Metal material used for preparing flow passage component of slurry pump and preparation method of metal material

A technology of flow parts and metal materials, which is applied in the field of metal materials for the flow parts of slurry pumps, can solve the problems of high cost, achieve good support, high hardness, and avoid breaking and peeling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in combination with specific embodiments.

[0023] According to the chemical composition requirements of the material of the present invention, a reasonable batching plan is formulated, see Examples 1-6; various furnace materials are sequentially added to the intermediate frequency furnace for melting according to the requirements of the smelting process, and the molten iron is released when it reaches 1520°C to 1580°C Pouring, resin sand molding, the pouring temperature is 1400 ℃ ~ 1450 ℃. After the casting is cooled, remove the sprue and riser. Castings are heated up to 930-950°C at a certain speed in the heat treatment furnace, kept warm for 4-7 hours and then air-cooled, and then tempered at 200-220°C in time.

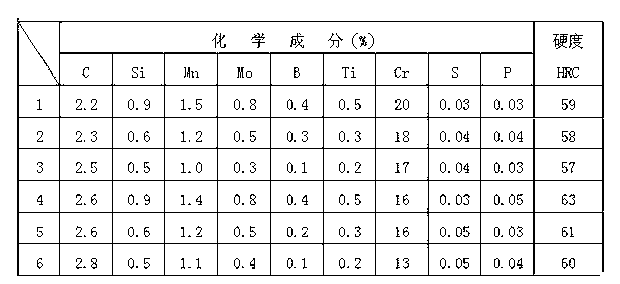

[0024] The chemical composition results are shown in Table 1.

[0025] The chemical composition of each embodiment of table 1, content in the table is weight percent composition

[0026]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com