Device and method for intensifying tar cracking in biomass gasification pyrolysis process

A tar cracking and biomass technology is applied in the field of devices for strengthening tar cracking in the process of biomass gasification and pyrolysis. rate and quality, the effect of high-strength cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

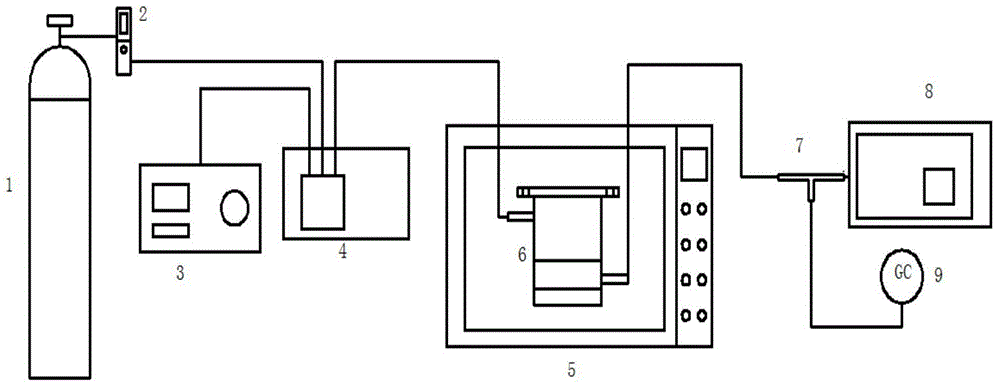

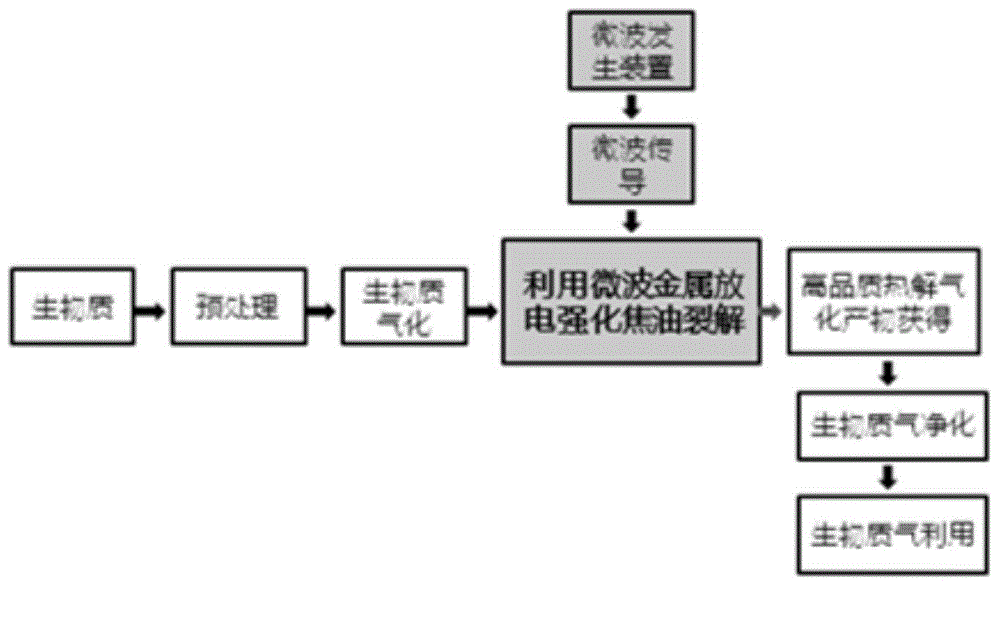

[0029] Such as figure 1 , 2 As shown, a simulation device for strengthening tar cracking in the process of biomass gasification and pyrolysis is composed of gas cylinder 1, laboratory push-pull injection pump 3, XYE digital display constant temperature electric heating mantle 4, Galanz household microwave oven 5, and quartz reactor 6 Connected in sequence through silicone tubes, glass rotameter 2 is set between gas cylinder 1 and XYE digital display constant temperature electric heating mantle 1, laboratory push-pull injection pump 3 is connected to XYE digital display constant temperature electric heating mantle 4 through silicone tube, quartz reactor 6 Placed in the Galanz household microwave oven 5, the position of the inlet pipe of the quartz reactor 6 is higher than the outlet pipe, and the outlet pipe of the quartz reactor 6 is connected with the Fourier infrared spectrometer 8 and the Clarus500GC gas chromatograph 9 through the three-way valve 7. Cut round glass wool w...

Embodiment 2

[0036] In the biomass pyrolysis gasification gas simulation system, toluene was used as the modeled tar product, and N 2 as carrier gas, N 2 The flow rate is 1000ml / min, the input amount of toluene is 1ml / min, and the heating evaporation temperature of toluene is 200°C. In the microwave field metal discharge reaction area, a microwave field environment with a fixed power of 700W is set, and the number of strips (for example, 8 metal materials) Ni with a stronger discharge degree is placed in the microwave field to generate a microwave metal discharge reaction. Let the toluene vapor of the tar mold compound pass through the metal discharge area created, and the cracked product is collected and detected by GC to obtain that the main component of the product is H 2 and N 2 , where H 2 About 4%.

Embodiment 3

[0038] In the biomass pyrolysis gasification gas simulation system, toluene was used as the modeled tar product, and N 2 as carrier gas, N 2 The flow rate is 1000ml / min, the input amount of toluene is 1ml / min, and the heating evaporation temperature of toluene is 200°C. In the microwave field metal discharge reaction area, a microwave field environment with a fixed power of 700W is set, and Ni of the number of strips with a weaker discharge degree (for example, 3 metal materials) is placed in the microwave field to generate a microwave metal discharge reaction. Let the toluene vapor of the tar mold compound pass through the metal discharge area created, and the cracked product is collected and detected by GC to obtain that the main component of the product is H 2 and N 2 , where H 2 About 1.2%.

[0039] In the case of ensuring that other experimental conditions are exactly the same, use the same type of metal strips and only change the number of metal strips for the experi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com