Method and system for heat insulation and efficiency enhancement in-situ conversion of oil shale

A technology of oil shale and oil shale layer, applied in the field of oil shale heat insulation and efficiency in-situ conversion method and system, which can solve the problems of inability to mine, low heat capacity coefficient of superheated steam, and difficulty in obtaining water source, etc. Achieve the effects of ensuring rapid heating and cracking, improving the ability to lock heat, and shortening the in-situ cracking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

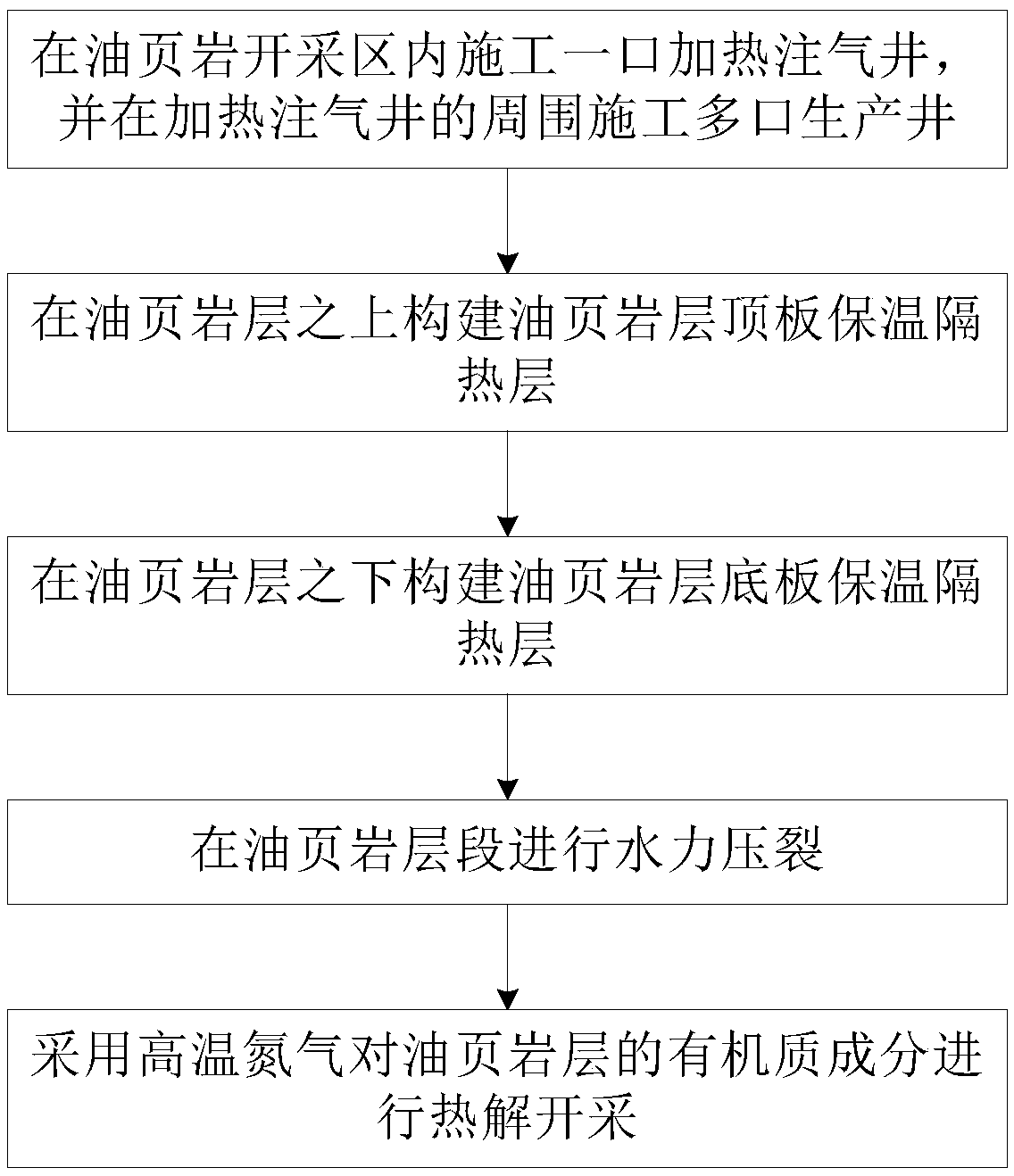

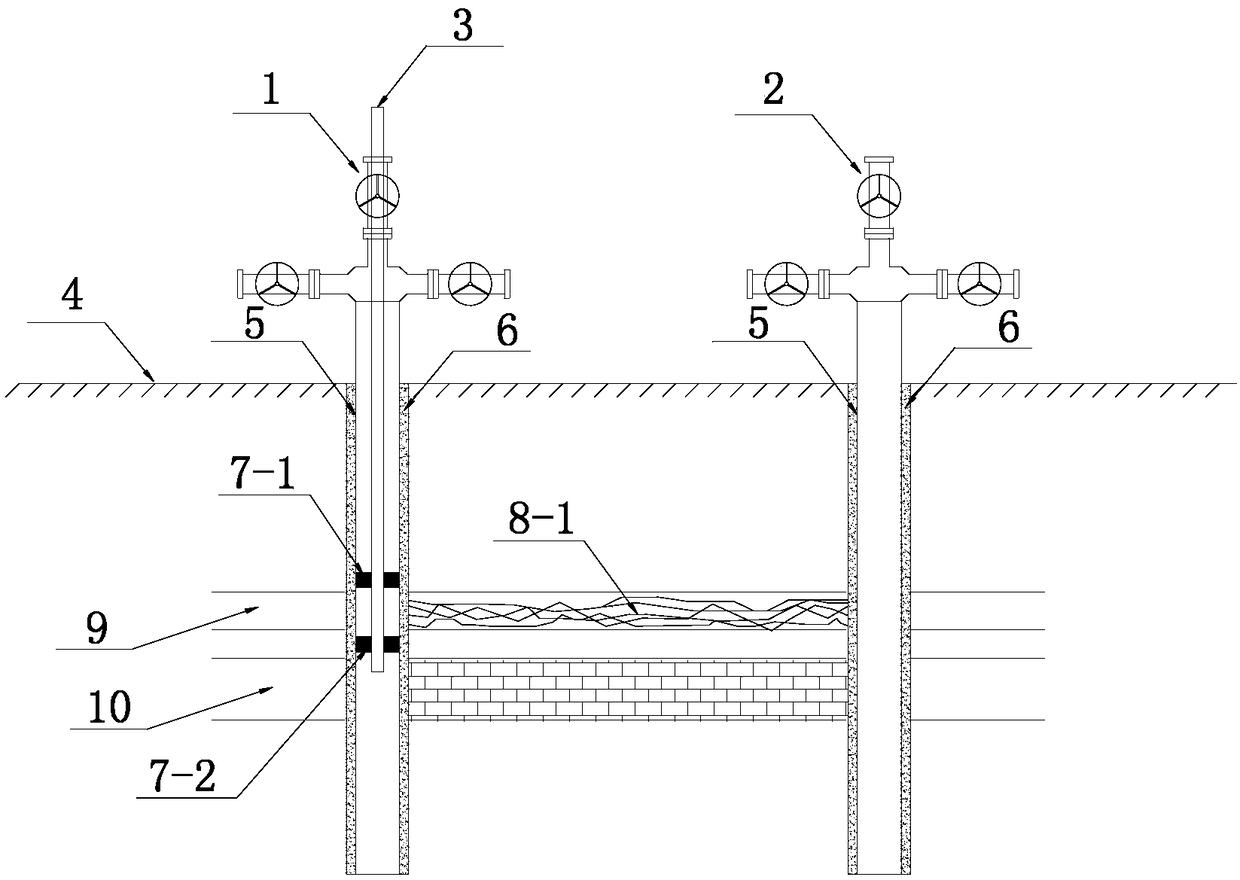

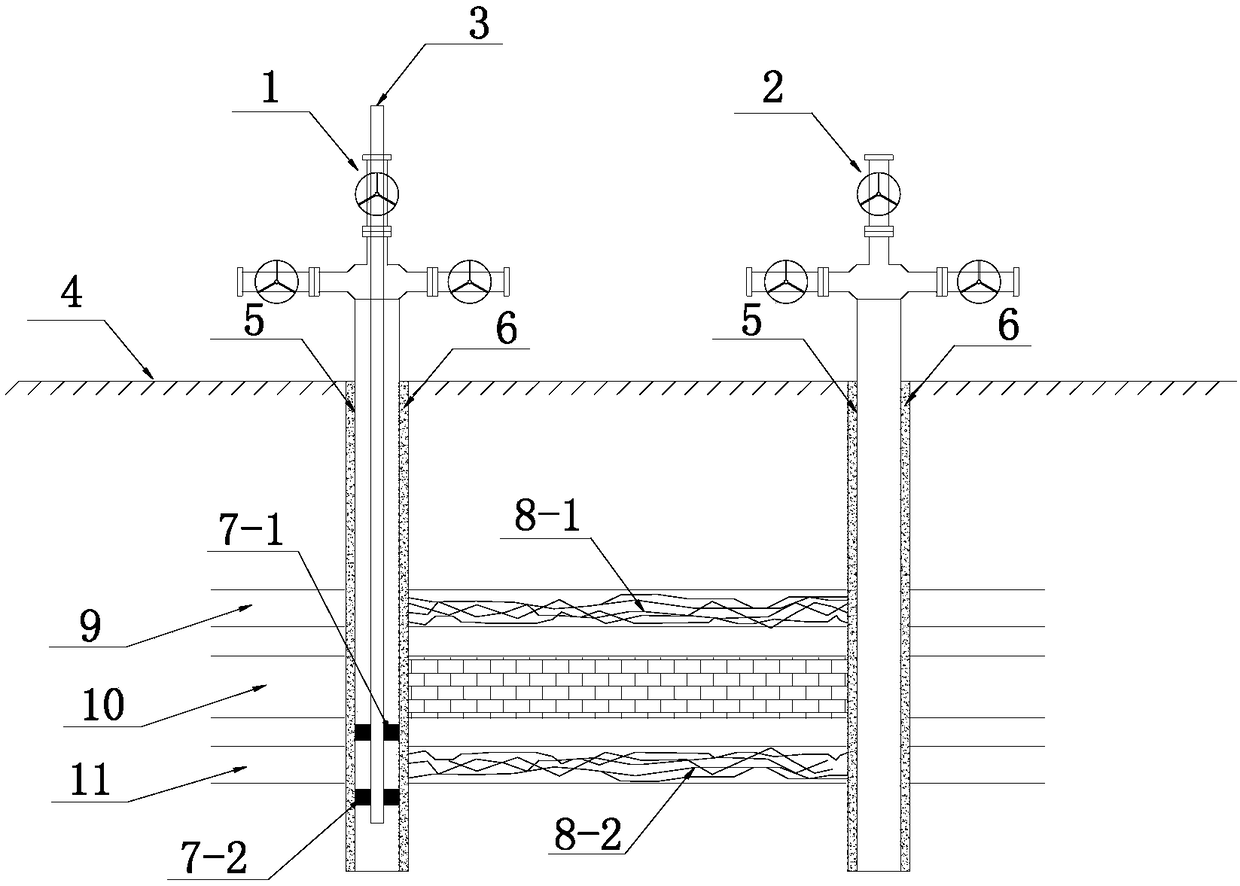

[0072] Such as figure 1 As shown, the oil shale thermal insulation synergistic in-situ conversion method of the present invention comprises the following steps:

[0073] Step 1, construct a heated gas injection well 1 in the oil shale mining area, and construct a plurality of production wells 2 around the heated gas injection well 1; oil shale layer 10 and drill to the underlying formation of oil shale;

[0074]During specific implementation, both the heating gas injection well 1 and the production well 2 are provided with a casing 5 and a cement sheath 6 for cementing at the periphery of the casing 5 . The depth of the oil shale layer 10 from the surface 4 is 300m-600m.

[0075] In this embodiment, the number of production wells 2 around the heating gas injection well 1 mentioned in step 1 is 3-10.

[0076] In this embodiment, the drilling depths of the heating gas injection well 1 and the production well 2 in Step 1 are both to pass through the underground oil shale layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com