Multi-segment plasma cracking carbonaceous material reactor system with hollow cathodes

A technology of reactor system and carbonaceous materials, applied in the direction of organic chemistry, hydrocarbons, hydrocarbons, etc., can solve energy waste, temperature distribution, inability to adjust reaction temperature and/or time at will, operating temperature, gas phase reaction temperature reduction And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

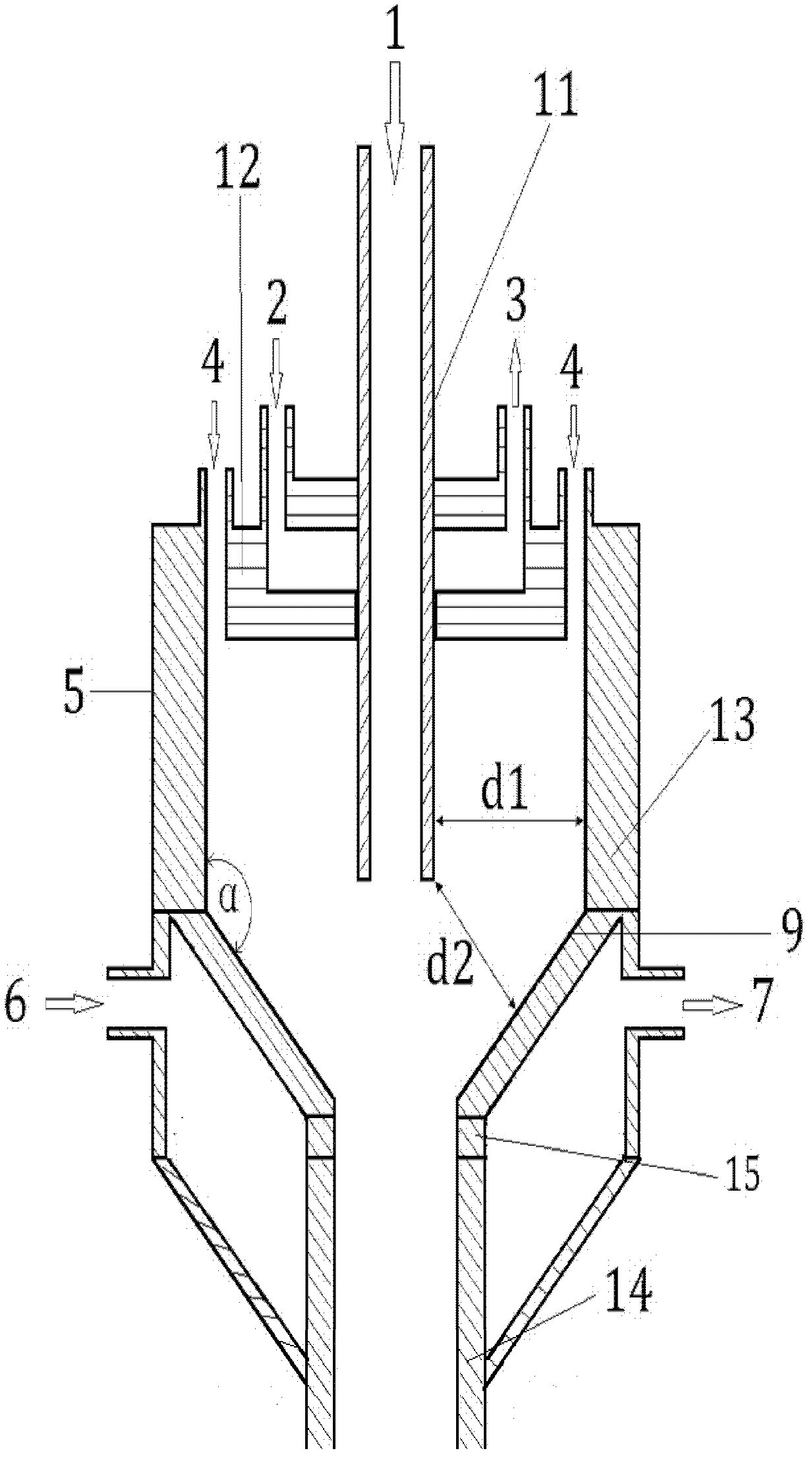

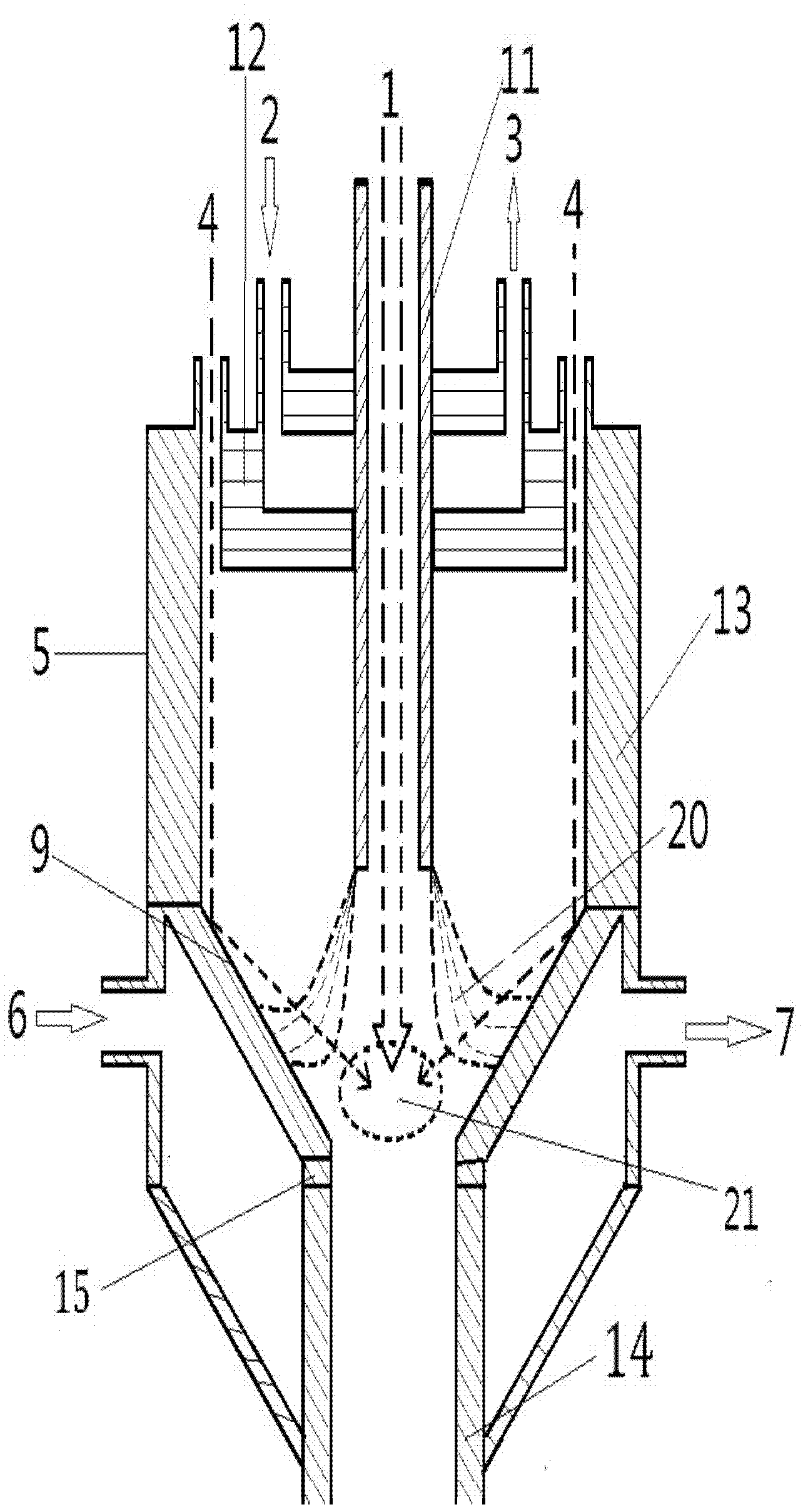

[0114] Its schematic diagram is represented in the Figure 4 A reactor system for two-stage plasma cracking of coal with a hollow cathode is used to convert coal to acetylene and other chemicals. The hollow cathode and / or anode of the plasma reactor system had an input power of 10 kW in order to form an arc that produced the plasma. Such as Figure 4 As shown, the reactor system is mainly composed of hollow cathodes 11 and 14, anodes 5 and 205, working gas 4 and 204 inlets, the first section reaction tube 14 and the second section reaction tube used as the second section hollow cathode 214. The inlet of the quenching medium 8 and the outlet of the quenched cold product 10, wherein the shortest horizontal distance d between the outer surfaces of the hollow cathodes 11 and 14 and the inner surfaces of the anodes 5 and 205 respectively 1 is 12 mm; the shortest distance d between the lower ends of the outer surfaces of the hollow cathodes 11 and 14 and the inner surfaces of the ...

