Kerosene heating system for supersonics burning test bed

A supersonic combustion and heating system technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as pipe and heater blockage, oil injection hole blockage, valve seal failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

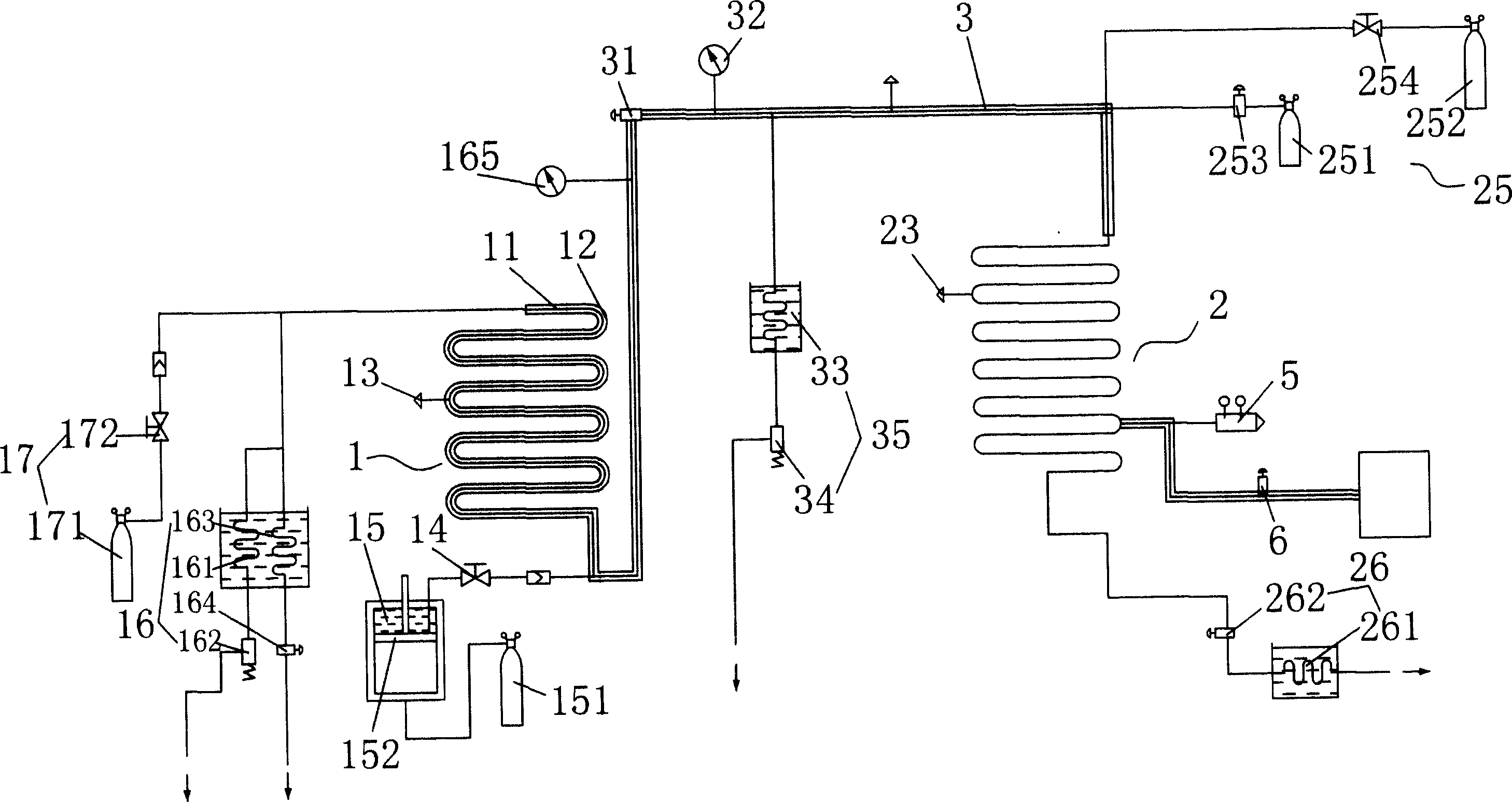

[0019] The present invention is specifically described below in conjunction with accompanying drawing:

