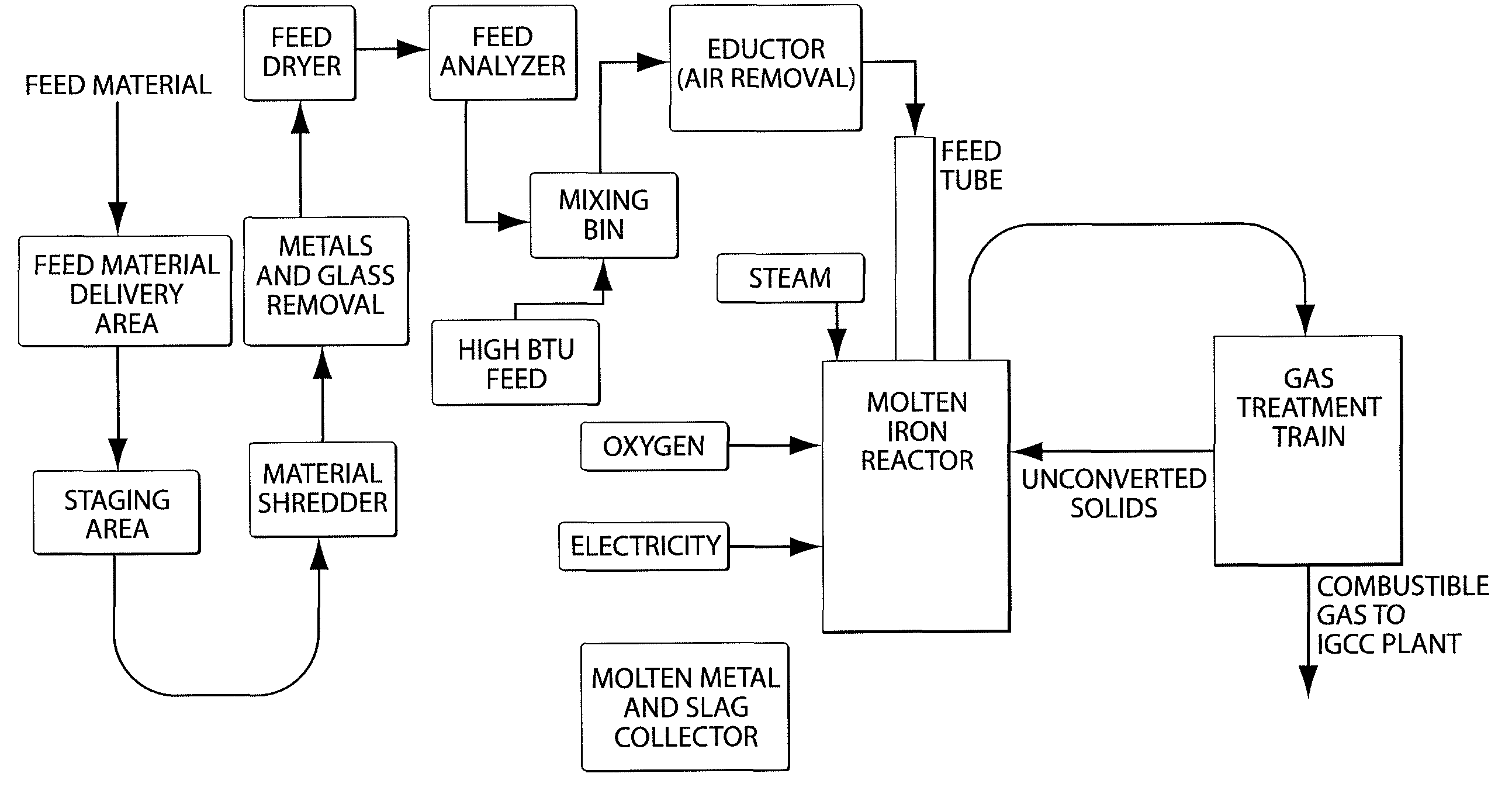

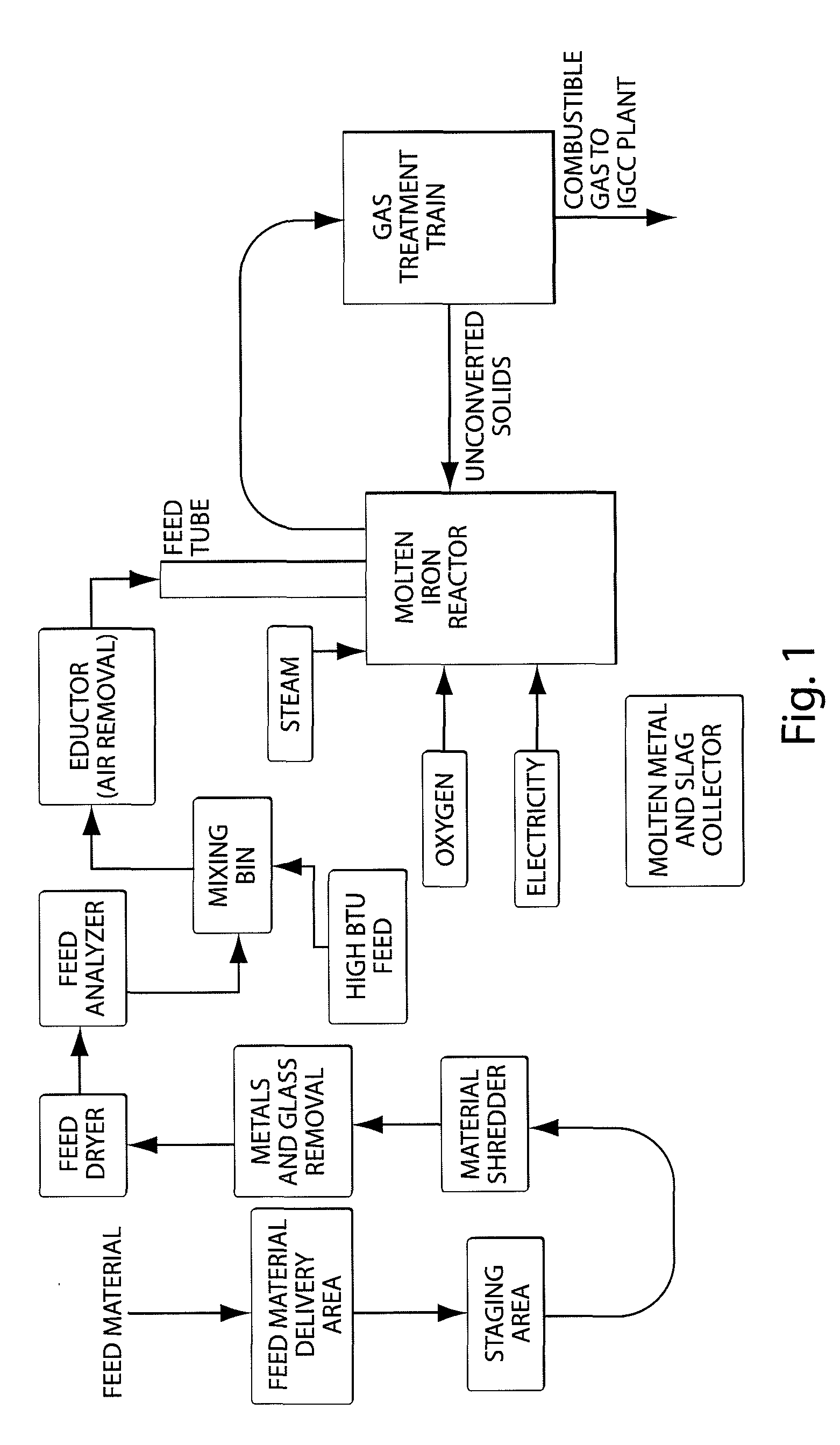

Method for controlling syngas production in a system with multiple feed materials using a molten metal bath

a technology of molten metal bath and syngas, which is applied in the direction of molten salt/metal gasification, combustible gas production, chemistry apparatus and processes, etc., can solve the problems of feed materials' chemical and physical characteristics that could change dramatically, feed materials' unpredictable nature, and did not allow appropriate scaling or commercialization of the process. achieve the effect of constant or substantially constant mass flow of syngas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

