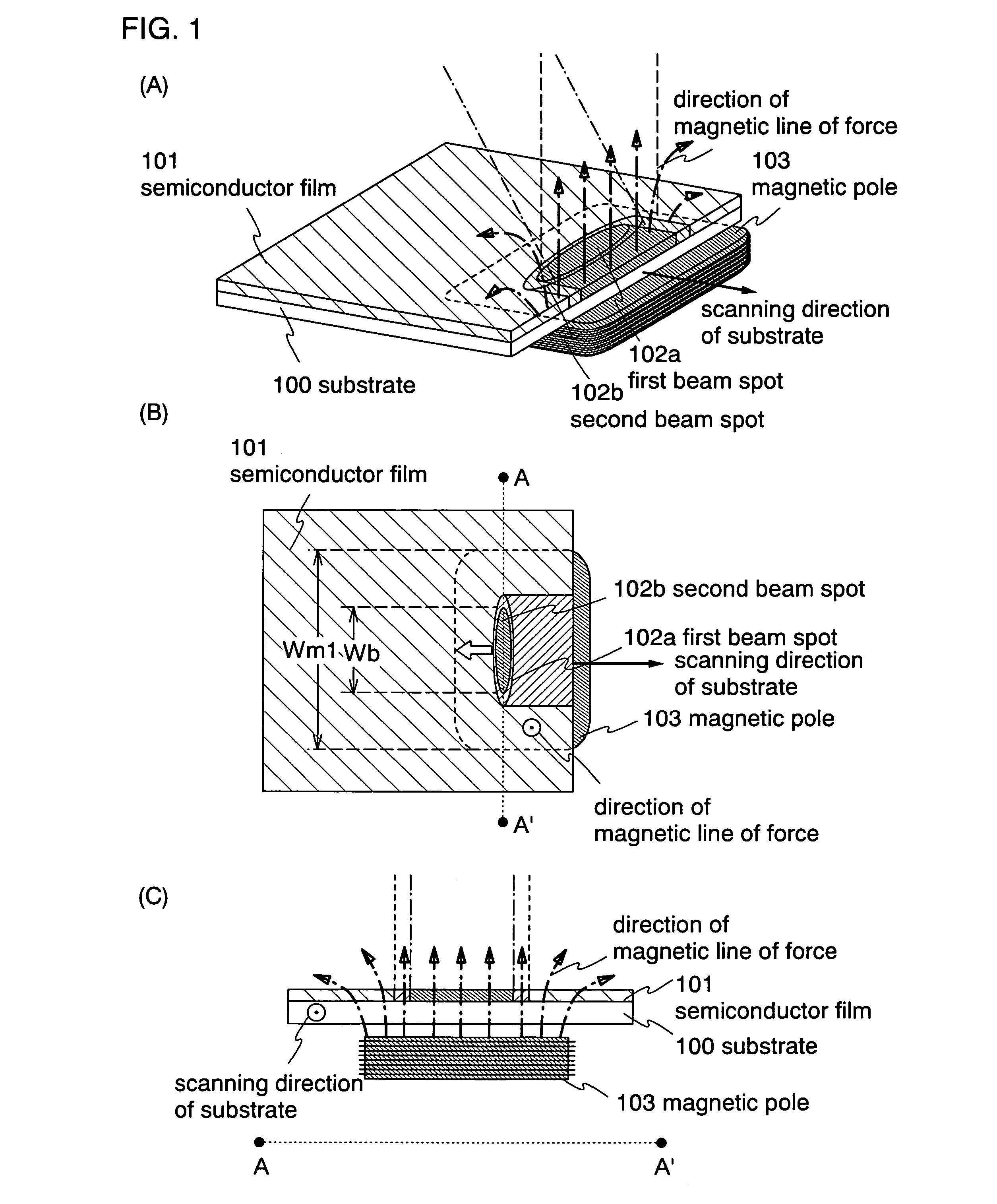

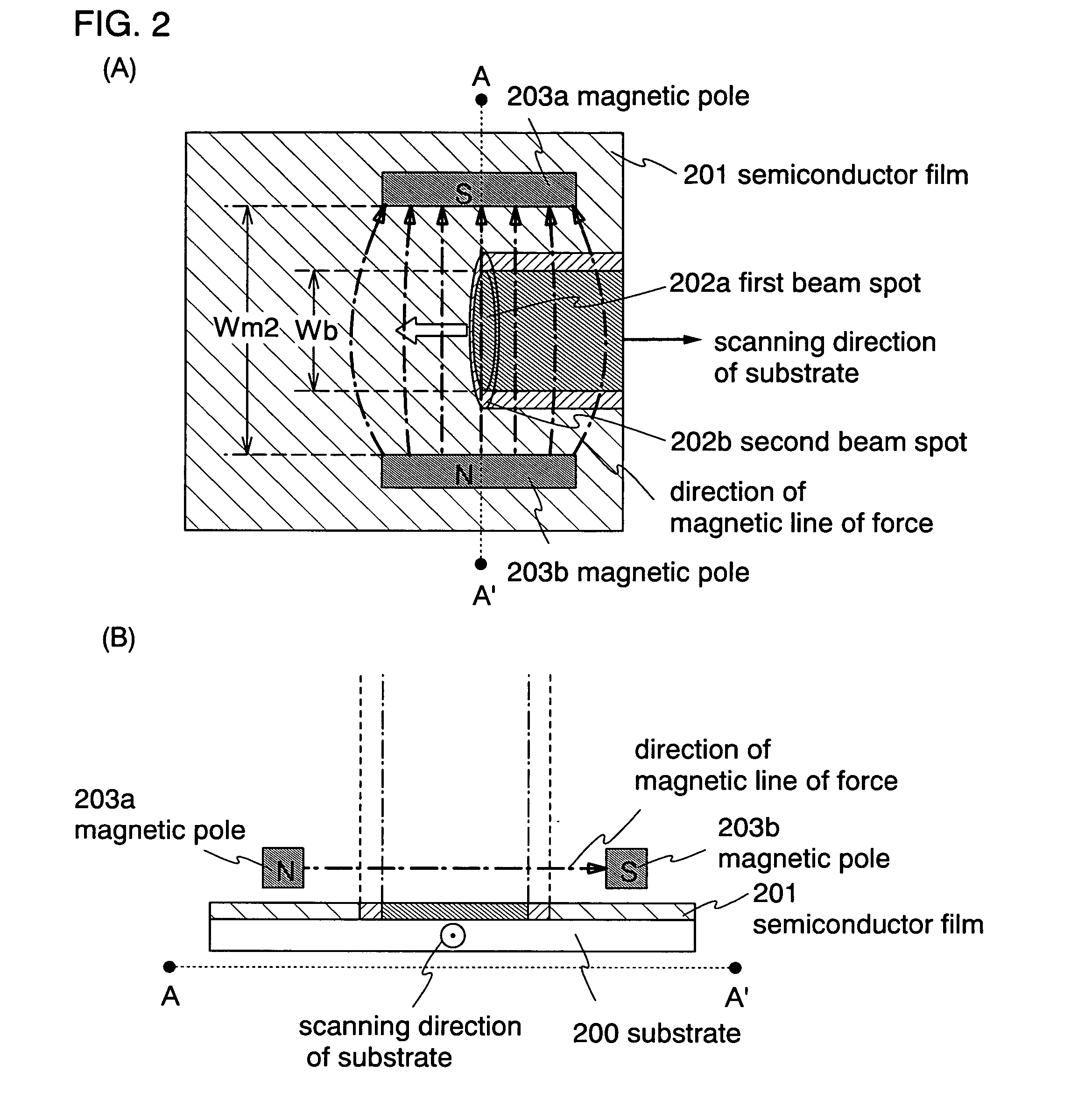

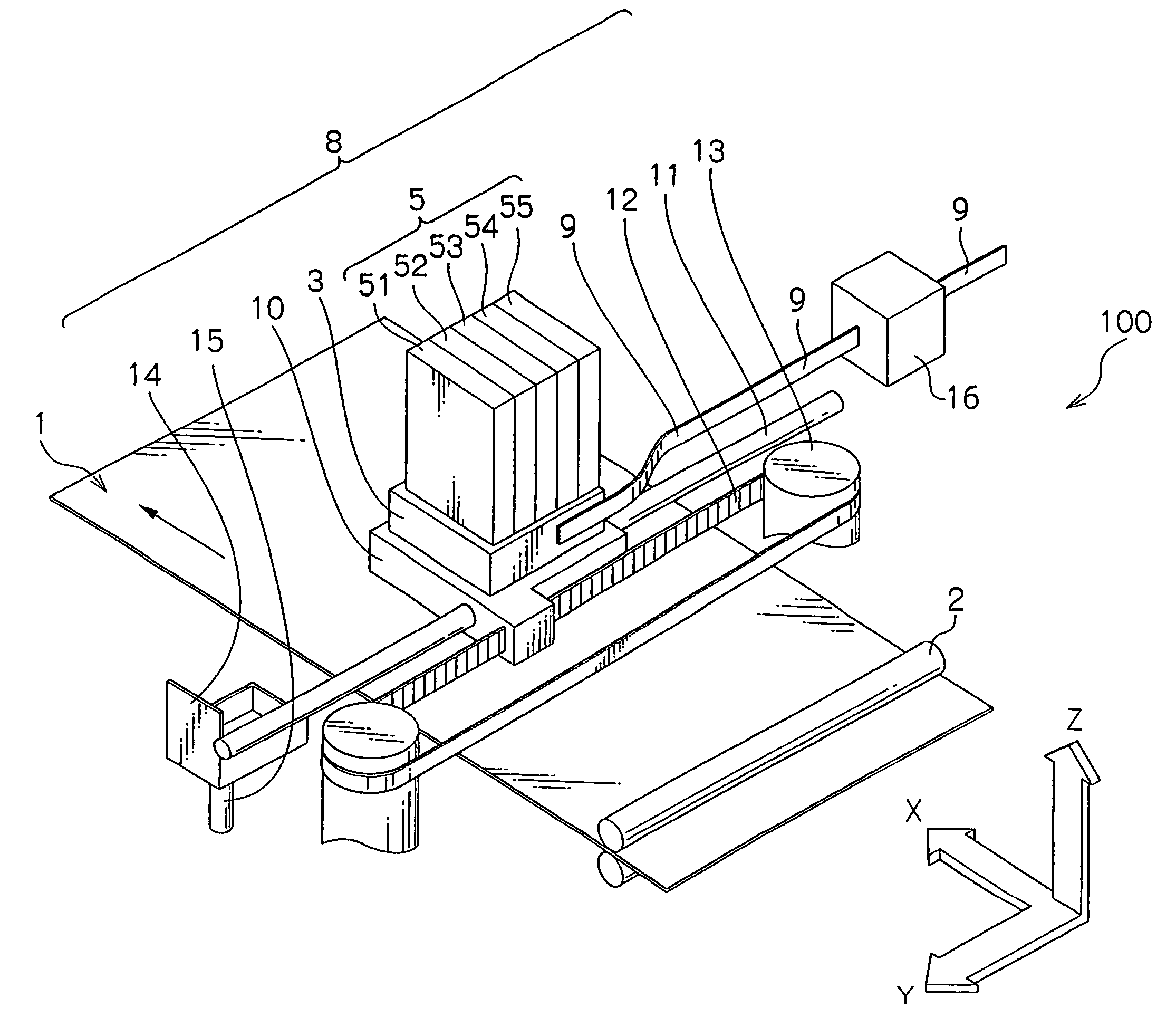

Laser irradiation apparatus and method of fabricating semiconductor device

InactiveUS20040259387A1Suppress of stateSuppress unevennessTransistorSemiconductor/solid-state device manufacturingHarmonicNitrogen

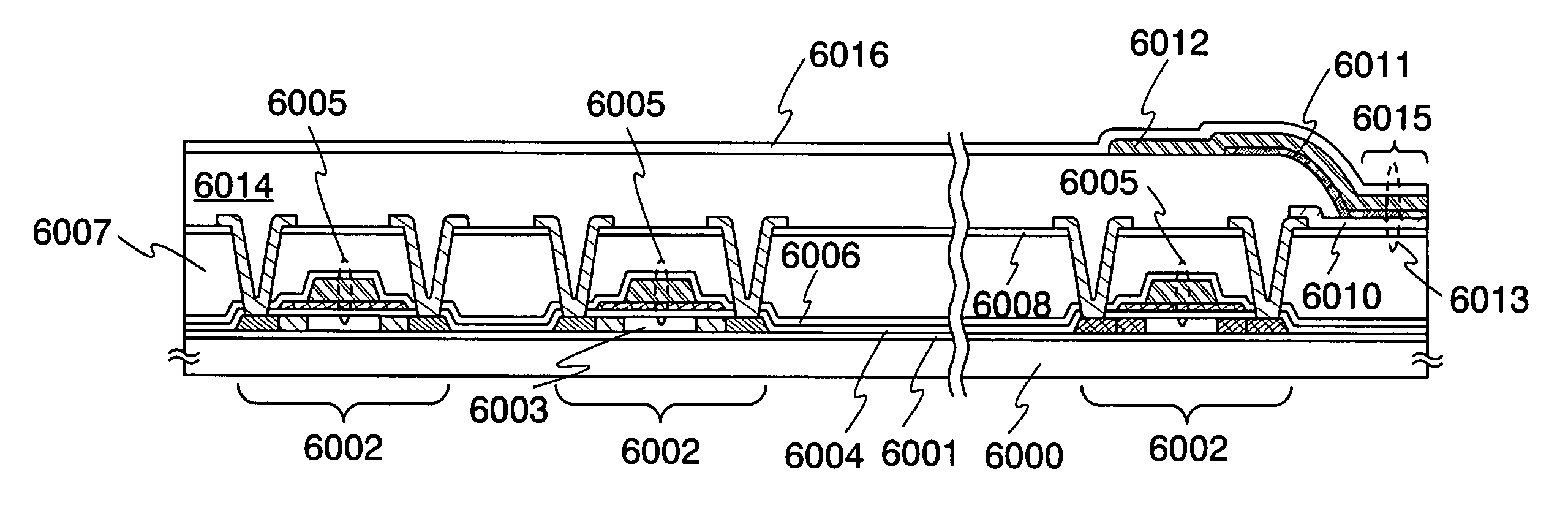

According to the present invention, oxygen and nitrogen are effectively prevented from mixing into the semiconductor film by doping Ar or the like in the semiconductor film in advance, and by irradiating the laser light in the atmosphere of Ar or the like. Therefore, the variation of the impurity concentration due to the fluctuation of the energy density can be suppressed and the variation of the mobility of the semiconductor film can be also suppressed. Moreover, in TFT formed with the semiconductor film, the variation of the on-current in addition to the mobility can be also suppressed. Furthermore, in the present invention, the first laser light converted into the harmonic easily absorbed in the semiconductor film is irradiated to melt the semiconductor film and to increase the absorption coefficient of the fundamental wave.

Owner:SEMICON ENERGY LAB CO LTD

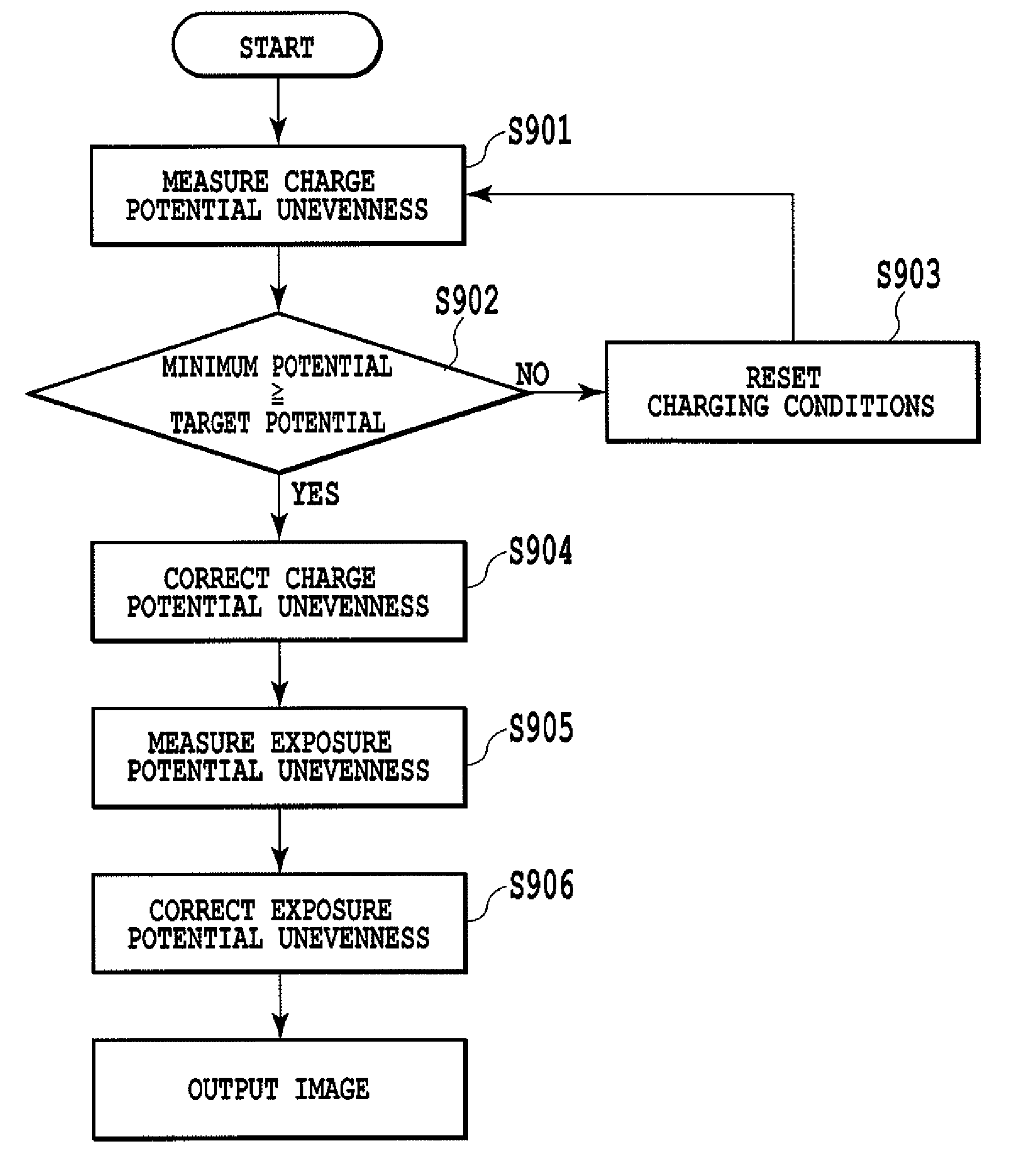

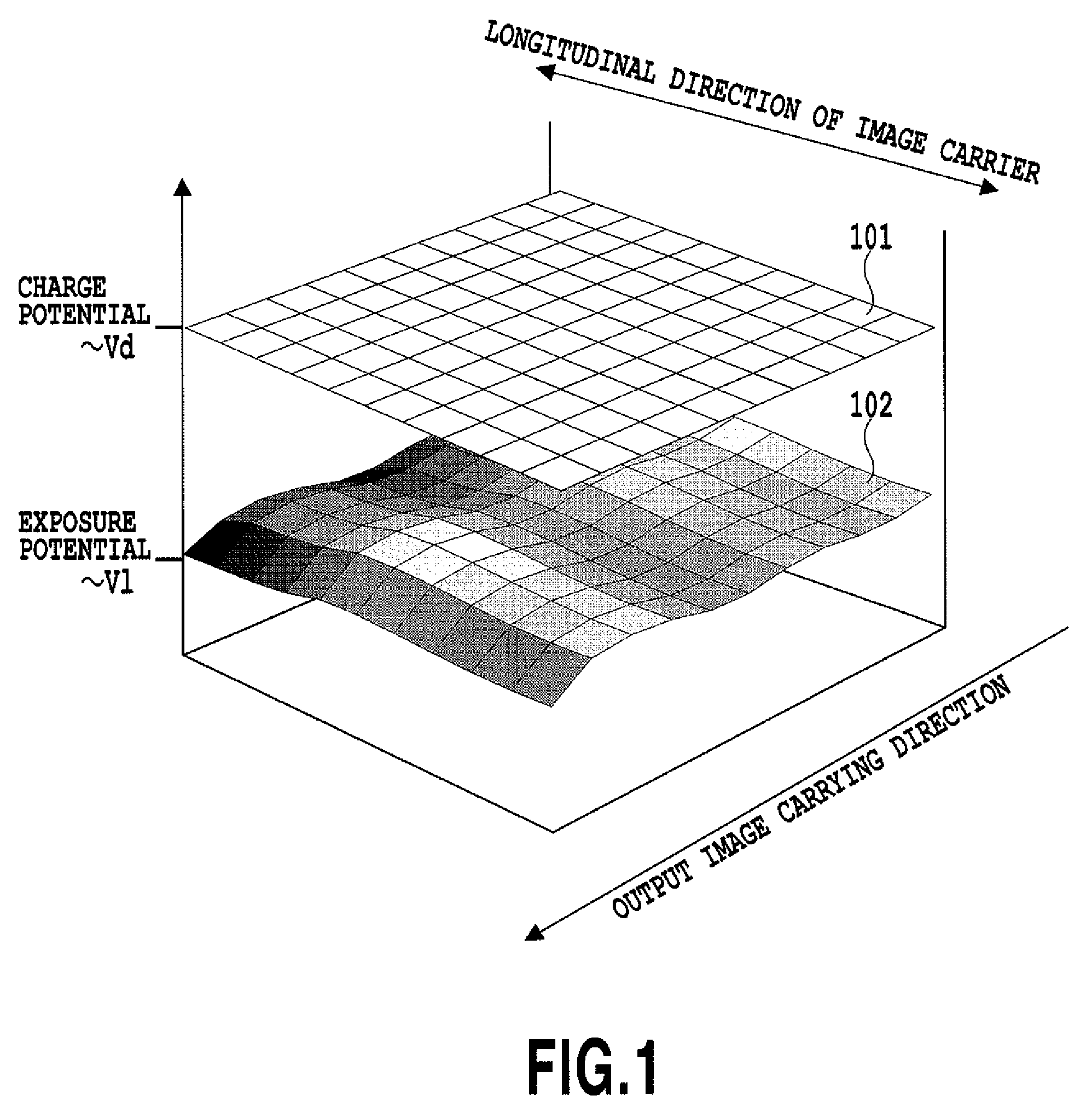

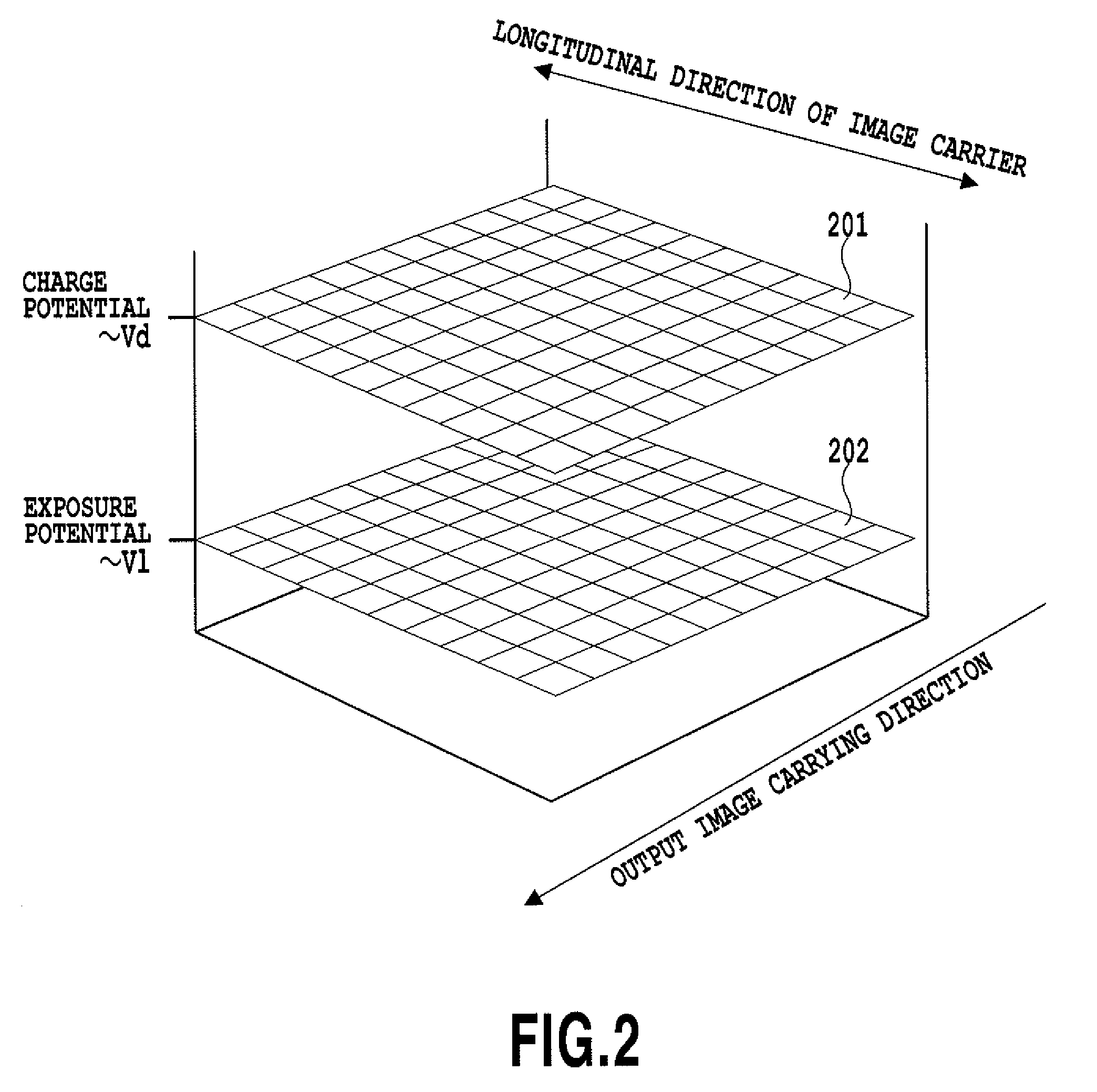

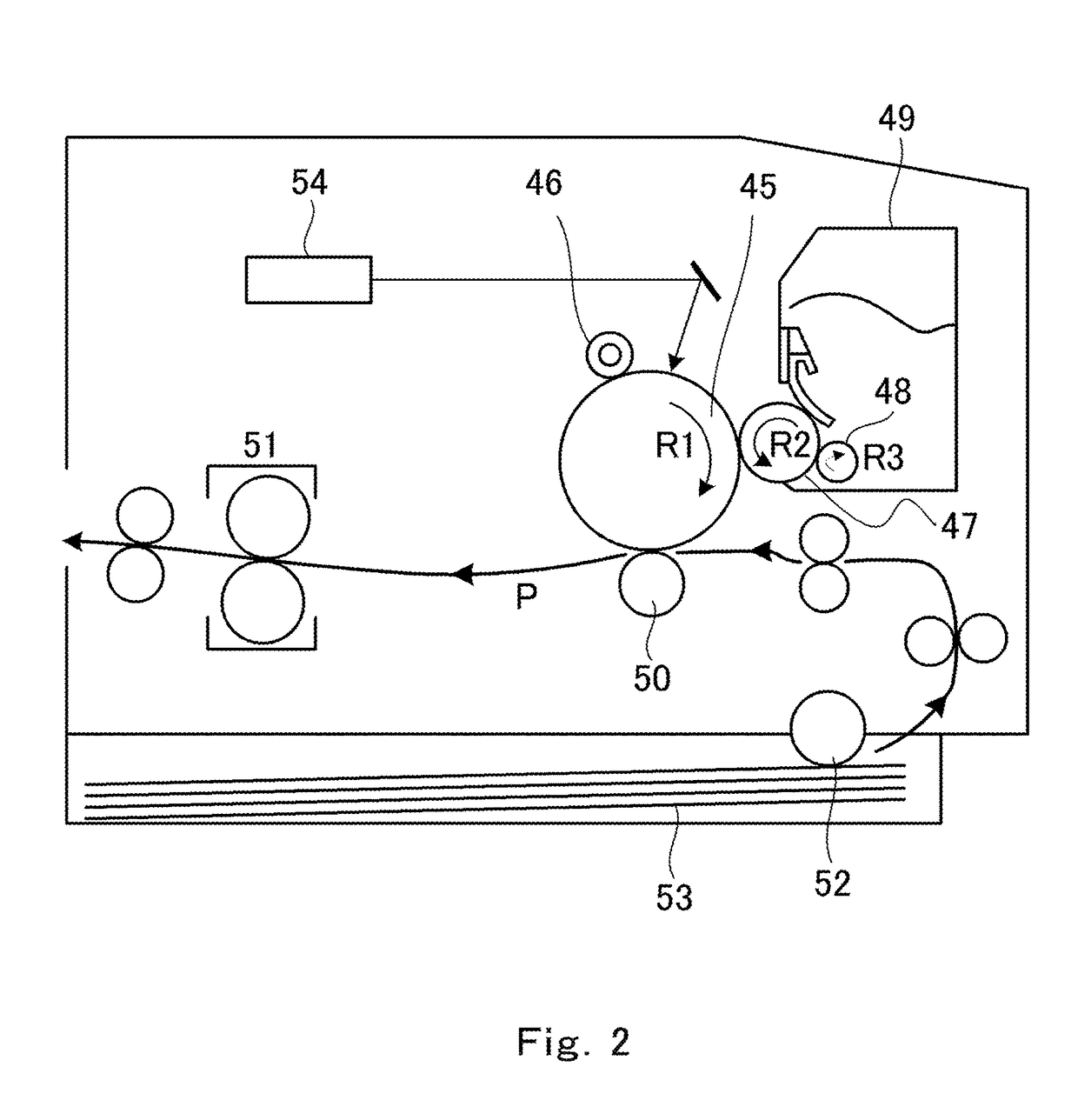

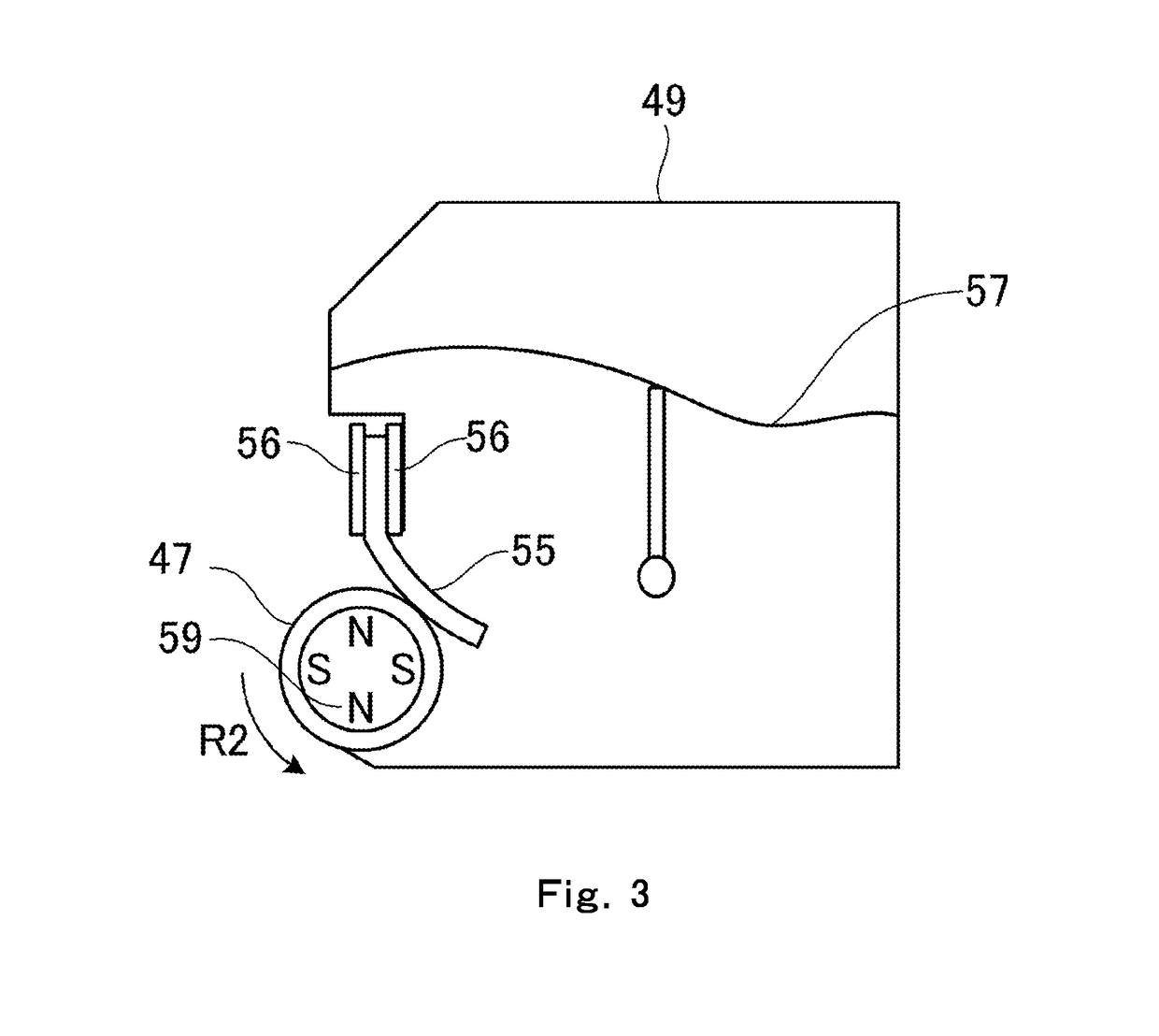

Image forming apparatus which corrects charge potential on an image carrier

ActiveUS7751737B2Excellent on-surface uniformity of colorSuppress unevennessElectrographic process apparatusCorona dischargeLatent imageImage formation

Owner:CANON KK

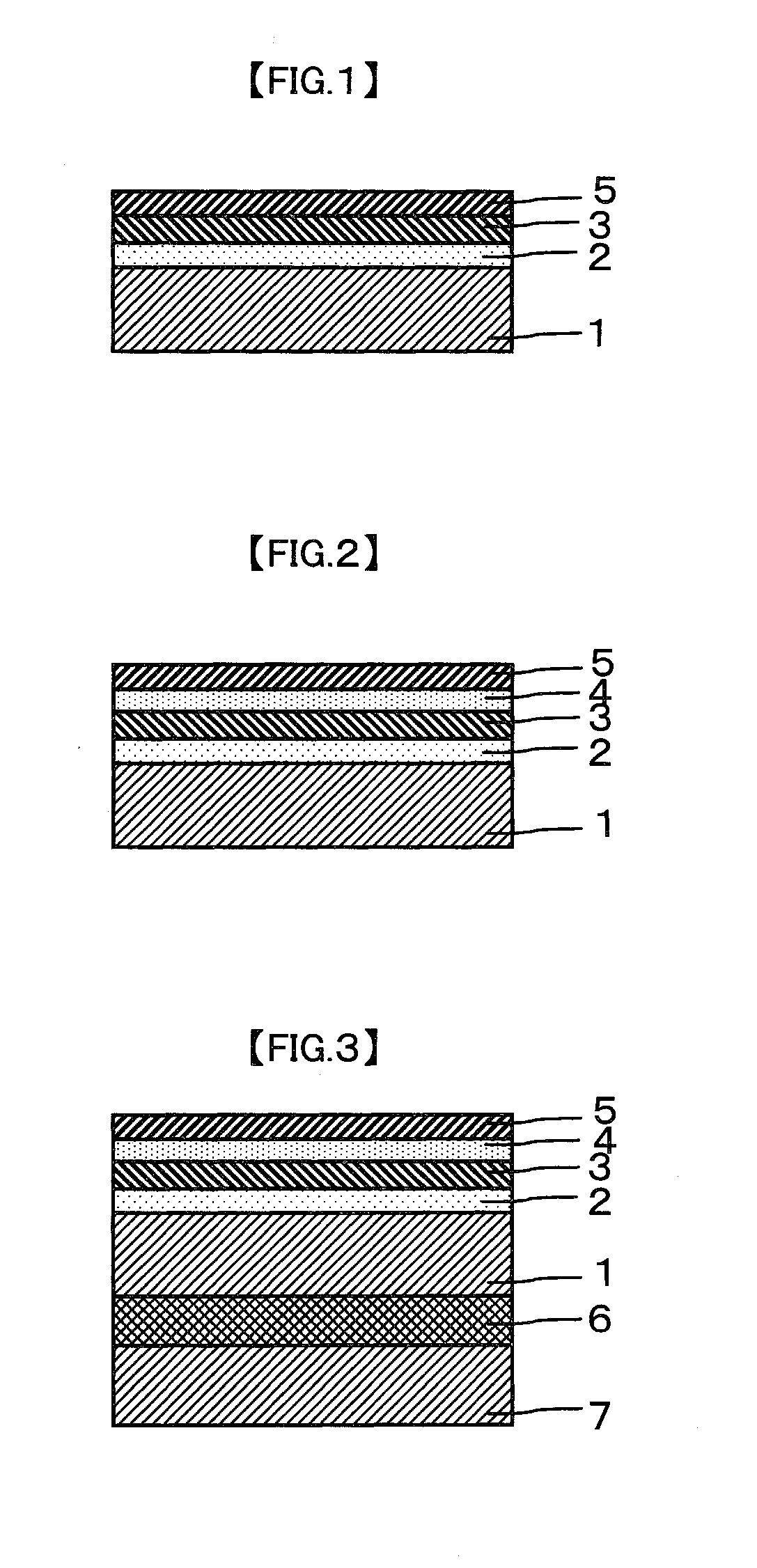

Optical pressure-sensitive adhesive, pressure-sensitive adhesive attached optical film, and image display

ActiveUS20090104445A1Suppress display unevennessSuppress unevennessLayered productsFilm/foil adhesivesMeth-Display device

An object of the invention is to provide an optical pressure-sensitive adhesive that is for use in pressure-sensitive adhesive attached optical films and so on, includes an acrylic copolymer and is less likely to cause display unevenness in the peripheral portion of a display screen. An optical pressure-sensitive adhesive, comprising: an acrylic copolymer containing alkyl (meth)acrylate (a1) and N-(2-hydroxyethyl)(meth)acrylamide (a2) as a monomer unit.

