Electrochemical lithium recovery method

An electrochemical and lithium recovery technology, applied in the field of energy materials and electrochemical lithium recovery, can solve the problems of high lithium recovery cost, surge in recovery cost, and low recovery efficiency, and achieve low cost, significant practical value, and realization of recycling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] Preparation of iron phosphate material:

[0021] 11.3g Fe(NO 3 ) 3 ·6H 2 O, 2.74gH 3 PO 4 Mix well, make 70ml aqueous solution, pour into 100ml Teflon-lined stainless steel reaction kettle, conduct hydrothermal reaction at 150°C for 24h, cool naturally to room temperature, remove all solvents to obtain precursor. Place the precursor in a drying oven at 60°C to dry to obtain the target product, iron phosphate.

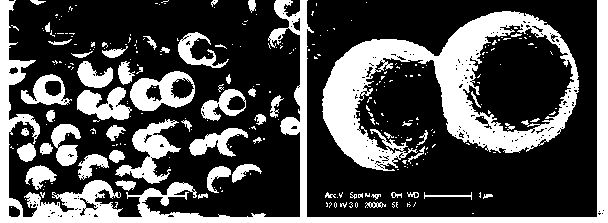

[0022] figure 1 This is the SEM picture of the obtained ferric phosphate material. It can be seen from the picture that the material synthesized by this method has a uniform and regular spherical structure with a particle size of 2-3 μm. Each microsphere is composed of nanoparticles with a diameter of about 100 nm. .

[0023] Preparation of iron phosphate electrode:

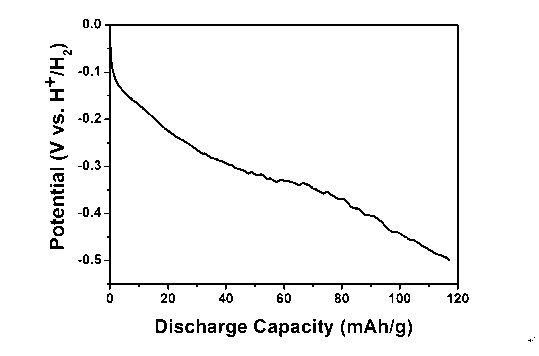

[0024] Will figure 2 The iron phosphate material and acetylene black are mixed evenly according to the mass ratio of 9:1, and 1% polytetrafluoroethylene emulsion is added to make a uniform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com