Energy-saving efficient continuous type plastic garbage thermal cracking refining equipment

A plastic waste and pyrolysis technology, which is applied in the preparation of liquid hydrocarbon mixtures, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of uneven heating of materials, incomplete utilization of heat energy, poor quality of oil products, etc., and shorten the production cycle , Improve thermal cracking efficiency and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. In order to make the drawings concise, only parts related to the present invention are schematically shown in the drawings, and only one of the components having the same structure or function is schematically shown in the drawings.

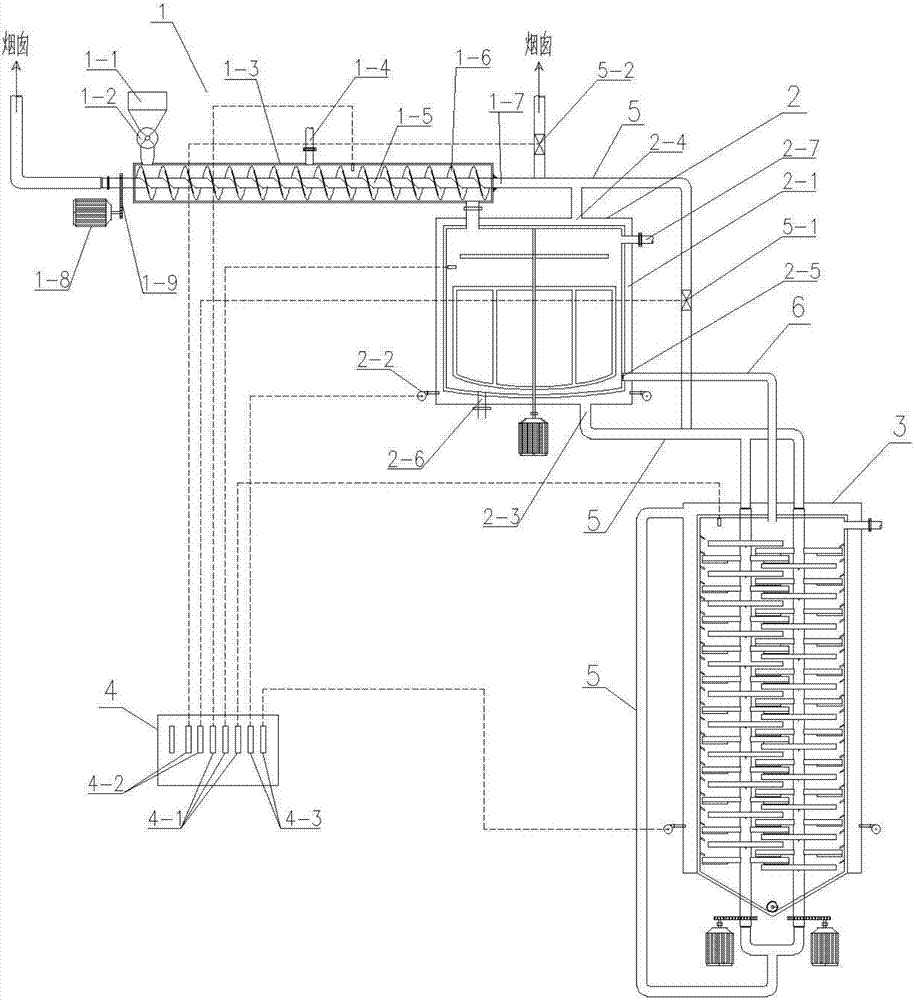