Owner:NITTO DENKO CORP

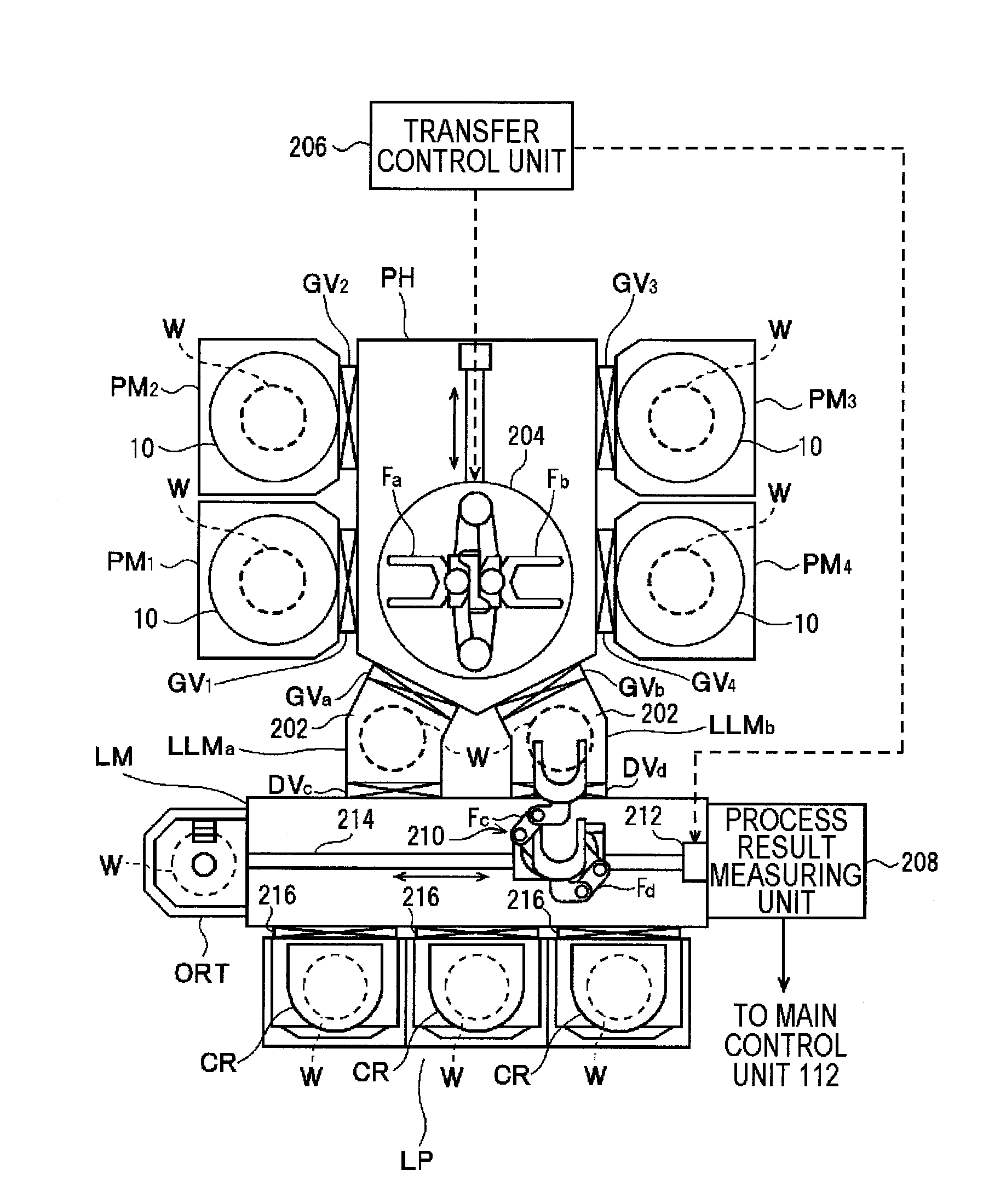

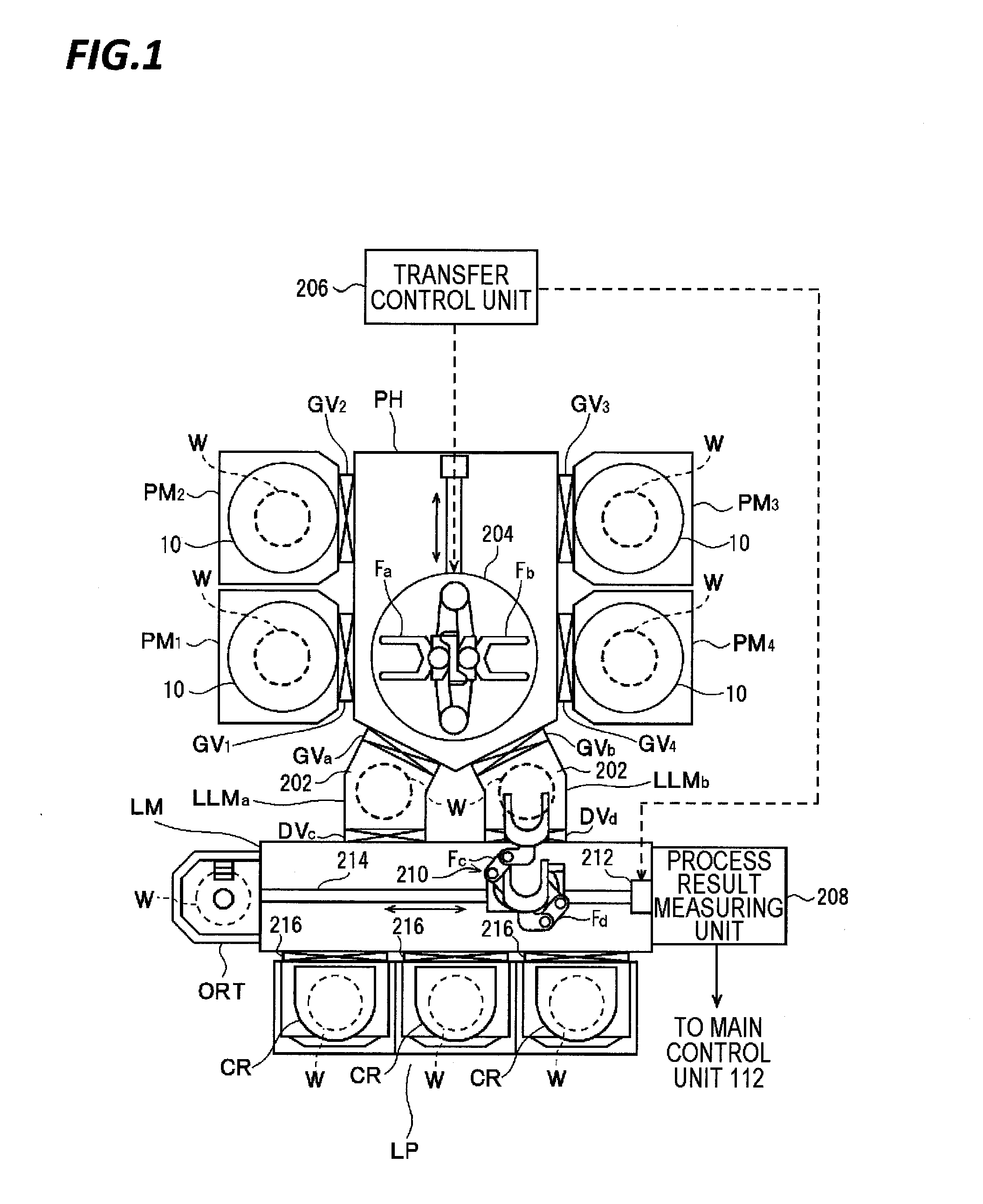

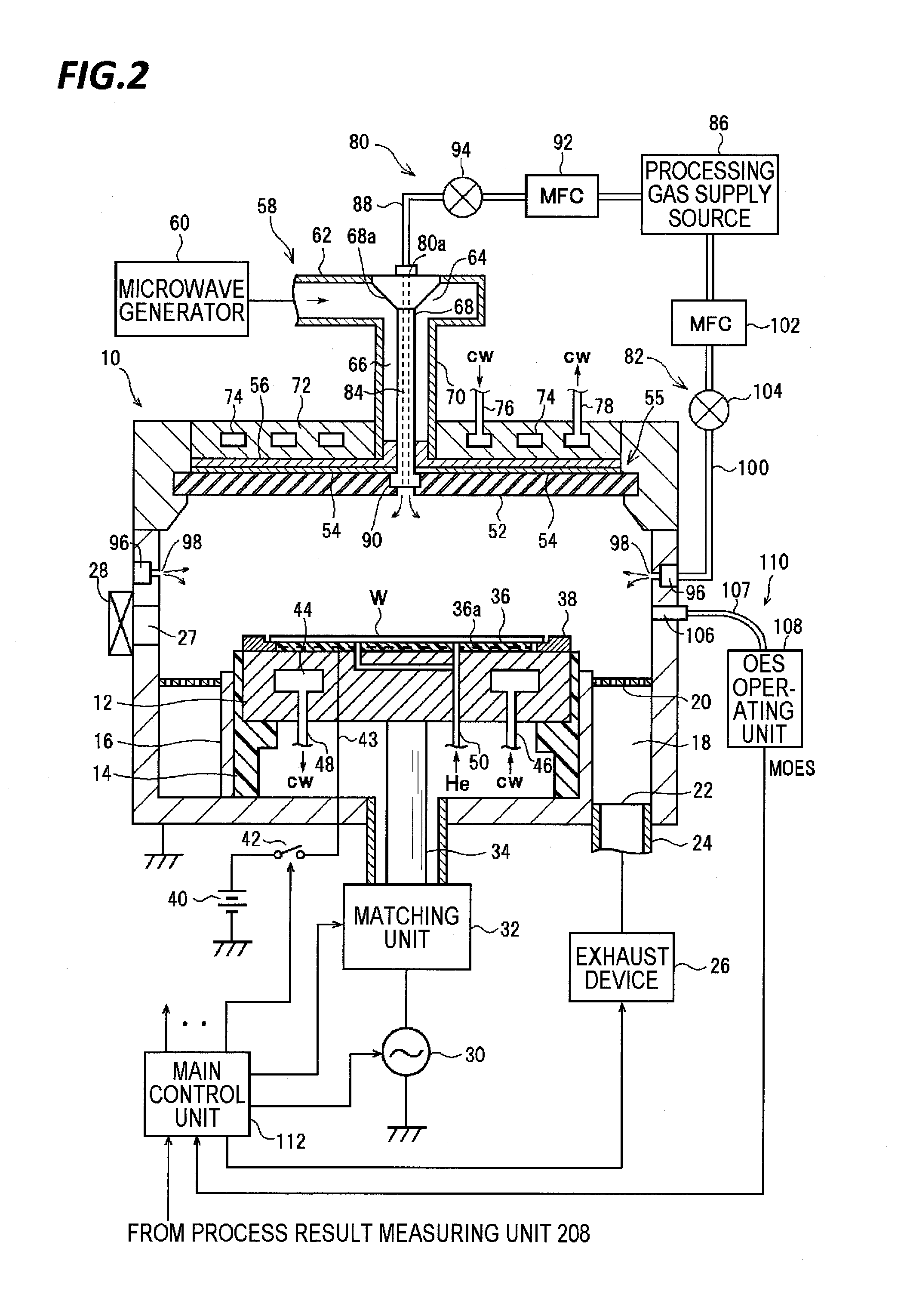

Plasma processing apparatus and plasma processing method

InactiveUS20150004721A1Suppress fluctuationsSuppress unevennessSemiconductor/solid-state device testing/measurementElectric discharge tubesControl subjectsAutomatic control

An OES measuring unit outputs a spectroscopically measured value for each step at the end of or immediately after each step. A CD estimating unit obtains an estimated CD value for each step using a CD estimation model and a spectroscopically measured value received from an estimation model storage unit. In the next step, a process control unit uses an estimated CD value for the previous step received from the CD estimating unit, in addition to a process condition setting value for the next step received from a recipe storage unit and a process control model for the next step received from a control model storage unit, for automatic control of the control subject

Owner:TOKYO ELECTRON LTD

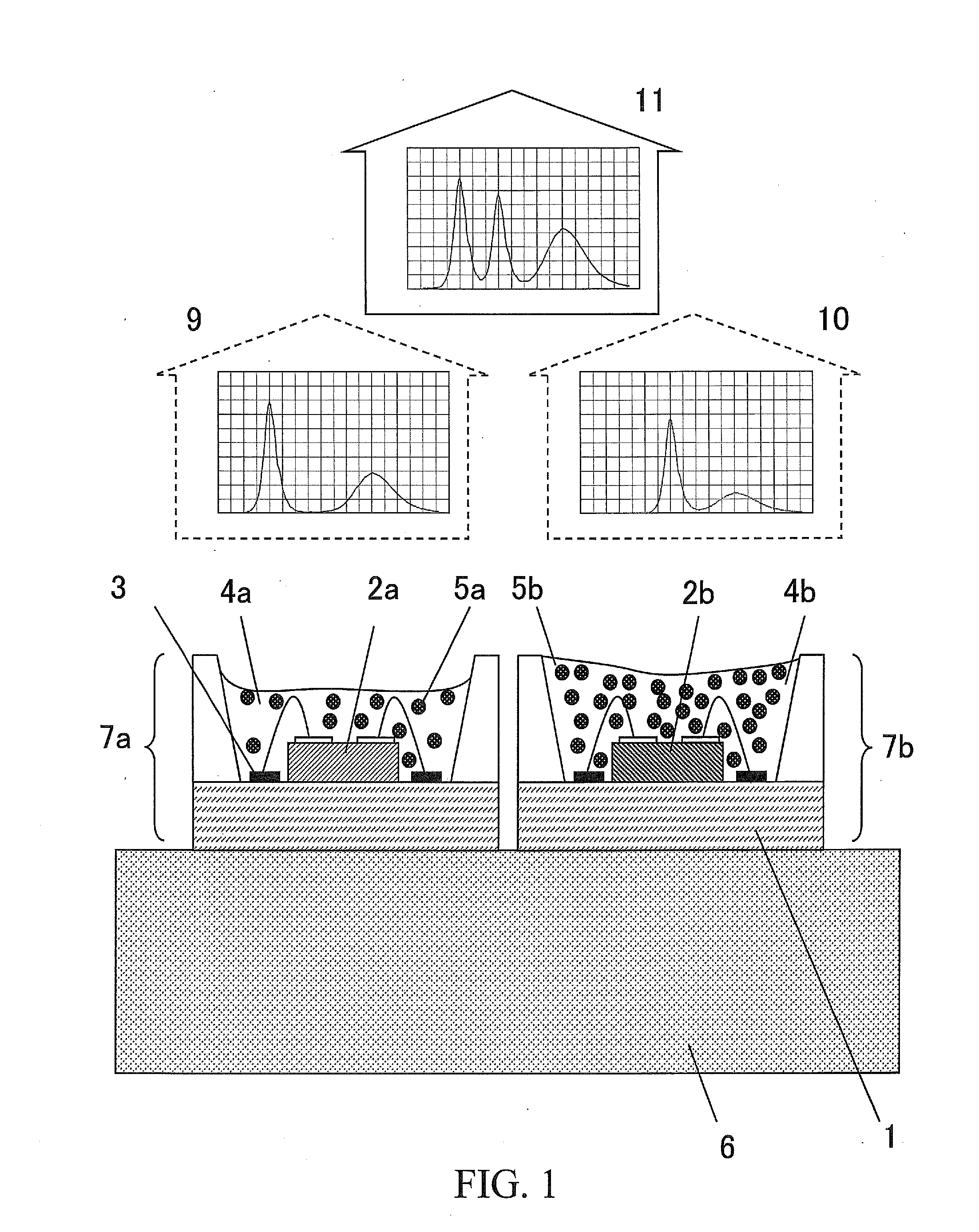

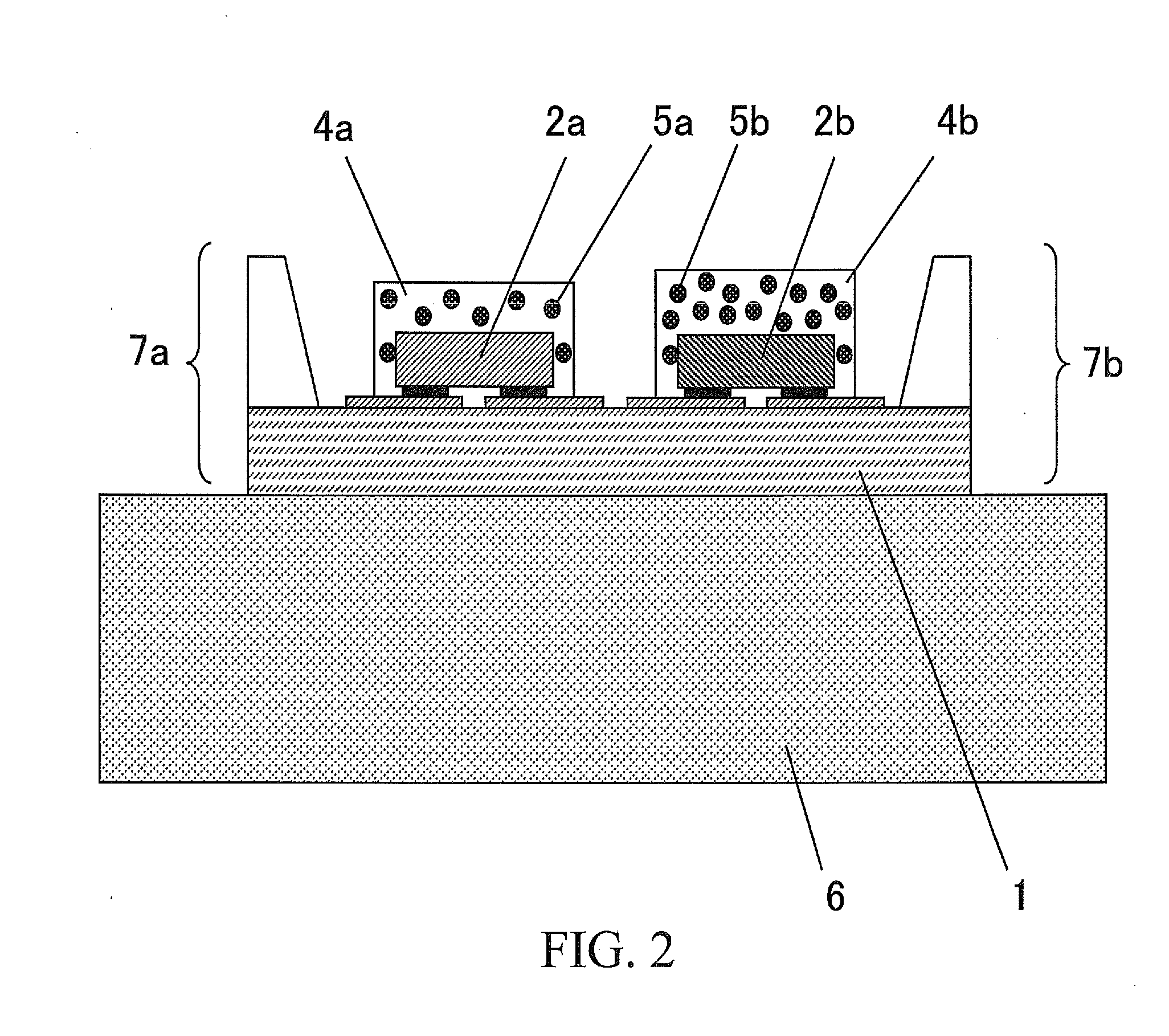

Light emitting device, and illumination light source, display unit and electronic apparatus including the light emitting device

InactiveUS20110211336A1No lot-to-lot variationColor tone is easilySolid-state devicesIlluminated signsOptical fluorescencePeak value

A light emitting device includes: a first semiconductor light emitting element having a solid-state blue light emitting element that emits blue light with a light emission peak in a wavelength range from 420 nm to less than 480 nm, and a first red phosphor layer that covers the solid-state blue light emitting element and includes a first red phosphor that emits red light with a light emission peak in a wavelength range from 600 nm to less than 680 nm; and a second semiconductor light emitting element having a solid-state green light emitting element that emits green light with a light emission peak in a wavelength range from 500 nm to less than 550 nm, and a second red phosphor layer that covers the solid-state green light emitting element and includes a second red phosphor that emits red light with a light emission peak in a wavelength range from 600 nm to less than 680 nm.

Owner:PANASONIC CORP

Color filter ink, color filter ink set, color filter, image display device, and electronic device

InactiveUS20100022700A1Improve discharge stabilityIncreased durabilityOptical filtersInksLiquid mediumPolymer chemistry

A color filter ink is adapted to be used to manufacture a color filter by an inkjet method. The color filter ink includes a colorant, a liquid medium that dissolves and / or disperses the colorant, and a resin material. The resin material includes a polymer X and a polymer Y. The polymer X has a monomer component x1 represented by a prescribed chemical formula, a monomer component x2 represented by a prescribed chemical formula, a monomer component x3 represented by a prescribed chemical formula, and a monomer component x4 represented by a prescribed chemical formula. The polymer Y has a monomer component y1 represented by a prescribed chemical formula and a monomer component y2 represented by a prescribed chemical formula.

Owner:SEIKO EPSON CORP

Co alloy target and its production method, soft magnetic film for perpendicular magnetic recording and perpendicular magnetic recording medium

InactiveUS20050223848A1Reduce unevennessReduce particlesBase layers for recording layersTransportation and packagingAlloyImpurity

Owner:HITACHI METALS LTD

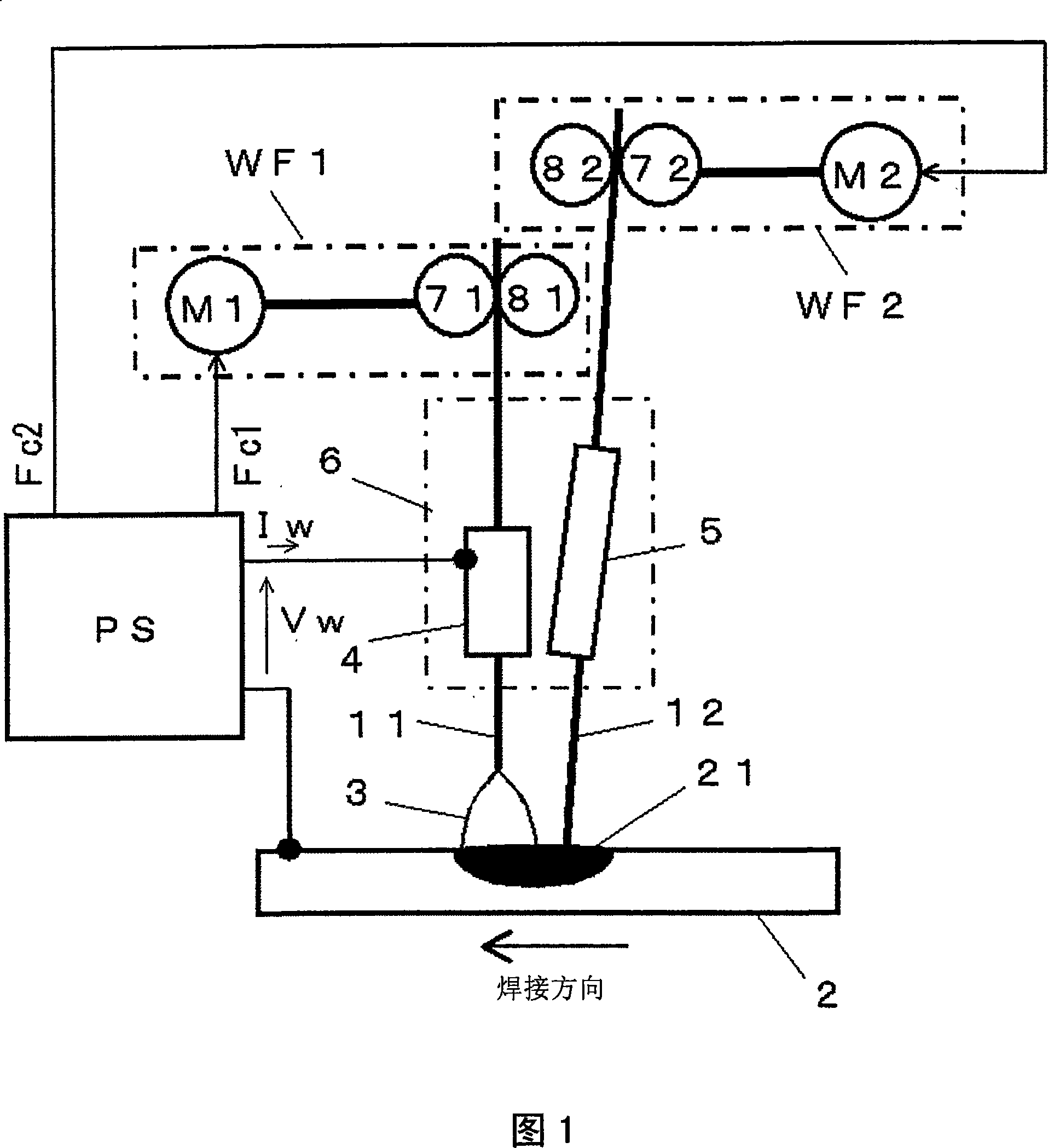

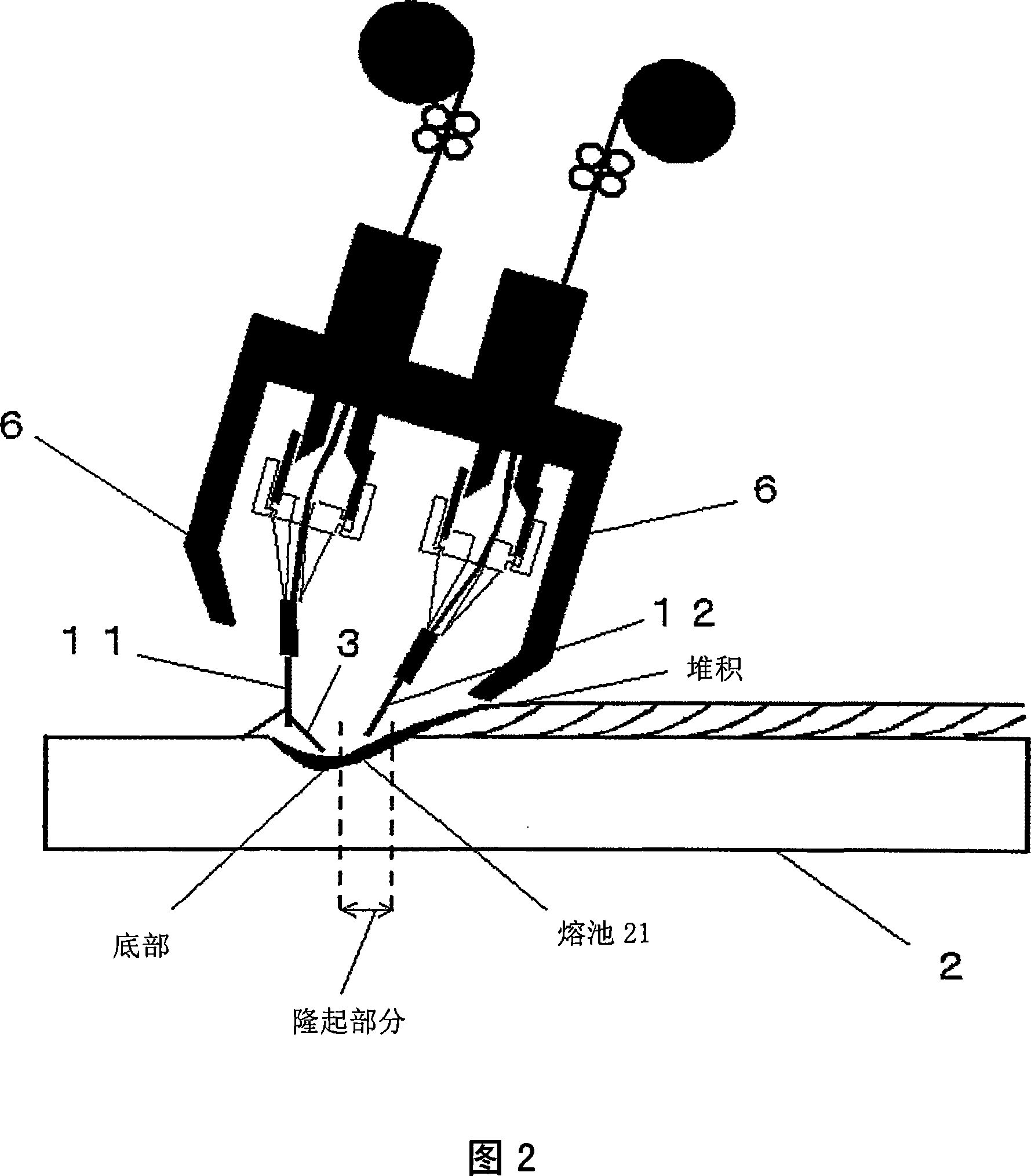

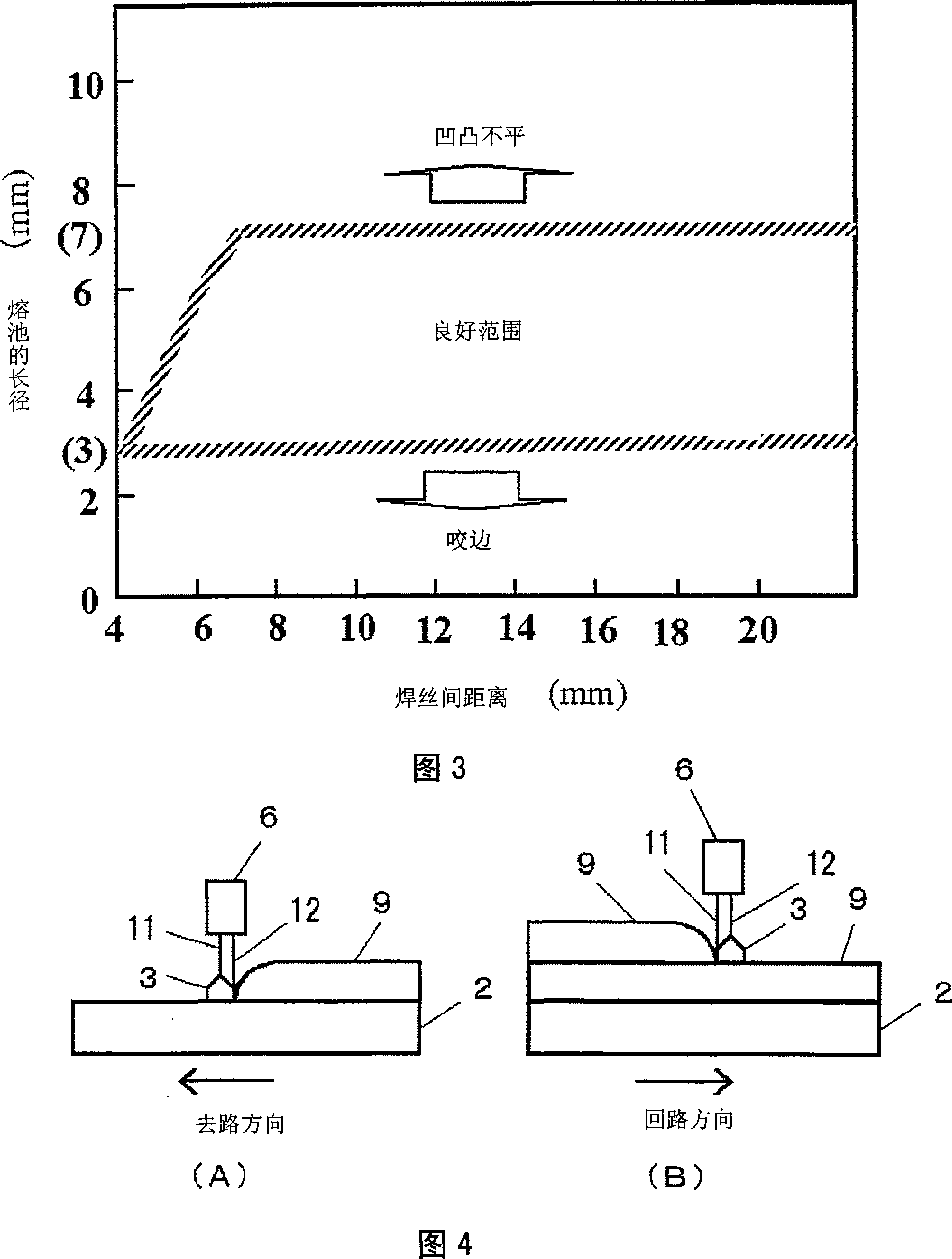

Double-wire feeding arc welding method and multi-layer surfacing method

ActiveCN101116925AReduce the temperatureIncrease surface tensionArc welding apparatusBead shapeEngineering

In the double-wire feeding arc welding method of the present invention, the first (leading) welding wire (11) and the second (backward) welding wire (12) that are insulated from each other are fed from the welding nozzle (6) at the front end of the welding torch, and the molten metal Welding the low-viscosity iron and steel materials, the welding current (Iw) is energized in the above-mentioned leading welding wire, and the arc (3) is generated to form a molten pool (21). The above-mentioned molten pool (21) under the pressure of the electric arc (3) is excavated to the raised position. Therefore, when welding iron and steel materials with low molten metal viscosity, a good bead shape without unevenness, undercut, and underfill can be obtained.

