Method of and Apparatus for Selective Catalytic NOx Reduction in a Power Boiler

a technology of catalytic nox and power boiler, which is applied in the direction of emission prevention, separation processes, flue gas purification components, etc., can solve the problems of permanent catalyst activity loss, reducing the effectiveness of the process, and affecting the efficiency of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

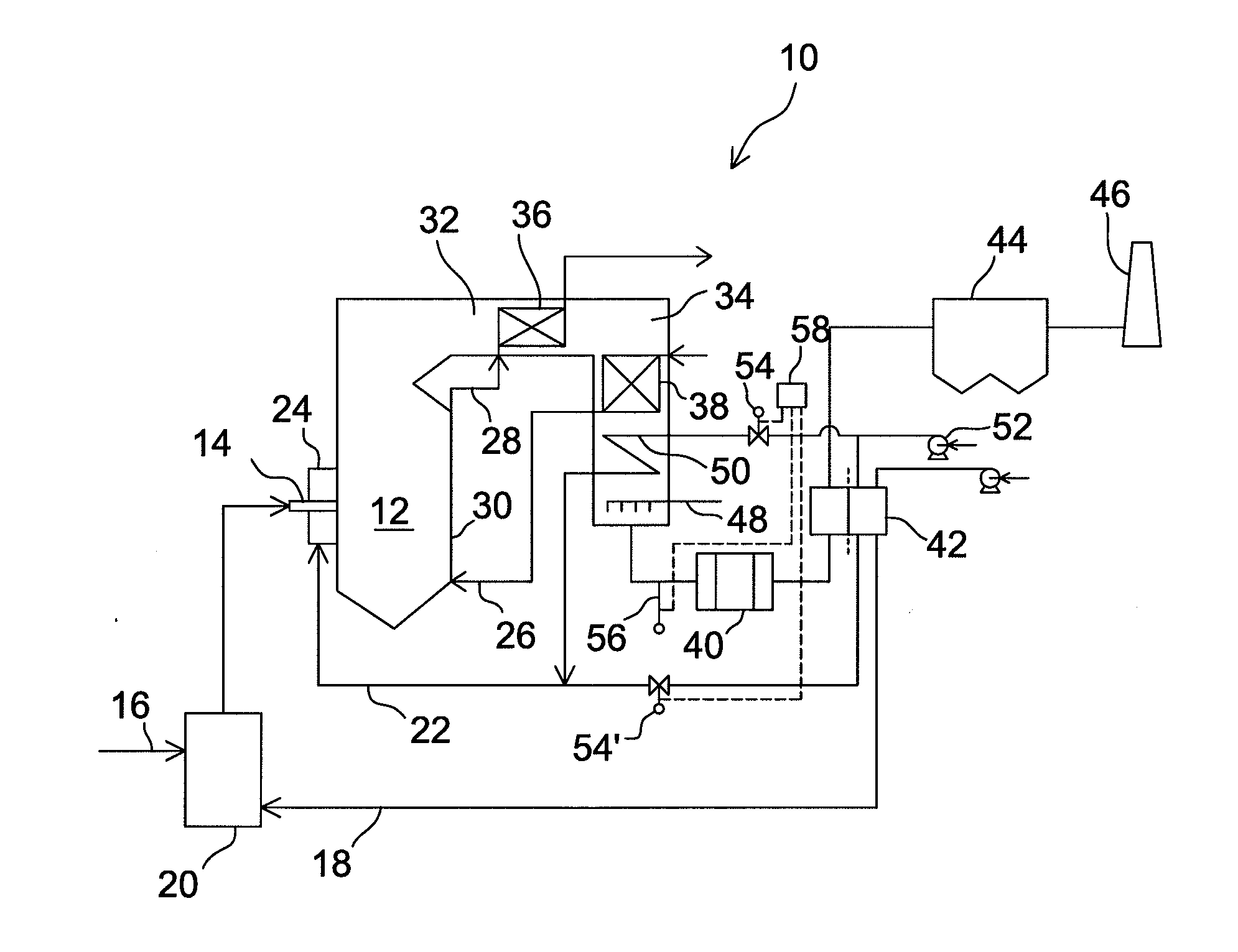

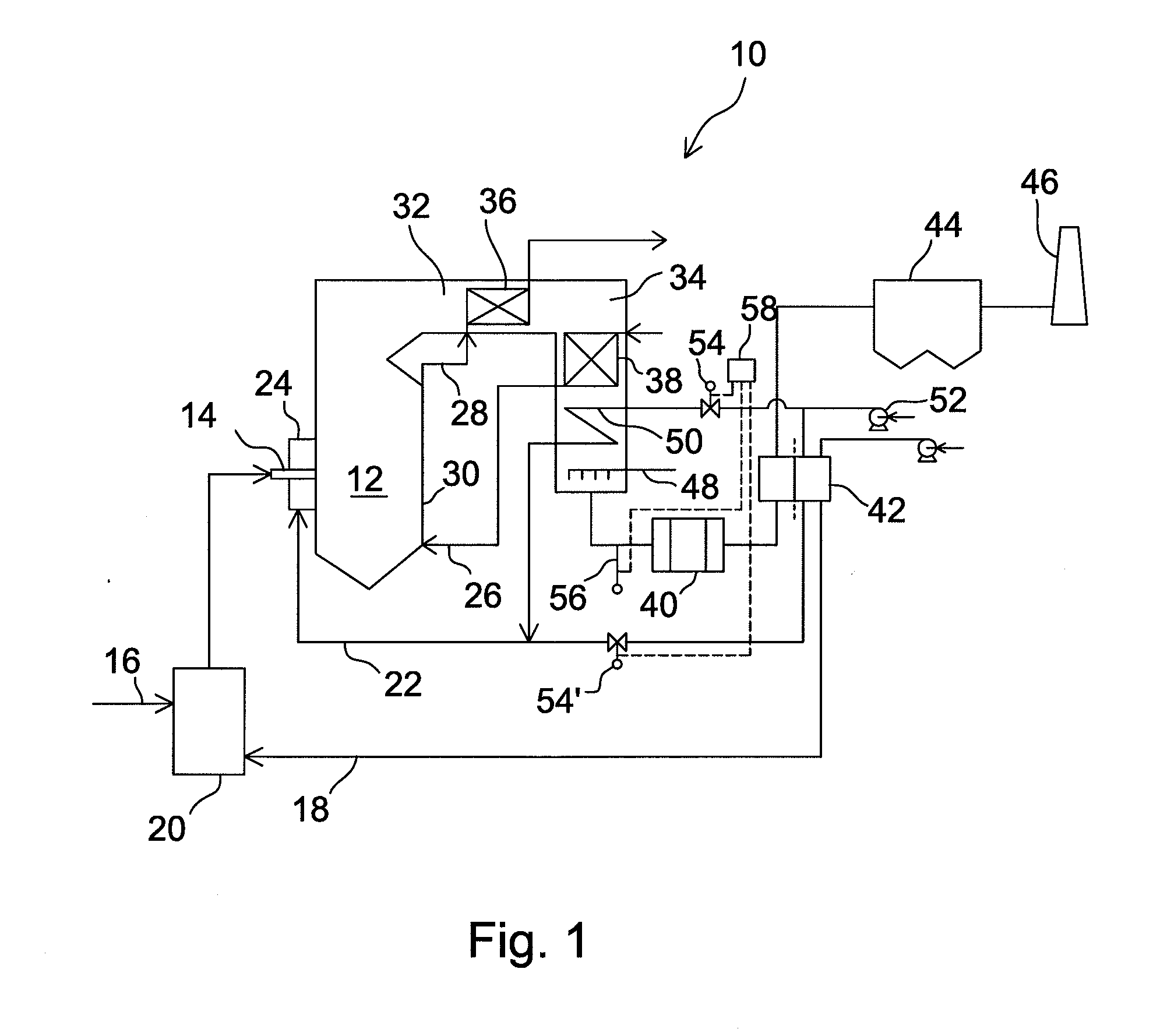

