High-gloss, polyvinylidene fluoride-based coating systems and methods

A polyvinylidene fluoride, polyvinylidene fluoride resin technology, applied in the field of high-gloss polyvinylidene fluoride-based coating systems and methods, capable of solving storage problems and complicated shelf life issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

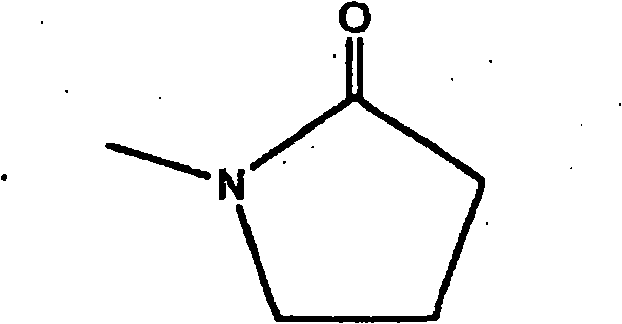

Image

Examples

example 1

[0074] Example 1: Coating Composition, Formulation A

[0075] 107.2 grams of Kynar 711 PVDF resin in powder form was mixed into 333.6 grams of NMP at room temperature. The resulting solution was mixed with a high speed pneumatic mixer until all the PVDF resin was dissolved to give a clear solution. At room temperature, this takes about 15-20 minutes. To this solution was slowly added while mixing the following: 333.6 grams of cyclohexanone, 77.0 grams of thermoplastic acrylic resin, 14.7 grams of thermoset acrylic resin, 7.0 grams of melamine (Cymel 303) and 0.3 grams of blocked acid catalyst and 0.8 grams of flowable agent. The resulting solution was then mixed for an additional 15 minutes at high speed to combine all materials.

[0076] Thermoplastic acrylic resin A used in all examples refers to a thermoplastic acrylic resin that combines 71.8 parts by weight of methyl methacrylate, 26.0 parts by weight of ethyl acrylate, 2.0 parts by weight of n-butyl methacrylate and 0...

example 2

[0082] Example 2: Coating Composition, Formulation A1

[0083] A coating composition was prepared using the procedure of Example 1, except that no cyclohexanone was used and the solvent component contained only NMP. The ingredients used in this example and the amounts of each ingredient are listed in the table below.

[0084] Formula A1

[0085] components

[0086] components

example 3

[0087] Example 3: Coating Composition, Formulation B

[0088] Coating compositions were prepared using the procedure of Example 1, except that no thermosetting resin was used. The ingredients used in this example and the amounts of each ingredient are listed in the table below.

[0089] Formula B

[0090] components

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com