Method for synthesizing 4-methylmorpholine N-oxide based on O2 oxidation catalyzed by ruthenium/nitrogen-doped porous carbon

A technology of nitrogen-doped porous carbon and methyl morpholine oxide, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problem of increasing vacuum distillation and azeotropic distillation separation and purification Pressure, N-methyl morpholine oxide quality impact, N-methyl morpholine oxide low and other problems, to achieve easy separation and purification, suitable for industrial production, and improve the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

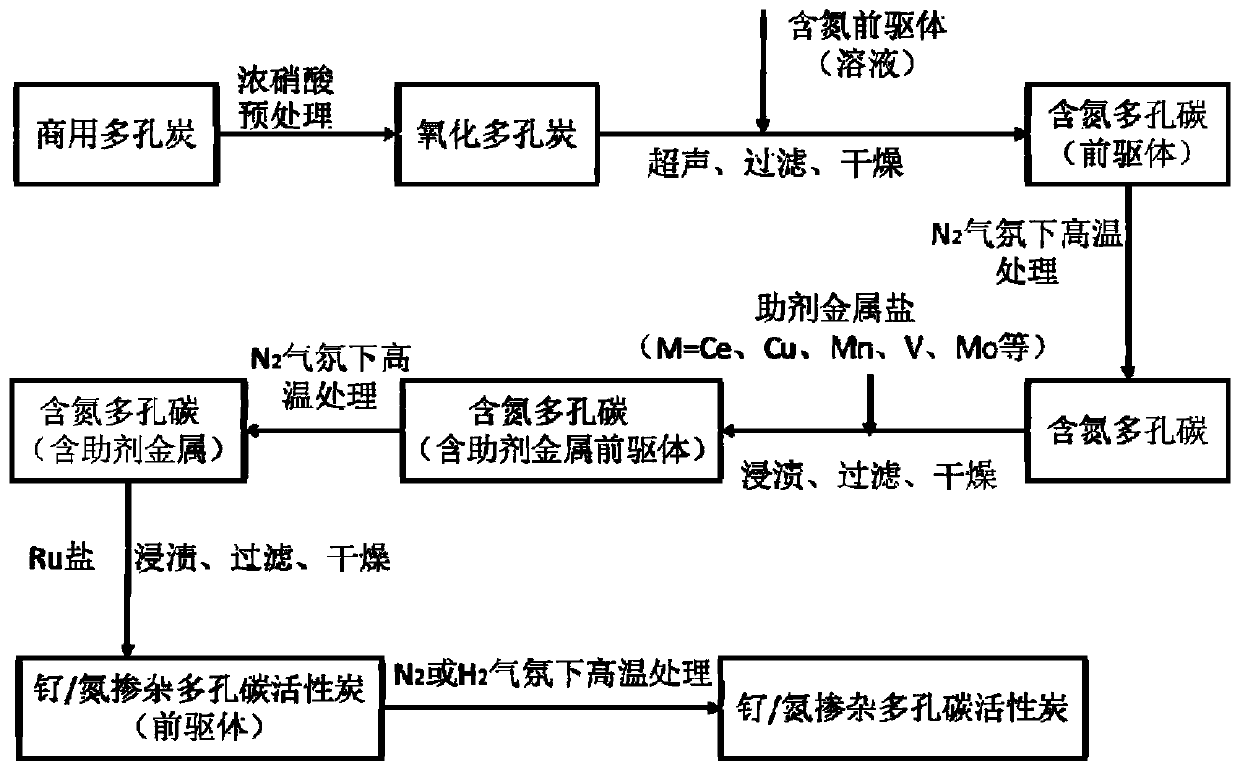

Method used

Image

Examples

Embodiment 1

[0033] A kind of catalyst based on ruthenium / nitrogen-doped porous carbon that the preferred embodiment of the present invention provides 2 The method for oxidizing and synthesizing N-methyl morpholine oxide, concrete steps are as follows:

