Patents

Literature

44results about How to "Improve environmental pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

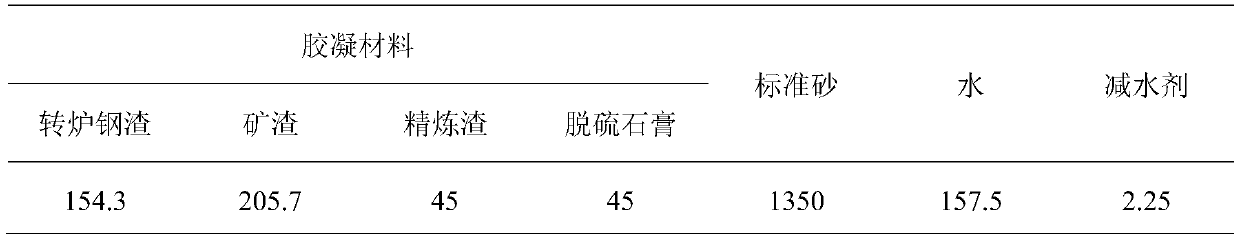

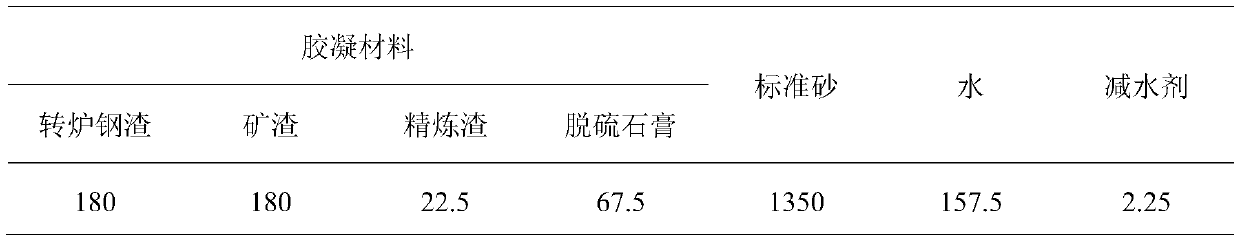

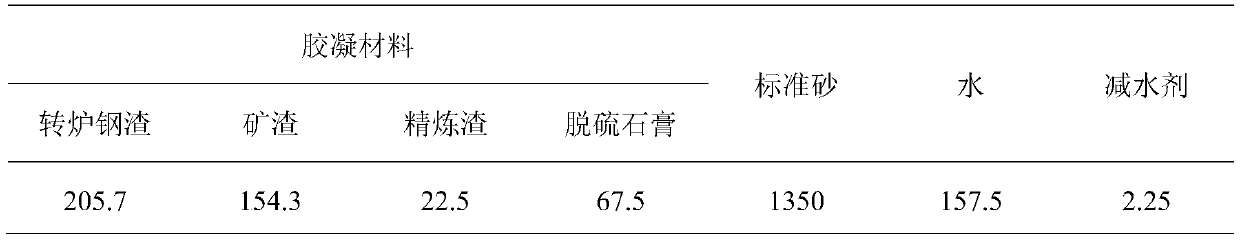

All-solid-waste cementing material containing refining slag and preparation method of all-solid-waste cementing material

The invention provides an all-solid-waste cementing material containing refining slag and a preparation method of the all-solid-waste cementing material, and belongs to the technical field of solid waste resource utilization. The cementing material is prepared from 1%-20% of the refining slag, 10%-20% of industrial by-product gypsum and the balance of converter steel slag and mineral slag, in preparation, the mineral slag and the converter steel slag are separately or mixedly grinded until the specific surface area is 400-650 m<2> / kg according to the mass ratio being 3 / 4-4 / 3, the refining slagand the industrial by-product gypsum are separately or mixedly grinded until the specific surface area is 300-600 m<2> / kg, the grinded mineral slag, the grinded refining slag, the grinded converter steel slag and the grinded industrial by-product gypsum are evenly mixed to prepare the all-solid-waste cementing material containing the refining slag. According to the all-solid-waste cementing material containing the refining slag and the preparation method of the all-solid-waste cementing material, the application efficiency of metallurgy residue solid waste is effectively improved, slag hydration in later stage is enhanced, and the concrete cost is obviously lowered; and meanwhile later-stage strength improving of the cementing material is promoted through the synergistic effect of the converter steel slag and the mineral slag, the initial setting time and the final setting time of steel-slag concrete are effectively shortened through the refining slag, and the application range of thecementing material containing the converter steel slag is widened.

