Production technology of polyethylene wax

A polyethylene wax and production process technology, applied in the field of chemical production, can solve the problems of low wax production rate, easily damaged stirring device or extruding device, and incapable of continuous production, so as to reduce production cost, speed up reaction speed, and improve production The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

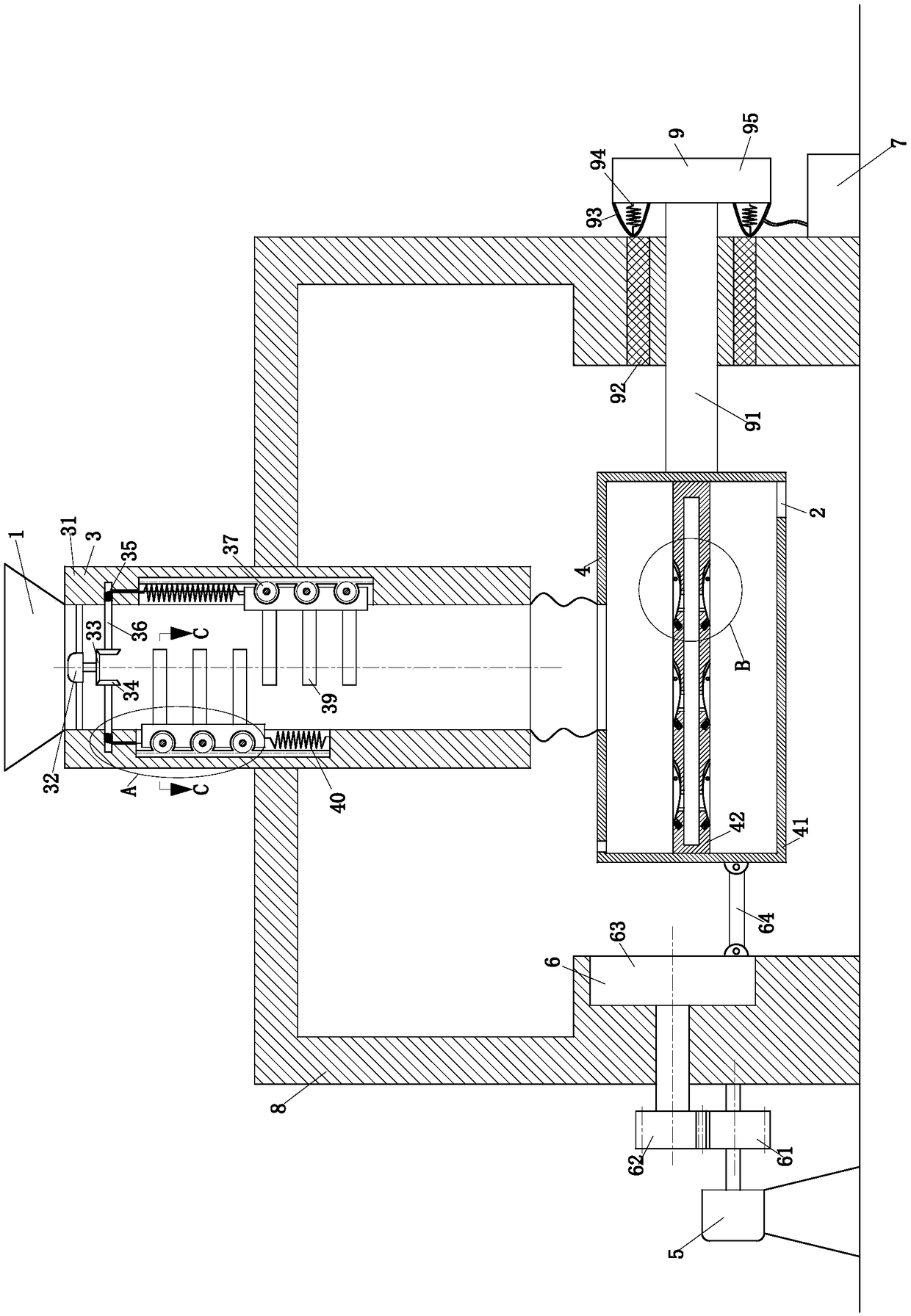

