Method for Recovering Hydrocarbon from Tar Sand Using Nanofluid

a technology of nanofluid and hydrocarbon, which is applied in the field of recovery of tar or tarlike hydrocarbons from tar sands, can solve the problems of large amount of energy required, carbon dioxide and other gases then become emission, and the surface and subsurface recovery is a major challenge, so as to increase the release of bitumen from the sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]Surface separation facilities for mining operations are well known. See, for example, a description of mining operations at www.mining-technology.com / projects / Syncrude. Oil sand is mixed with hot water and caustic soda in tumblers, forming a slurry and conditioning the oil sand for bitumen separation. It is then discharged onto vibrating screens where large material is rejected and the blended slurry is fed into primary separation vessels, where bitumen froth floats to the top and sand sinks. The sand is further treated with surfactants to separate more bitumen. Improved water wetting of the sand by a surfactant solution will increase rate of bitumen removal and total recovery. This can be accomplished by adding nanoparticles as disclosed herein to the prior art surfactant solutions or by adding the nanoparticle-surfactant solutions disclosed herein to the water used to remove bitumen from sand in surface facilities.

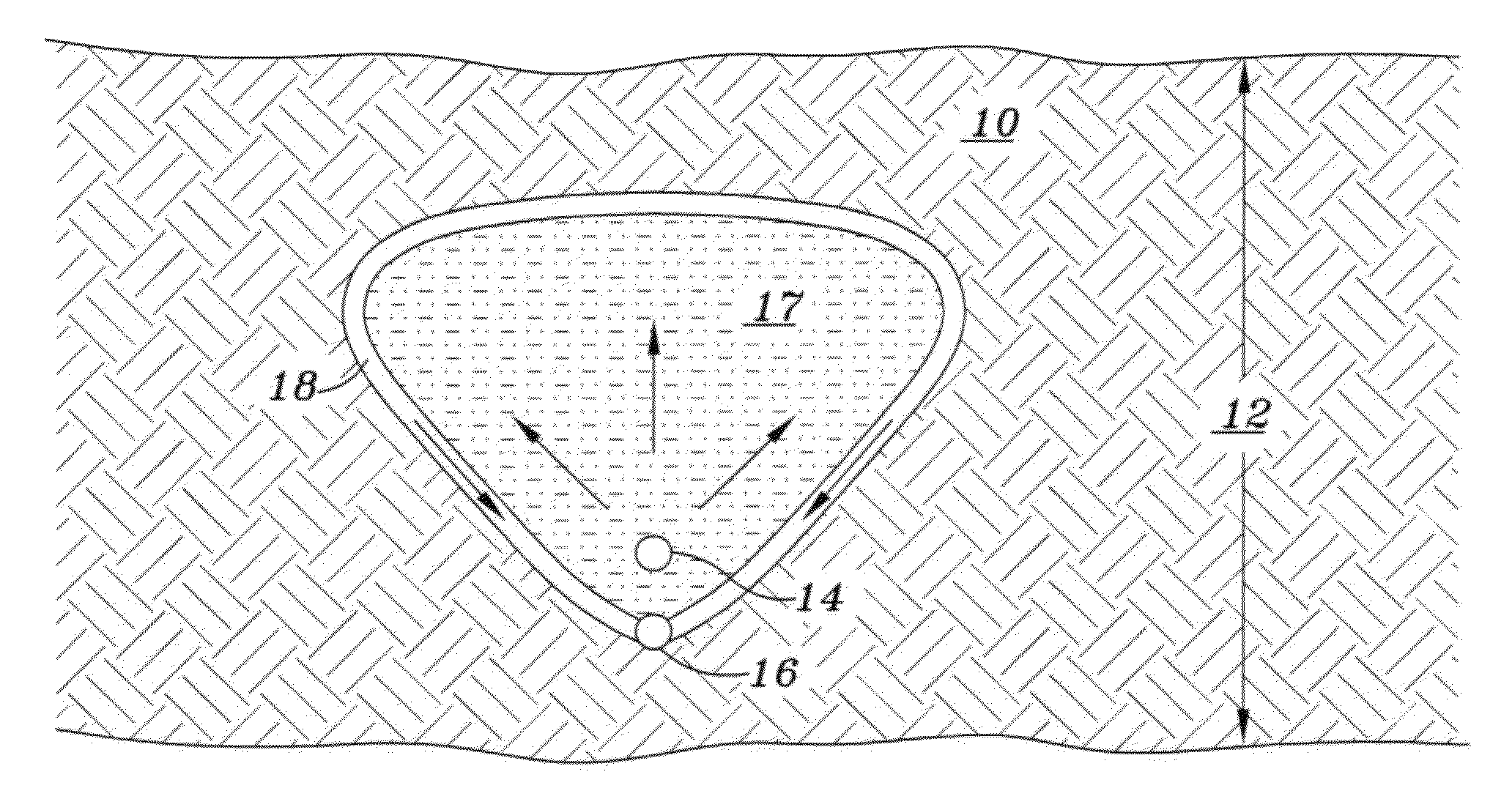

[0016]FIG. 1 is a sketch illustrating fluid flow in reservoir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com