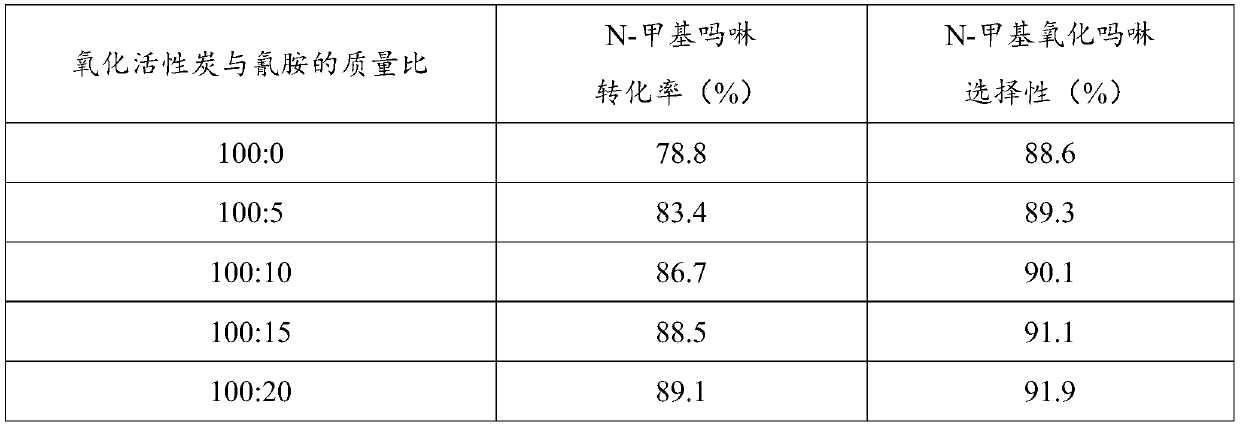

[0034] Put activated carbon into 1mol / L nitric acid solution, stir at 60°C for 3 hours, then suction filter, wash, and dry to obtain oxidized activated carbon materials; put the obtained oxidized activated carbon materials into cyanamide solution for ultrasonic treatment, and oxidize The mass ratios of activated carbon to cyanamide were 100:0, 100:5, 100:10, 100:15, and 100:20, respectively, followed by suction filtration and drying to obtain five nitrogen-doped activated carbon precursors with different nitrogen contents; The resulting five nitrogen-doped activated carbon precursors were placed at 350 °C and N 2 Treated under atmosphere to get 5 kinds of nitrogen-doped activated carbon; put 5 kinds of nitrogen-doped activated carbon into...

Embodiment 2

[0040] A kind of catalyst based on ruthenium / nitrogen-doped porous carbon that the preferred embodiment of the present invention provides 2 The method for oxidizing and synthesizing N-methyl morpholine oxide, concrete steps are as follows:

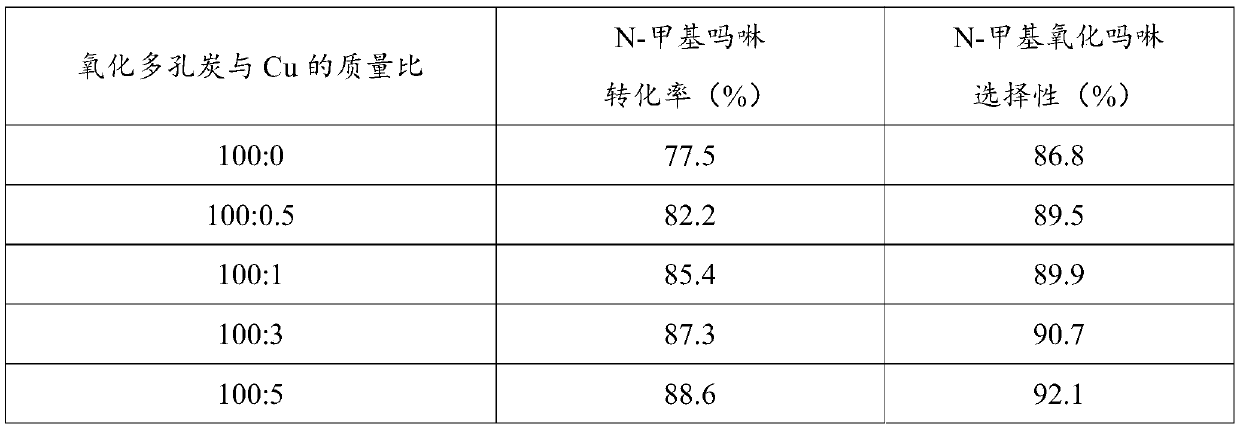

[0041] Put graphene into 1mol / L nitric acid solution, stir at 60°C for 4 hours, then suction filter, wash, and dry to obtain oxidized porous carbon material; put the obtained oxidized porous carbon material into dipolycyanamide solution for ultrasonic Treatment, wherein the mass ratio of oxidized porous carbon to dipolycyanamide is 100:5, followed by suction filtration and drying to obtain a nitrogen-doped porous carbon precursor; the resulting nitrogen-doped porous carbon precursor is placed at 550 ° C and N 2 Nitrogen-doped porous carbon was obtained by treatment under atmosphere; the nitrogen-doped porous carbon was put into different concentrations of Cu(NO 3 ) 2 Immersed in the solution for 24 hours, wherein the mass ratios of oxidi...

Embodiment 3

[0047] A kind of catalyst based on ruthenium / nitrogen-doped porous carbon that the preferred embodiment of the present invention provides 2 The method for oxidizing and synthesizing N-methyl morpholine oxide, concrete steps are as follows:

[0048] Put the carbon nanotubes into a 1mol / L nitric acid solution, stir at 60°C for 4 hours, then filter, wash, and dry to obtain an oxidized porous carbon material; put the obtained oxidized porous carbon material into a melamine solution for ultrasonic treatment, Among them, the mass ratio of oxidized porous carbon to melamine is 100:10 respectively, and then the nitrogen-doped porous carbon precursor is obtained by suction filtration and drying; the obtained nitrogen-doped porous carbon precursor is placed at 650 ° C and N 2 Treat under the atmosphere to obtain nitrogen-doped porous carbon; put the obtained nitrogen-doped porous carbon into MnCl 2 After soaking in the solution for 24 h, filter and dry in N 2 Calcination treatment at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com