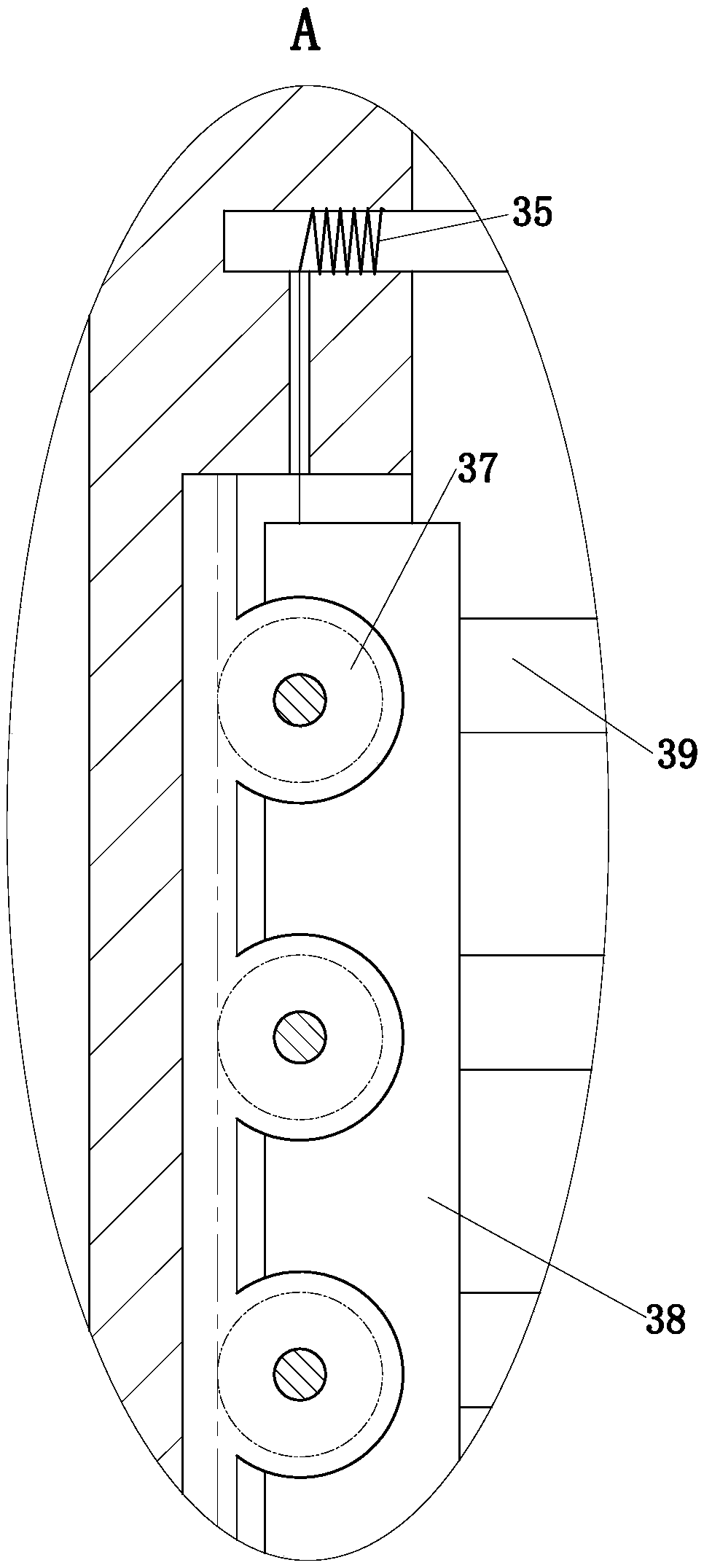

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

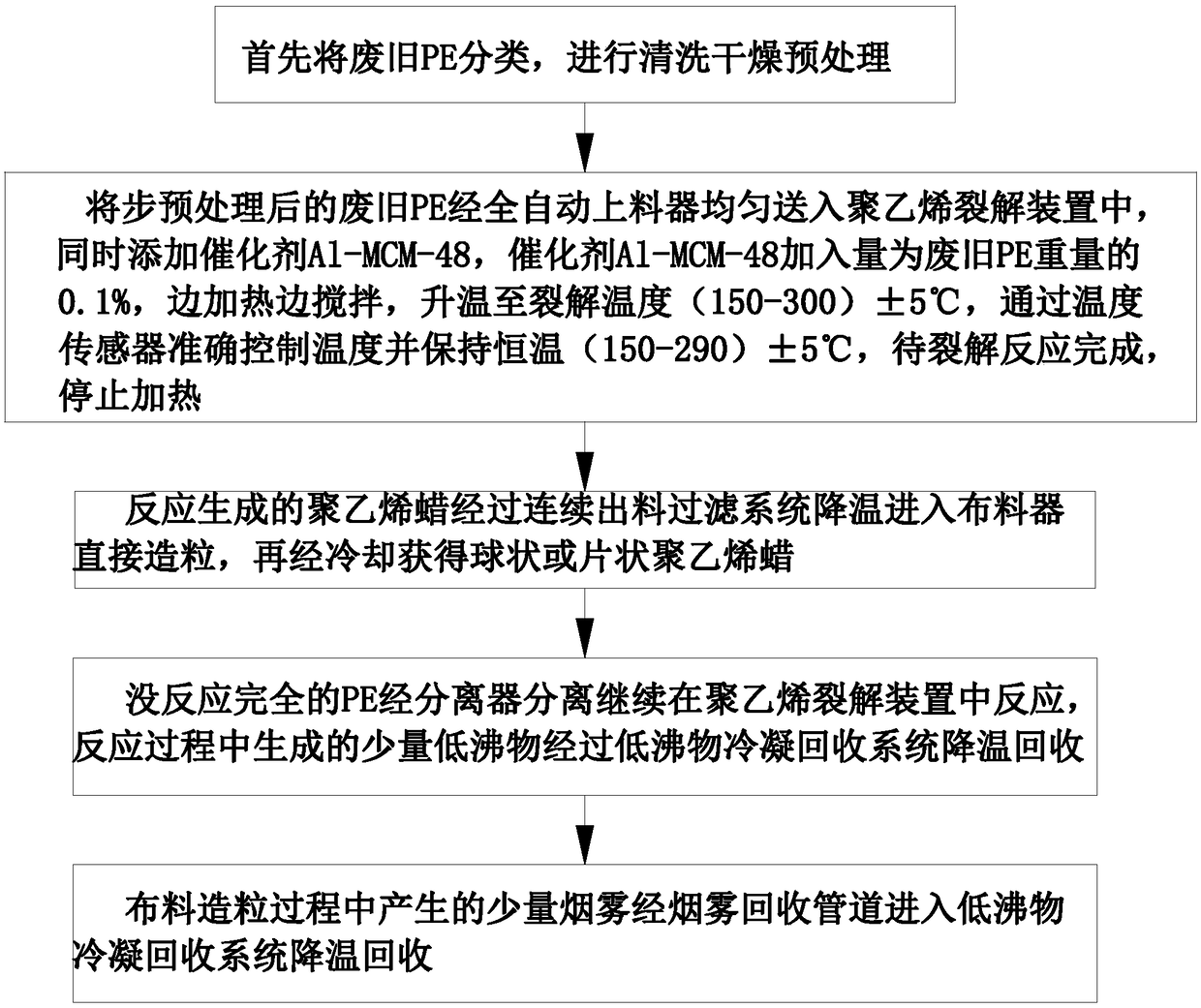

[0031] like Figure 1 to Figure 6 Shown, a kind of polyethylene wax production technique of the present invention, this technique comprises the steps:

[0032] Step 1: first classify the waste PE, and carry out cleaning and drying pretreatment;

[0033] Step 2: The waste PE pretreated in step 1 is evenly sent to the polyethylene cracking device through a fully automatic feeder, and the catalyst Al-MCM-48 is added at the same time. 0.1%, stir while heating, heat up to the cracking temperature (150-300) ± 5 ° C, accurately control the temperature through the temperature sensor and maintain a constant temperature (150-290) ± 5 ° C, stop heating after the cracking reaction is completed;

[0034] Step 3: The polyethylene wax produced by the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com