Owner:DAIHEN CORP

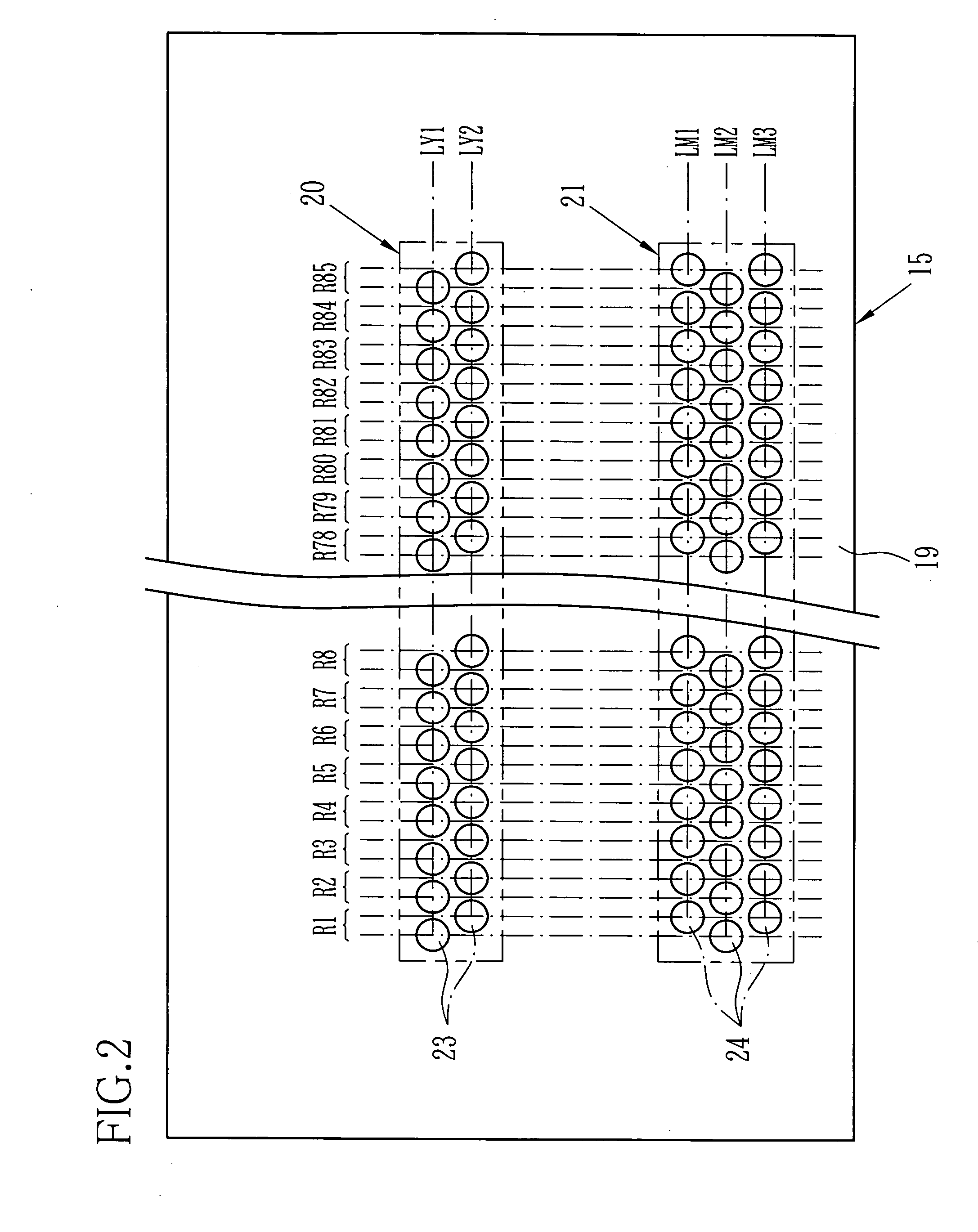

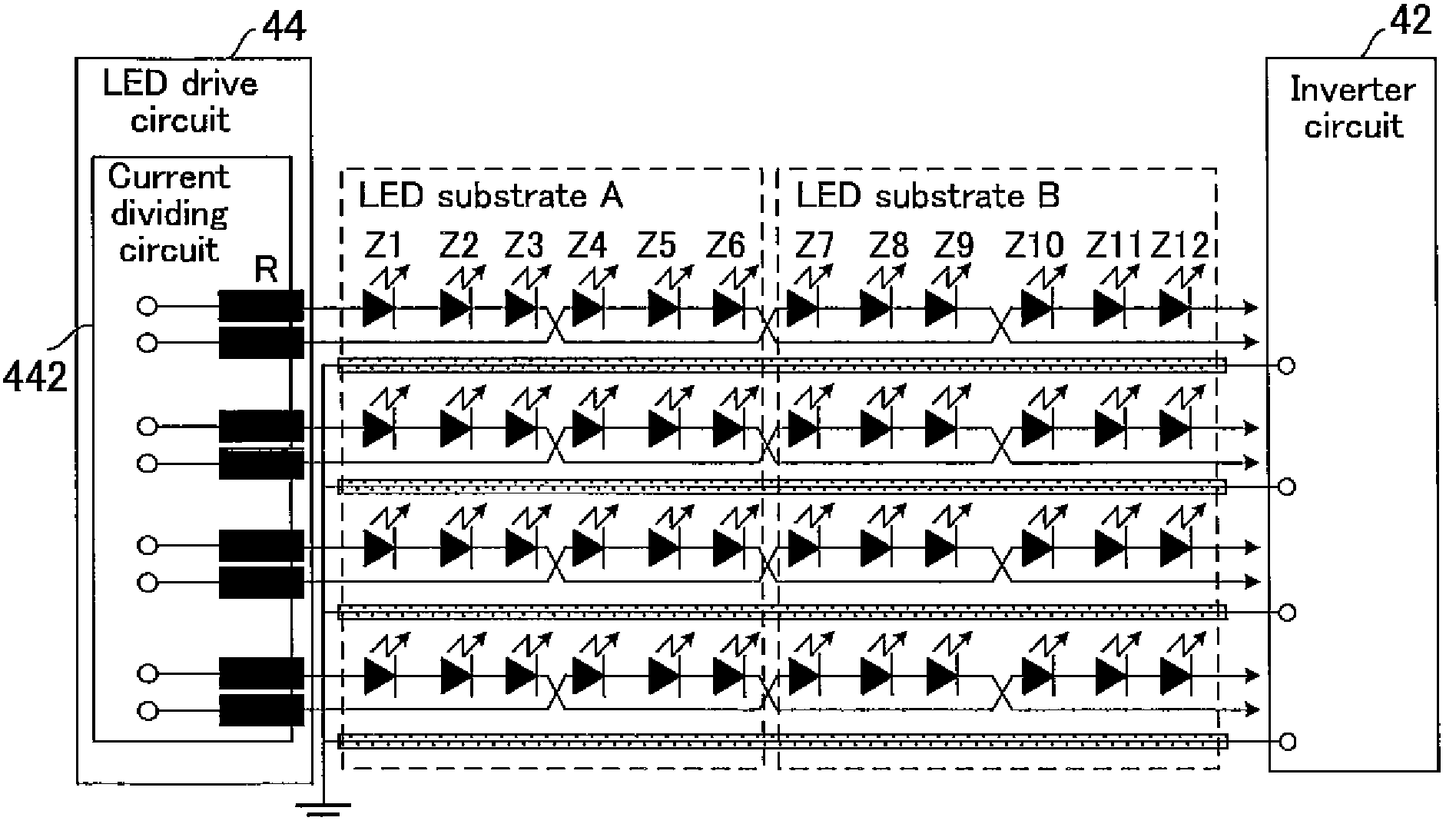

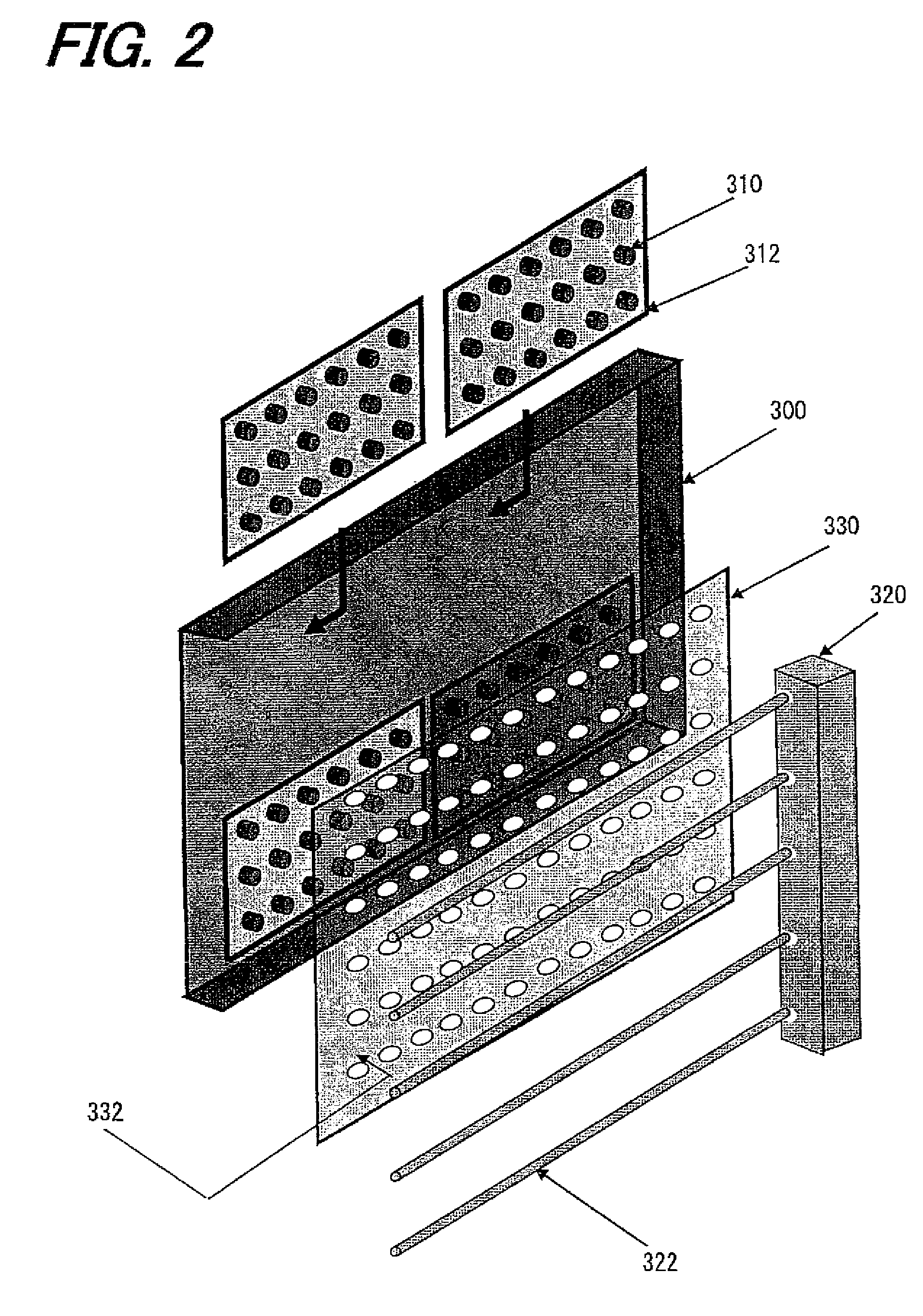

Backlight device and liquid crystal display device

InactiveUS20090168396A1Suppress brightness unevennessSuppress color unevennessElectroluminescent light sourcesIlluminated signsLiquid-crystal displayDividing circuits

In order to control light emission of light emitting diodes, current dividing circuits are used to supply currents of a substantially fixed level to all lines. Light emitting diodes are arranged in groups of a predetermined number of LEDs in series, and sets of the light emitting diodes connected to the first line and sets of the light emitting diodes connected to the second line are laid out on the same straight line so as to form a single row. Substrates with these formed thereon are arranged adjacent to each other in the direction of the rows, so that sets of the light emitting diodes connected to the first line and sets of the light emitting diodes connected to the second line are arranged alternately. With this configuration, it is possible to provide a backlight device with a plurality of LED arrays arranged thereon, which can uniformly illuminate the entire screen with light from the LED arrays.

Owner:SHARP KK

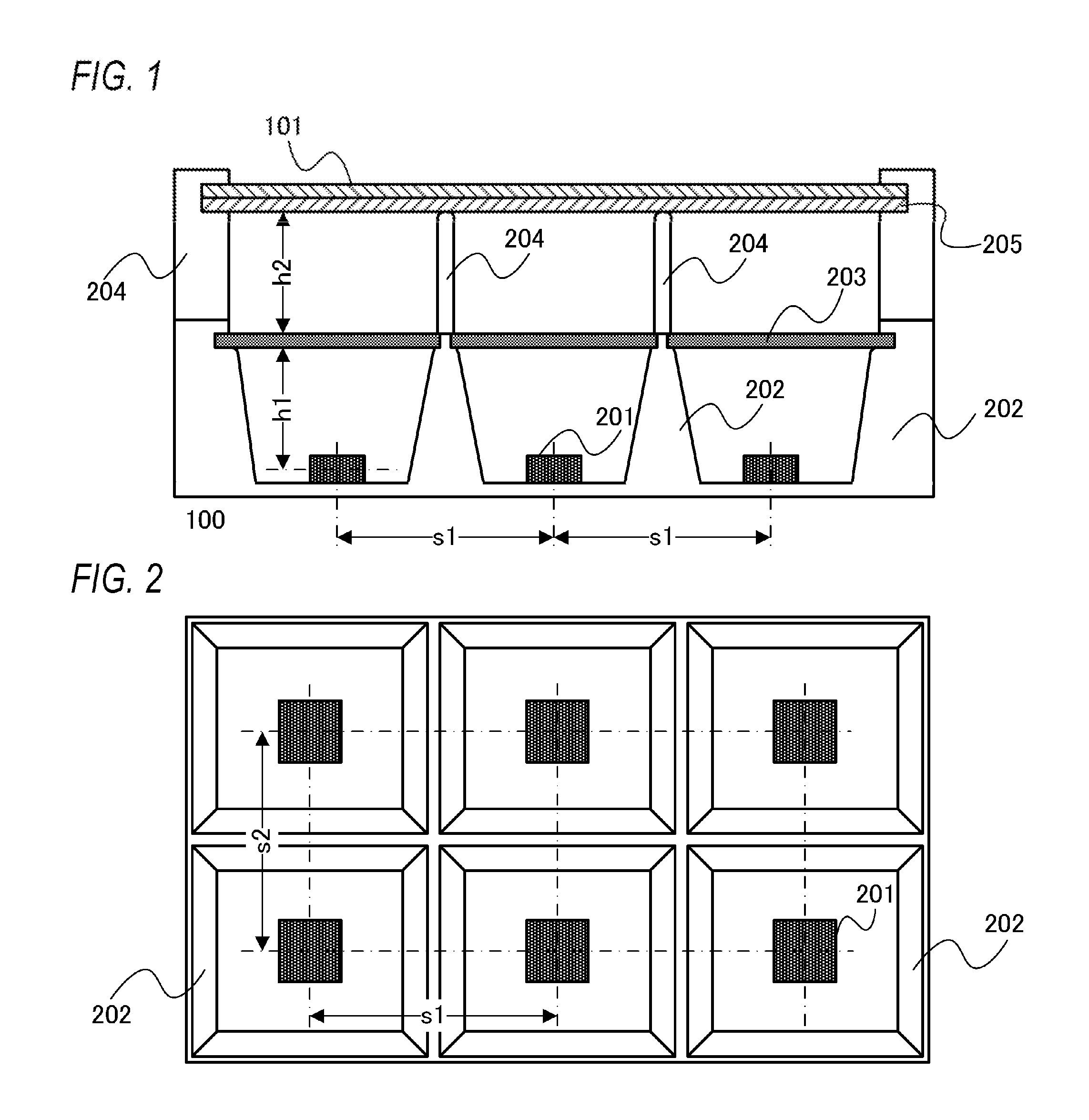

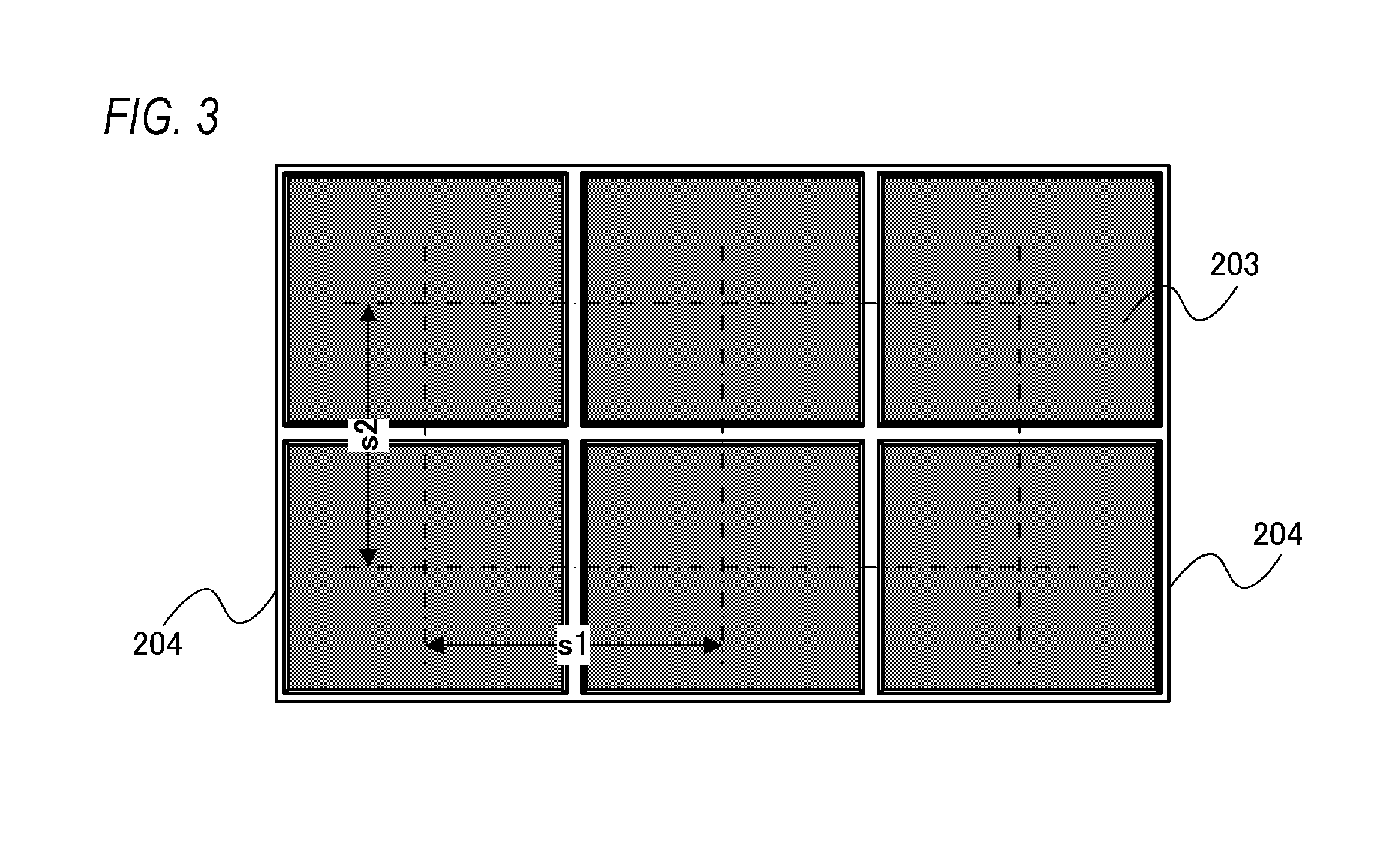

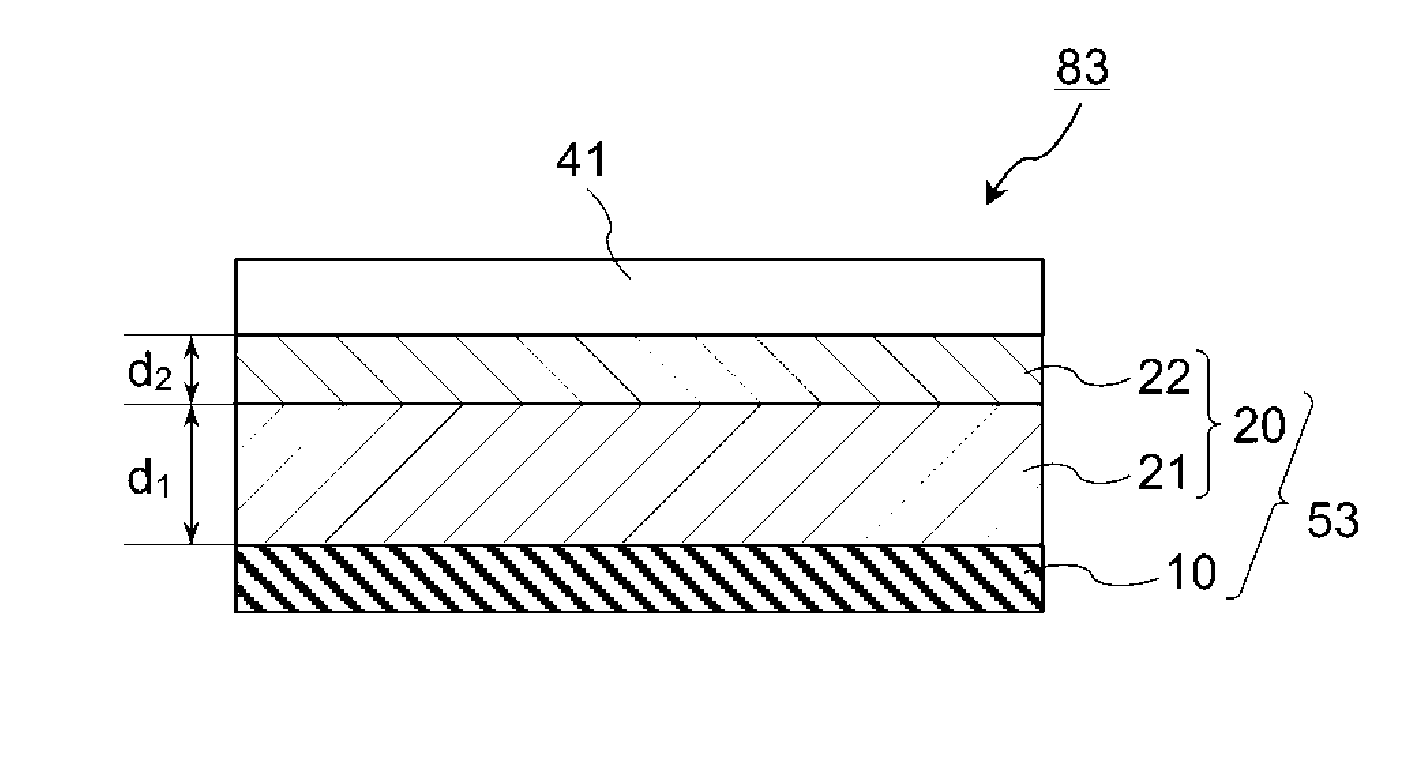

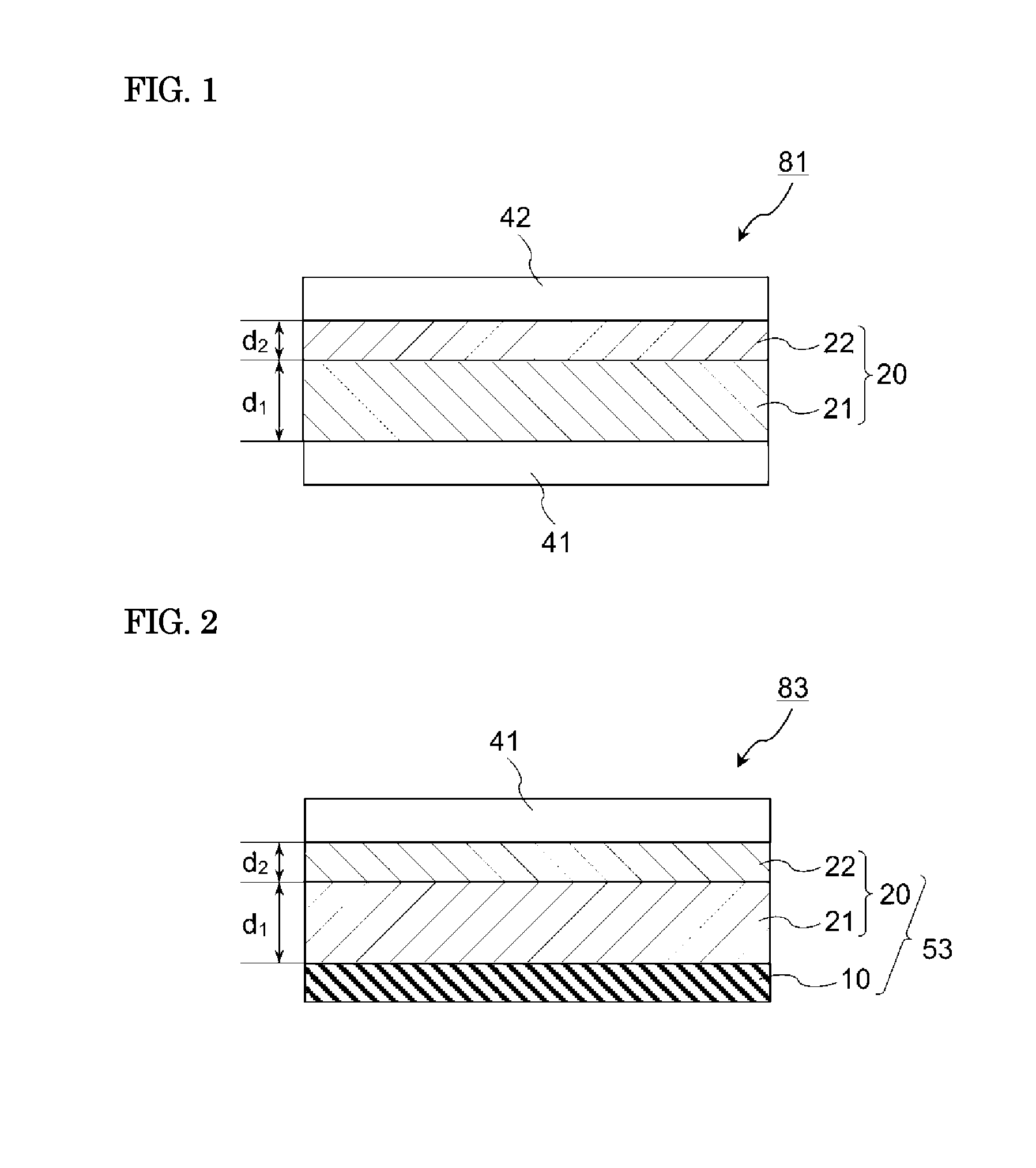

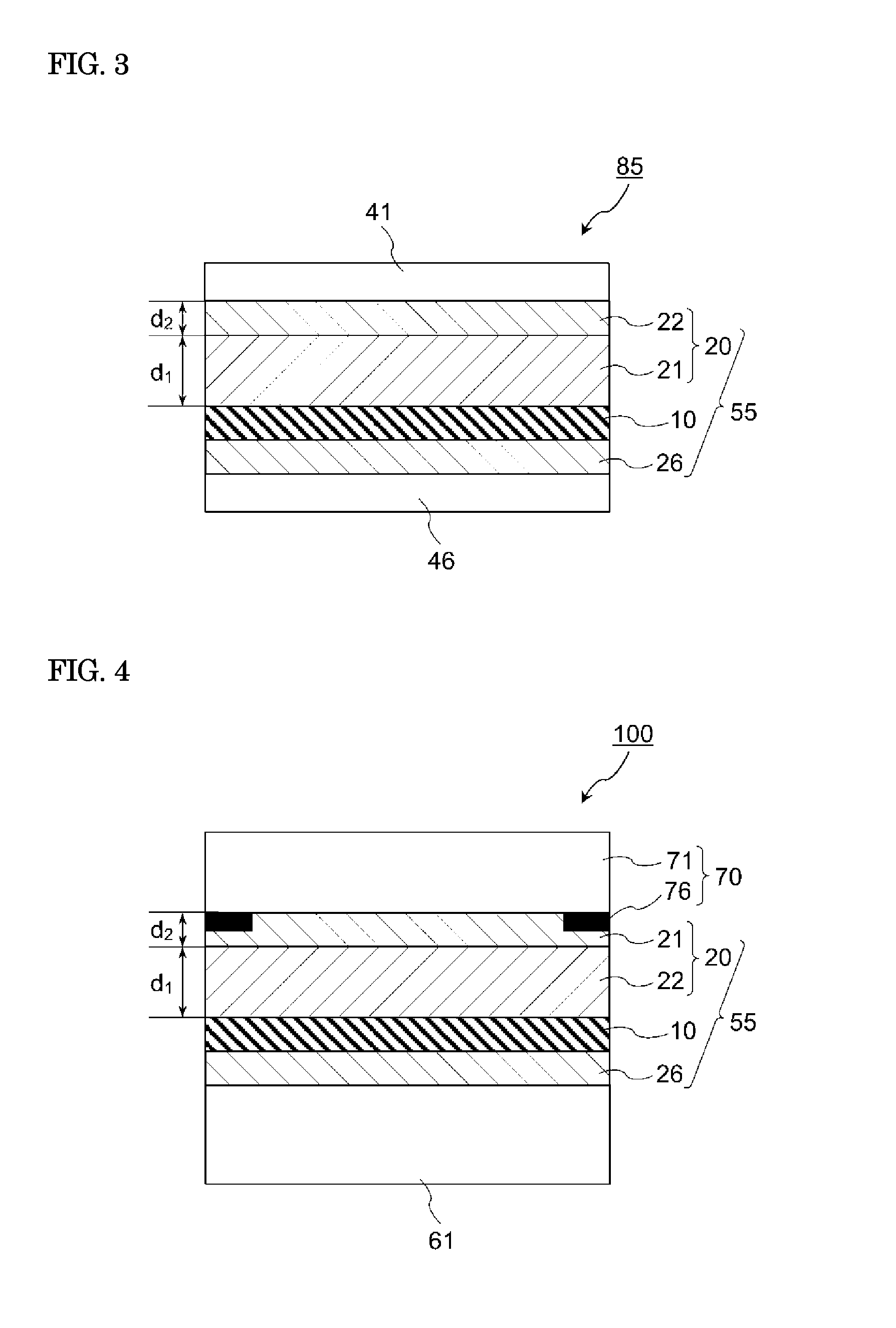

Light source apparatus and image display apparatus

ActiveUS20150300576A1Good colorImprove unevennessNon-electric lightingPoint-like light sourceOptoelectronicsLight source

A light source apparatus includes: a plurality of light sources provided, respectively, in a plurality of first divided regions; a first suppressing member that suppresses, for each of the plurality of first divided regions, spreading of light emitted from a light source provided in the first divided region; a conversion member that converts the color of the light emitted from the light sources and emits light of the converted color; and a diffusing member that is provided on a side closer to the emission surface than the conversion member so as to diffuse the light emitted from the conversion member, wherein the diffusing member is apart from the conversion member by a predetermined distance.