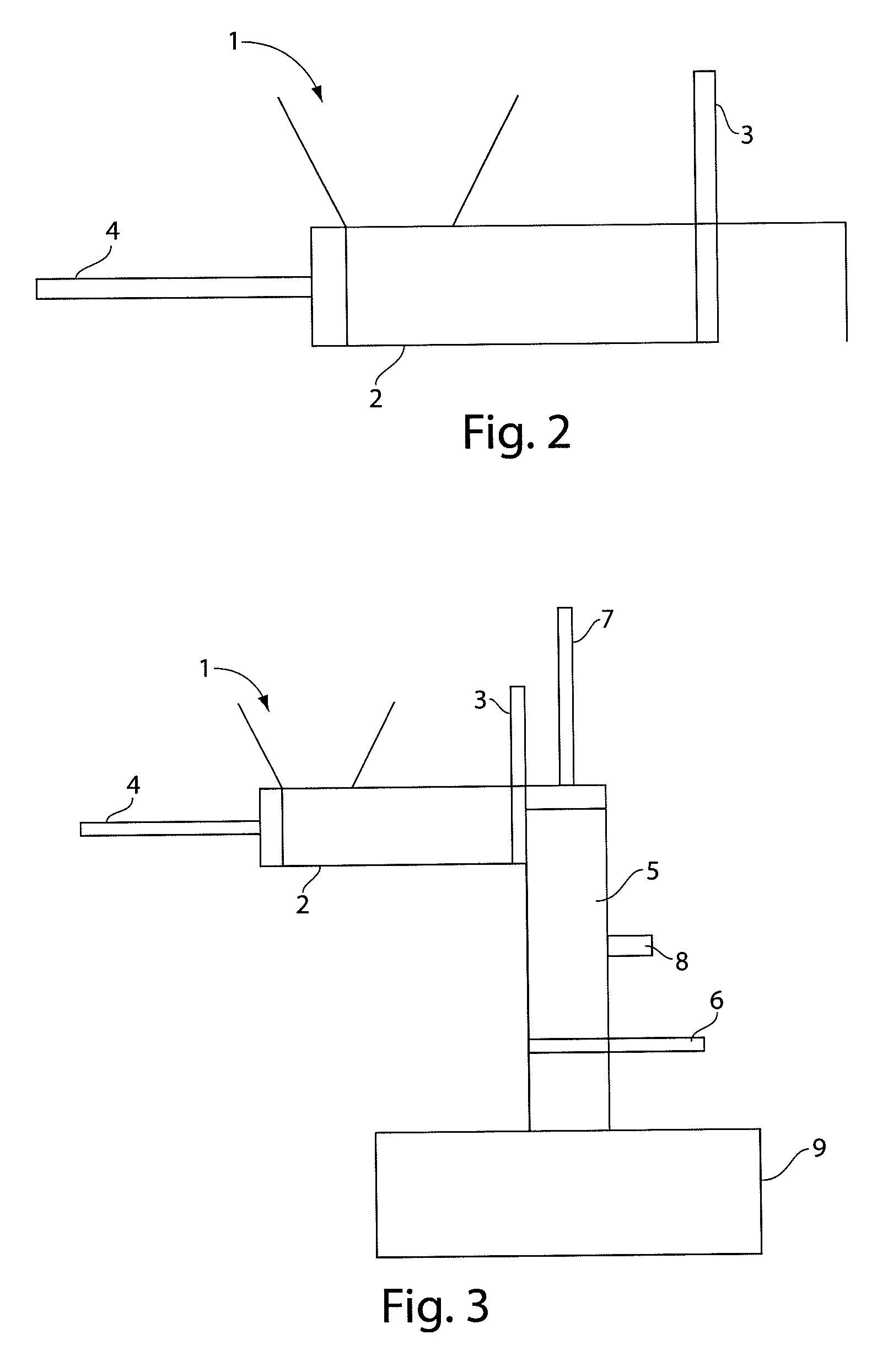

[0109]Dried pelletized refuse derived fuel (RDF) with a capacity of 250 tons per day (TPD) is processed in a 40-ton channel induction reactor (Ajax Model VS-40), modified to have a sealed lid and increased dimensions to provide additional head space. RDF at a rate of 10.4 tons an hour (TPH) is fed into the reactor through a feeding mechanism, consisting of a screw type educator feeder. This feeder accomplishes two tasks: air extraction from the RDF, and product movement with the required speed to the feeding tube. The feeding tube is a graphitized alumina pipe with internal diameter (ID) of 4″. It is installed in the center of the reactor lid.

[0110]The RDF feed material as received has moisture content of about 35% and contains material of varying size. The feed material is prepared as follows: it is dried using a Eagle II (available from Sweet Manufacturing Company, Springfield, Ohio) to a moisture level of 7%, sized using a shredder (Model # VVZ-310 available from Vecoplan, LLC, H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| feed rate | aaaaa | aaaaa |

| energy content | aaaaa | aaaaa |

| mass flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com