Method of preparing Sn-Sb alloy material for negative electrode of lithium ion cell

A technology for lithium-ion batteries and alloy materials, which is applied in the field of preparation of SnSb alloy materials, can solve the problems of harsh process conditions, high cost, and low yield, and achieve the effects of simple preparation process, low cost, and stable cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

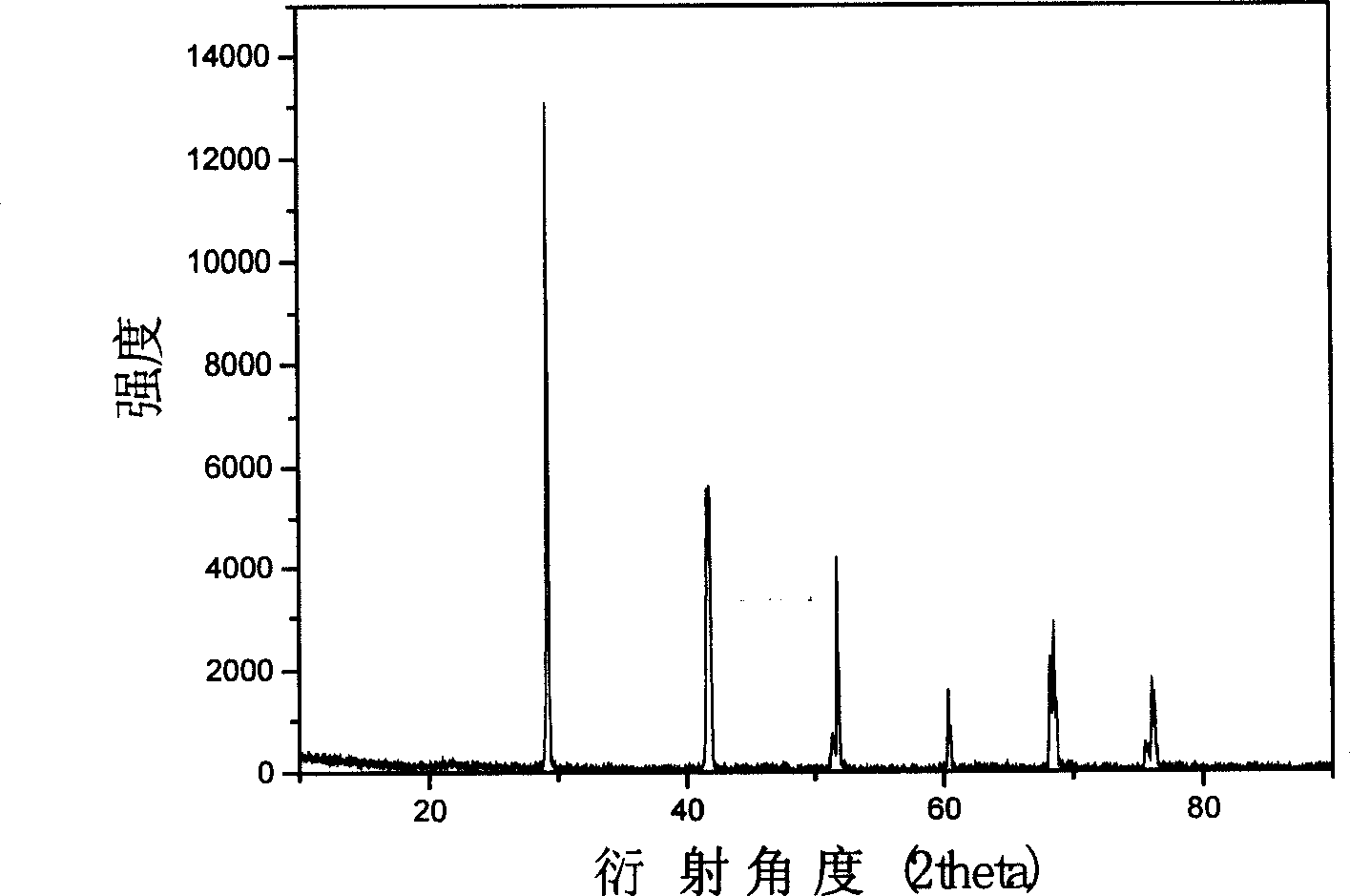

[0016] with SnO 2 (purity 99.9%), Sb 2 o 3 (99.9%) and activated carbon (purity > 99%) are the initial raw materials, and the molar ratio is 2:1:7. The heating rate was raised to 850°C, and the temperature was kept for 2 hours, then the power was turned off, and it was naturally cooled to room temperature. The XRD phase analysis results of the obtained sample show that the synthesized product is a single SnSb phase without any other impurity phases.