Owner:CANON KK

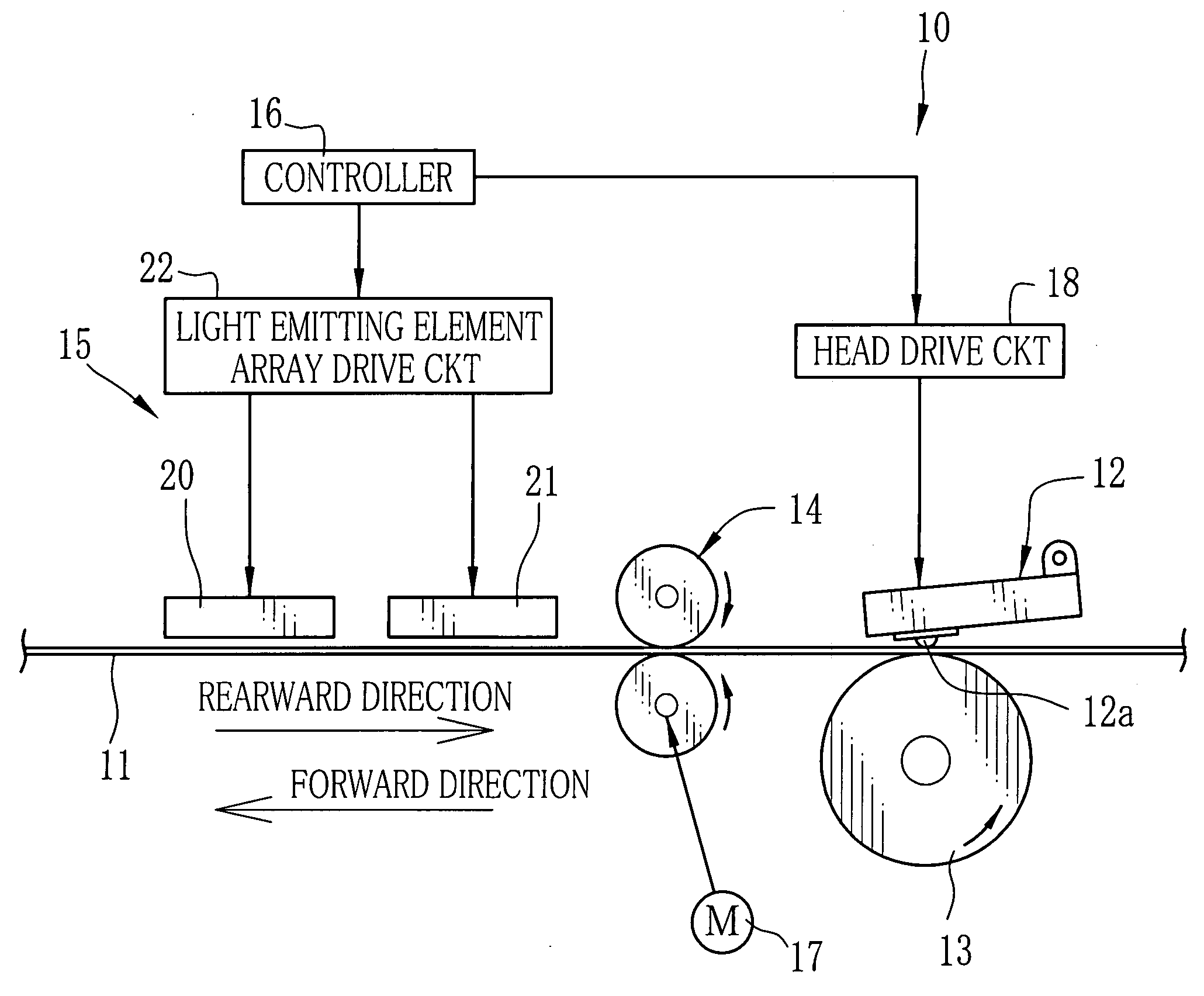

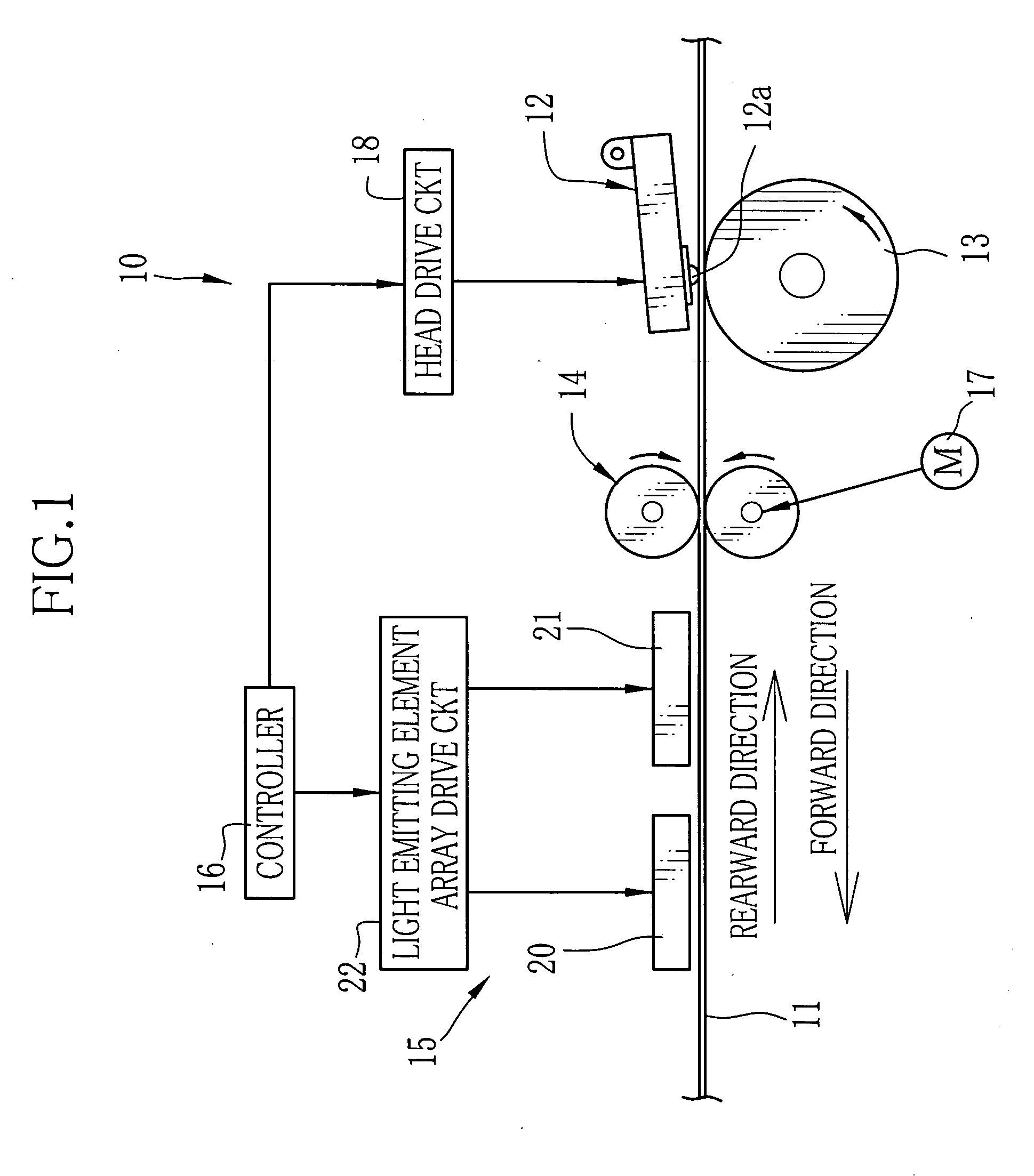

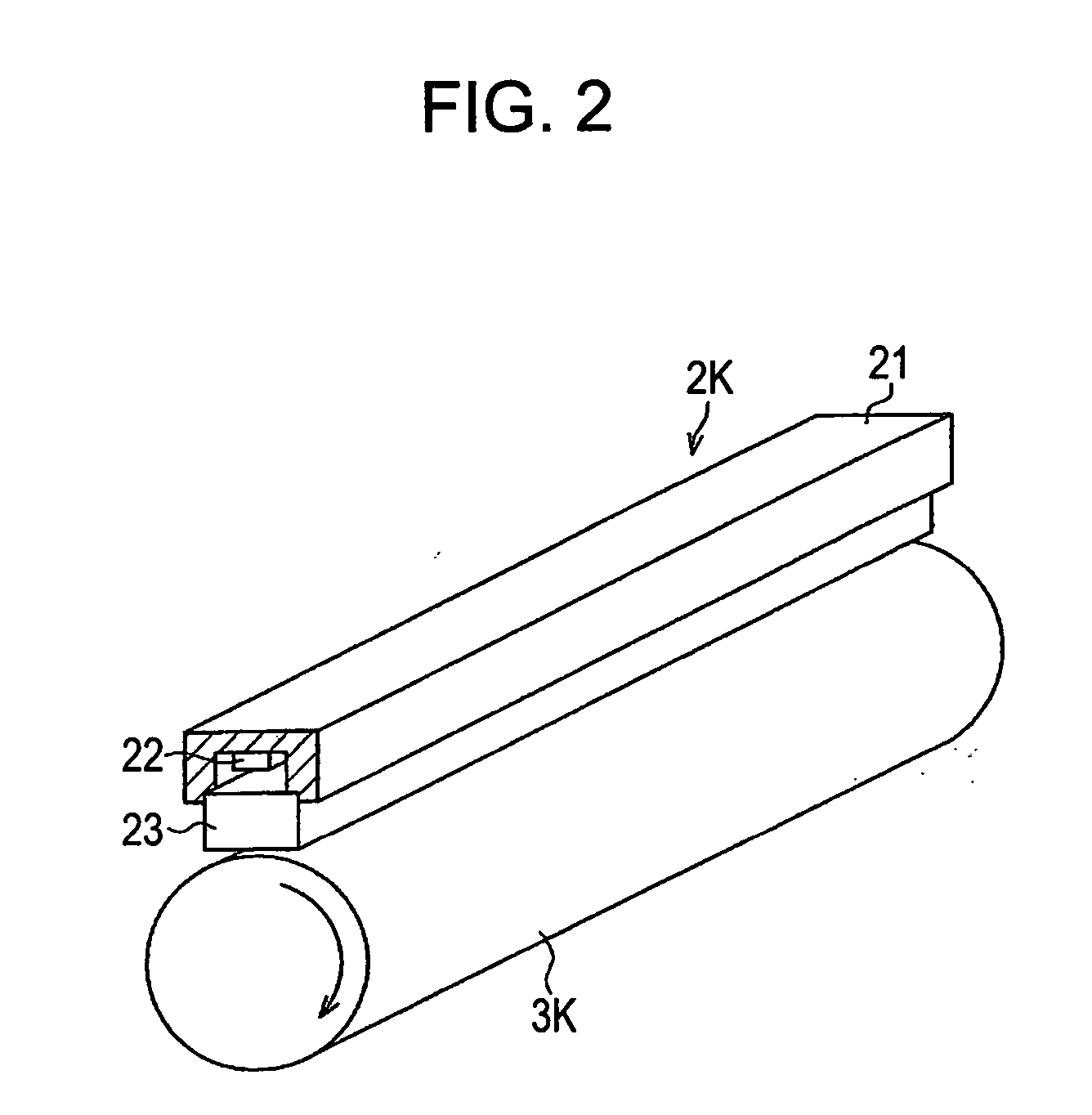

Luminous device and optical fixing device

InactiveUS20060050133A1Reduce in quantityLow costElectrographic processes using charge patternPrintingIlluminanceLed array

A luminous device comprises an array of LEDs aligned in a plural number “m” of lines which extend in a main scan direction, and are apposed in a sub scan direction orthogonal to the main scan direction. The array is grouped into a number of blocks to be driven block by block, each block consisting of a number “q” of LEDs connected in serial to one another, wherein q=m. Where the numbers “q” and “m” are five and two respectively, two or three of the five LEDs of the same block are located in one of the two lines (L1), whereas other LEDs of that block are located in the other line (L2), such that the LEDs of the different blocks are located substantially in the same column in the sub scan direction, to distribute the LEDs of the same block in the main scan direction. Thereby, unevenness in integral illuminance in the sub scan direction is reduced even if there are illuminance variations between the blocks.

