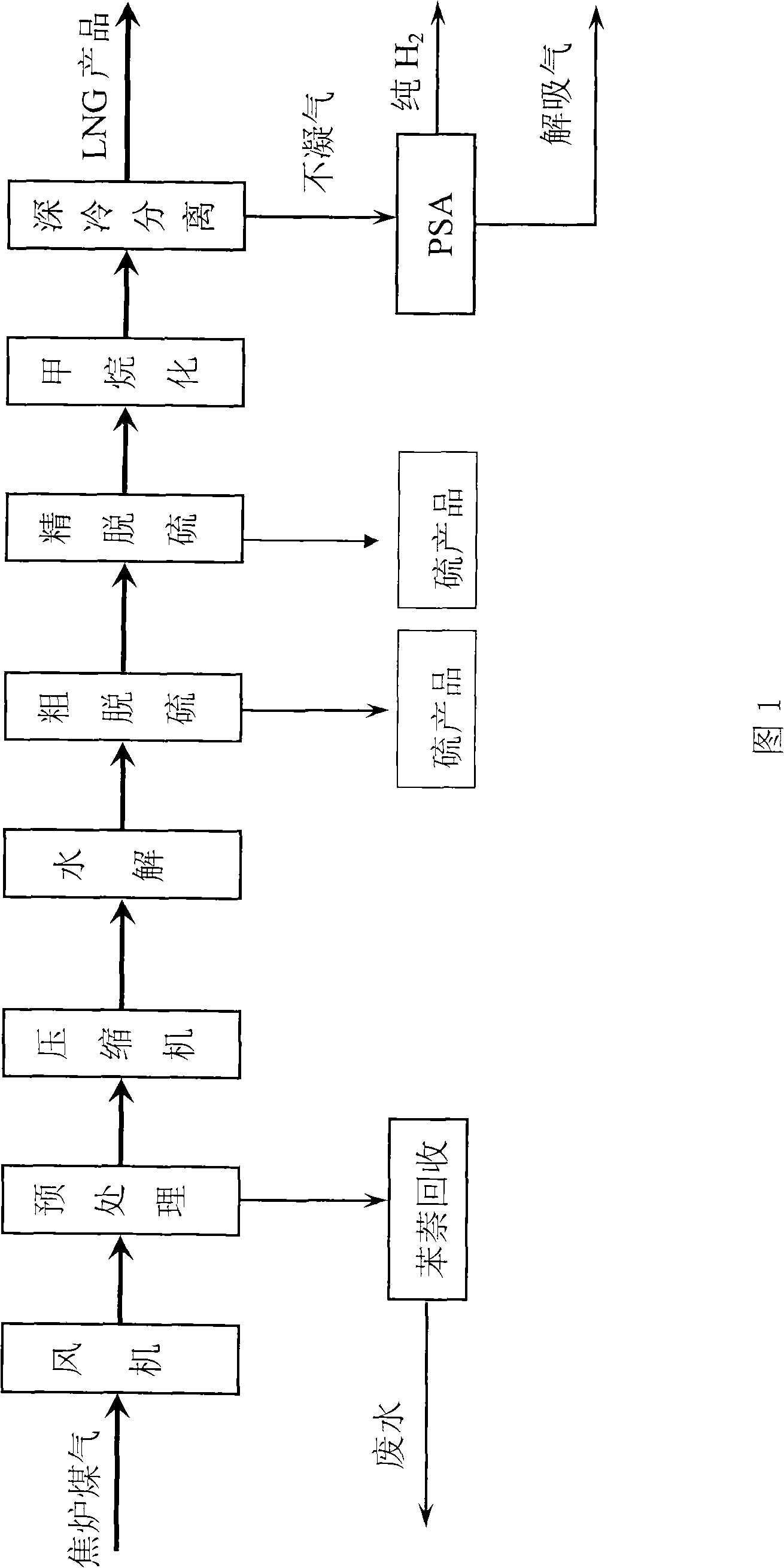

Method for preparing liquefied natural gas from coke oven gas

A technology for liquefied natural gas and coke oven gas, which is applied in the direction of gas fuel, combustible gas purification, combustible gas chemical modification, etc., to achieve the effects of saving investment, simple process and reasonable process combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 30000Nm from outside without preliminary desulfurization 3 / h coke oven gas, the pressure is about 5kPa, the temperature is 35℃, the centrifugal blower first boosts the pressure to 35kPa, and then enters the preliminary desulfurization process, adopts the desulfurization process of tannin extraction, and uses NH 3 As the alkali source, with PDS and tannin extract as the catalyst, the H in the coke oven gas 2 S can be removed to 30mg / Nm 3 the following. After the temperature swing adsorption TSA pretreatment process, the tar, naphthalene, benzene and NH contained in the gas are further removed. 3 , HCN and other impurities, tar + naphthalene ≤ 1mg / Nm 3 , Benzene + NH 3 +HCN≤12ppm.

[0034] The coke oven gas is compressed to 2.0MPa in three stages by a reciprocating piston compressor, and the temperature rises to about 180°C. -1 Under the conditions, using the BS-01 wide temperature hydrolysis catalyst produced by Quzhou Baichuan Catalyst Co., Ltd., the organic sulf...

Embodiment 2

[0040] The 30,000Nm that has been preliminarily desulfurized from the outside world 3 / h coke oven gas, the pressure is about 5kPa, the temperature is 35°C, the pressure is first raised to 20kPa by the Roots blower, and then enters the temperature swing adsorption TSA pretreatment process to further remove tar, naphthalene, benzene, NH contained in the gas 3 , HCN and other impurities, tar + naphthalene ≤ 1mg / Nm 3 , Benzene + NH 3 +HCN≤12ppm.

[0041] The coke oven gas is compressed to 2.0MPa by a centrifugal compressor, and the temperature rises to about 120°C. -1 Under the conditions, using the domestic T504 hydrolysis catalyst, the organic sulfur in the gas is hydrolyzed into H 2 S, the conversion rate of COS is over 95%.

[0042] Then enter the rough desulfurization process, adopt the low-temperature methanol washing (Rectisol) process for deep desulfurization (simultaneous decarbonization), the CO in the gas 2 ≤10ppm,H 2 S2 S content≤0.1ppm, NH 3 +HCN≤7ppm.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com