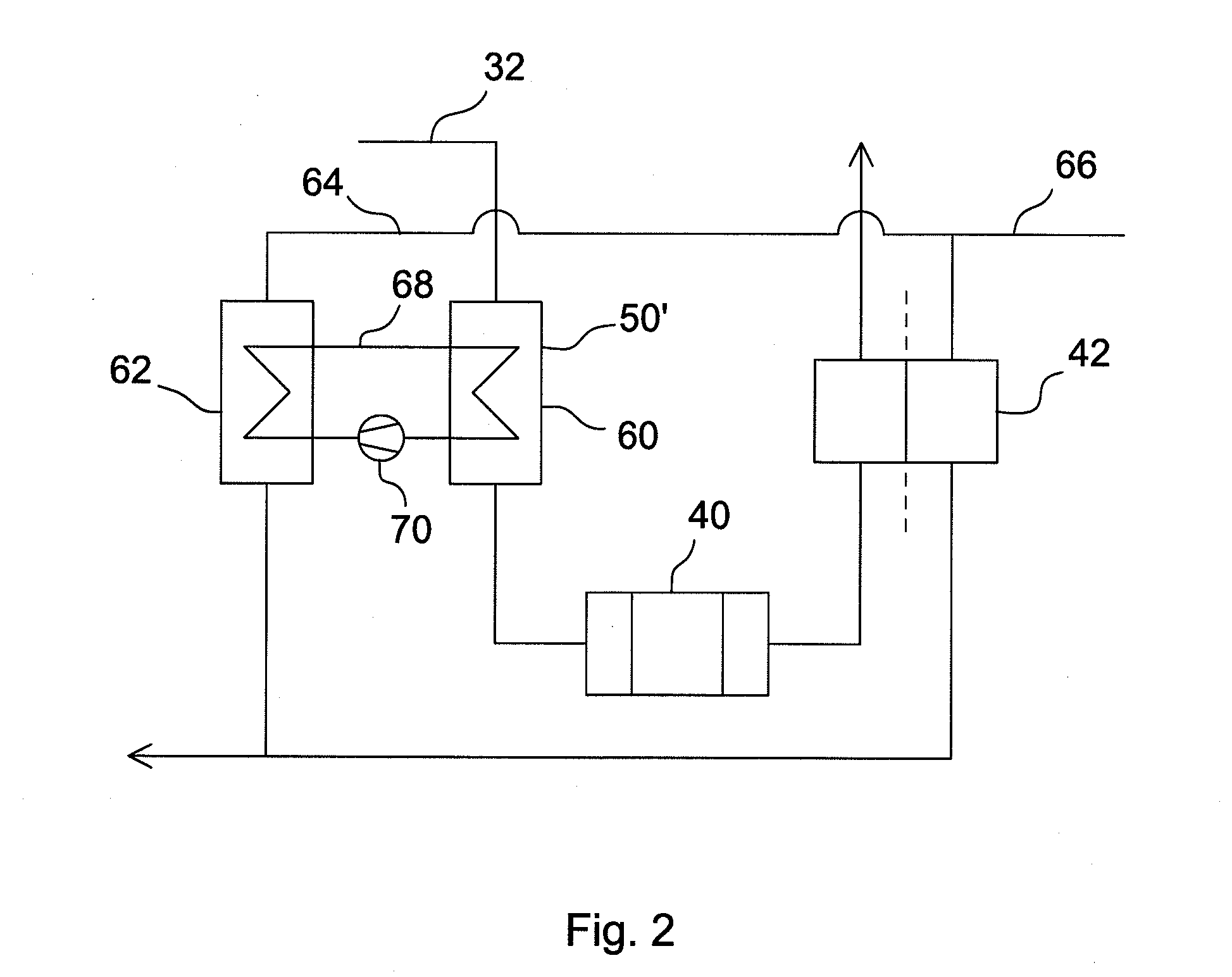

[0026]FIG. 1 is a schematic diagram of a pulverized coal combusting power boiler 10 in accordance with the present invention. The boiler comprises a furnace 12 with a burner 14 for injecting a mixture of pulverized coal 16 and primary air 18 from a coal mill 20 to the furnace. Usually, a power boiler comprises multiple burners but, for the sake of simplicity, only one burner is shown in FIG. 1. The fuel is combusted in the furnace with the primary air and secondary air 22, injected to the furnace via a windbox 24 adjacent to the burner, and hot flue gas is generated. The combustion may in practice be completed by tertiary air and / or overfire air injected in the furnace downstream of the burners, but, for the sake of simplicity, injection of tertiary air and / or overfire air is not shown in FIG. 1. Generated hot flue gases rise within the furnace, giving up a portion of their energy in evaporator surfaces 30 at the walls of the furnace to evaporate feed water 26 to steam 28. The flue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com