Owner:FUJIFILM HLDG CORP

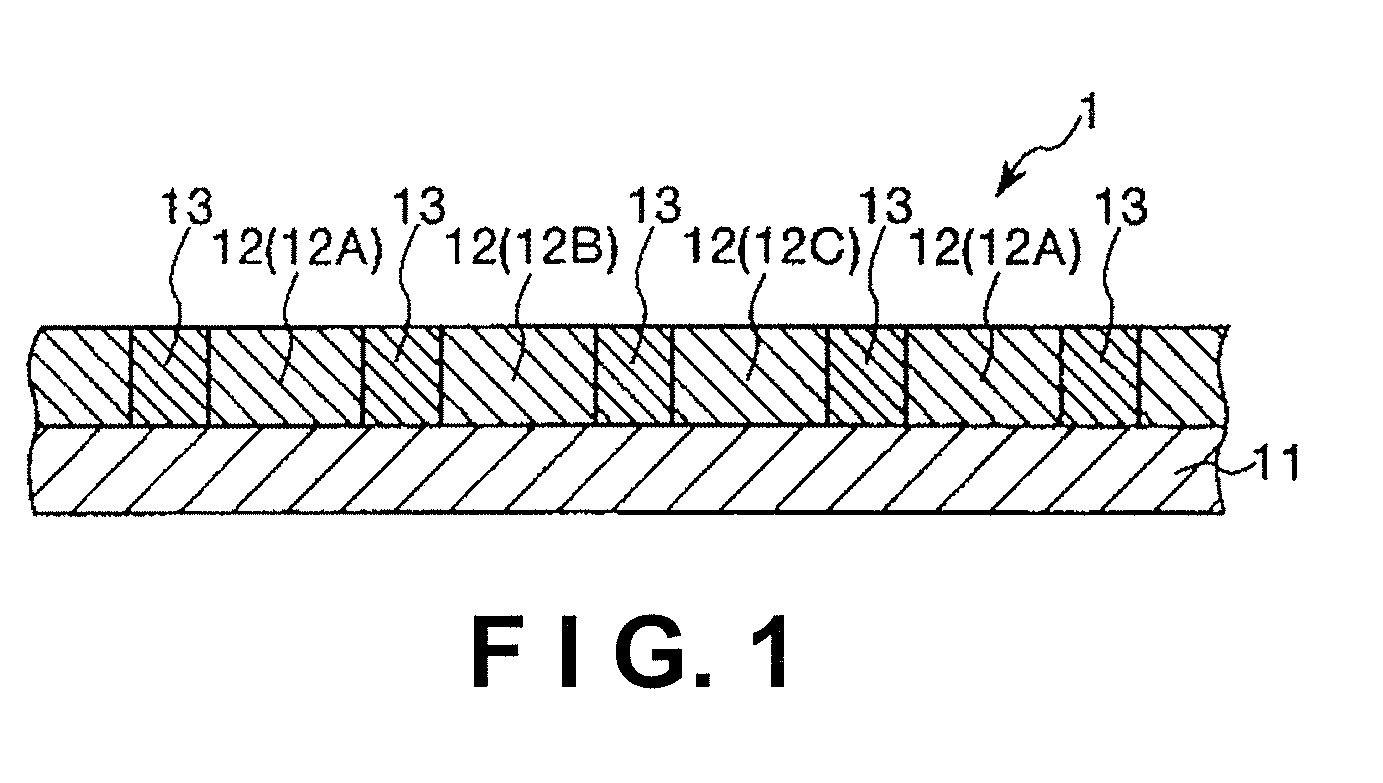

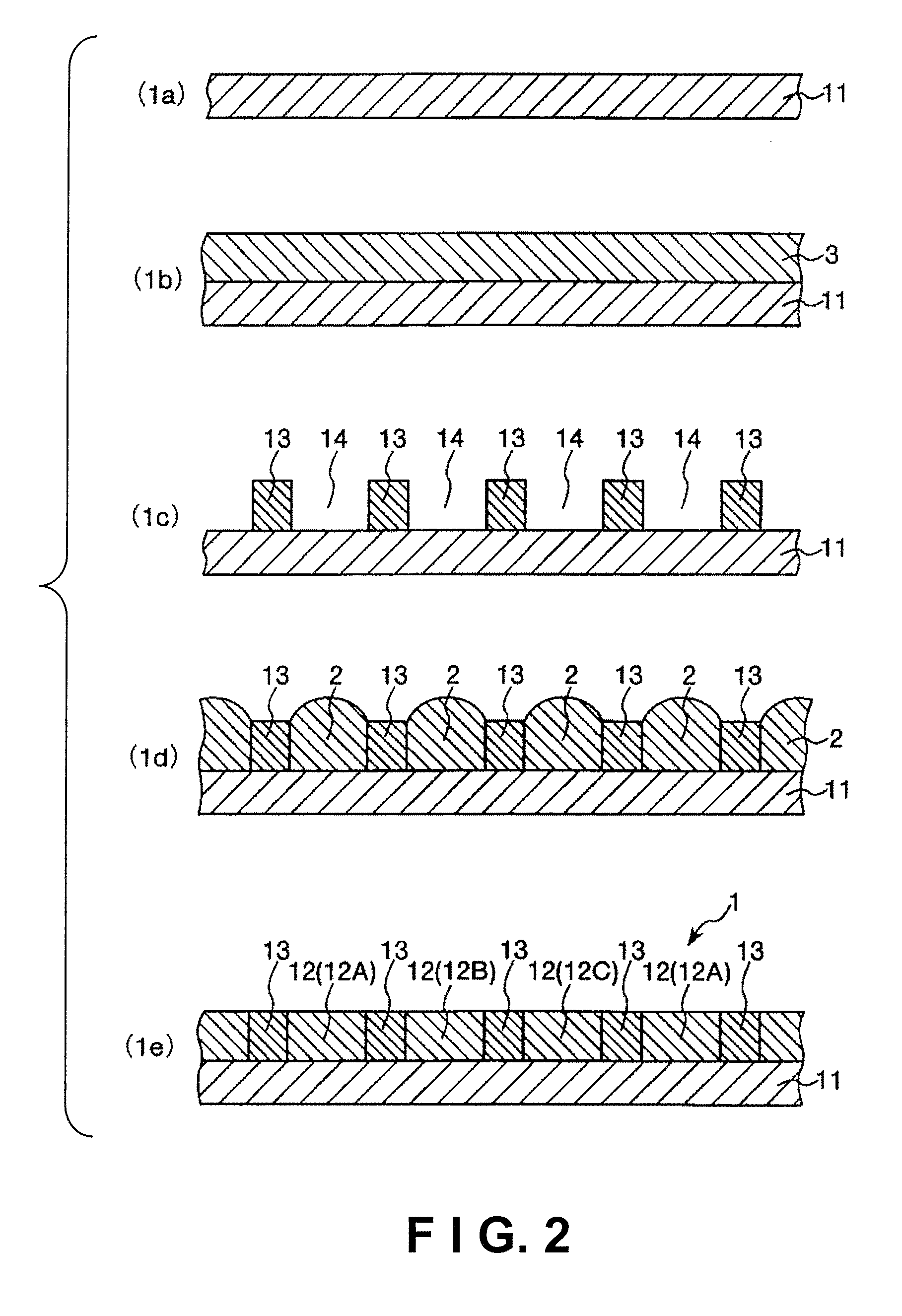

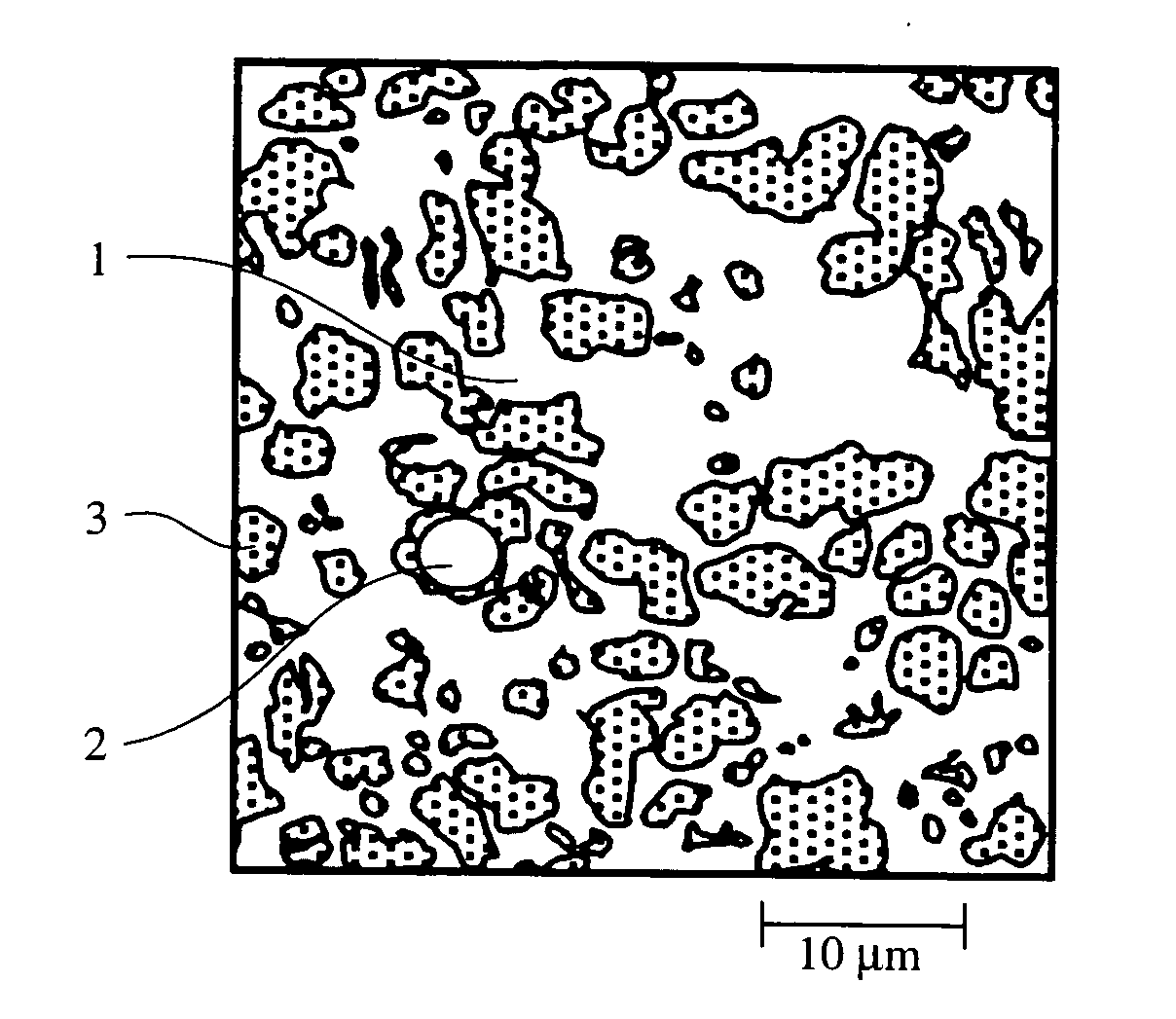

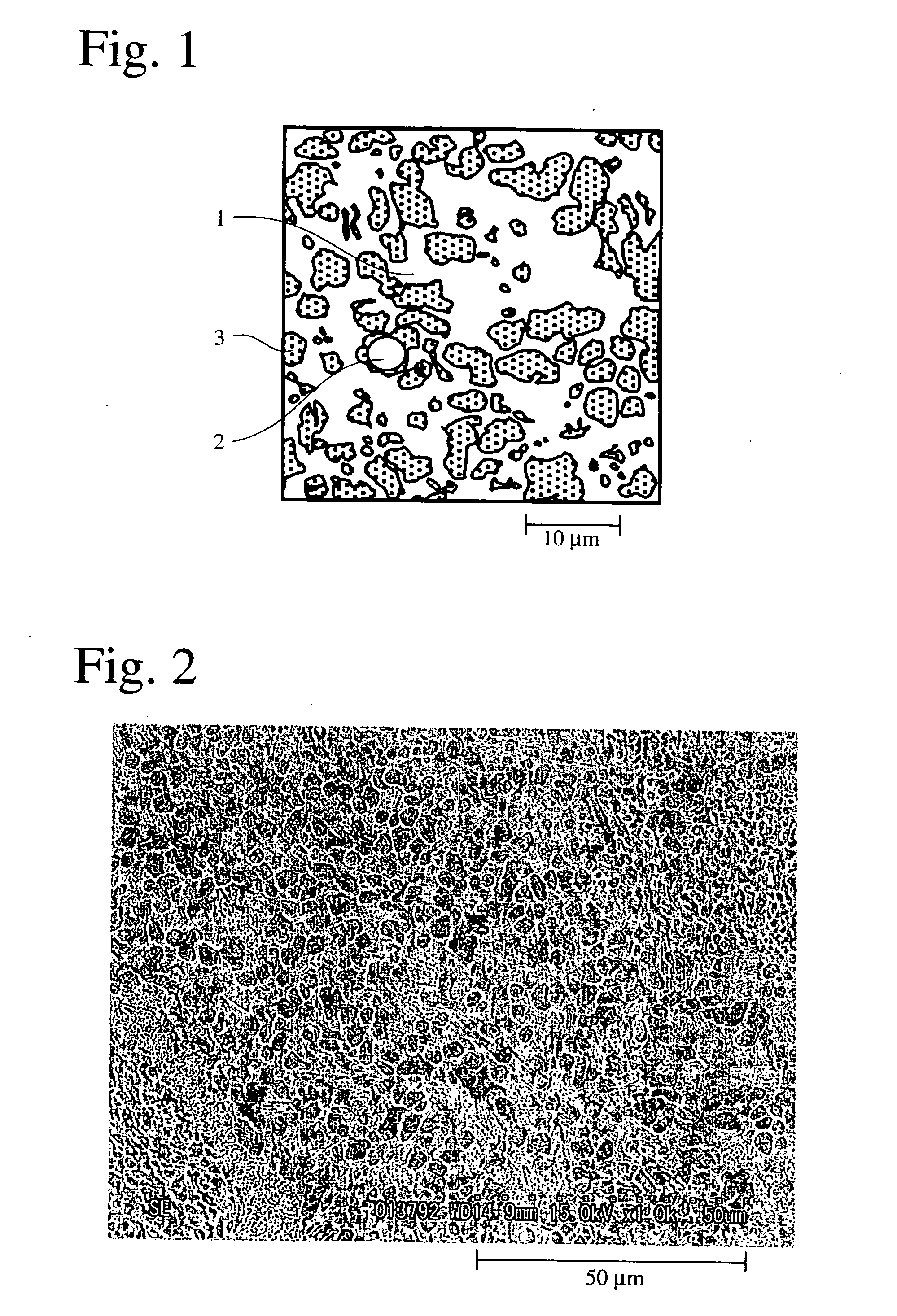

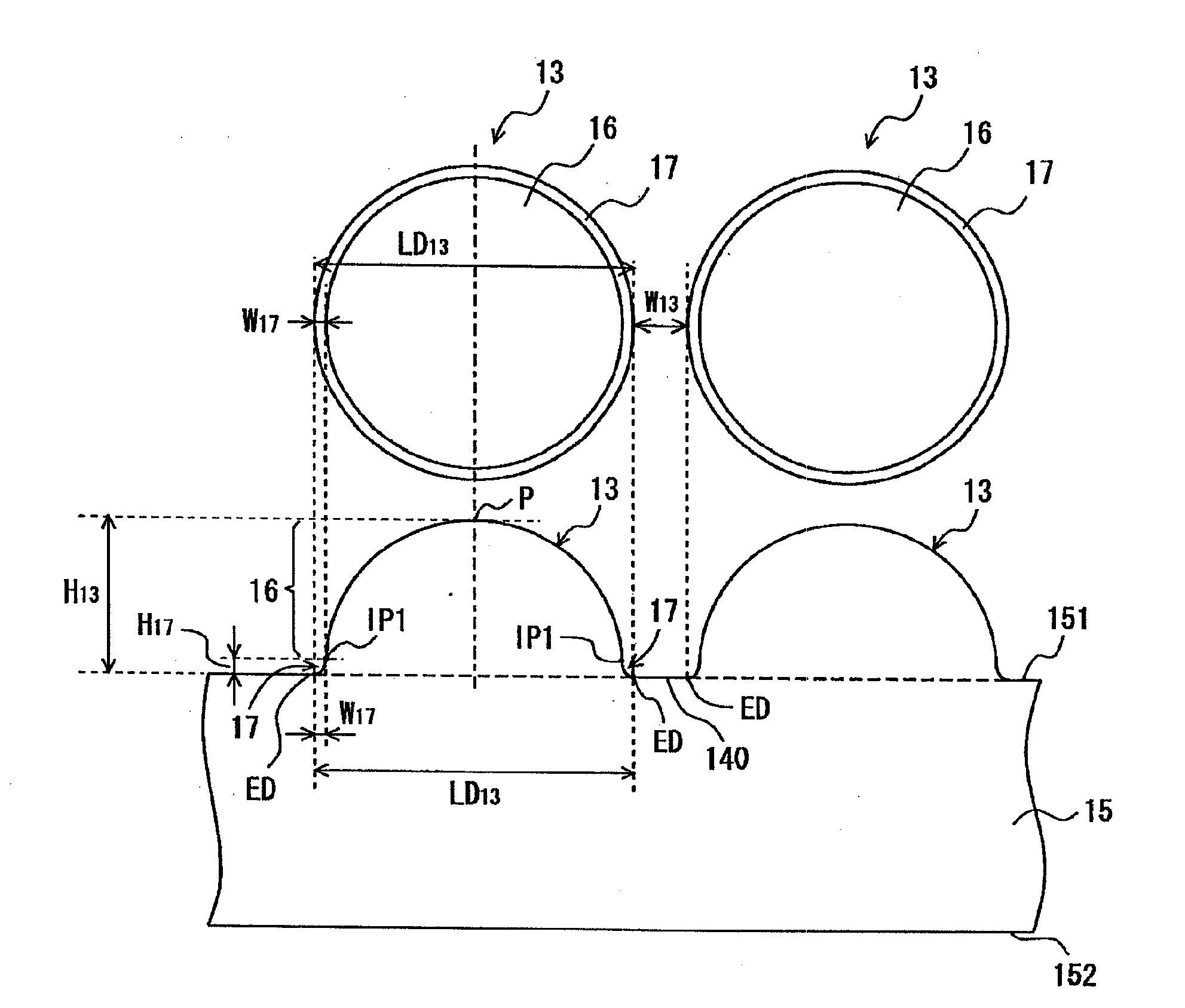

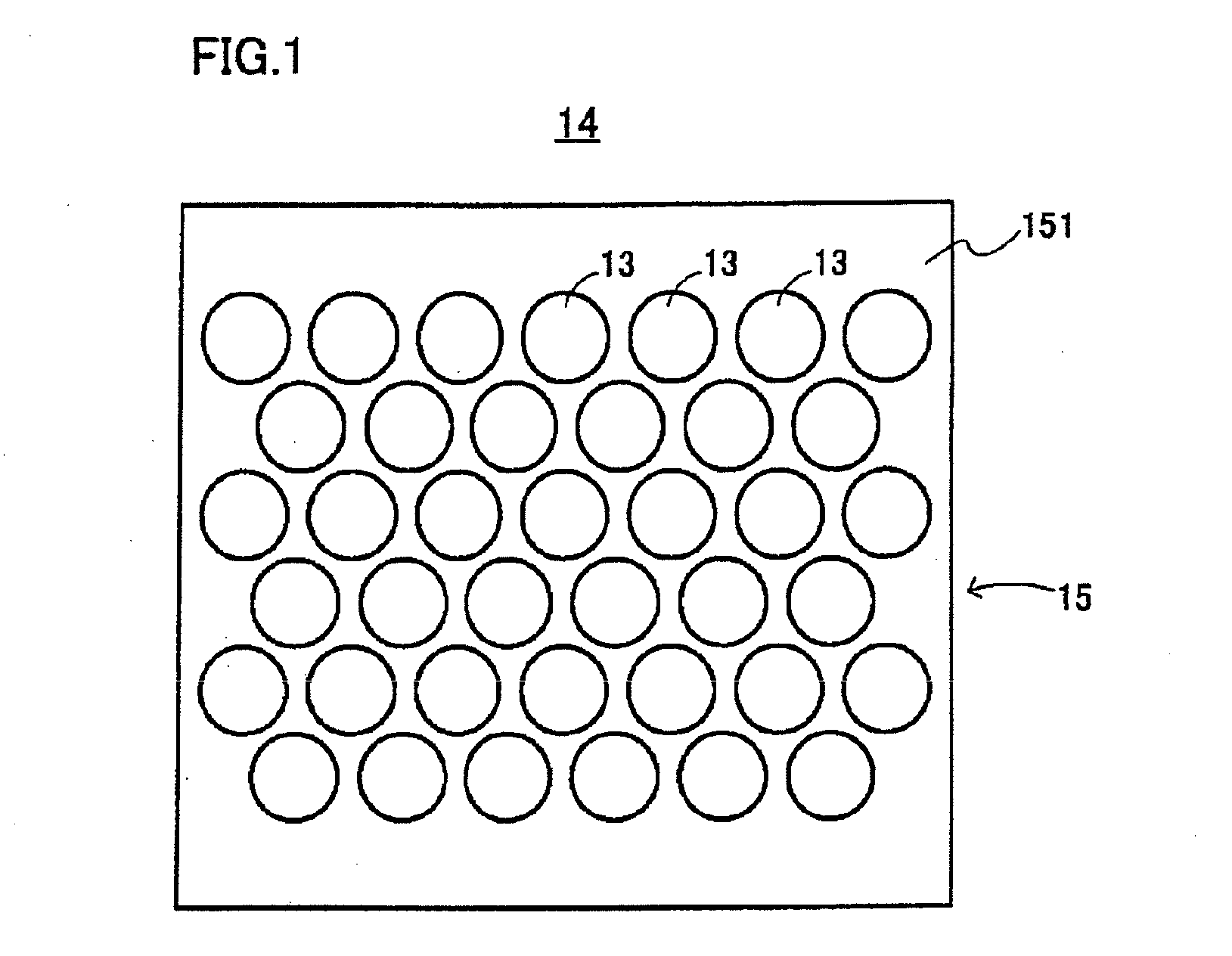

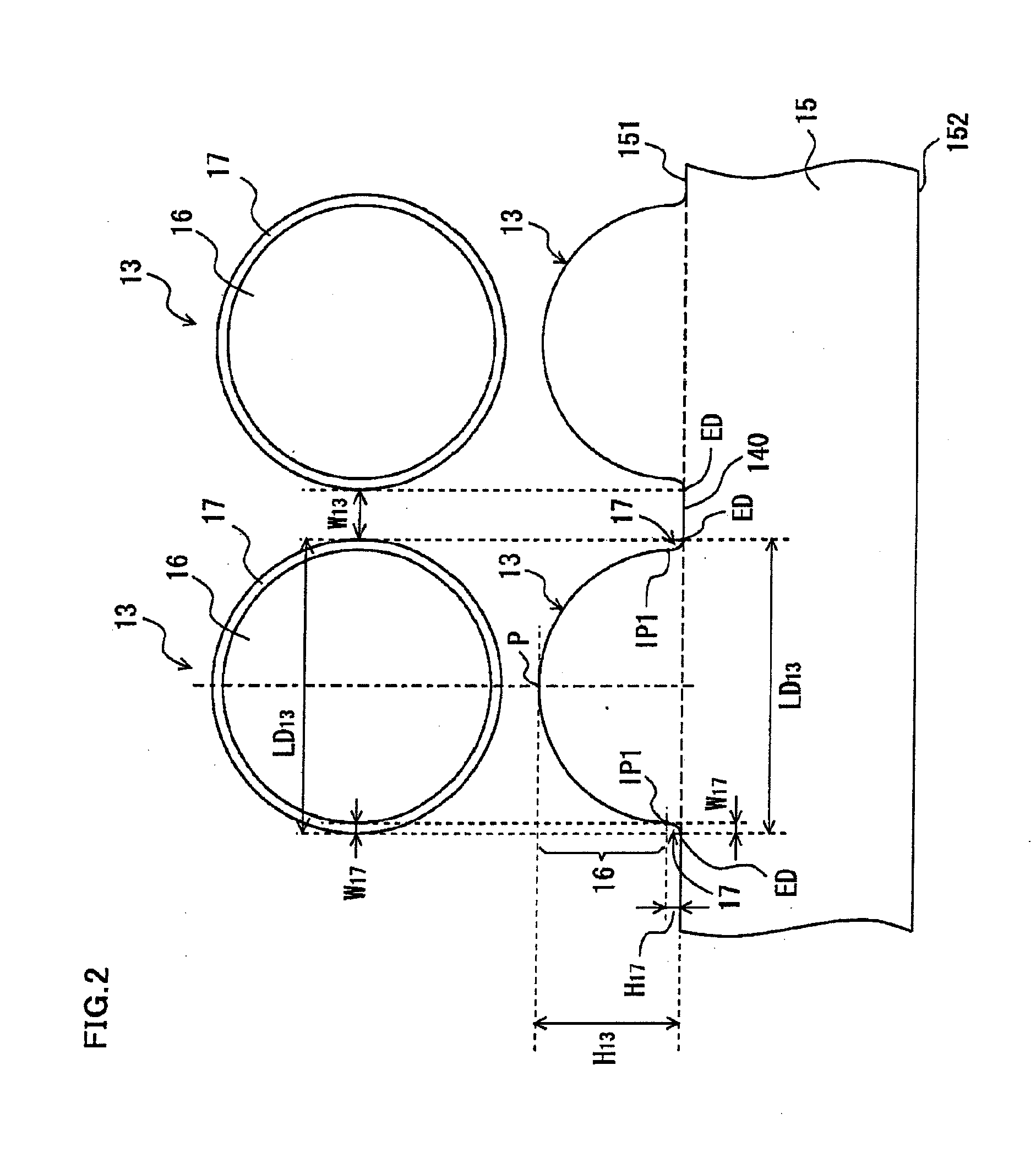

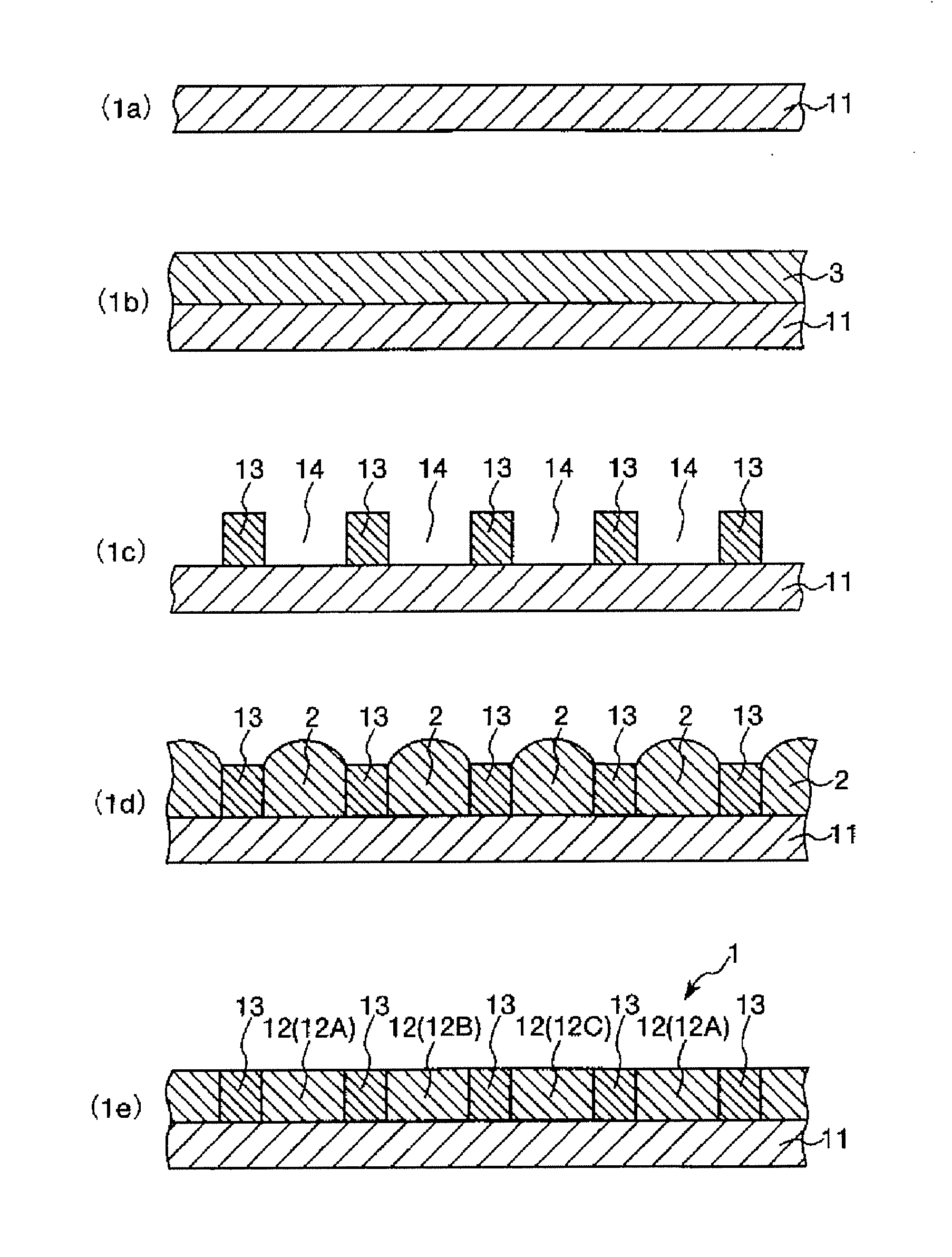

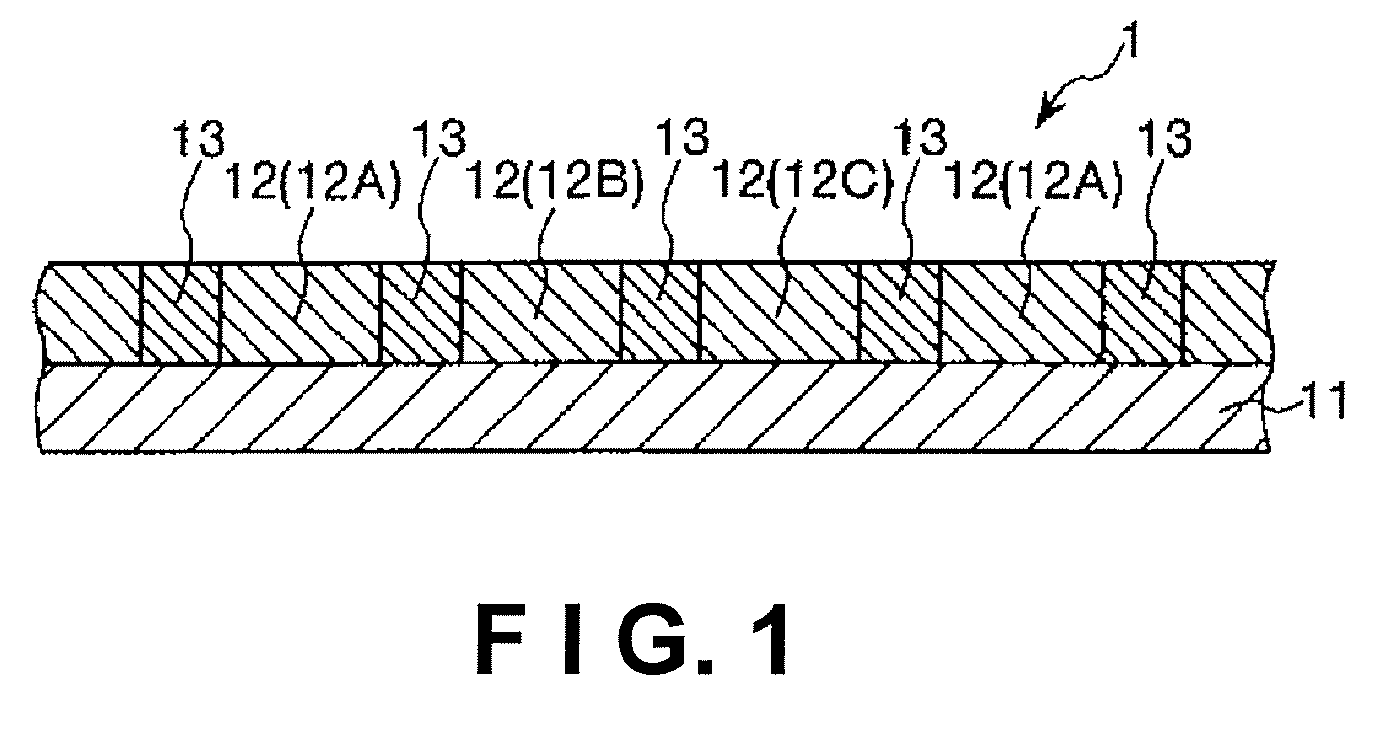

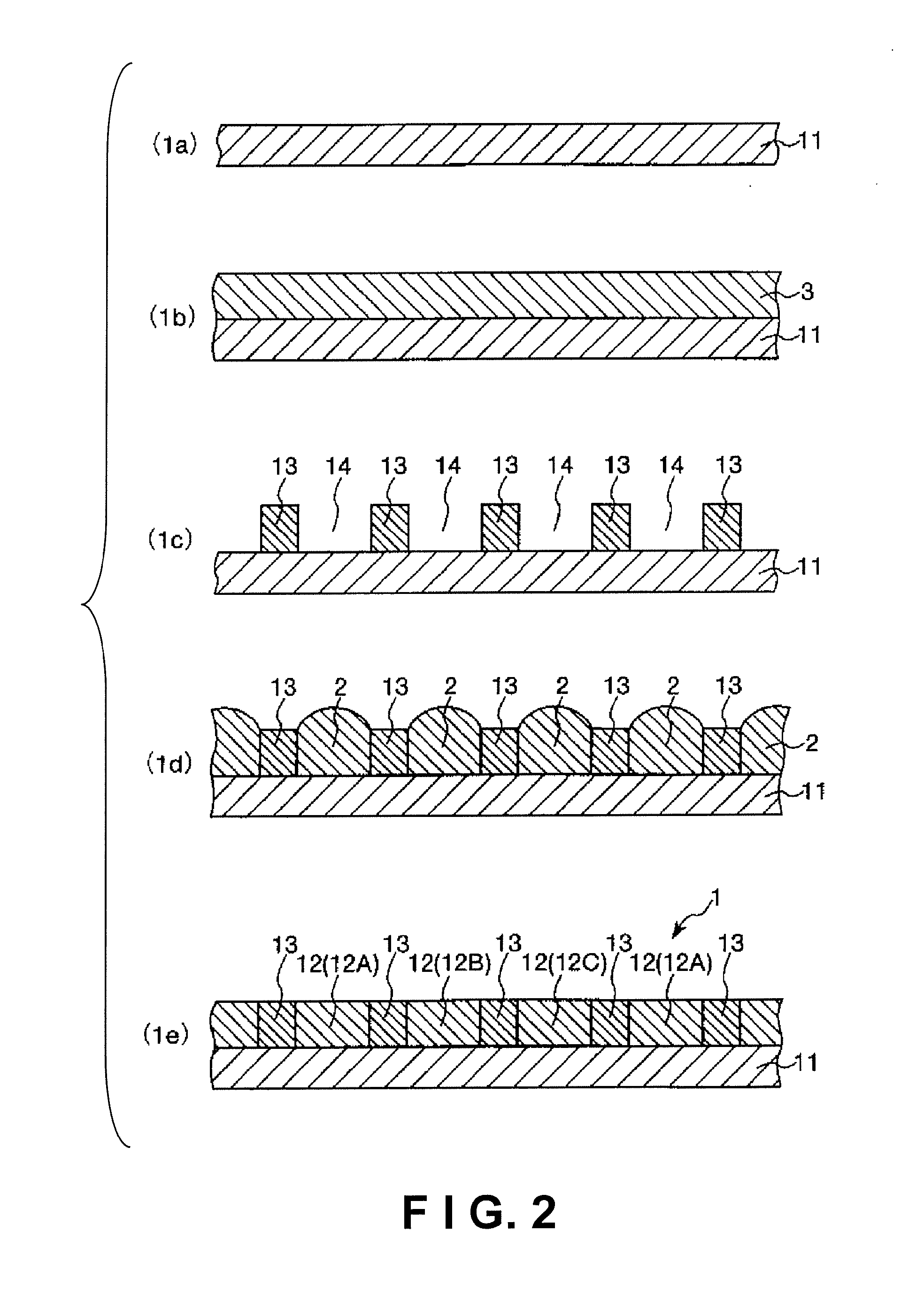

Micro lens array sheet for use in backlight device and molding roll for manufacturing such mirco lens array sheet

ActiveUS20090244713A1Easy to disassembleSuppression of uneven brightnessDiffusing elementsConfectioneryEngineeringMicro lens array

A micro lens array sheet includes a sheet type base and a plurality of micro lenses arranged on the base. The surface of each micro lens includes a convex part and a peripheral edge part. The convex part has a spherical or elliptical surface. The peripheral edge part is formed between the convex part and the base and curved in a concave shape. Since the surface of the peripheral edge part is curved in a concave shape, the flat part can be narrower than a conventional micro lens array sheet. Therefore, luminance unevenness attributable to the flat part can be suppressed.

Owner:MAXELL HLDG LTD

Back grinding method for wafer

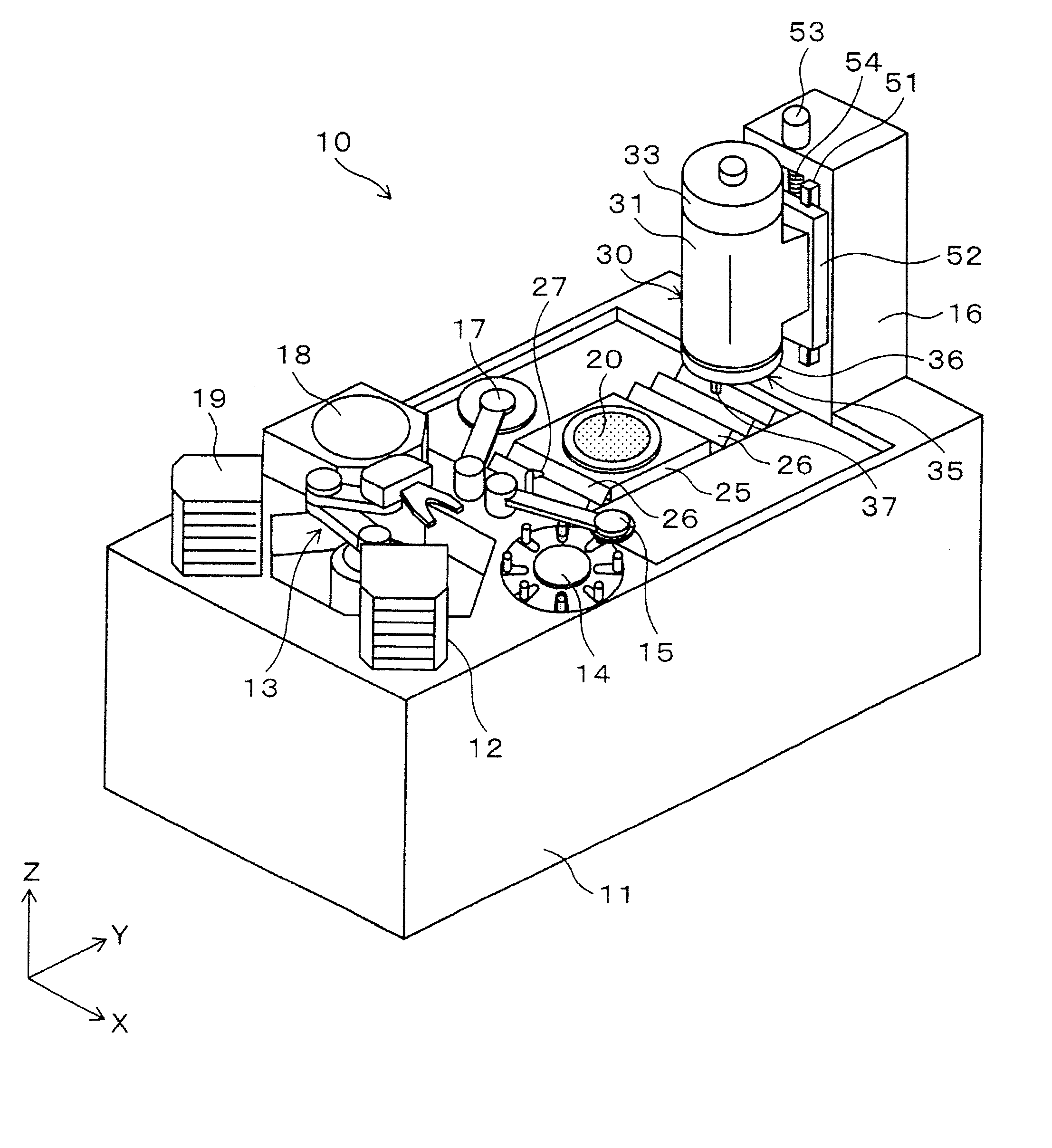

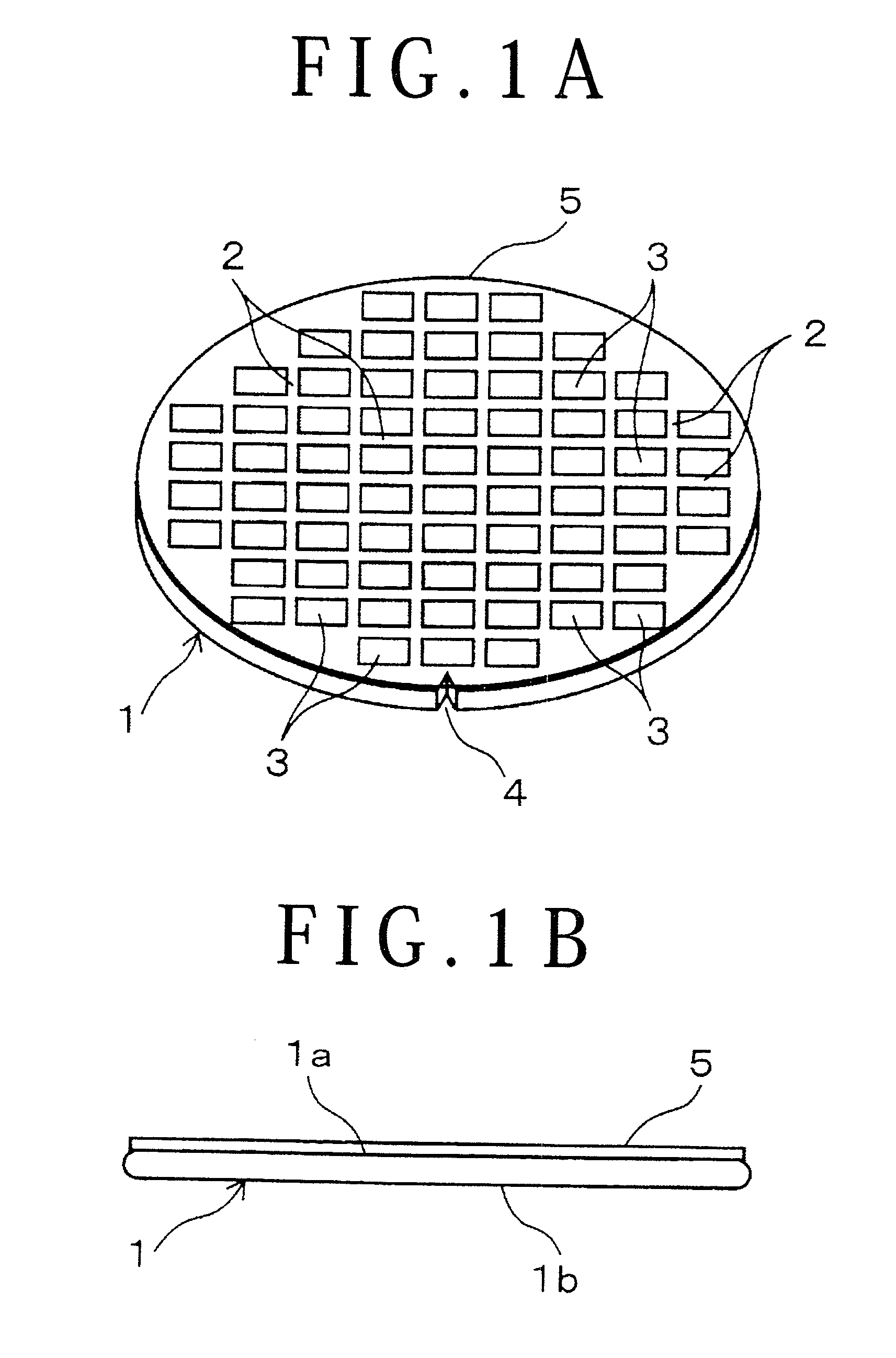

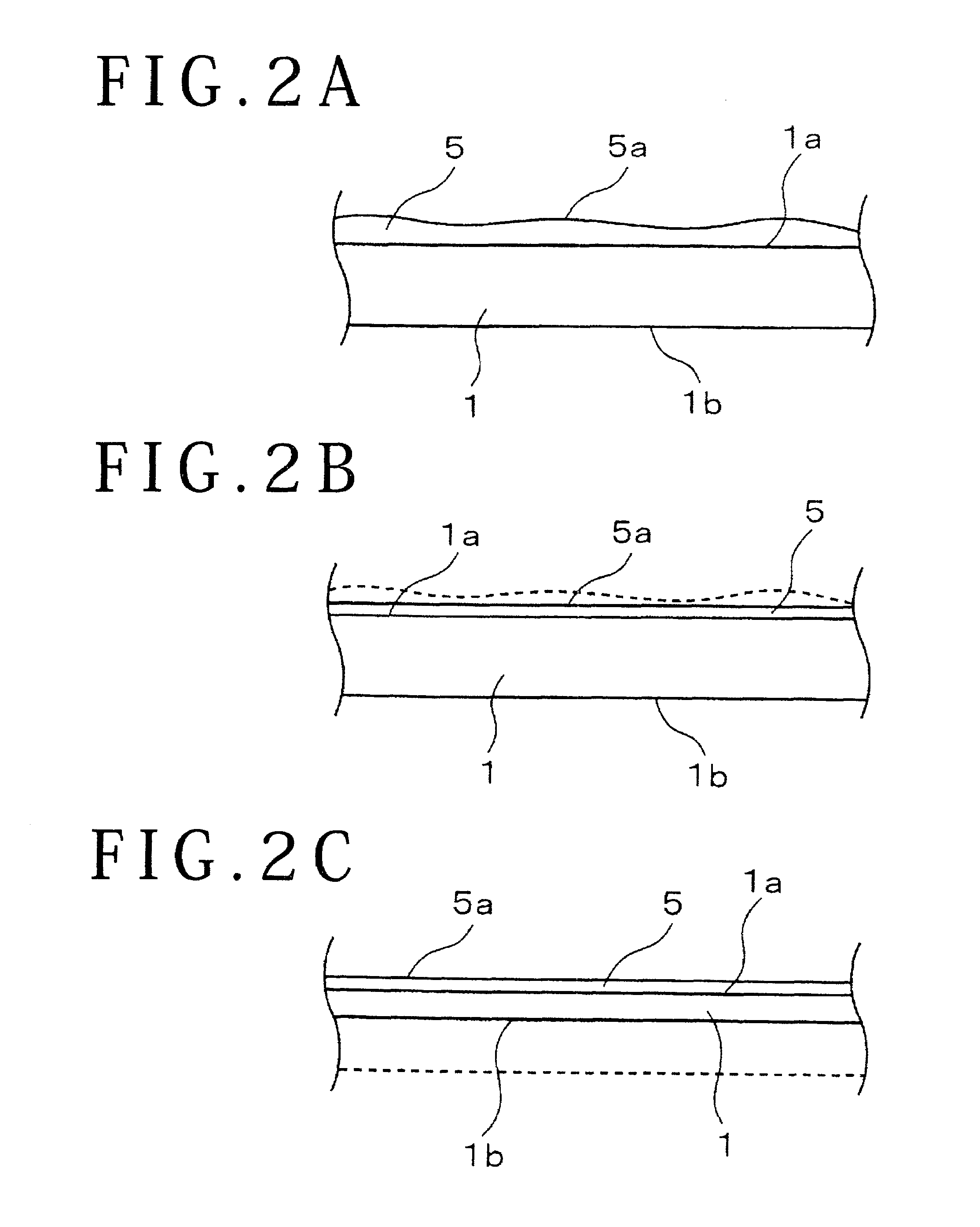

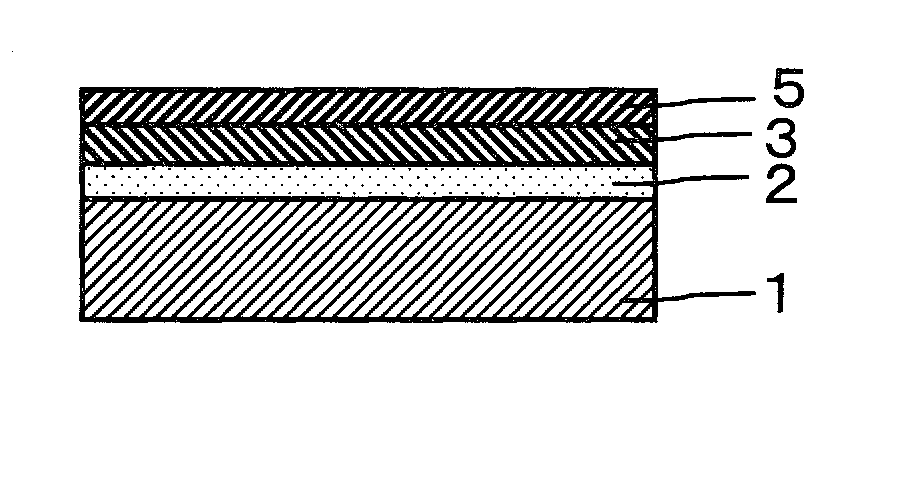

ActiveUS20090042488A1Uniform thicknessImprove accuracyGrinding feed controlAutomatic grinding controlEngineeringSuction surface

A back grinding method for a wafer includes covering a face-side surface of the wafer with a resin film, and cutting the surface of the resin film to form a flat surface parallel to the face-side surface of the wafer. The wafer is held with the surface of the resin film in contact with a suction surface of a chuck table in a grinding apparatus, and the exposed back-side surface of the wafer is ground. Unevenness in thickness of the resin film is suppressed, whereby the thickness of the wafer subjected to back grinding is made to be uniform.

Owner:DISCO CORP

Pressure-sensitive adhesive optical film and image display

InactiveUS20080145572A1Display unevenness can be preventedSuppress display unevennessLiquid crystal compositionsFilm/foil adhesivesMeth-Display device

A pressure-sensitive adhesive optical film of the present invention comprises: an optical film comprising a transparent base film and a discotic liquid crystal layer on one side of the transparent base film; and a pressure-sensitive adhesive layer that is provided on the discotic liquid crystal layer, wherein the pressure-sensitive adhesive layer is made from a pressure-sensitive adhesive containing an acrylic polymer comprising an alkyl(meth)acrylate (a1) and a ring structure-containing (meth)acrylate (a2) as monomer units and having a weight average molecular weight of 1,000,000 to 3,000,000, and a crosslinking agent. The pressure-sensitive adhesive optical film has durability and can be prevented from causing display unevenness in a peripheral portion of a display screen.

Owner:NITTO DENKO CORP

Optical film with pressure sensitive adhesive and image display device

InactiveUS20160237319A1Reduce interfaceReduce the presence of air bubblesFilm/foil adhesivesSynthetic resin layered productsDisplay devicePressure sensitive

The optical film with pressure sensitive adhesive comprises an optical film and a front-side pressure sensitive adhesive sheet. The front-side pressure sensitive adhesive sheet is a laminated pressure sensitive adhesive sheet and includes a first pressure sensitive adhesive layer disposed in contact with the optical film, and a second pressure sensitive adhesive layer disposed at the furthest from the optical film. The first pressure sensitive adhesive layer has a storage elastic modulus of 9×103 Pa or less at 150° C., and a ratio G′20 / G′150 of 20 or more, where G′20 is a storage elastic modulus at 20° C. and G′150 is a storage elastic modulus at 150° C. The second pressure sensitive adhesive layer has a storage elastic modulus of 4×105 Pa or less at 20° C., and a storage elastic modulus of 1×104 Pa or more at 150° C.