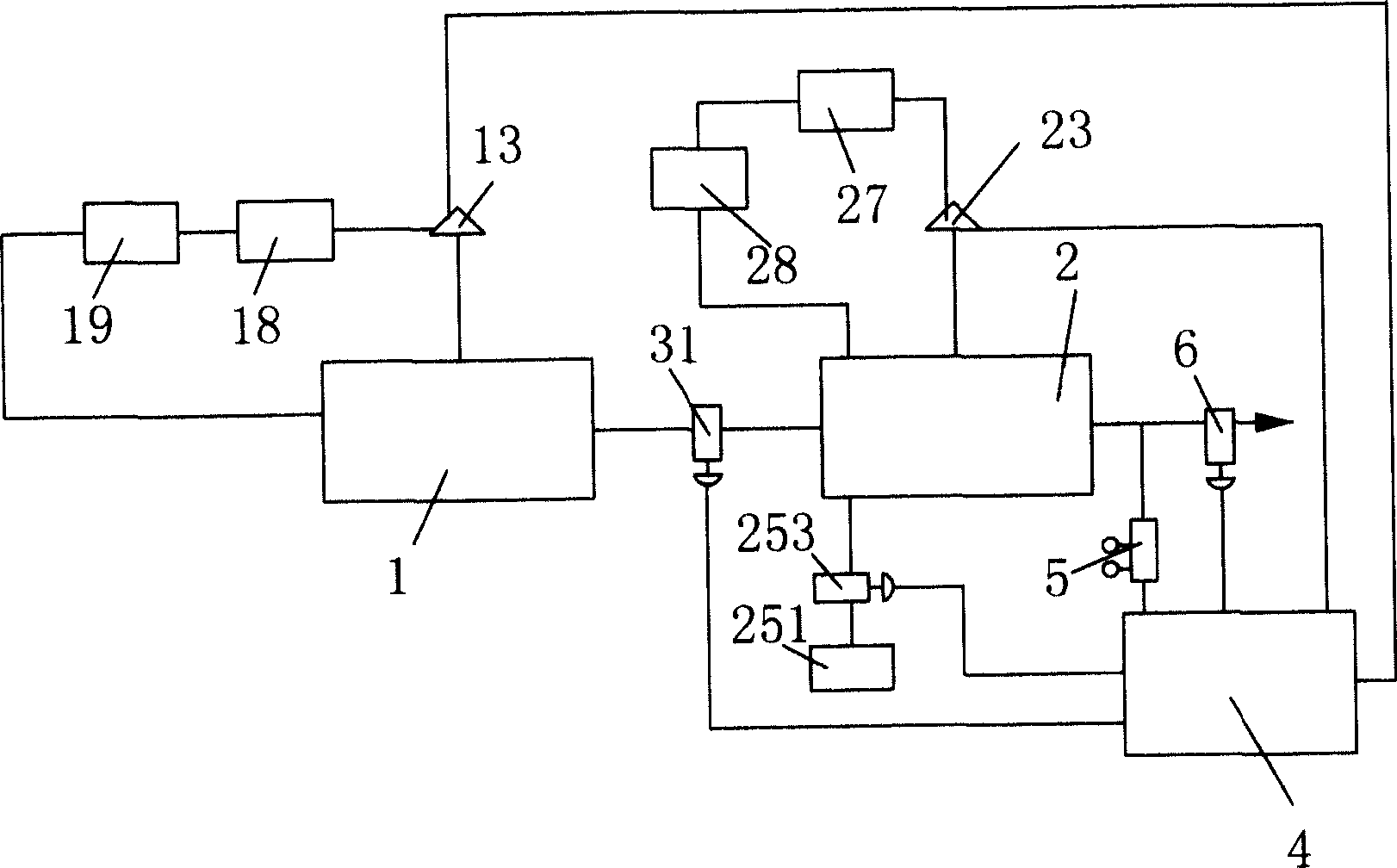

[0020] The present invention is used for the kerosene heating system of the supersonic combustion test bench, and its structural diagram is as follows figure 1 As shown, the system includes:

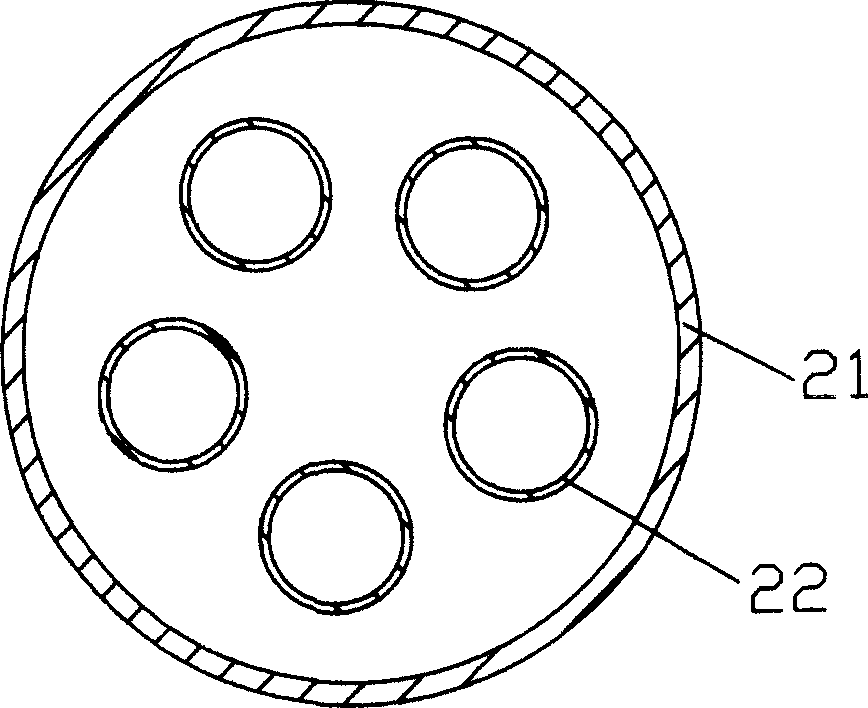

[0021] The primary heater 1 is composed of a spiral tube 11 arranged in the inner layer and a heating belt 12 coated on the spiral tube. The tube wall of the spiral tube 11 is welded with a K-type thermocouple 13 for measuring the temperature of the tube wall. The thermocouple can also penetrate the pipe wall to directly measure the kerosene temperature; one end of the spiral pipe 11 is connected to a high-pressure oil source 15 through a valve 14, and the other end is equipped with a double safety system 16 and a drive system 17, and the high-pressure oil source is pushed by a high-pressure gas 151 to a piston 152 Entering the primary heater, the double safety system 16 includes a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com