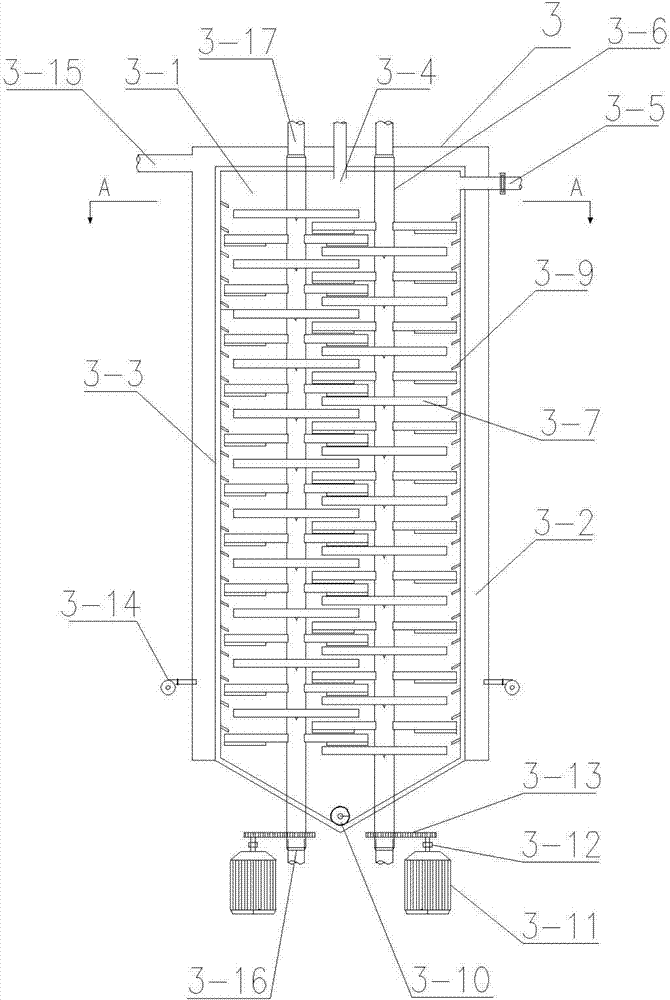

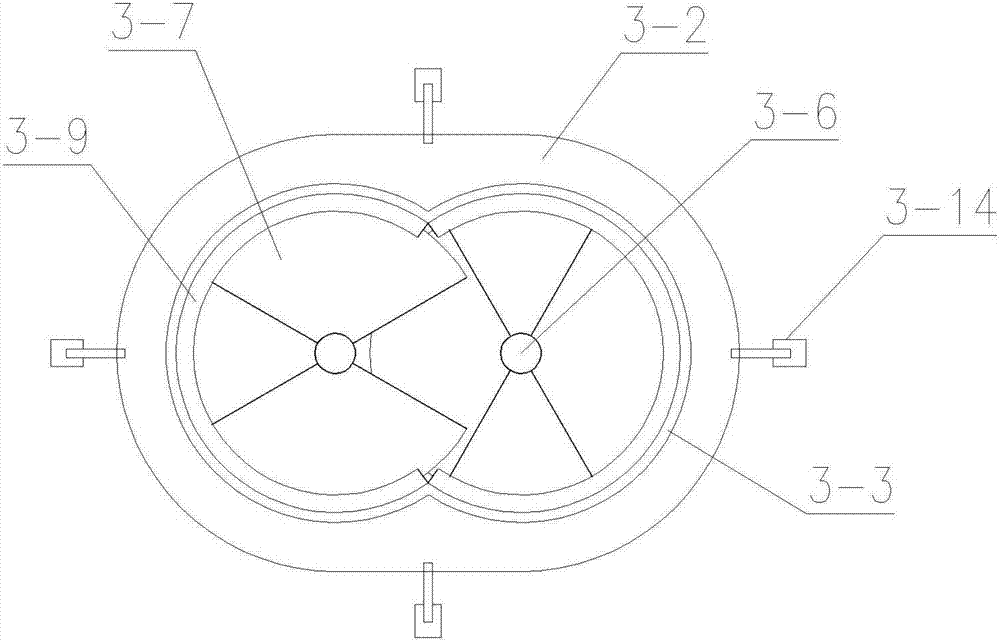

[0024] Such as figure 1 — Figure 4 As shown, the energy-saving and high-efficiency continuous plastic waste pyrolysis refinery equipment of the present invention includes a feed system 1, a liquefaction system, a cracking system (i.e. a cracking furnace 3) and an automatic control system; the liquefaction system includes a liquefier 2 and a liquefaction combustion chamber 2- 1. The liquefaction combustion chamber 2-1 is arranged on the periphery of the liquefier 2, and is supplied with heat by the burner 2-2 and / or the tail gas of the pyrolysis combustion chamber 3-2, and provides heat e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com