Owner:NITTO DENKO CORP

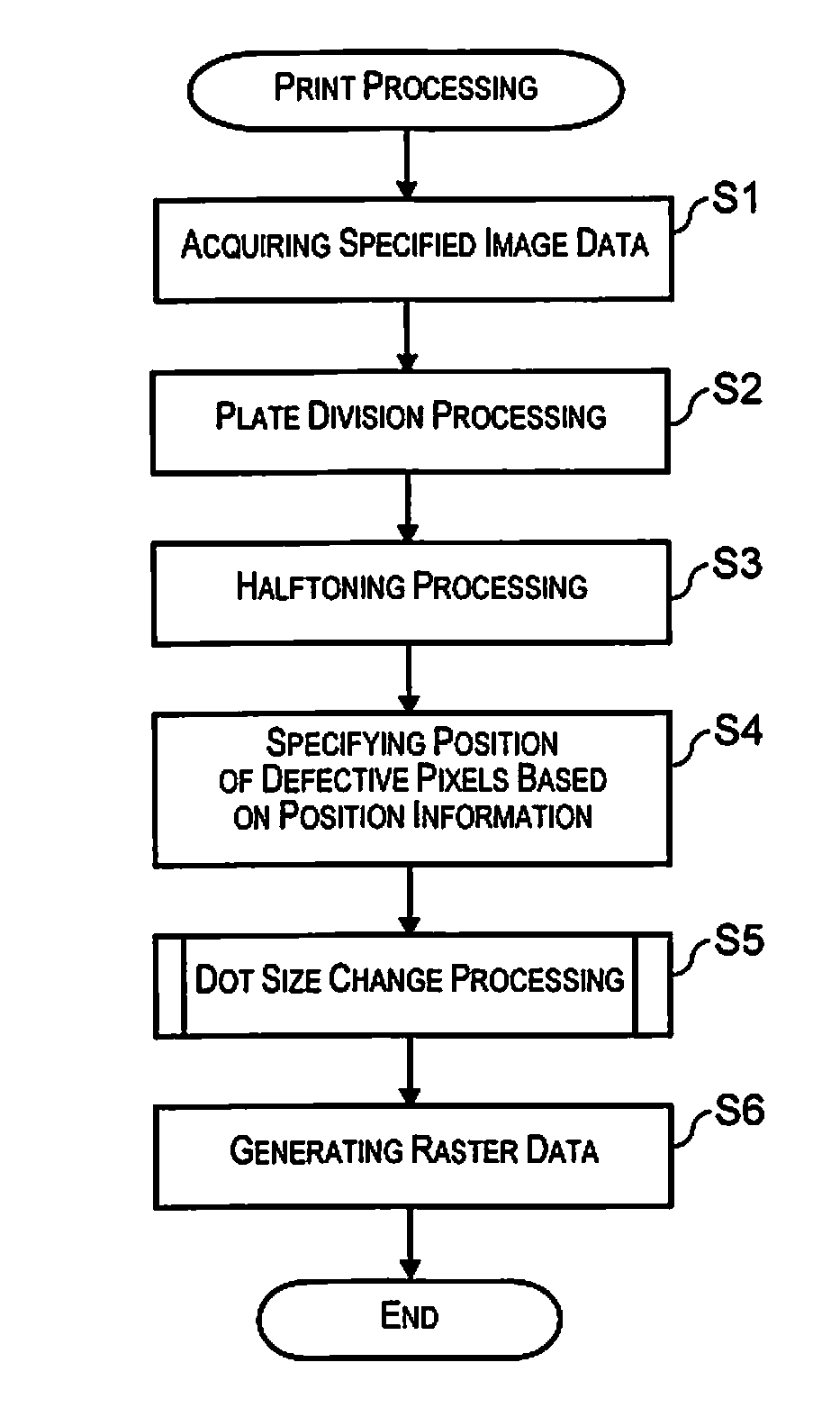

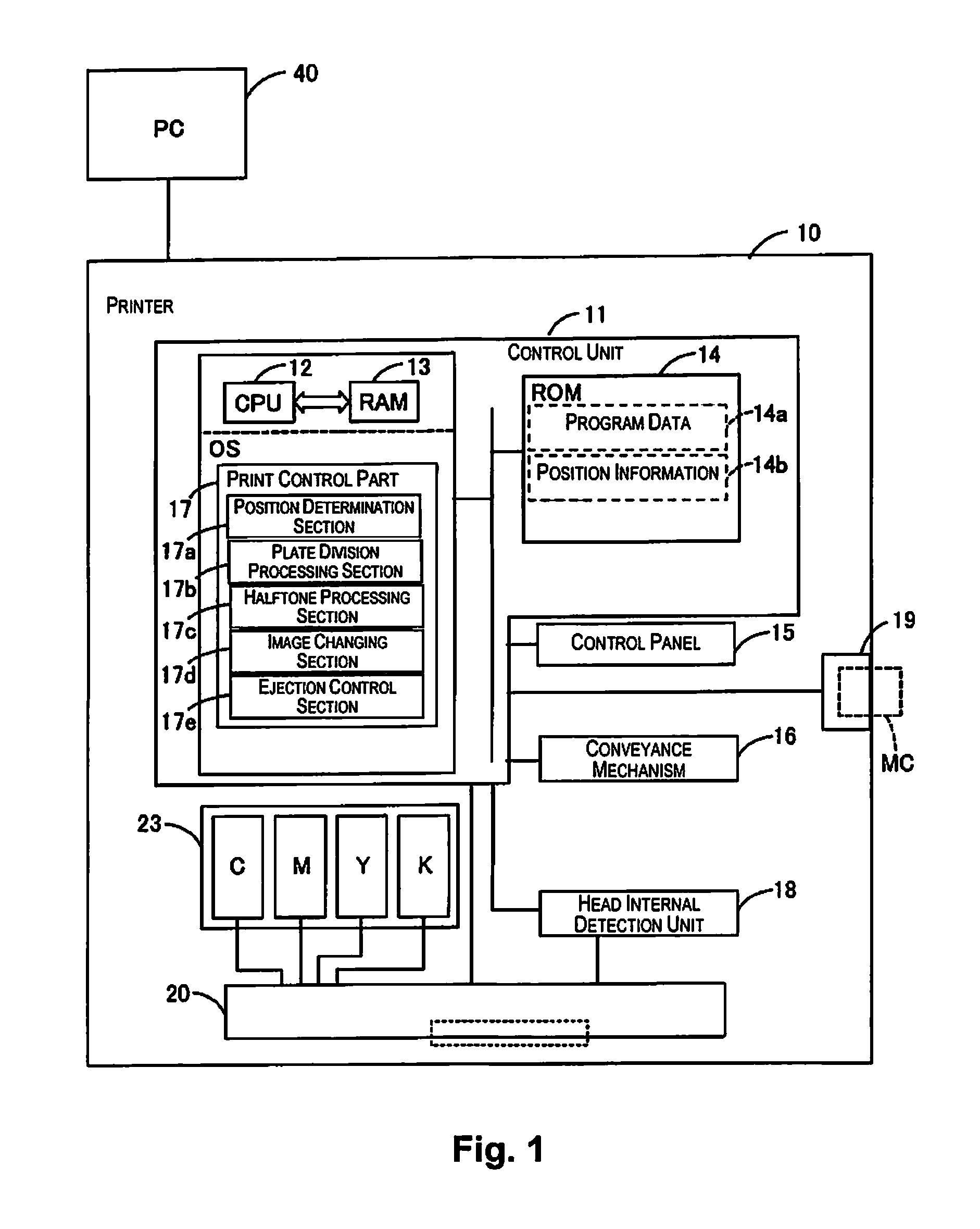

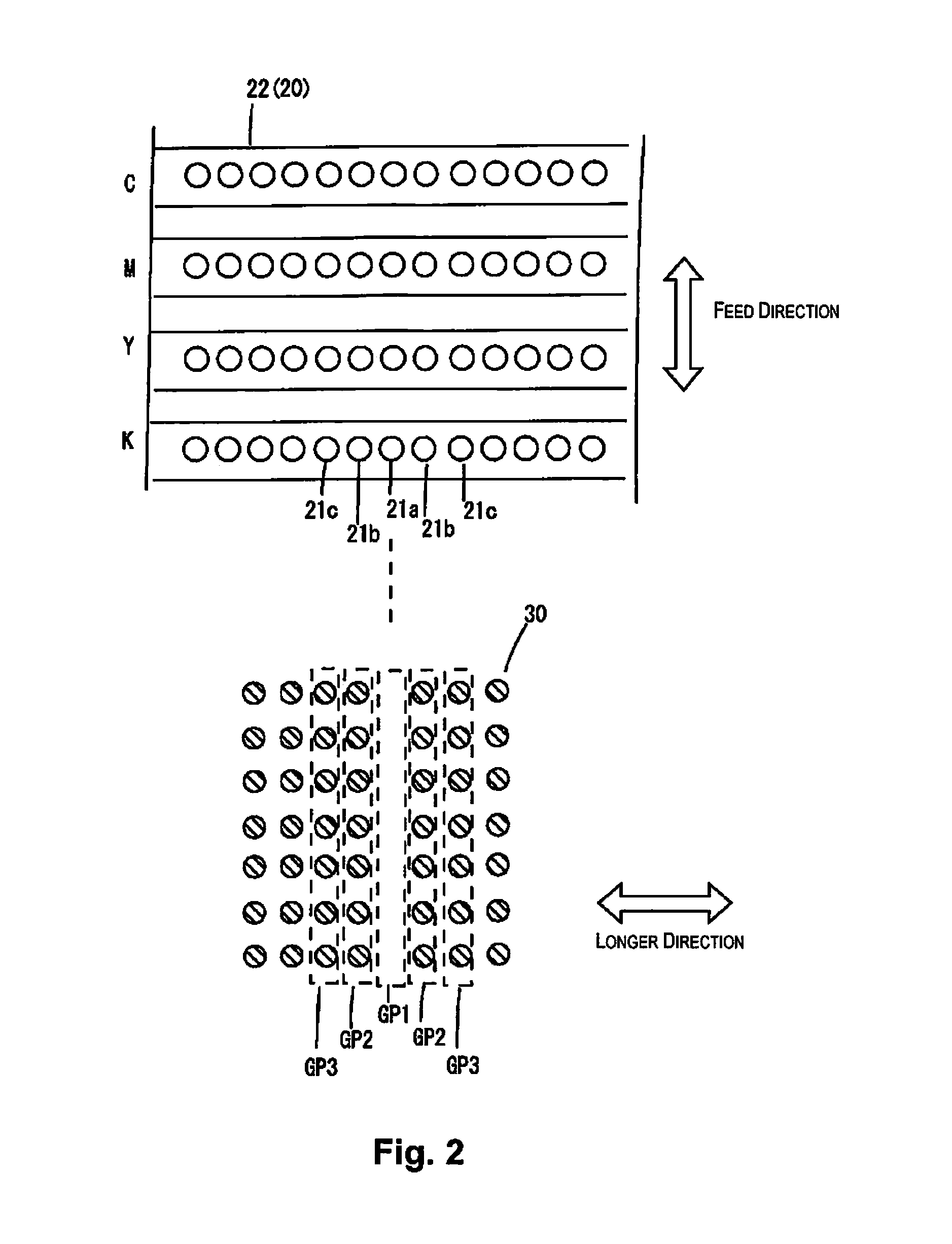

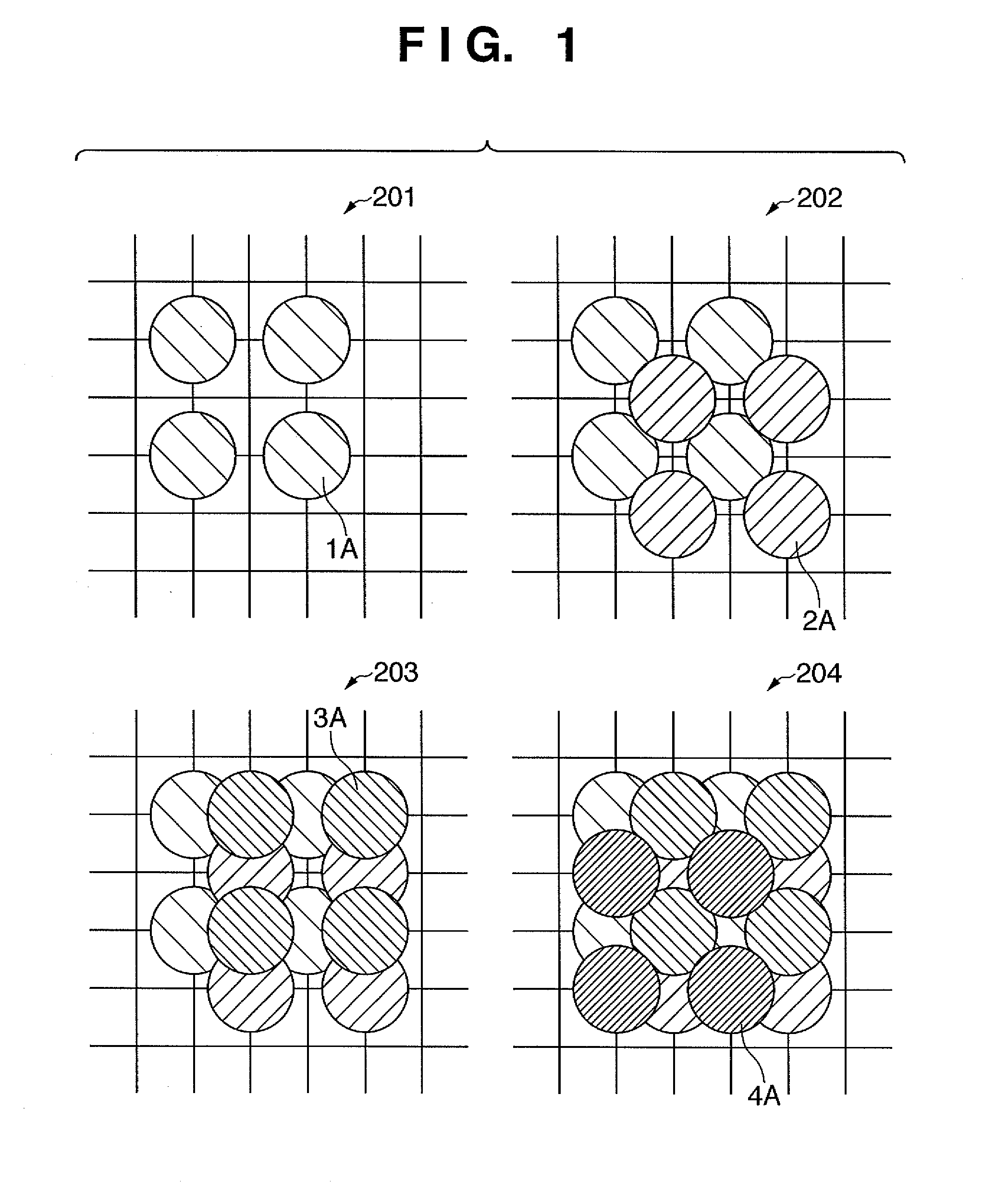

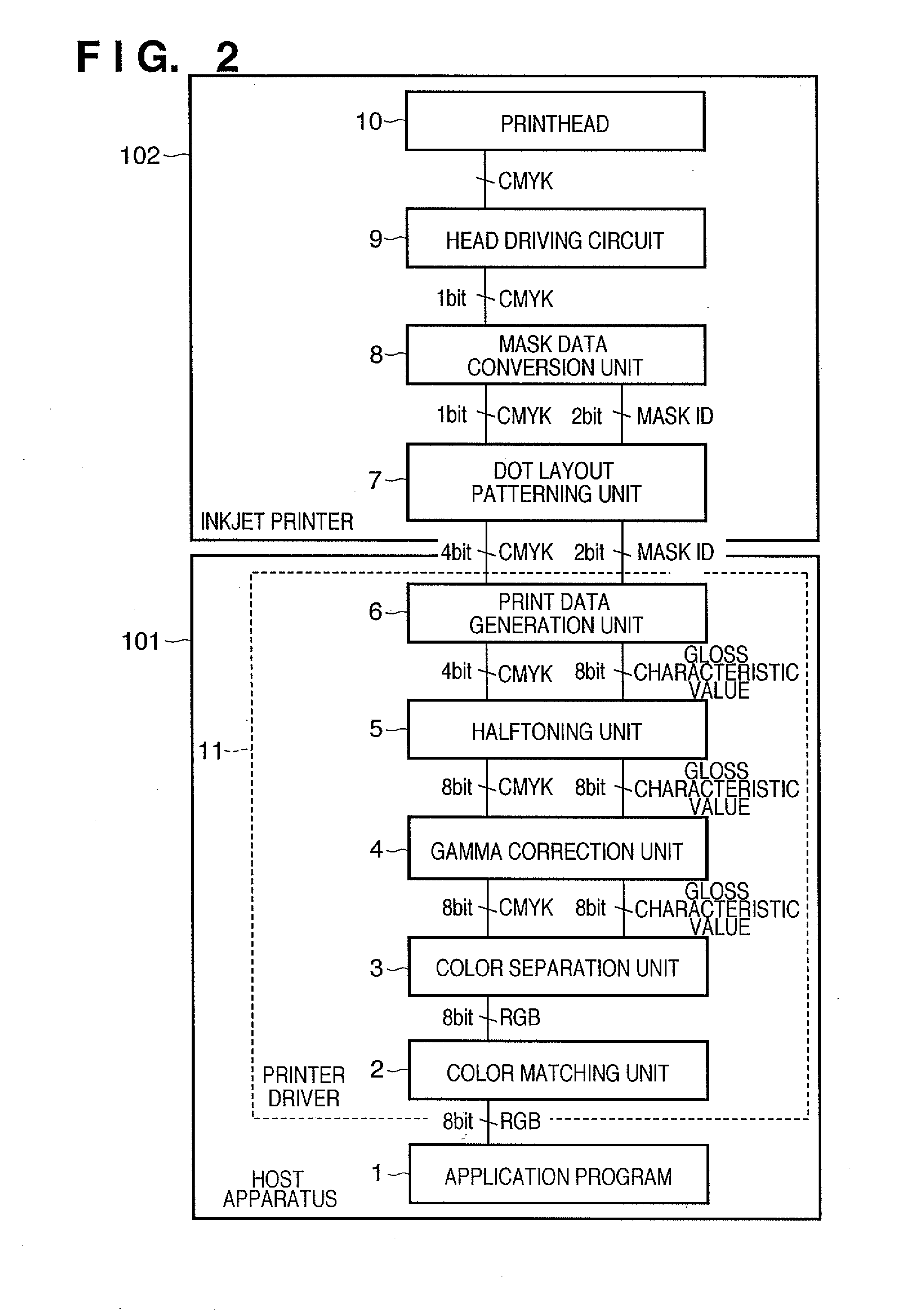

Inkjet printer and printing method

ActiveUS20150070428A1Improve printing qualityOverlapping of the dots can be suppressedOther printing apparatusSpray nozzleInk printer

An inkjet printer includes a print head, a nozzle position specifying section and a print control section. The print head includes a plurality of nozzles to eject ink. The nozzle position specifying section is configured to specify a position of a first nozzle that exhibits defective ejection. The print control section is configured to print dots in a plurality of sizes. The print control section is configured to change a dot size of a dot to be printed by a second nozzle, which is positioned adjacent to the first nozzle, to a larger size than a dot size specified in an image data, and to change a dot size of a dot to be printed by a third nozzle, which is positioned adjacent to the second nozzle, to a smaller size than the dot to be printed by the second nozzle after the change.

Owner:SEIKO EPSON CORP

Toner, developing device, and image forming apparatus

ActiveUS10156800B2Satisfactory characteristicSuppress unevennessElectrographic process apparatusDevelopersPolyesterMaterials science

Provided is a toner comprising a toner particle including a binder resin, an amorphous polyester, and a colorant, wherein the binder resin includes a vinyl resin, the toner has a softening point of at least 110° C. and not more than 140° C., an amount of the amorphous polyester is at least 4.0 parts by mass and not more than 30.0 parts by mass with respect to 100 parts by mass of the binder resin, and a temperature T at which an area increasing rate of one toner particle sample becomes 1.40, is not more than 110° C., and a slope of the area increasing rate with respect to a temperature in the range of the area increasing rate of 1.40 to 2.00 is not more than 0.07.

Owner:CANON KK

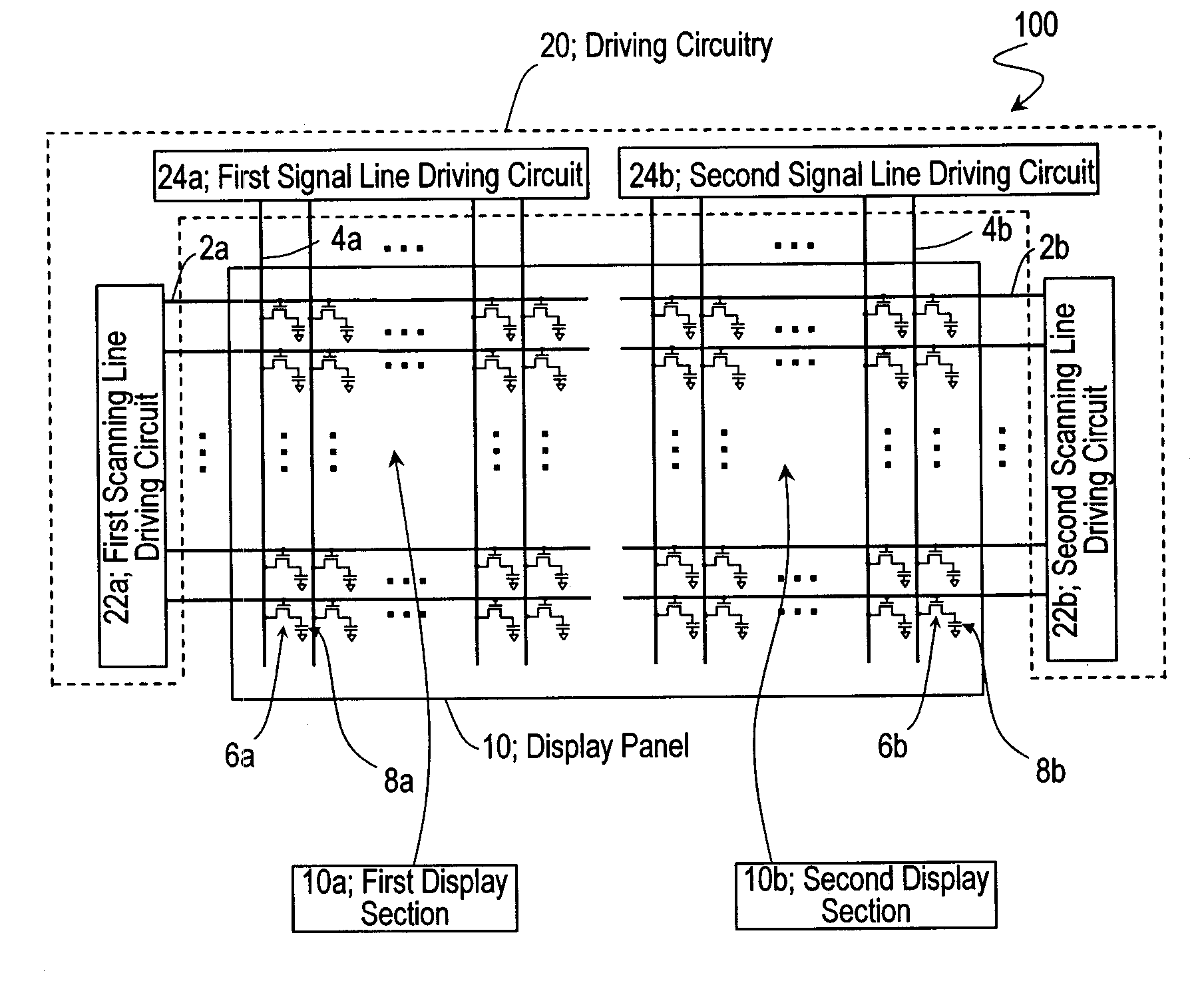

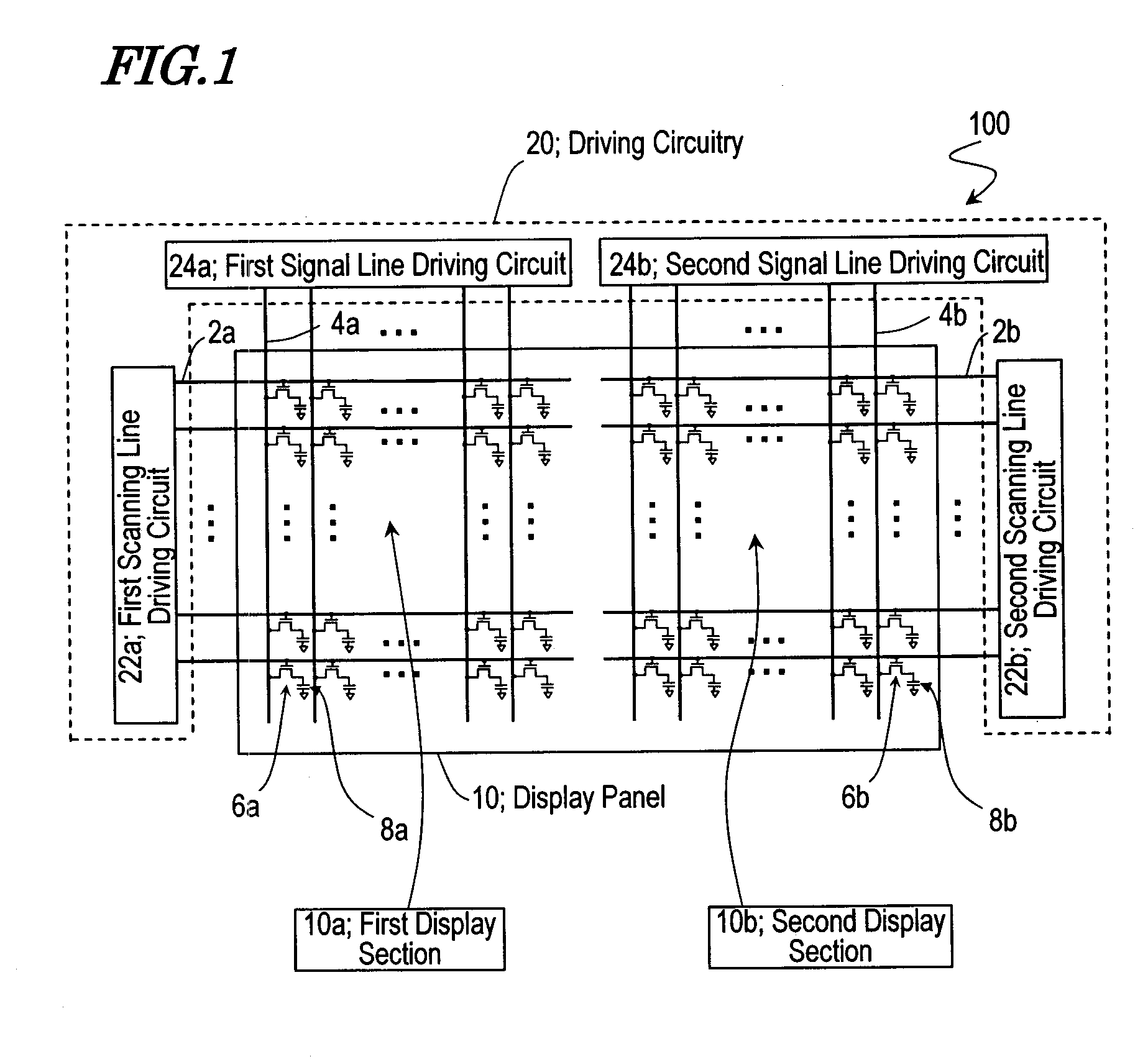

Display device and automobile having the same

InactiveUS20070139355A1Reduce decreaseSuppress parasitic capacitanceStatic indicating devicesInstrument arrangements/adaptationsDisplay deviceData signal

There are provided a display device which consumes little power and which is suitable for displaying multiple contents, and an automotive vehicle having the same. The display device according to the present invention includes a display panel having a first display section and a second display section, and driving circuitry for driving the display panel. The driving circuitry includes a first scanning line driving circuit for supplying a scanning signal to scanning line of the first display section, a first signal line driving circuit for supplying a data signal to signal lines of the first display section, a second scanning line driving circuit for supplying a scanning signal to scanning lines of the second display section, and a second signal line driving circuit for supplying a data signal for signal lines of the second display section. The driving circuitry is capable of driving the first display section and the second display section with different vertical scanning frequencies.

Owner:SHARP KK

Display unevenness correction apparatus, display apparatus, method for correcting display unevenness, an method for manufacturing the display apparatus

InactiveUS20160027354A1Reduction in luminanceSuppress display unevennessStatic indicating devicesPhotometry electrical circuitsComputer graphics (images)Luminance meter

A display unevenness correction apparatus for use in the manufacture of an LCD display including an LCD panel having display pixels arranged in rows and columns, the apparatus including: a luminance meter which measures a luminance of the LCD panel while the LCD panel is being illuminated to obtain a luminance; a block luminance calculation unit which segments the luminance map into first blocks and calculate, for each of the first blocks, a block luminance of the first block using luminances included in the first block, the block luminance representing the luminances included in the first block; an interpolation unit which calculates a target luminance for each of the display pixels, using a corresponding one of the block luminances; and a correction gain calculation unit which calculates a correction coefficient for each display pixel using the target luminance.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

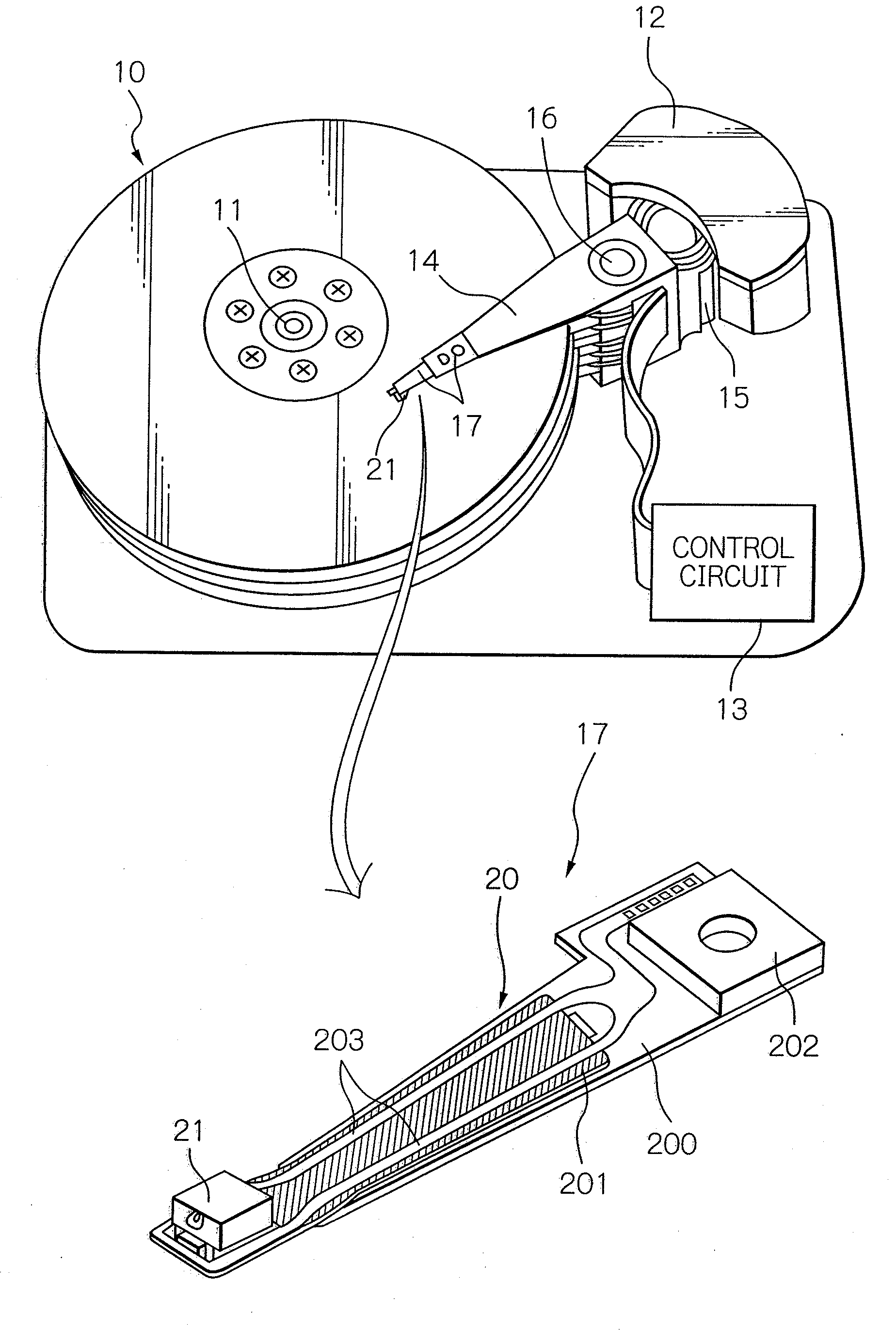

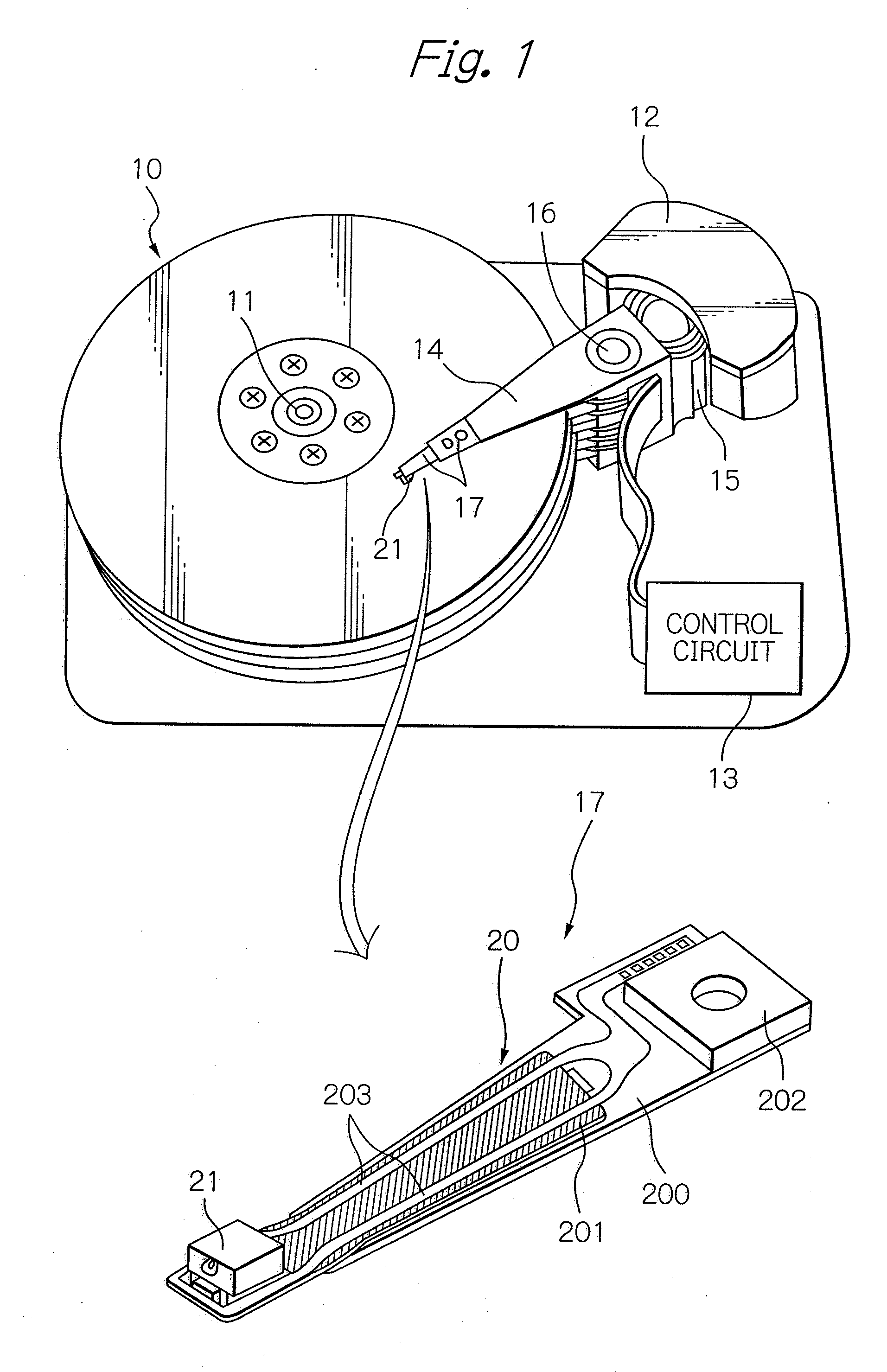

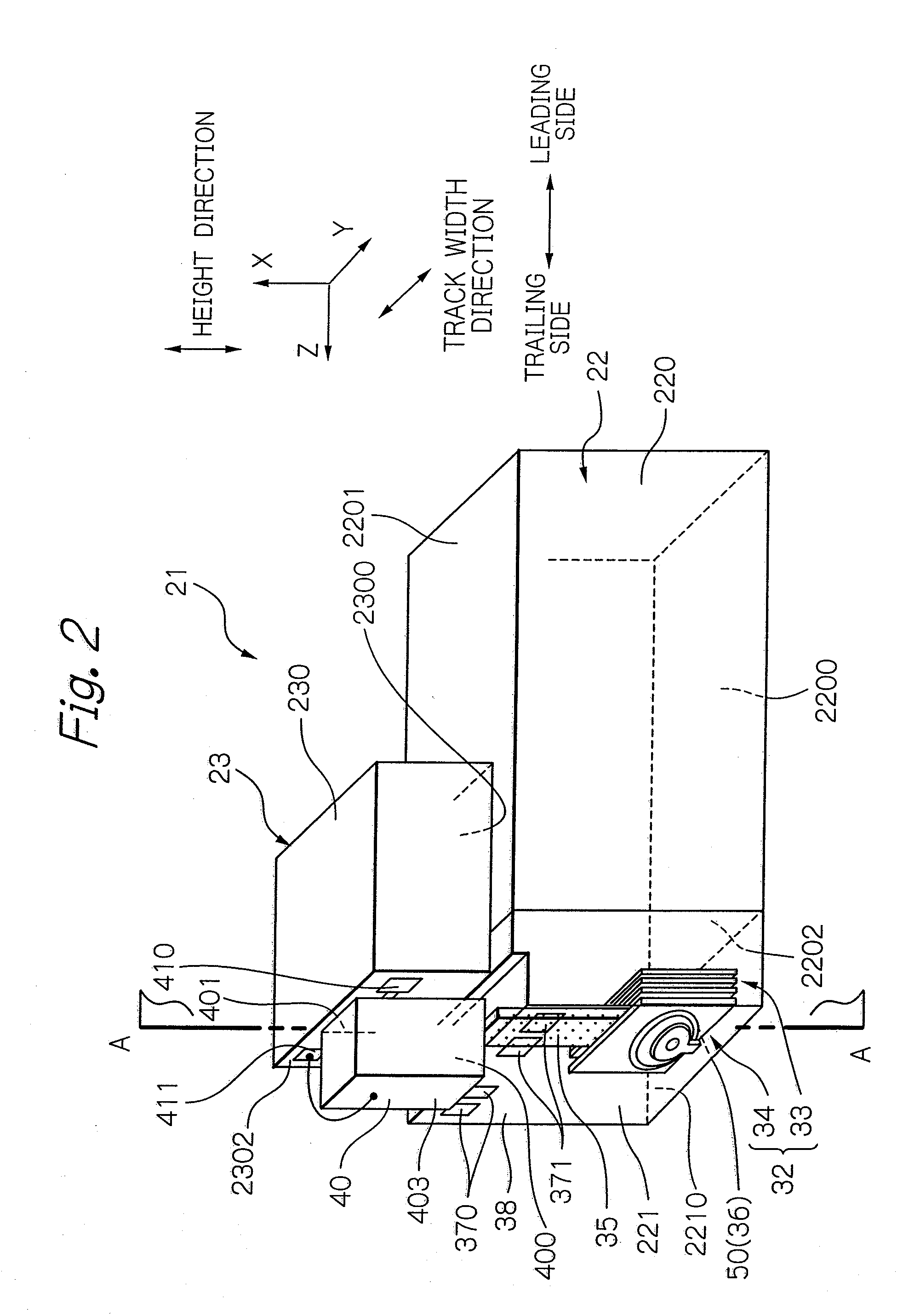

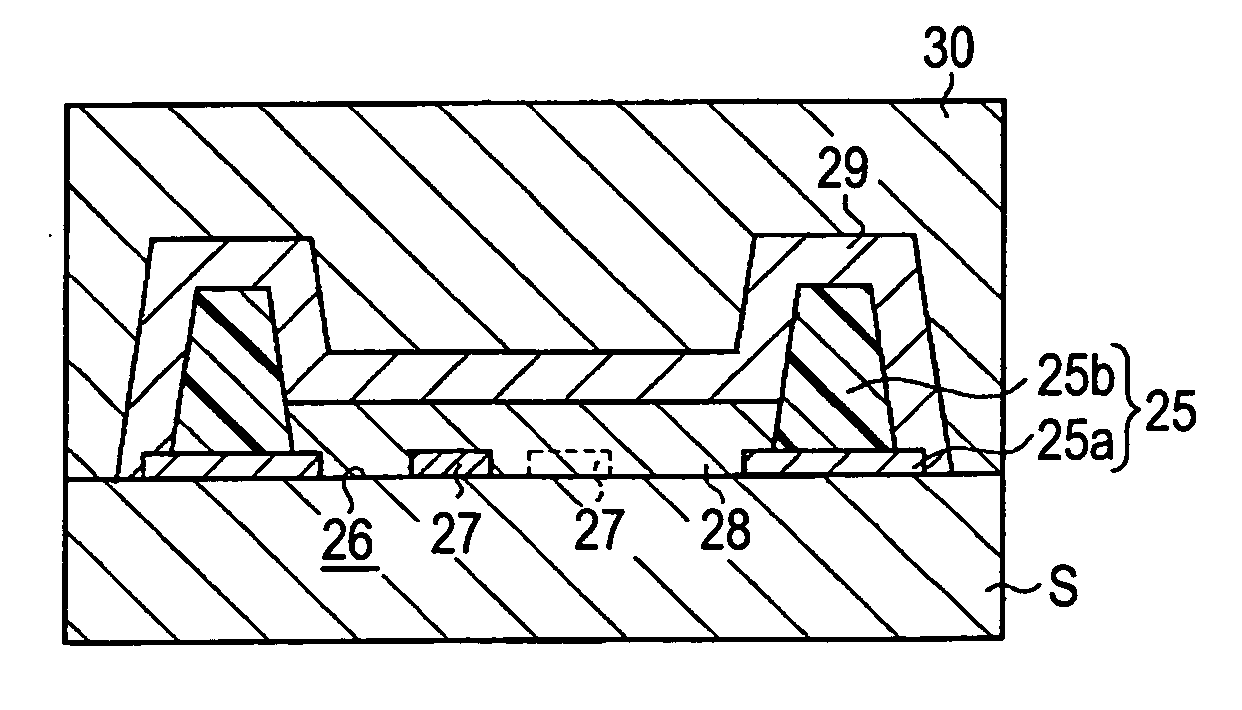

Near-Field Light Generating Element And Method For Forming The Element

ActiveUS20100142079A1Suppression of distortionSuppress unevennessDecorative surface effectsRecord information storageDistortionPhysics

