Method and device for synthesizing natural gas by using coke oven gas

A technology for synthesizing natural gas and coke oven gas, which is applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of underutilization of hydrogen, underutilization of hydrogen, underutilization of precious resource hydrogen, etc. Industrial application value, the effect of enhancing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

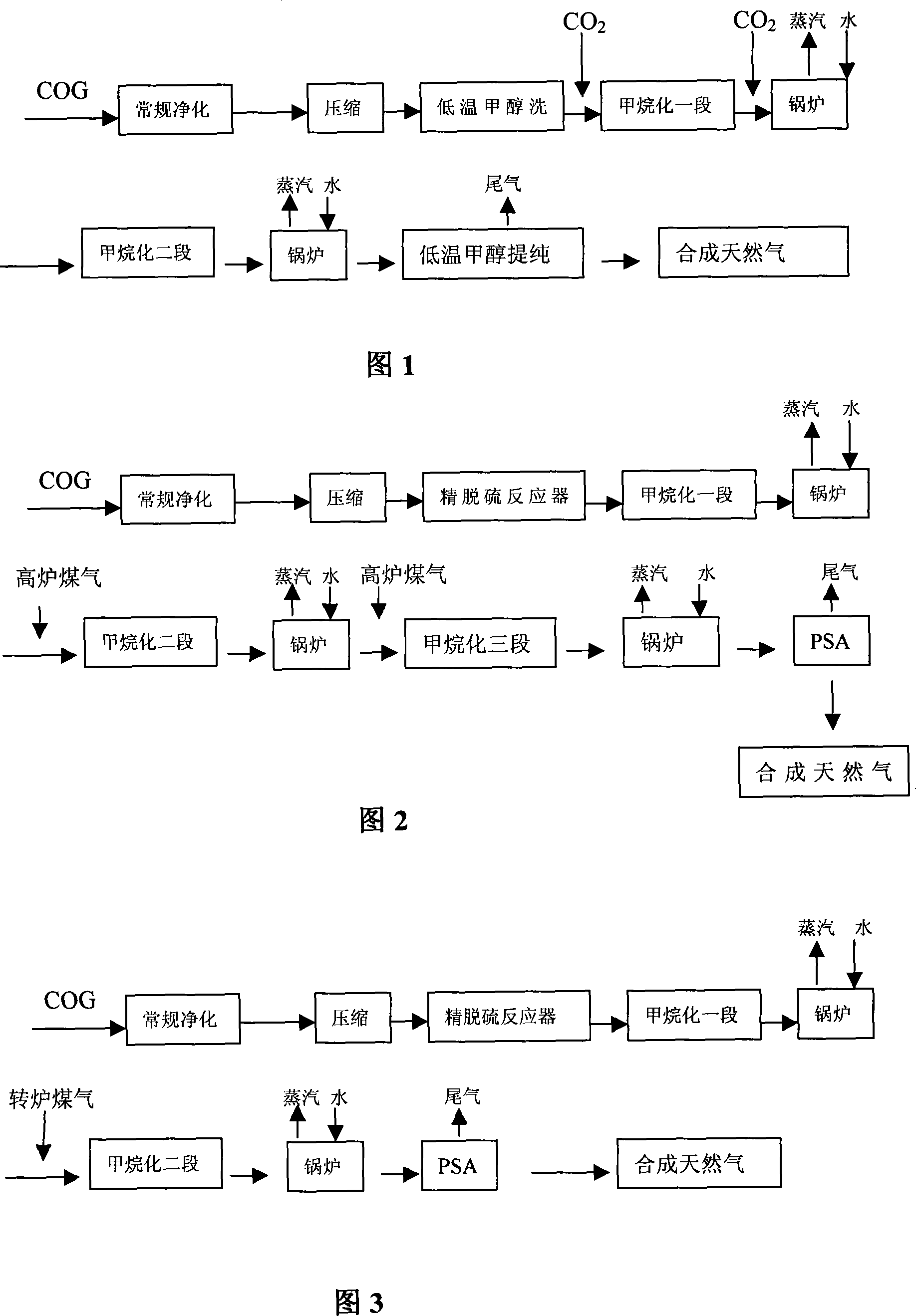

[0036] As shown in Figure 1, the coke oven gas is compressed to 3.0 MPa after conventional purification, de-tarring, desulfurization, de-ammonia, de-benzene and de-naphthalene, and the composition is (vol%) H 2 60%, CH 4 25%, CO6%, CmHn3%, CO 2 2%, N 2 4%, O 2 0.5%, and then enter the low-temperature methanol elution device for fine desulfurization, and the purified gas is supplemented with the waste CO discharged from the urea device 2 Then enter the first stage of methanation reactor, CO 2 The supplemental amount is 5% of the coke oven gas, the reaction temperature is 250~500℃, the catalyst is nickel / alumina, and the reacted gas is supplemented with 10% CO 2 Then it enters the boiler to produce steam. After cooling, it enters the second stage methanation reactor. The reaction temperature is 250~500℃. The catalyst is nickel / alumina. The hydrogen content in the outlet mixture of the second stage reactor is 10%~20%. The product flows into the boiler to produce steam. After cooling ...

Embodiment 2

[0038] As shown in Figure 2, the coke oven gas is conventionally purified to remove tar, desulfurization, ammonia, benzene, and naphthalene, and then compressed to 1.0MPa, and the composition is (vol%) H 2 60%, CH 4 25%, CO6%, CmHn 3%, CO 2 2%, N 2 4%, O 2 0.5%, and then heat up to 150℃, after entering the conversion absorption fine desulfurization reactor, it is equipped with absorption conversion desulfurizer, the carrier is manganese ore, the active tissue is Co, Mo and Zn, and the gas after fine desulfurization enters the isothermal bed for methanation The first stage reactor, the reaction temperature is 300°C, the methanation catalyst is nickel / diatomaceous earth, after the reaction, the gas boiler is cooled and the blast furnace gas is added and then enters, and then enters the second stage reactor of methanation. The composition CO of the blast furnace gas is 30%. CO 2 18%, H 2 1.5%, N 2 29.2%, O 2The supplemental amount is 5% of the volume of coke oven gas. The high-temper...

Embodiment 3

[0040] As shown in Figure 3, the coke oven gas is conventionally purified to remove tar, desulfurization, deammonia, debenzene and denaphthalene, and then compressed to 4.0MPa, then heat exchanged and heated to 400°C, after entering the conversion and absorption fine desulfurization reactor, Built-in absorption conversion desulfurizer, the carrier is diatomaceous earth, the active components are Ni, Cu, and Zn, the gas after fine desulfurization enters the first stage of methanation reactor, the reaction temperature is 250-500℃, the catalyst is nickel / ceramic, and the reaction produces After the high temperature gas enters the boiler to produce steam, the temperature is reduced and the converter gas is added, and then it enters the second-stage methanation reactor. The composition of the converter gas is CO 60%, CO 2 16%, the supplemental amount is 20% of the coke oven gas. The high-temperature gas exiting the second-stage methanation reactor enters the boiler to produce steam and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com