A kind of ultra-high wear-resistant hypereutectic high-chromium cast iron material, preparation method and application thereof

A high-chromium cast iron, hypereutectic technology, applied to the application of slurry pumps, ultra-high wear-resistant hypereutectic high-chromium cast iron materials, in the field of preparation, can solve the problems of insufficient wear resistance and short service life, and achieve Improved wear resistance, improved hardening depth, high carbon and chromium content effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

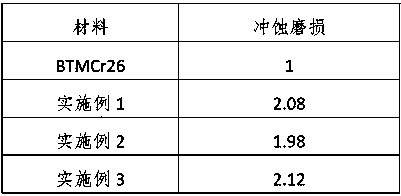

Examples

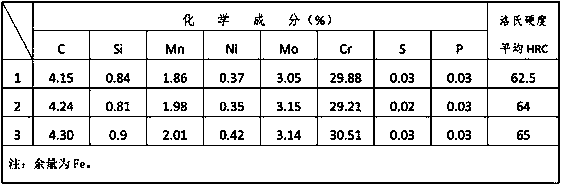

Embodiment 1

[0033] Embodiment 1: 1214.7 kg of steel scrap, 10 kg of recarburizer, 1524.5 kg of ferrochromium, 173.3 kg of ferromolybdenum, 11.1 kg of nickel plate, and 76.5 kg of ferromanganese are added to a 3-ton intermediate frequency furnace for heating and melting; when the molten iron reaches 1540 ℃, add rare earth elements and ferrotitanium into the furnace, and the total amount added is 15 kg. After melting, it comes out of the oven.

[0034] When the temperature in the bag reaches 1420°C, pour the casting. When pouring, add chromium carbide powder or tungsten carbide powder to incubate with the flow, and the addition is 2 kg.

Embodiment 2

[0035] Embodiment 2: 1238.4 kg of steel scrap, 23 kg of recarburizer, 1490.3 kg of ferrochromium, 179 kg of ferromolybdenum, 10.5 kg of nickel plate, and 81.9 kg of ferromanganese are added to a 3-ton intermediate frequency furnace for heating and melting; when the molten iron reaches 1550 ℃, add rare earth elements and ferro-titanium into the furnace, and the total amount added is 12 kg. After melting, it comes out of the oven.

[0036] When the temperature in the bag reaches 1410°C, pour the casting. When pouring, add chromium carbide powder or tungsten carbide powder to incubate with the flow, and the addition is 2 kg.

Embodiment 3

[0037] Embodiment 3: Add 1168.5 kilograms of scrap steel, 25 kilograms of recarburizer, 1556.6 kilograms of ferrochrome, 178.4 kilograms of ferromolybdenum, 12.6 kilograms of nickel plates, and 83.8 kilograms of ferromanganese into a 3-ton intermediate frequency furnace for heating and melting; when the molten iron reaches 1540 °C, add rare earth elements and ferrotitanium into the furnace, the total amount added is 9 kg. After melting, it comes out of the oven.

[0038] When the temperature in the bag reaches 1420°C, pour the casting. When pouring, add chromium carbide powder or tungsten carbide powder to incubate with the flow, and the addition is 2 kg.

[0039] After the castings of the above three embodiments are cooled to 350-400° C. in the sand box, generally 40 hours after pouring, the box is shaken. After cooling to normal temperature, remove the pouring and riser, and then polish it.

[0040] After grinding, the casting is annealed in a heat treatment furnace. The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com