Construction waste comprehensive utilization method

A technology of construction waste and new method, which is applied in the direction of calcium/strontium/barium halide, silicon dioxide, calcium/strontium/barium chloride, etc. effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

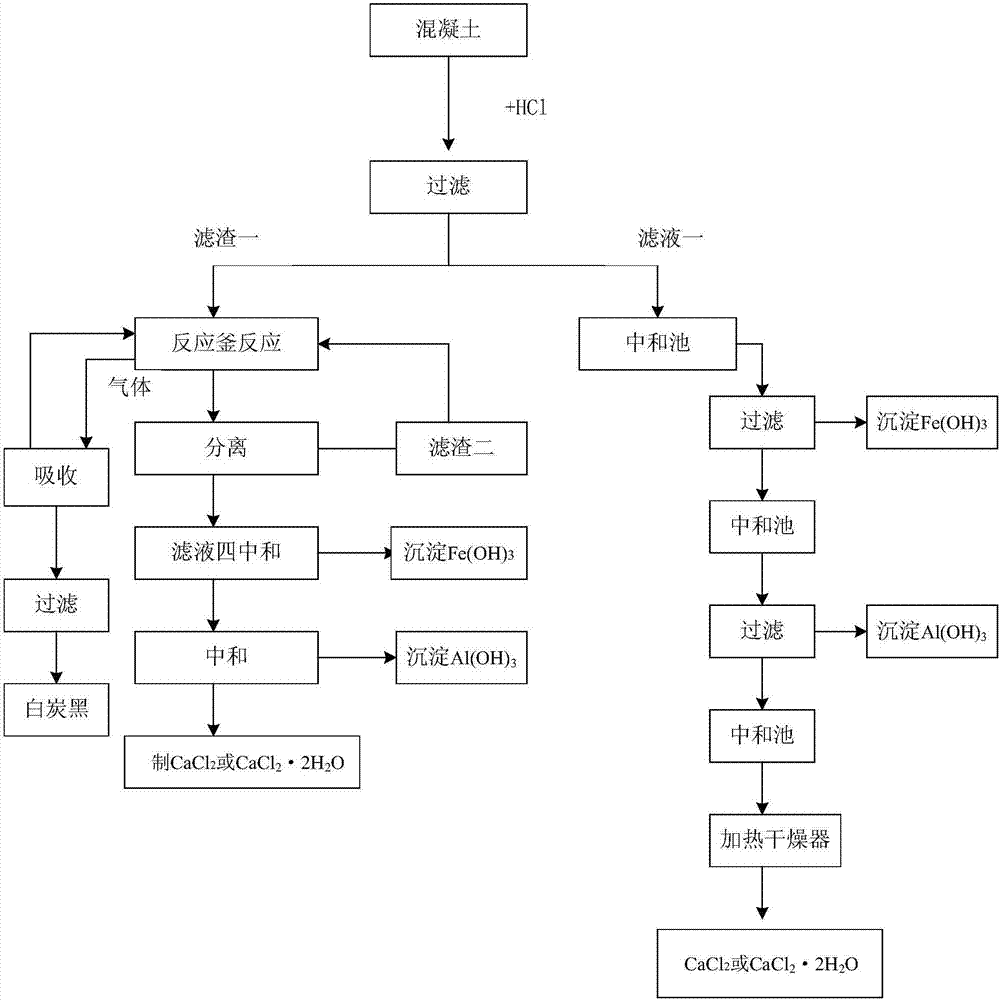

Image

Examples

Embodiment 1

[0028] Take 5g of the concrete sample crushed to 200 mesh, put it into a 250ml beaker, mix with 20ml of 1:1 HCl (hydrochloric acid obtained by mixing 1 volume of concentrated hydrochloric acid with 1 volume of water, the concentration is about 6mol / L), mix and boil for 1 hour, filter , to obtain filtrate 1 and filter residue 1, with a decomposition rate of 29%.

[0029] The filtrate after water dissolving and filtering is the Ca(OH) of 5% with mass percentage concentration 2 Adjust the pH of the emulsion to 4, filter and separate the reddish-brown precipitated ferric hydroxide, continue with 5% Ca(OH) 2 The pH of the emulsion was adjusted to 7, and the white flocculent precipitated aluminum hydroxide was separated by filtration, and then the filtrate was evaporated to dryness at 300°C to obtain white solid calcium chloride with strong water absorption.

[0030] Dissolve the filtered filter residue 1 in water, add 6ml of fluosilicic acid with a mass percentage concentration of...

Embodiment 2

[0033] In the enamel reaction kettle, add 4mol / L hydrochloric acid 2m 3 (cubic), under constant stirring, slowly add 1t of concrete samples crushed to 120 mesh, filter after stirring and reacting for 1 hour, and obtain filtrate and solid after entering the filter press for separation.

[0034] Filtrate with 20% Ca(OH) 2 Adjust the pH to 4, Fe(OH) 3 Basically completely precipitate out, filter to get Fe(OH) 3 solid and filtrate, adjust the pH of the filtrate to 7, Al(OH) 3 Almost completely precipitated, filtered to obtain Al(OH) 3 Solid and filtrate, only CaCl in the filtrate at this time 2 , evaporated to dryness at 300°C to obtain CaCl 2 solid.

[0035] Solid 0.7t with 30% fluosilicic acid according to 4m 3 The ingredients are mixed and reacted in the reactor, and evaporated to dryness at 150°C to obtain volatile gas. Reference patent: CN201310534326.8 (CN103588209A) A comprehensive utilization method for recovering SiF4 gas to produce white carbon black, and the abso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com