Provided is a method for forming a near-field light generating element, which is capable of sufficiently suppressing the unevenness of a waveguide surface and the distortion within the waveguide. The forming method comprises the steps of: forming a first etching stopper layer on a lower waveguide layer; forming a second etching stopper layer; forming, on the second etching stopper layer, a plasmon antenna material layer; performing etching with the second etching stopper layer used as a stopper, to form a first side surface of plasmon antenna; forming a side-surface protecting mask so as to cover the first side surface; and performing etching with the first and second etching stopper layers used as stoppers, to form the second side surface. By providing the first and second etching stopper layer, over-etching can be prevented even when each etching process takes enough etch time, which allows easy management of etching endpoints.

Owner:TDK CORPARATION

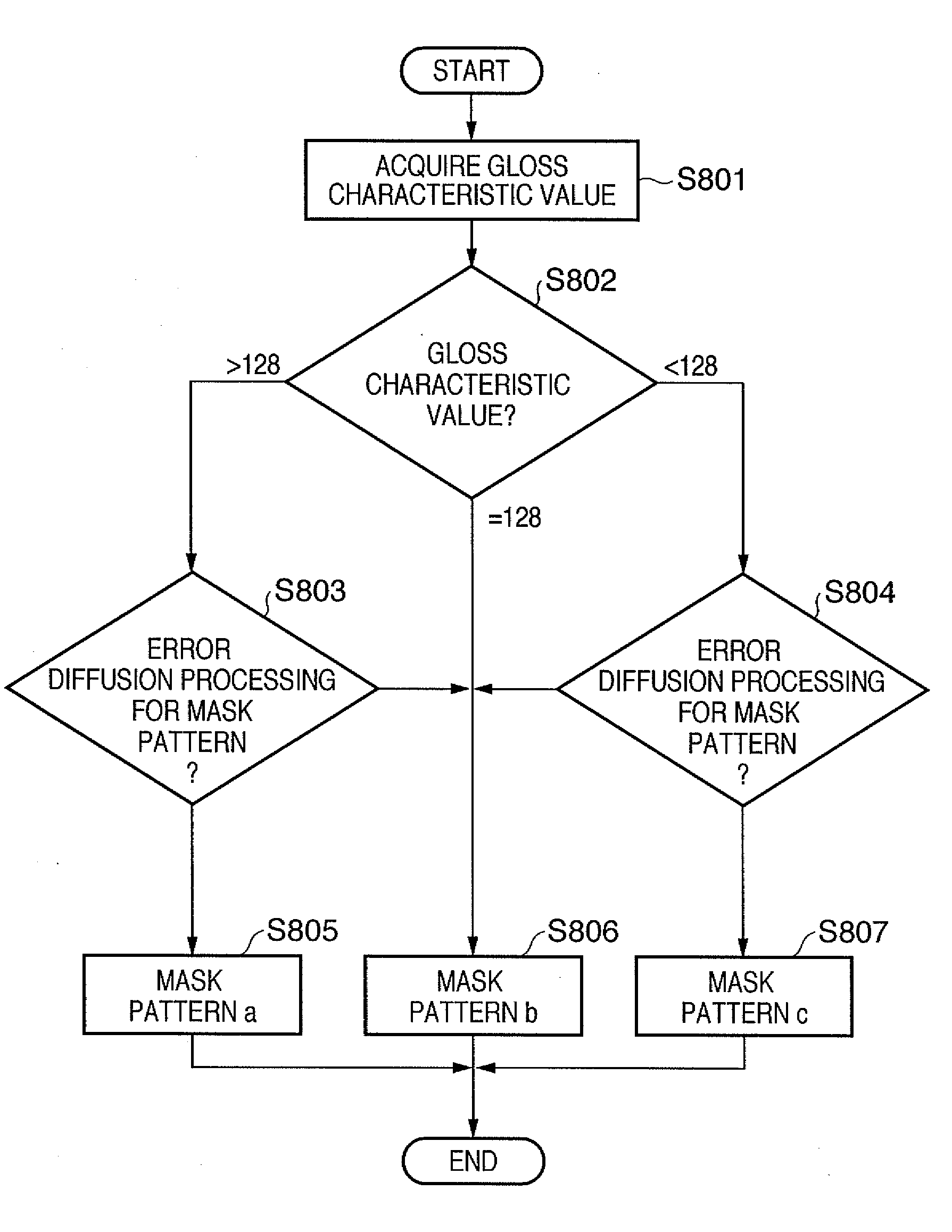

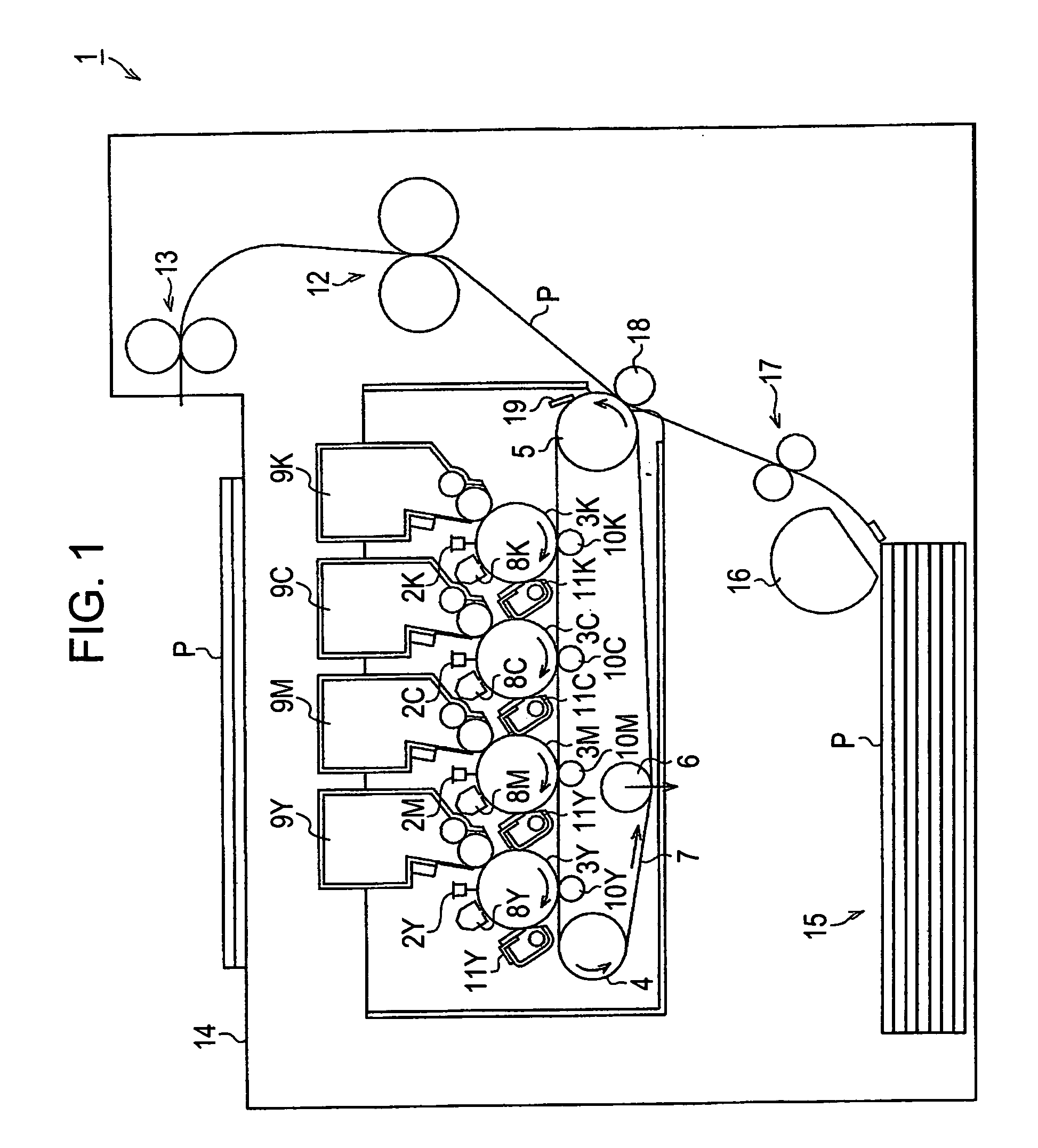

Image forming apparatus and control method thereof

InactiveUS20080158280A1Suppresses gloss unevennessSuppress unevennessDigitally marking record carriersDigital computer detailsImage formationComputer science

In multipass printing, a mask pattern which increases the degree of dot dispersion in each pass is used for a combination of inks for increasing glossiness when printing an image. Contrary, a mask pattern which decreases the degree of dot dispersion in each pass is used for a combination of inks for decreasing glossiness. Thus, an entire image can be made uniformly glossy by suppressing gloss unevenness within the image.

Owner:CANON KK

Electrooptical apparatus and method of manufacturing electrooptical apparatus

InactiveUS20060220532A1Improve the immunityGood reproducibilityDischarge tube luminescnet screensElectroluminescent light sourcesLight emissionElectro-optics

An electrooptical apparatus includes a light emission element array in which a plurality of light emission elements are arranged, and a barrier rib which surrounds the light emission element array.

Owner:SEIKO EPSON CORP

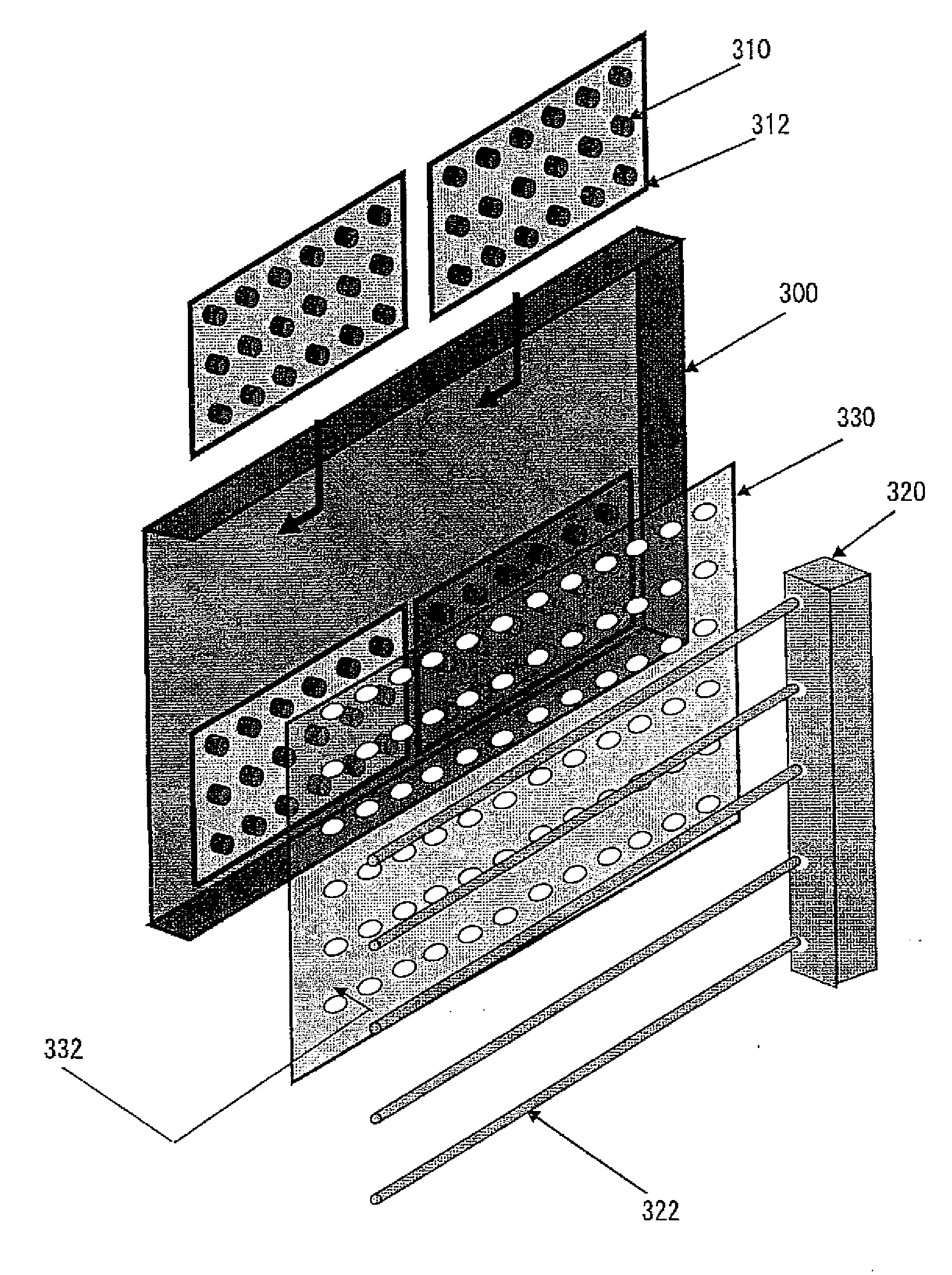

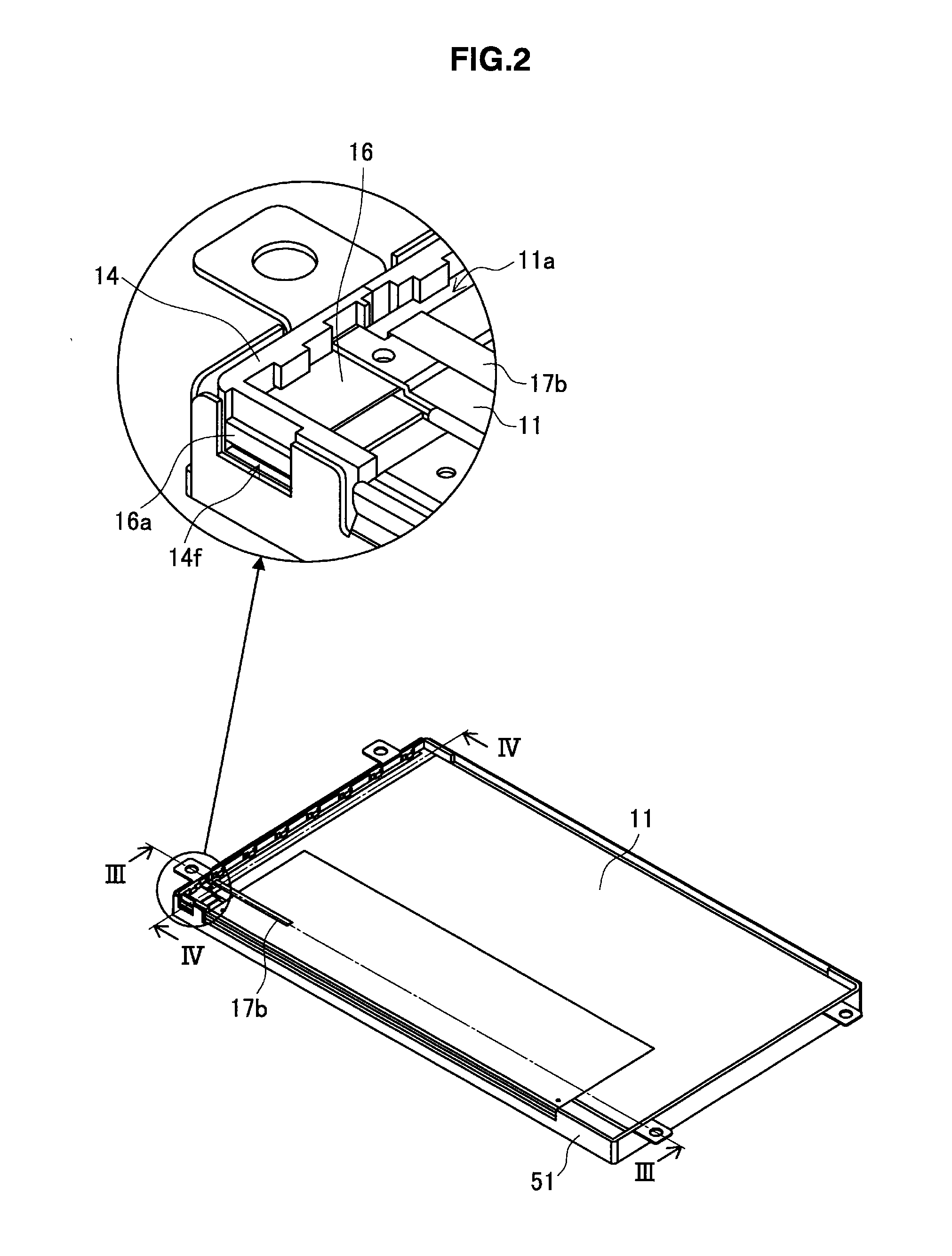

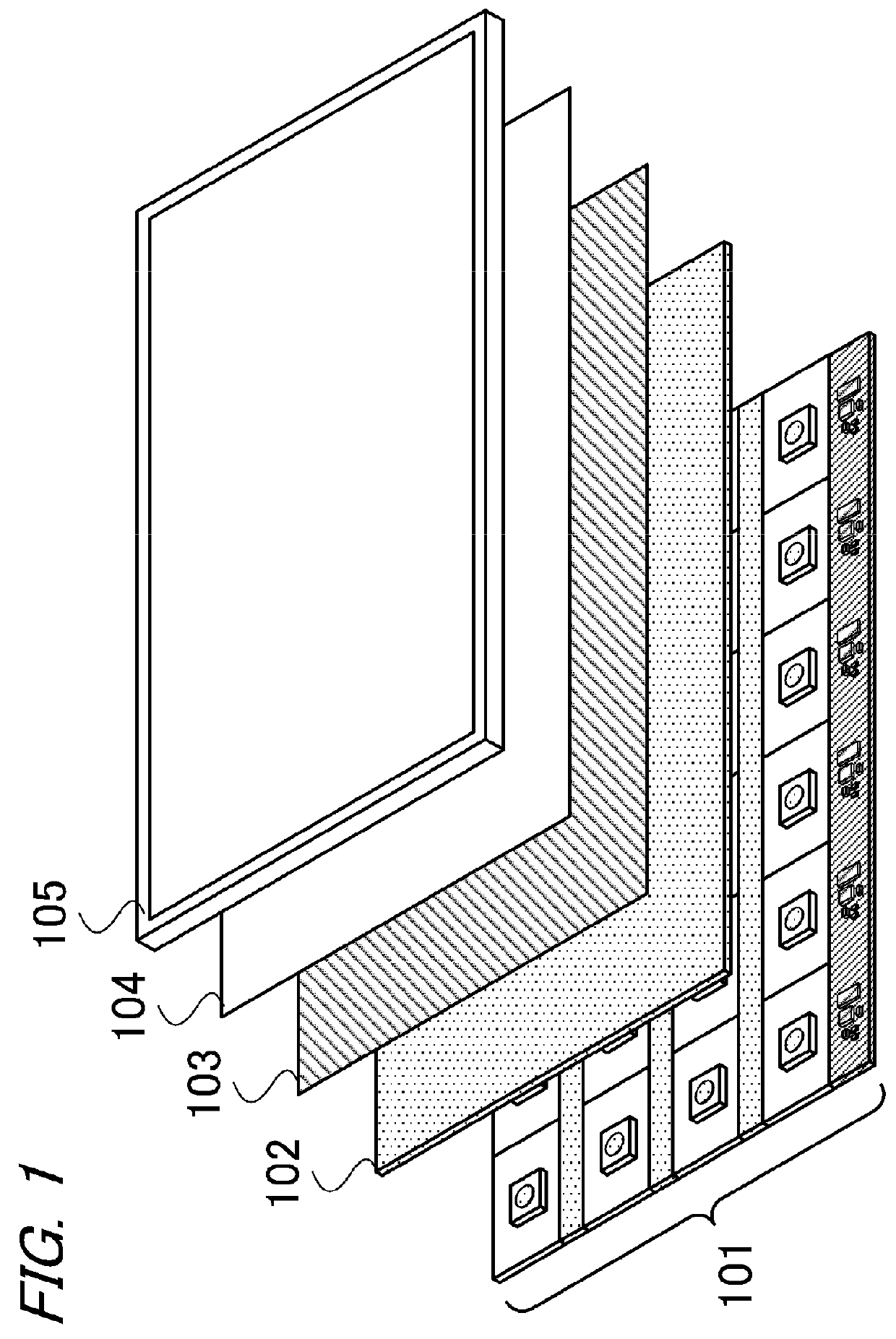

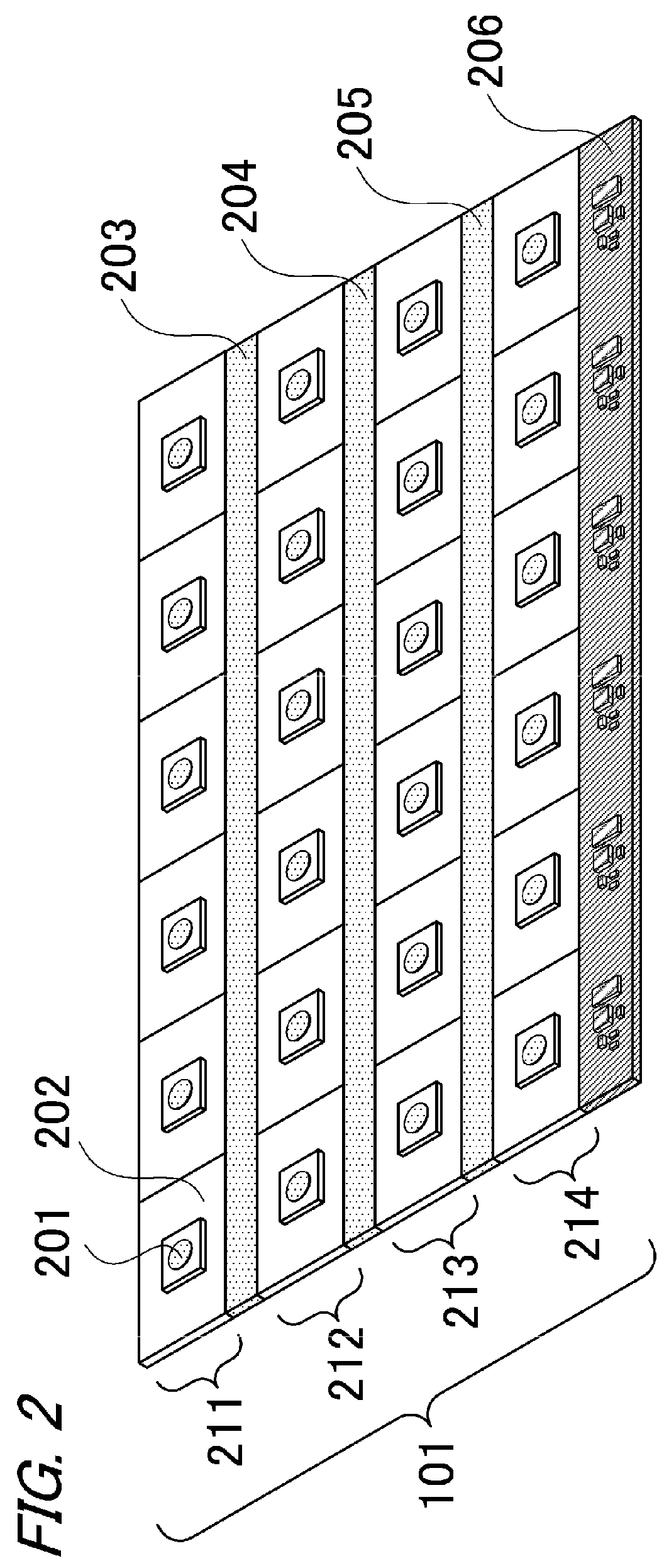

Backlight unit

InactiveUS20120033447A1Easy to disassembleEasy to implementOptical light guidesIlluminated signsLight guideOptoelectronics

Provided is a device including a backlight unit including a LED-mounted board having LEDs as a backlight source, a light guide plate to which the LEDs are disposed to face, and which has a light receiving surface to which light from the LEDs incidents and an emission surface from which the incident light is output, and a frame which holds the light guide plate. The frame 14 has a protrusion for positioning which engages the LED-mounted board.

Owner:JAPAN DISPLAY INC

Backlight device and liquid crystal display device

InactiveUS7744233B2Suppress colorSuppress unevennessLighting support devicesElectroluminescent light sourcesLiquid-crystal displayLed array

Owner:SHARP KK

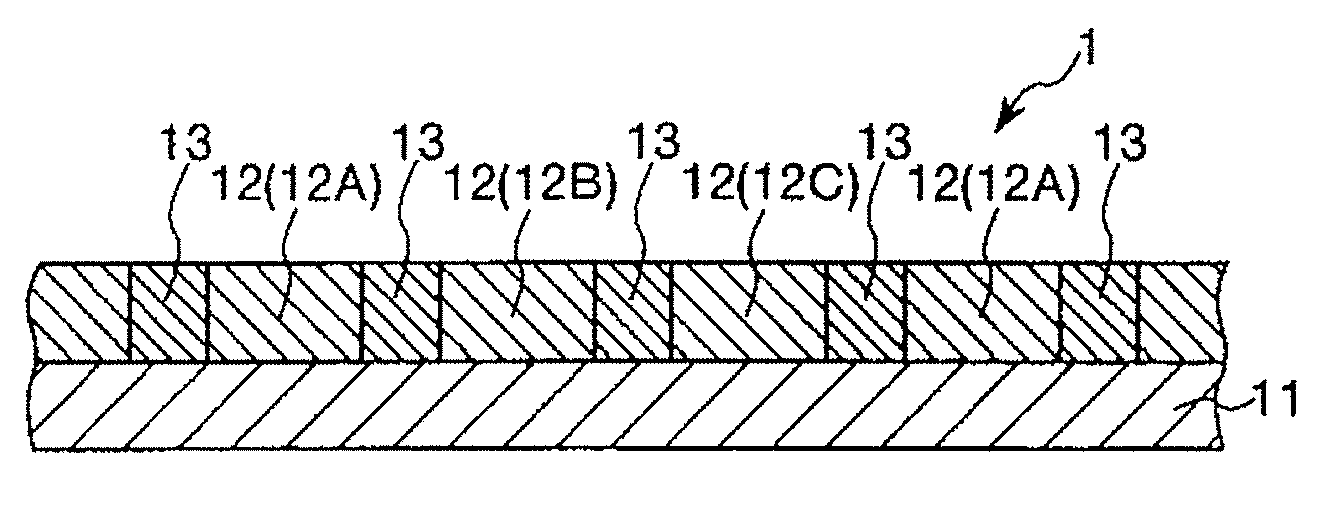

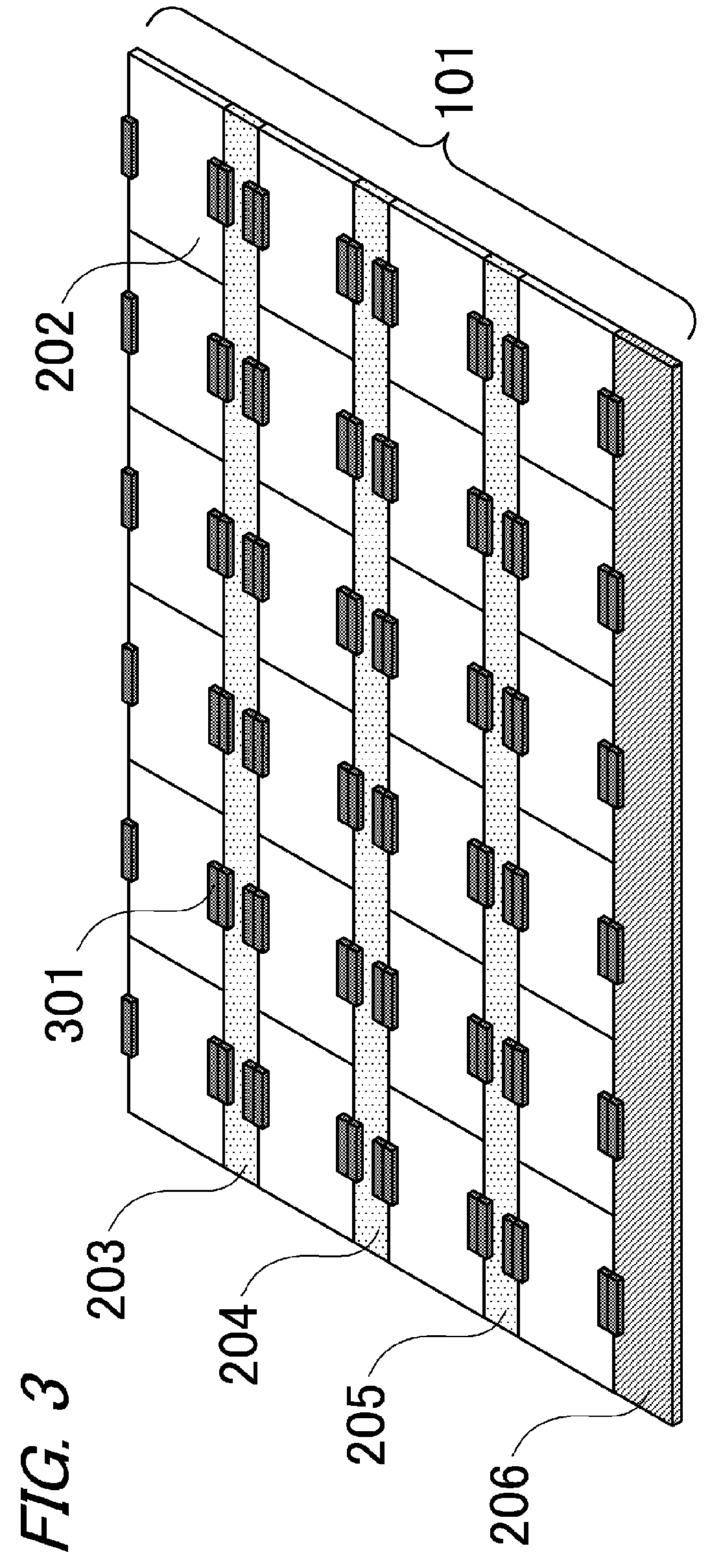

Light source apparatus

InactiveUS20130069560A1Reduce thicknessSuppress unevennessElectrical apparatusStatic indicating devicesOptoelectronicsLight source

A light source apparatus according to the present invention includes: a plurality of light emitting substrates arranged in matrix form, each having at least one light source; an intermediate substrate provided between respective rows of the plurality of light emitting substrates; and a driving unit that outputs a drive signal for driving the light sources, wherein a first supply wiring for supplying the drive signal to the light source provided on each of the plurality of light emitting substrates is printed on each of the light emitting substrates, and a first connection wiring for electrically connecting the first supply wirings printed on two light emitting substrates sandwiching the intermediate substrate is printed on the intermediate substrate.

