Chemical recovery method for waste polycarbonate material in ionic liquid surrounding

An ionic liquid and polycarbonate technology, which is applied in chemical instruments and methods, plastic recycling, organic carbonate preparation, etc., can solve the problems of catalysts that cannot be recycled, reaction conditions, equipment corrosive environment, consumption of large inorganic strong acids or strong bases, etc. , to achieve the effect of improving equipment corrosion and environmental pollution problems and reducing the discharge of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

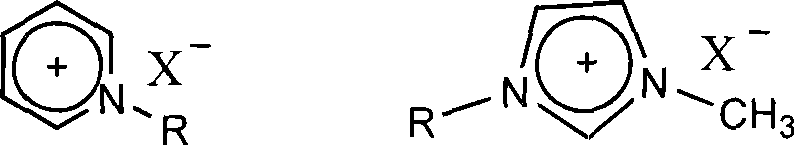

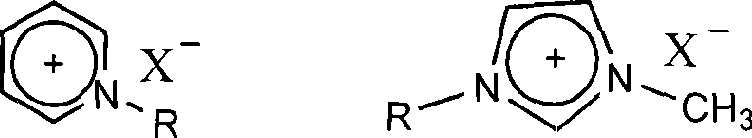

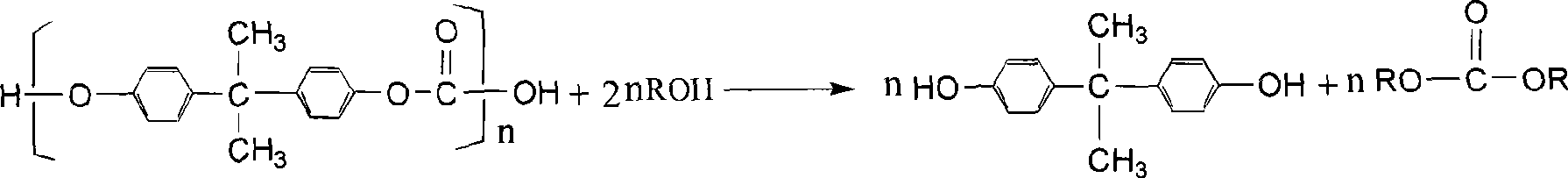

[0021] Example 1: Put 15.0 g of waste PC into an autoclave, add 15.0 g of water and 15 g of 1-allyl-3-methylimidazole chloride in sequence, and stir and react at 150°C for 2.5 hours after the addition, until After room temperature, the reaction solution was filtered, extracted, distilled, etc., and the degradation rate of PC was 100%, and 12.6 g of bisphenol A product was obtained with a yield of 93.5%.

Embodiment 2

[0022] Embodiment 2: The experimental conditions and steps are the same as in Example 1, except that 1-allyl-3-methylimidazole chloride is changed to 1-butyl-3-methylimidazole bromide, and the degradation rate of PC is 100%. Bisphenol A product 12.0g, the yield is 89.1%.

Embodiment 3

[0023] Embodiment 3: Experimental condition and step are the same as embodiment 1, just change 1-allyl-3-methylimidazole chloride into 1-ethyl-3-picoline bromide, PC degradation rate 100%, obtain Bisphenol A product 12.4g, yield is 92.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com