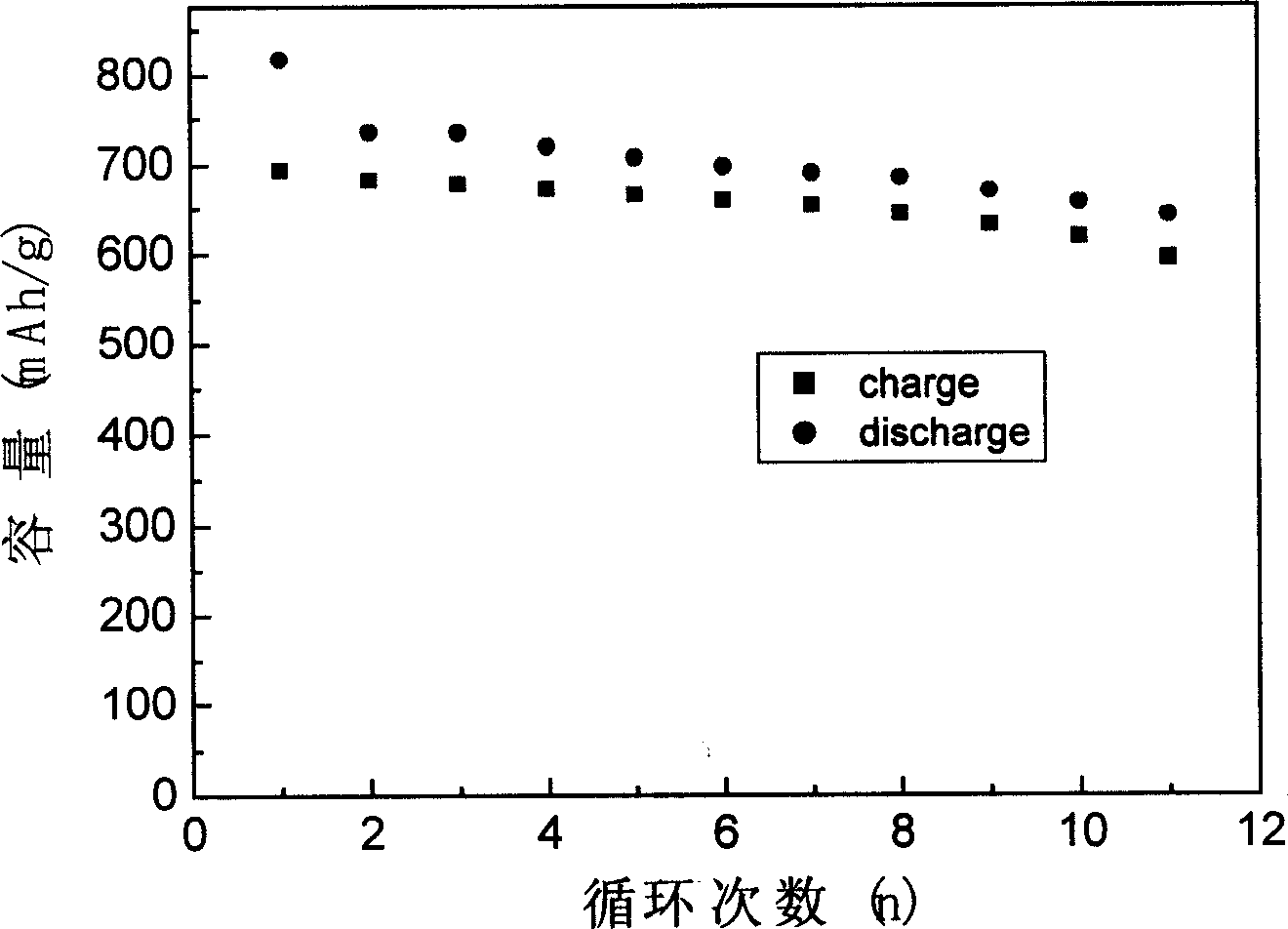

[0017] Add 10wt% conductive agent acetylene black to the synthesized material, 8wt% binder PVDF to make a slurry, evenly spread it on copper platinum, after drying, stick it into a circular pole piece, and form a test battery with metal lithium. Carry out constant current charge and discharge experiments, the charge and discharge current is 50mA / g, and the charge and discharge voltage range is controlled between 0.01-1.2V. The initial reversible capacity of the prepared SnSb negative electrode material is 700mAh / g, the specif...

Embodiment 2

[0019] with SnO 2 (purity 99.9%), Sb 2 o 3 (99.9%) and carbon powder (purity > 99%) are the initial raw materials, and the reactants are dosed in a molar ratio of 4:1:11. After the mixture is dry-mixed by ball milling, it is placed under a flowing argon atmosphere at 20 ° C. The heating rate was increased to 900°C at a rate of 1 / min, and the temperature was kept for 3 hours, then the power was turned off, and it was naturally cooled to room temperature. According to the XRD phase analysis of the obtained sample, the synthesized product is two phases of SnSb and Sn, and no other impurity phase exists.

[0020] Add 12wt% conductive agent acetylene black to the synthesized material, 8wt% binder PVDF to make a slurry, evenly spread it on copper platinum, after drying, clamp it into a circular pole piece, and form a test battery with metal lithium. Carry out constant current charge and discharge experiments, the charge and discharge current is 100mA / g, and the charge and dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com