Entrained bed gasifier with integrated medium temperature plasma

A plasma and entrained bed technology, applied in gasification process, combustible gas purification, gasification device electrodes, etc., can solve problems such as high processing cost, achieve the effect of low hydrogen content change, and reduce electric power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

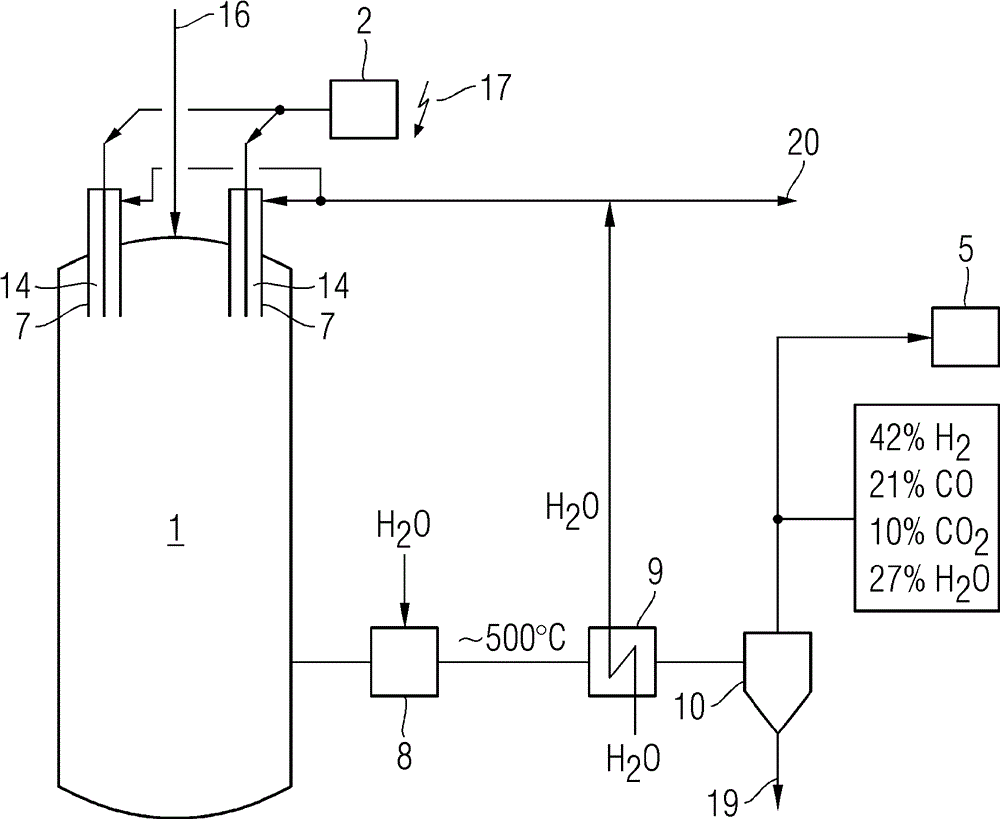

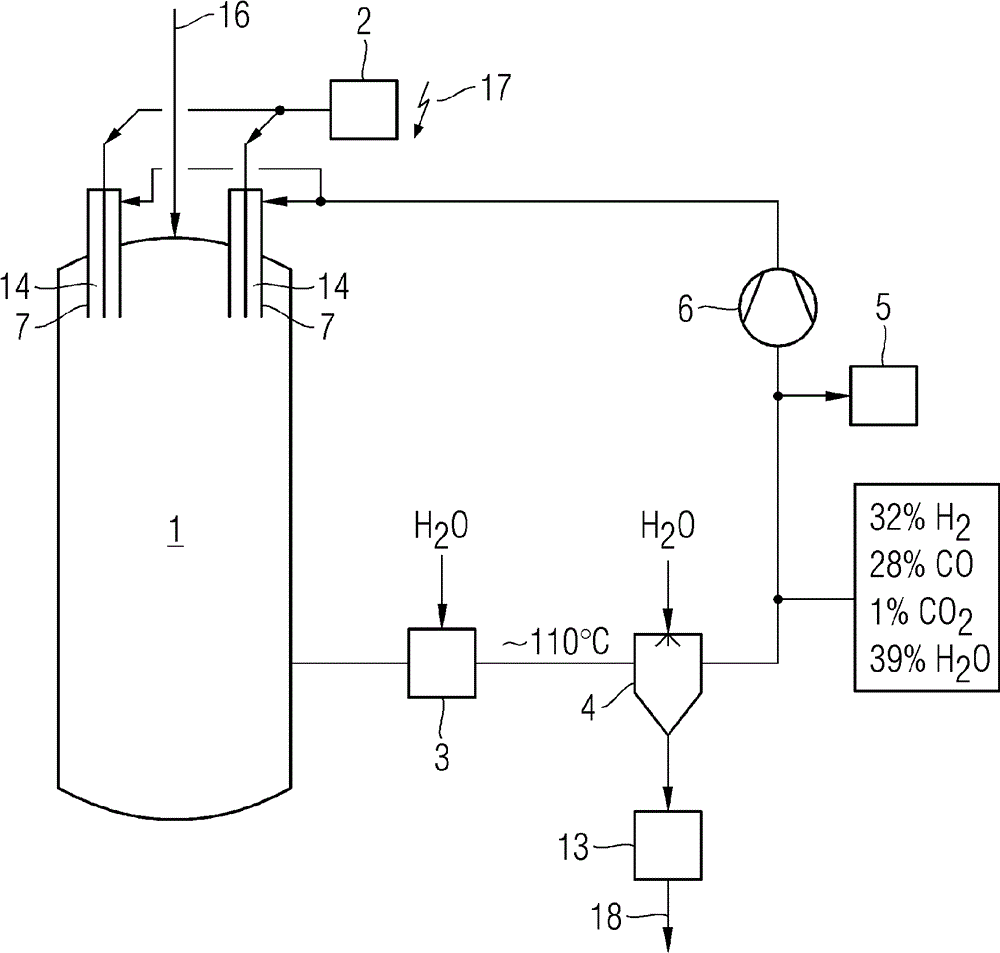

[0048] Three possible methodological implementations of the invention are enumerated.

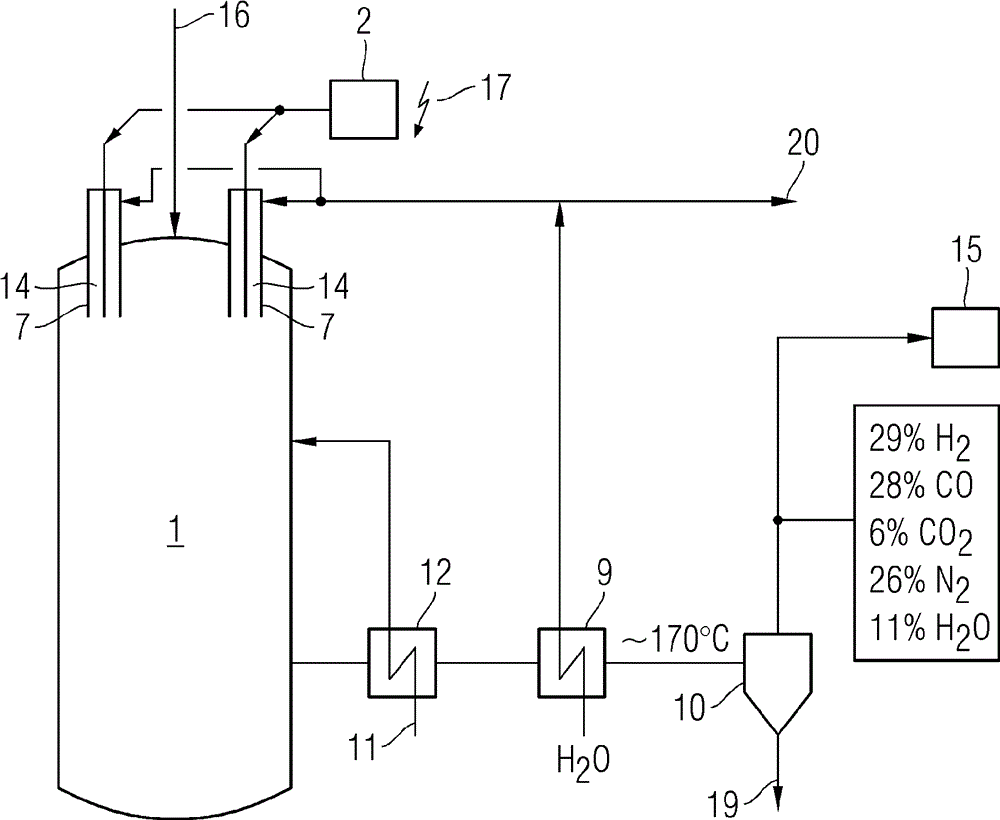

[0049] according to figure 1 Variant shown:

[0050] with the help of figure 1 The method configuration according to the invention is explained in principle.

[0051] The structure according to the invention has two main components:

[0052] - gasification reactor (1),

[0053] - Plasma generators (2).

[0054] The conversion of biomass is carried out in the gasification generator (1) by means of the plasma generator (2) and the return moist synthesis gas is fed at a temperature between 800°C and 1500°C below the ash melting temperature, The input of biomass (eg sawdust) with an average particle size of less than 2 mm is done there via a screw conveyor. High calorie syngas is formed due to the endothermic water vapor reaction of the fuel. The hot raw gas flows from the gasification reactor ( 1 ) into the quench chamber ( 3 ) and is cooled there to a temperature of approximately 110° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com