Owner:QIANAN WEISHENG SOLID WASTE ENVIRONMENTAL PROTECTION IND CO LTD +1

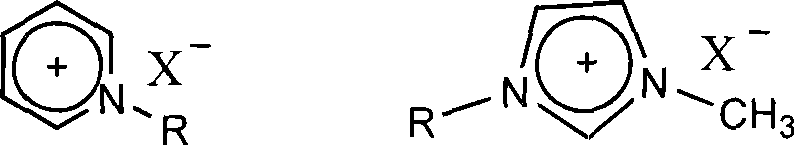

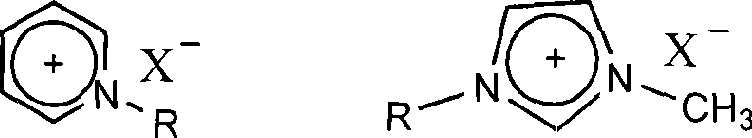

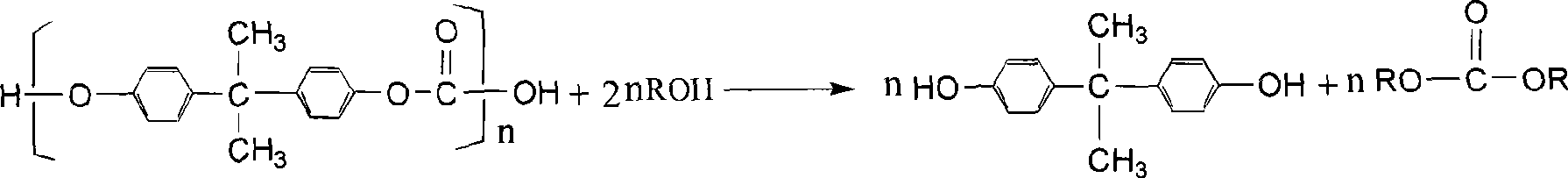

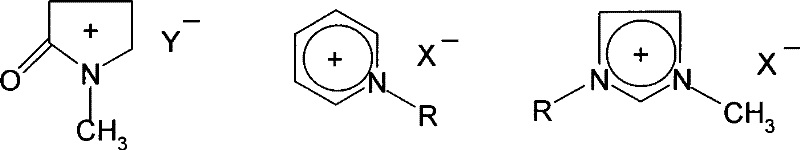

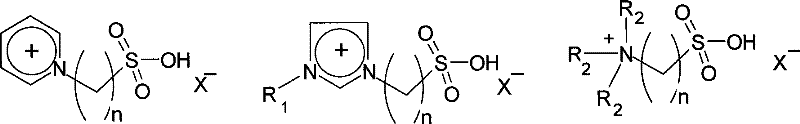

Chemical recovery method for waste polycarbonate material in ionic liquid surrounding

InactiveCN101429100ARelaxed reaction conditionsReduce the discharge of three wastesOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSolubilityHigh concentration

The invention relates to a novel method for generating bisphenol A and dialkyl carbonate by chemical degradation of waste polycarbonate (PC) to realize chemical recycling of the bisphenol A and the dialkyl carbonate. The method is characterized in that reusable ionic liquid such as chloridized 1-allyl-3-methylimidazole and bromized 1-butyl-3-methylimidazole is taken as a reaction medium and catalyst, and subjected to hydrolysis reaction or alcoholysis reaction at a temperature of between 60 and 170 DEG C; after reaction is over, bisphenol A products are obtained after extraction, distillation and other operations (as for alcoholysis reaction, the dialkyl carbonate is obtained simultaneously); reclaimed ionic liquid is directly reused without any treatment; and the yield of the bisphenol A is more than 93 percent. Compared with the prior art, the method has the characteristics that: firstly, the method overcomes the defects in the prior art that high-concentration inorganic strong acid / strong alkali is applied and can not be recycled; and secondly, due to adoption of the ionic liquid which has certain solubility on the PC as the reaction medium and the catalyst, the method relieves the reaction conditions on one hand and can realize reutilization of the ionic liquid on the other hand, and obviously solves the problems of equipment corrosion and environmental pollution.

