Micro bacteria cracking reactor based on surface acoustic waves and bacteria cracking method

A pyrolysis reactor, surface acoustic wave technology, applied in specific-purpose bioreactor/fermenter, combination of bioreactor/fermenter, stress-stimulated microbial growth method, etc., can solve inapplicable rapid analysis, sample volume Large size, long processing time, etc., to achieve the effect of low attenuation, small sample volume, and short rupture time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

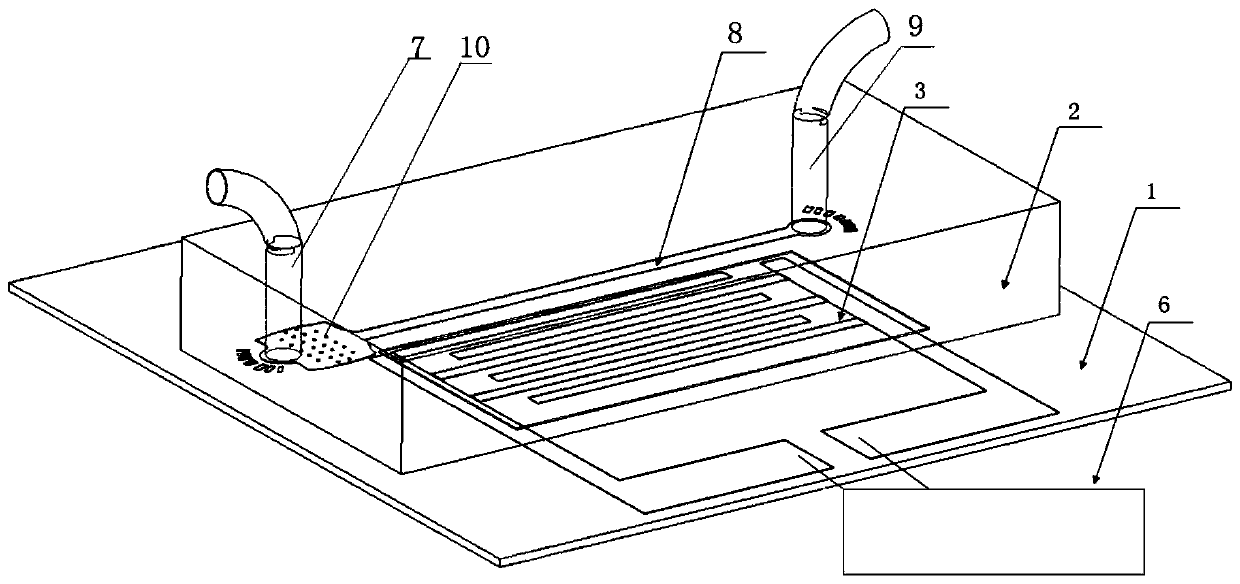

[0037]Connect the injection hole 7 and the product outflow hole 9 at the upper cover plate 2 of the miniature bacterial lysis reactor based on the surface acoustic wave to the syringe with the bacterial suspension to be cracked on the syringe pump and the catheter for the bacterial lysate collection tube respectively. connected. Set the flow rate of the syringe pump to 1 mL / h. Input a pulse signal with a duty cycle of 33% and a frequency of 333Hz into the pulse signal generator. Connect the positive and negative poles of the output signal of the power amplifier to the interdigitated electrodes on the surface acoustic wave generating structure 3 respectively, adjust the output signal frequency of the pulse signal generator to be 13MHz, and the power input to the surface acoustic wave generating structure 3 is 14W; Turn on the signal control system and the syringe pump to lyse the bacteria. Escherichia coli, a commonly used experimental bacterium, was selected. Driven by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com