Owner:CANON KK

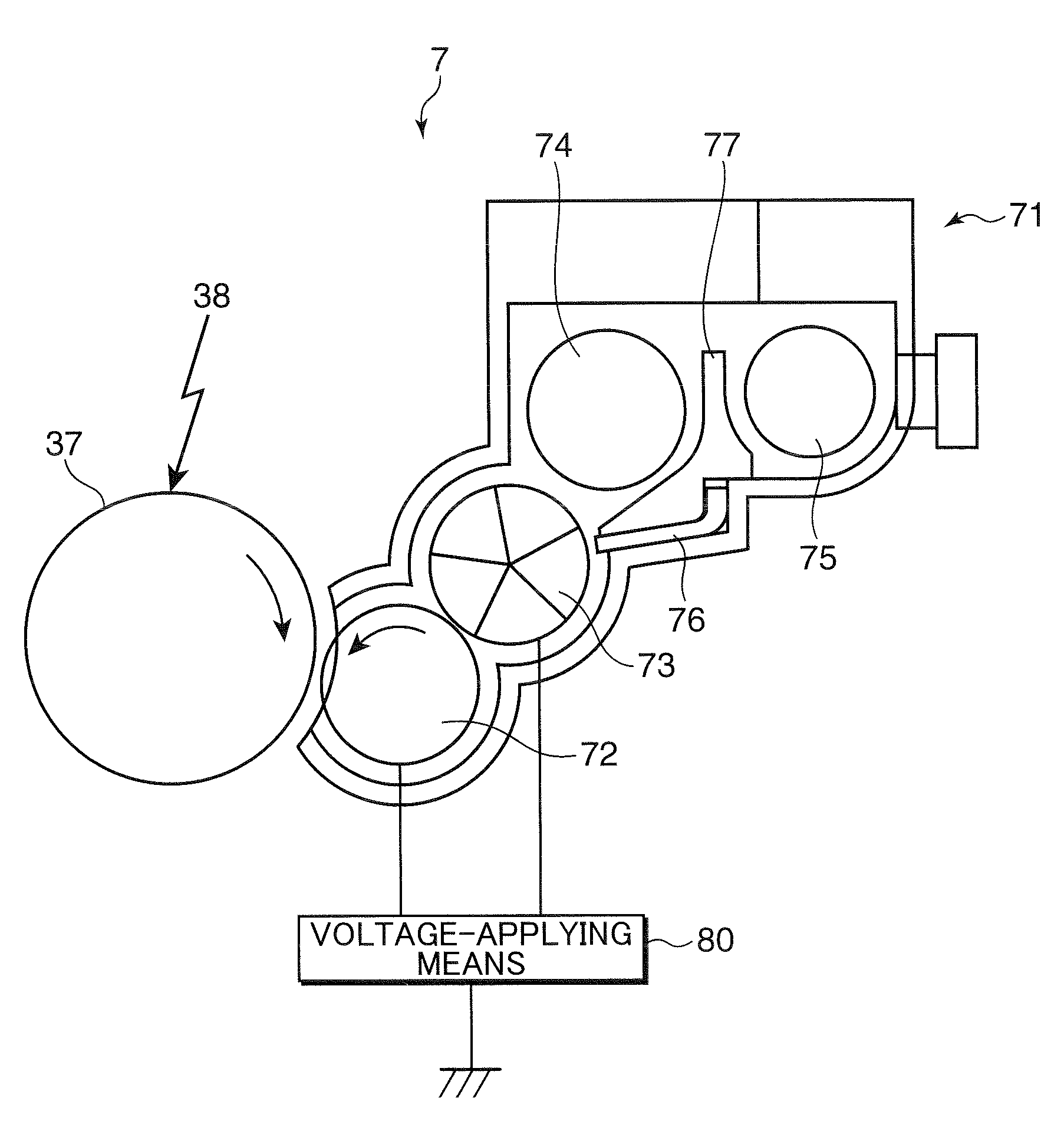

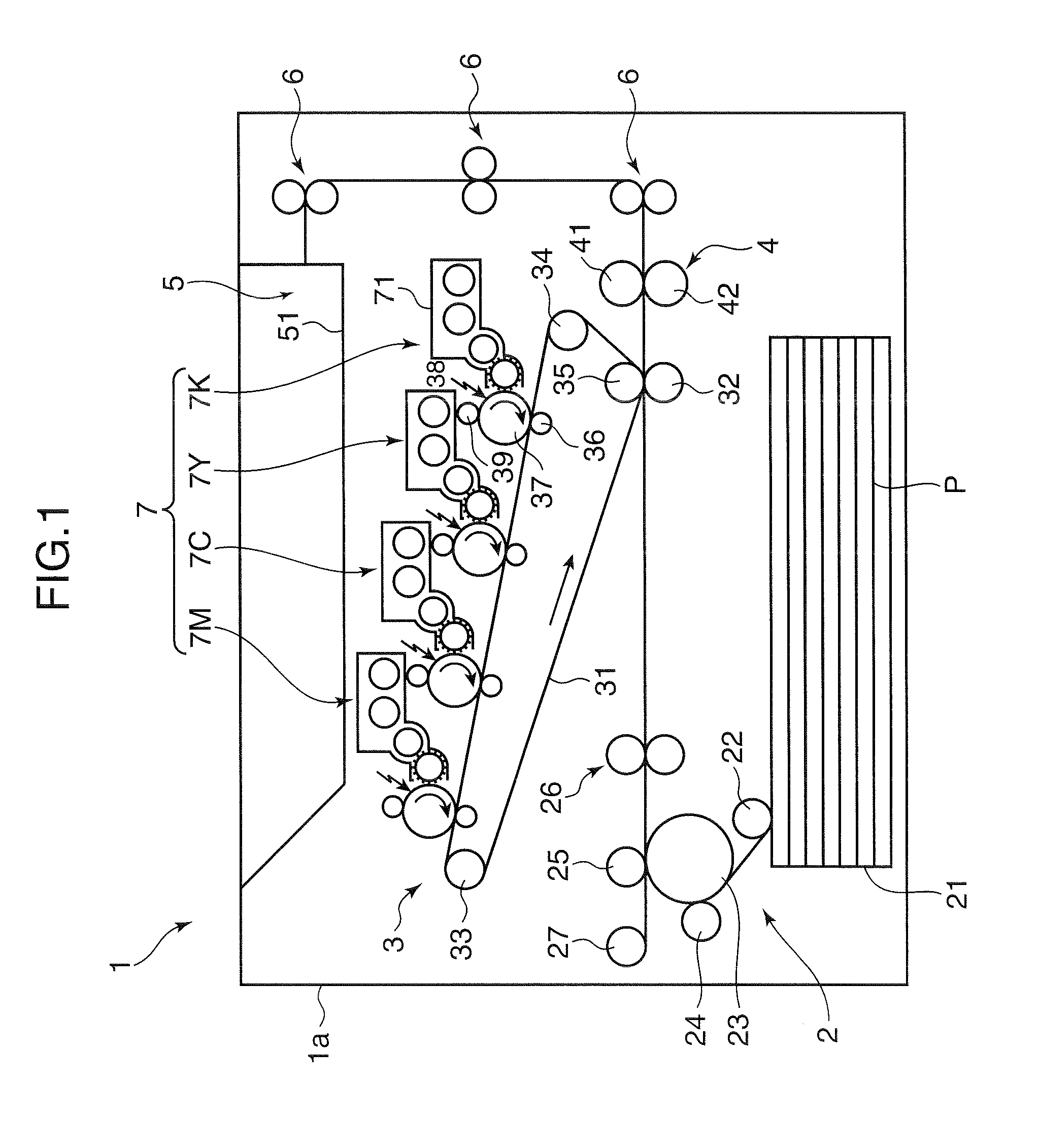

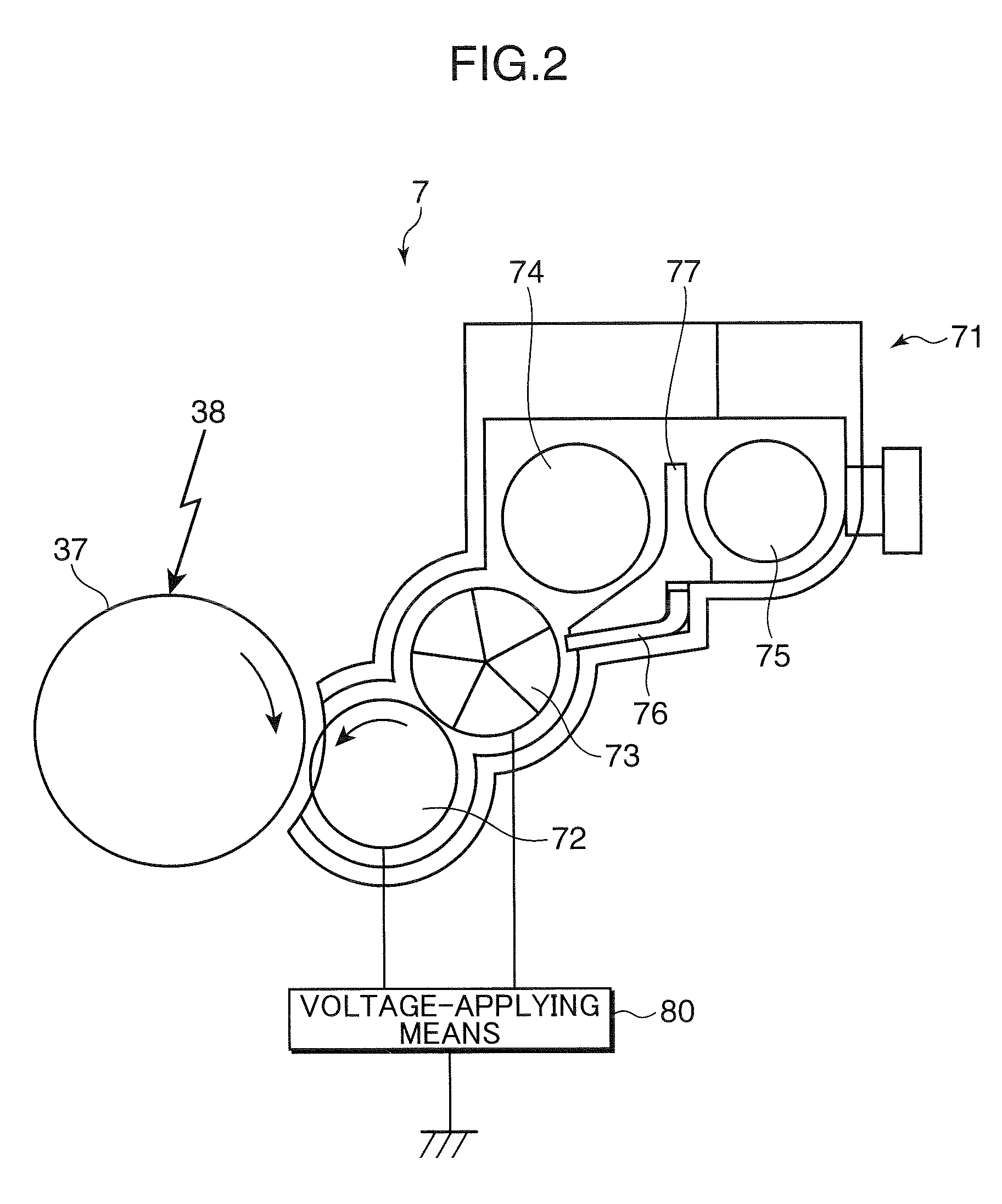

Developing unit and image forming apparatus

ActiveUS20080226320A1Suppress image unevennessLow densityElectrographic process apparatusLatent imageImage formation

A developing unit has a voltage-applicator (80) to apply a developing bias voltage to a developing roller (72). The voltage-applicator (80) applies the developing bias voltage for a first duration to apply an AC voltage having a rectangular waveform, and a second duration to stop applying the AC voltage. The AC voltage has a duty ratio of 50% or more in a direction for causing toner to develop an electrostatic latent image. The number of cycles of the AC voltage in the first duration is two or more, and the AC voltage has a voltage in a direction for pulling the toner back to the developing roller, just before transition to the second duration. The developing unit suppresses occurrence of image unevenness due to a fluctuation in developing gap. Thus, an image forming apparatus equipped with the developing unit forms a high-quality image while suppressing image unevenness.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

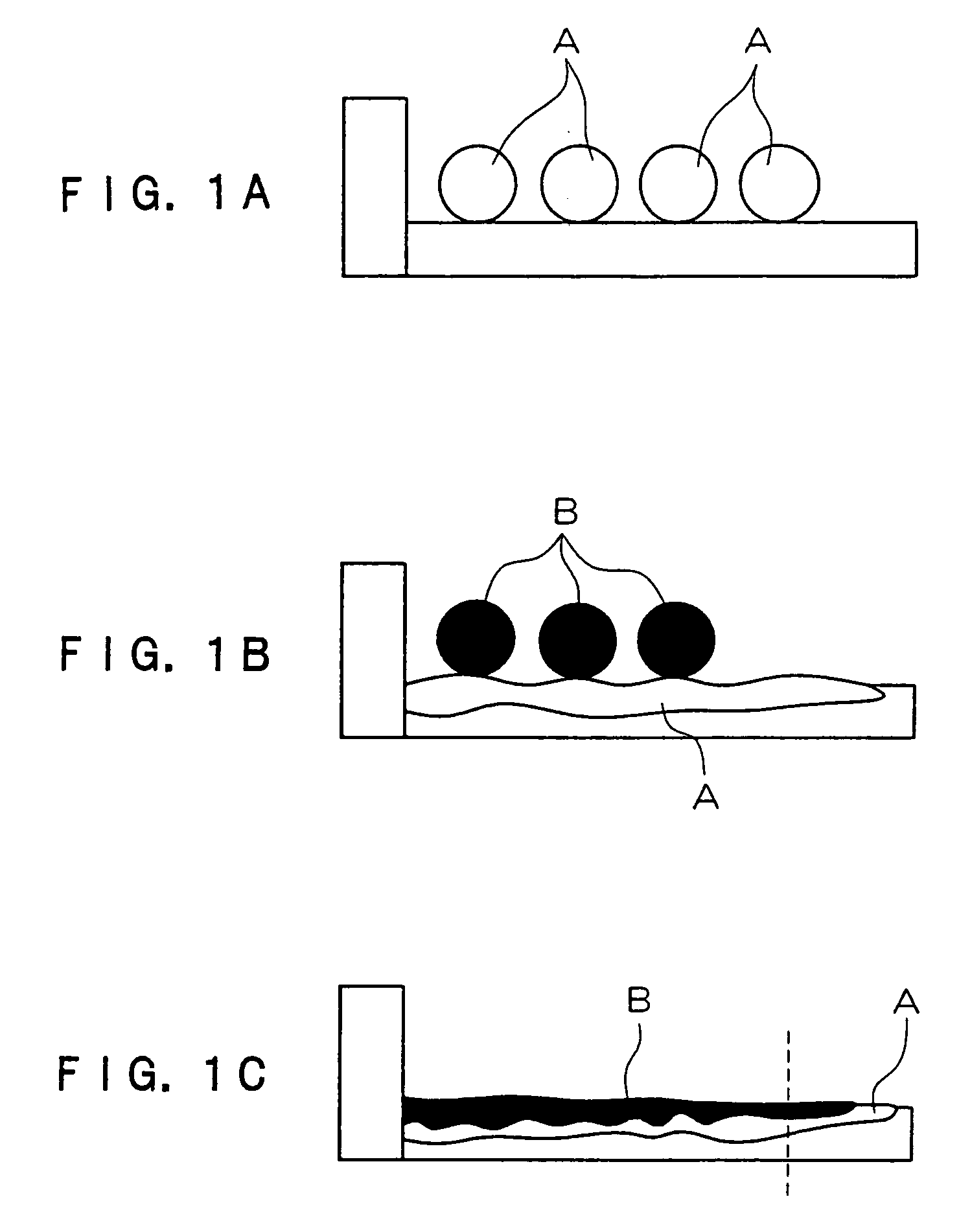

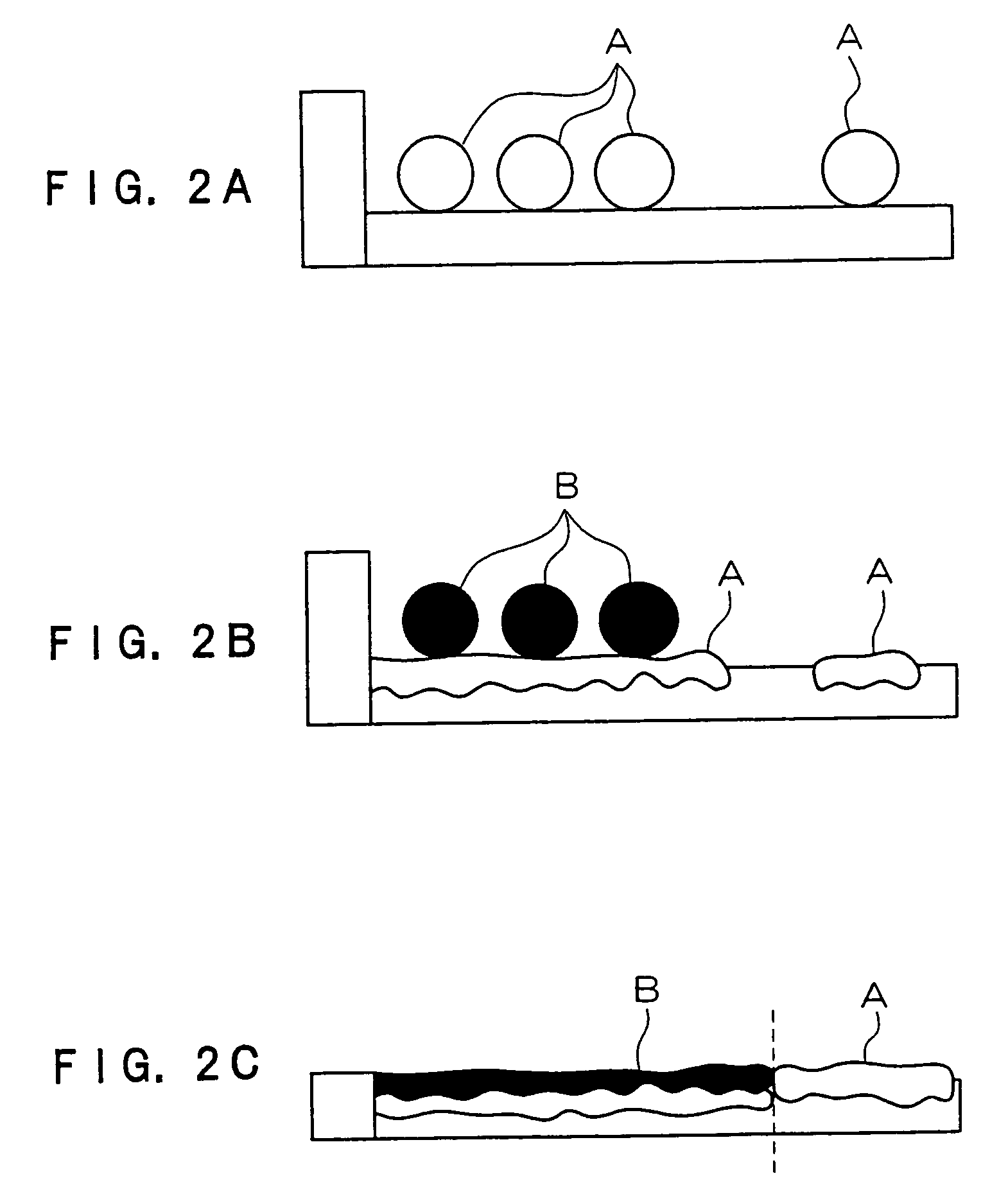

Ink jet recording method and ink jet recording apparatus

InactiveUS20060066661A1Satisfactory drying timeSatisfy fixationMeasurement apparatus componentsDuplicating/marking methodsLiquid compositionColoring agents

The present invention provides an ink jet recording method and an ink jet recording apparatus for recording an image on a recording medium by using an ink containing a coloring agent and a liquid composition containing a component for coagulating and / or thickening the ink. The method is characterized in that the ink and the liquid composition are ejected onto the recording medium such that they are not in contact with each other on the recording medium immediately after the ejection and come into contact when a certain period of time has lapsed since the application.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Method for manufacturing color filter ink, color filter ink, color filter, image display device, and electronic device

InactiveUS20090135349A1Increased durabilityImprove uniformityOrganic compound preparationOptical filtersSolventFine dispersion

A method for manufacturing a color filter ink is adapted to be used to manufacture a color filter by an inkjet method. The method includes dispersing a dispersing agent in a solvent to obtain a dispersing-agent-dispersed liquid by agitating a mixture of the dispersing agent, a thermoplastic resin and the solvent, performing a fine dispersion treatment to obtain a pigment dispersed material by adding a pigment to the dispersing-agent-dispersed liquid and by adding inorganic beads to the dispersing-agent-dispersed liquid in multiple stages, and mixing the pigment dispersed material with a curable resin.

Owner:SEIKO EPSON CORP

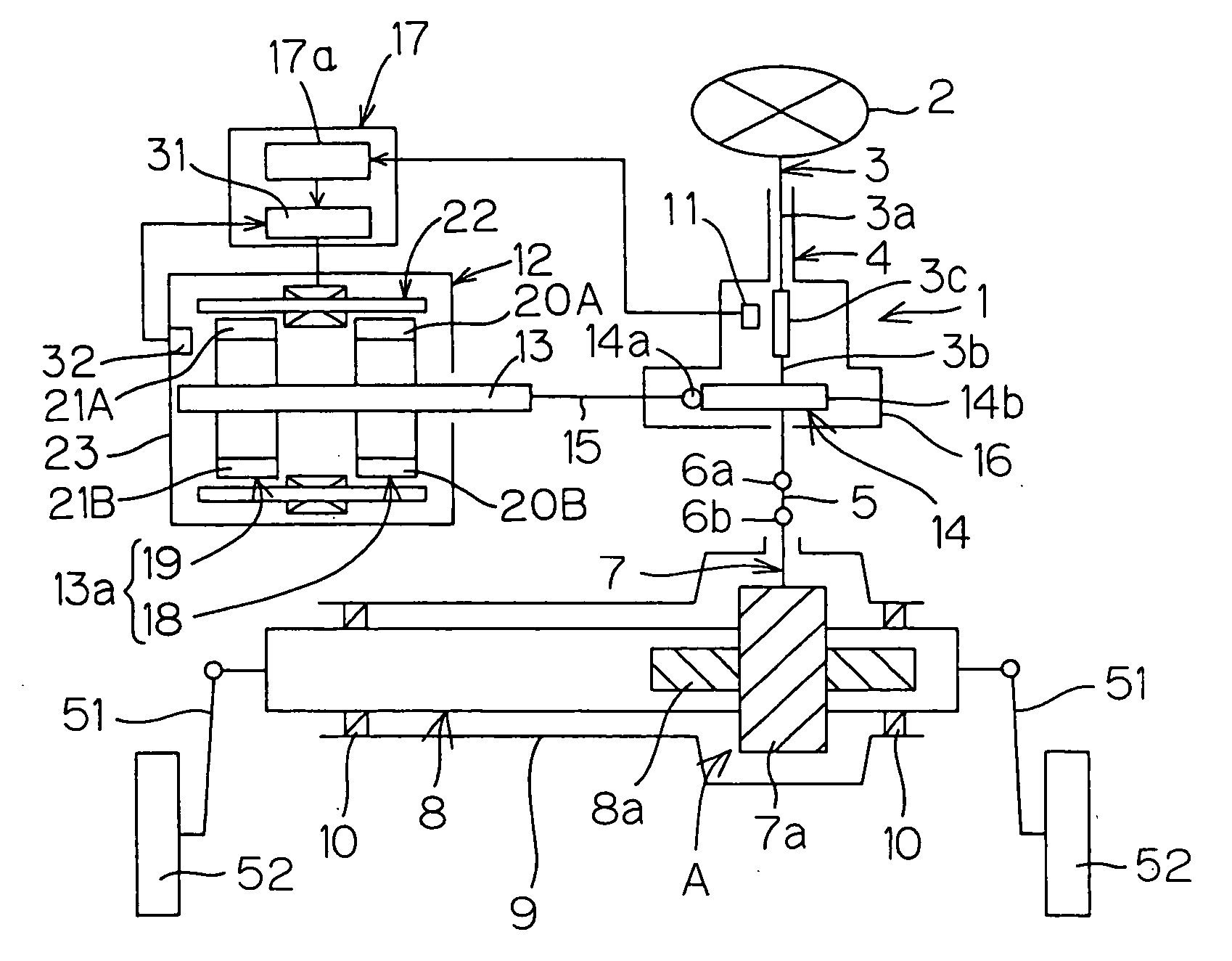

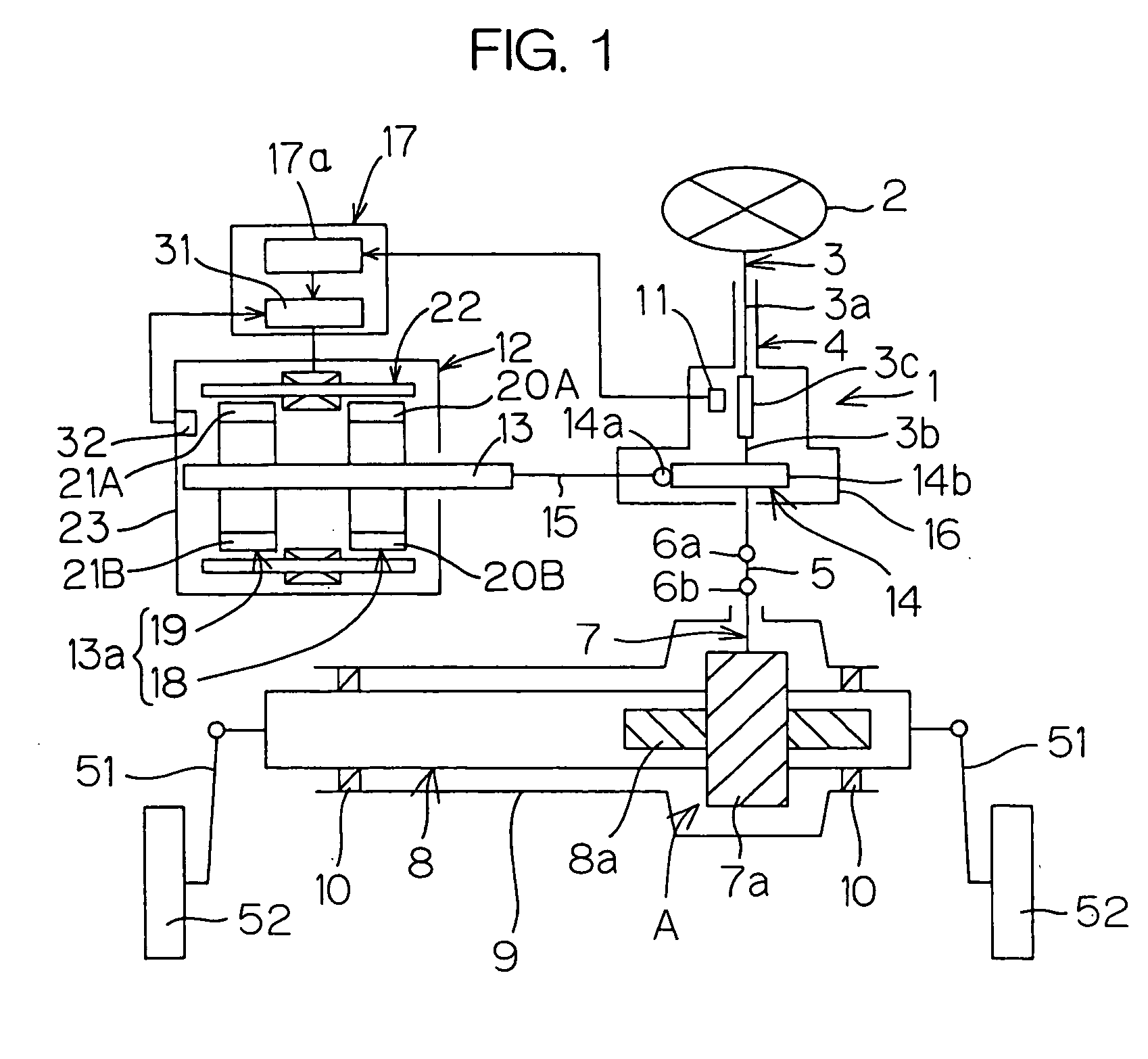

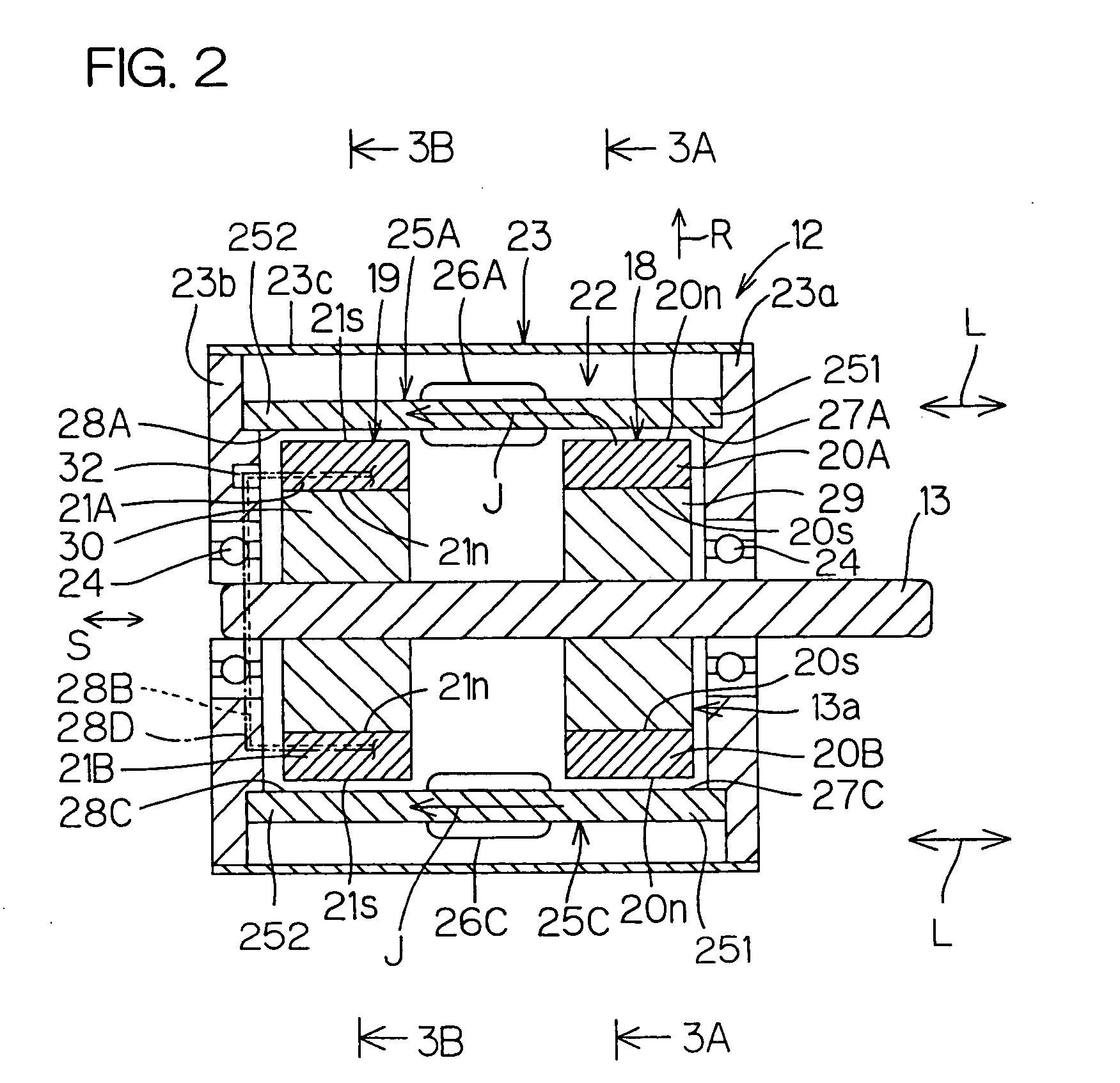

Steering device for vehicle

InactiveUS20070107974A1Loss of the magnetic fluxes can be suppressedSuppress unevennessMagnetic circuit rotating partsSteering linkagesMagnetic polesEngineering

An automotive steering device (1) includes an electric motor (12) which generates a steering assist force. The electric motor (12) includes a stator (22) surrounding a rotation shaft (13), and first and second rotors (18, 19) rotatable together with the rotation shaft (13). The stator (22) includes a plurality of cores (25A-25D) elongated parallel to an axis of the rotation shaft (13). An electric current is caused to flow through coils (26A-26D) wound around the respective cores (25A-25D), whereby the cores (25A-25D) are each formed with first and second magnetic poles (27A-27D, 28A-28D) having opposite polarities. The first and second magnetic poles (27A-27D, 28A-28D) are disposed longitudinally (L) opposite to each other with respect to the corresponding cores (25A-25D). As the rotation shaft (13) is rotated, a third magnetic pole (20n) of the first rotor (18) and a fourth magnetic pole (21s) of the second rotor (19) are respectively brought into opposed relation to the first and second magnetic poles (27A-27D, 28A-28D) of the cores (25A-25D) in the same phase. Magnetic fluxes (J) interlink with the coils (26A-26D) around the cores (25A-25D) in predetermined directions longitudinally (L) of the cores (25A-25D).

Owner:JTEKT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com