Embodiment 2

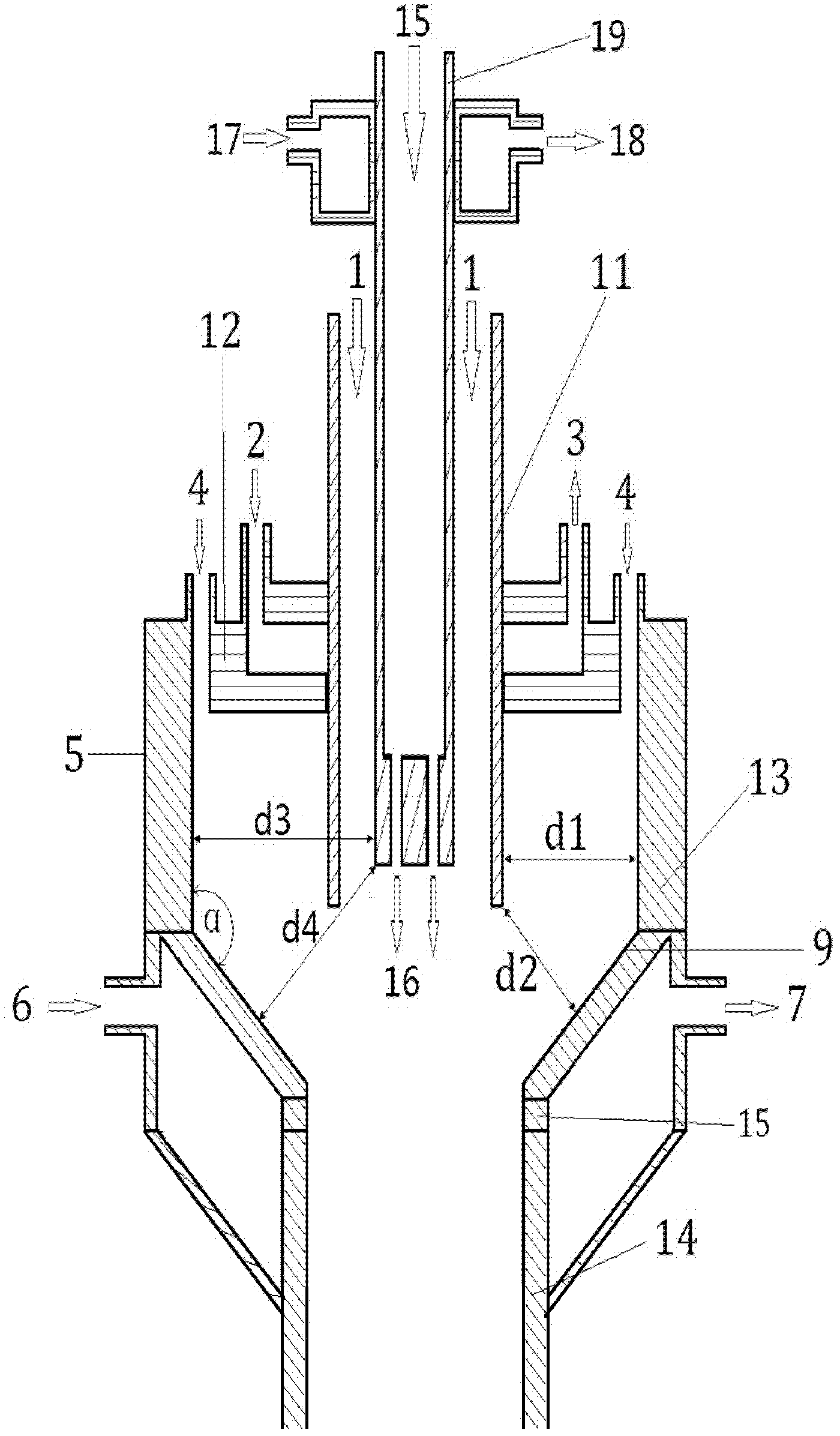

[0131] In addition to using Figure 5 The three-stage plasma reactor system shown in place of Figure 4 Outside the two-stage plasma reactor system shown, repeat the experimental procedure described in embodiment 1, wherein the input power of the first section hollow cathode and / or anode of the three-stage plasma reactor system is 10kW, the second section and a third hollow cathode and / or anode with an input power of 15 kW in order to form an arc that produces plasma. Such as Figure 5 As shown, the reactor system is mainly composed of hollow cathodes 11, 14 and 214, anodes 5, 205 and 305, inlets of working gas 4, 204 and 304, reaction tube 14 used as the second section of hollow cathodes and used as The reaction tube 214 and the third reaction tube 314, the inlet of the quenching medium 8 and the outlet of the quenching cold product 10 are composed of the reaction tube 214 and the third segment of the hollow cathode, wherein the outer surfaces of the hollow cathodes 11, 14 ...

Embodiment 3

[0132] The coal powder used in Example 3 was the same as that used in Example 1, and was ground into a fine powder with a particle size distribution (PSD) of: 80% by weight < 106 microns; and 100% by weight < 120 microns.

[0133]Operate the reactor system under the following operating conditions: the system pressure is 125kPa, the output power of the first hollow cathode 11 and / or the anode 5 is 10kW, the second and third hollow cathodes 14 and 214 and / or the second The output power of segment anodes 205 and 305 is 15kW, the flow rate of pulverized coal is 800g / h, and the flow rate of argon-hydrogen gas mixture with a volume ratio of 2:8 is 105g / h, wherein the working gases 4, 204 and The flow rate of 304 is 100g / h; as a carrier gas flow rate is 5g / h. After the argon-hydrogen gas mixture is used as the working gas 4, 204 and 304, the temperature in the area close to the arc column is about 3300K, and the pulverized coal and carrier gas feed and / or pyrolysis volatiles are obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com