Thermosetting epoxy asphalt materials for pavement and bridge and process for preparing same

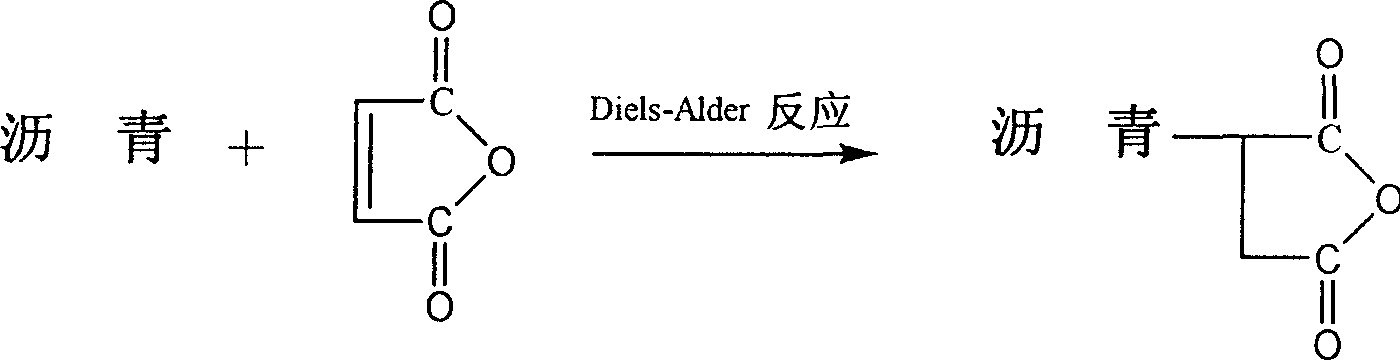

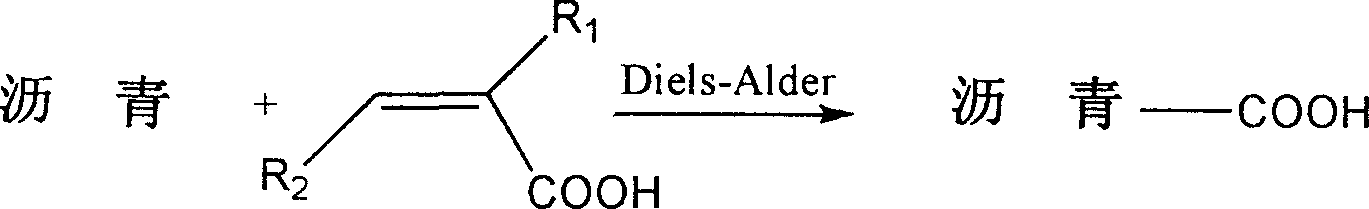

A technology of epoxy asphalt material and asphalt material, which is applied to building insulation materials, roads, roads, etc., can solve the problem of not considering the pot life, it is difficult to meet the requirements of large-span bridge paving, and the control of the pot life is not involved. , to achieve the effect of outstanding high temperature stability, high strength and excellent fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The present invention will be further described below through specific examples, but none of the examples limits the present invention. Example 1: Add 57 parts (mass, the same below) of petroleum asphalt (origin: Shanjiasi) heated to 90-140°C into the reactor, add 1.14 parts of maleic anhydride, heat up to 150-155°C, and wait for the pressure to stabilize , into N 2 , keep the total pressure at 0.25MPa, and after 4 hours of reaction, slowly release the pressure to 0.1MPa. Then add 17.16 parts of oxalic acid, 5 parts of polyisobutylene succinic anhydride (average molecular weight: 5100, Changzhou Guanghui High-tech Chemical Co., Ltd.), polyoxalic anhydride (average molecular weight: 1500, Changzhou Guanghui High-tech Chemical Co., Ltd.) 17.6 parts, 0.24 parts of triethylamine, pre-mixed for 30 minutes; then dispersed at high speed through a colloid mill to obtain part A, and finally added part B epoxy resin (E-51, Wuxi resin plant) mix well. This material can be used ...

Embodiment 2

[0039] Example 2: Add 57.3 parts of petroleum asphalt (US Shell) heated to 90-140 ° C into the reactor, add 4 parts of maleic anhydride, heat up to 155-160 ° C, and after the pressure is stable, feed N 2 , keep the total pressure at 0.45MPa, and after 5 hours of reaction, slowly release the pressure to 0.1MPa. Then add 15.13 parts of dimer acid (Zhejiang Yongzai Chemical Factory), 10 parts of adipic acid, 3 parts of polyisobutylene succinic anhydride (average molecular weight 2400, Changzhou Guanghui High-tech Chemical Co., Ltd.) that have been heated to 90-140 ° C in advance, 10 parts of polyazelaic anhydride (average molecular weight 1200, Changzhou Guanghui High-tech Chemical Co., Ltd.) and 0.57 parts of triethylamine were pre-mixed for 30 minutes and dispersed at high speed through a colloid mill to obtain part A. When using, part A and part B (ring Oxygen resin E-51) was heated up to 120°C, and mixed uniformly at a ratio of 4:1. This material can be used as a bonding lay...

Embodiment 3

[0040] Example 3: Add 68 parts of petroleum asphalt (US Shell) heated to 90-140°C into the reactor, add 8.2 parts of maleic anhydride, heat up to 230°C for reaction, and reflux with 80°C warm water at the same time, after 6 hours of reaction, the alcohol Acid resin (brand 3370A, Jiangsu Sanmu Group Co., Ltd.) 14.4 parts, methyl nadic anhydride (Changzhou Guanghui High-Tech Chemical Co., Ltd.) 5 parts, polyglutaric anhydride (average molecular weight 1200, Changzhou Guanghui High-Tech Chemical Co., Ltd.) 7 1 part, and 0.6 part of diethylenetriamine were added to the reactor, stirred and mixed for 1 hour, and finally dispersed at high speed in the colloid mill to obtain part A; when in use, part A and part B (epoxy resin E-44 ) to 120°C and mix at a ratio of 5:1. This material can be used as a bonding layer for pavement. See Table 1 for specific properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com