Owner:QINGDAO UNIV OF SCI & TECH

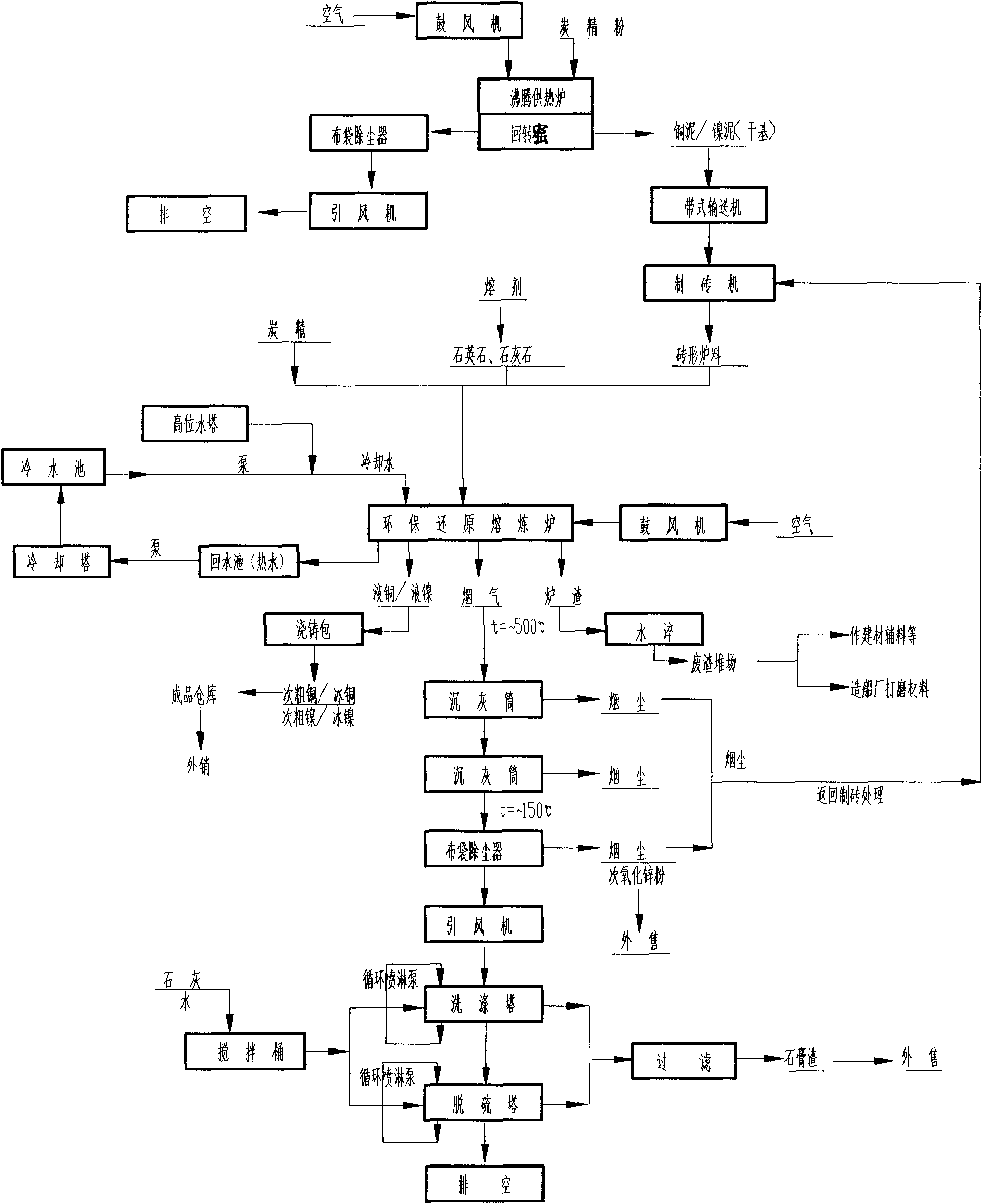

Process method for treating solid waste containing copper and nickel

InactiveCN101597691AImprove environmental pollutionReduce dust and other pollutionProcess efficiency improvementLiquid copperOxide

The invention discloses a process method for treating solid waste containing copper and nickel, which is characterized in that: the solid waste is pretreated by a boiling rotary drying method to obtain a charging material; the charging material is subjected to reduction smelting by a reduction method; the reduction smelting comprises the following steps: adding carbon fuel into a reduction smelting furnace, melting the charging material by heat generated by combustion of the carbon fuel, and simultaneously forming carbon monoxide reduction atmosphere to reduce metallic oxides of copper or nickel; liquid copper or liquid nickel obtained by reduction melting passes through a casting ladle, and crude copper, crude nickel, copper matte or nickel matte is obtained; slag obtained by the reduction melting is subjected to water quenching treatment and then is recycled; and flue gas obtained by the reduction melting is recycled by an off-gas treating system. The process method changes the prior small cupola smelting furnace production technology which is out-dated for treating the solid waste, adopts harmless treatment technology, and greatly improves the problem of environmental pollution caused by small cupola furnace production; and the whole technological process is environment-friendly, and has low consumption and high recovery rate of the copper, the nickel and the like.

Owner:杭州富阳申能固废环保再生有限公司

All-solid-waste ecological cementing material

InactiveCN110041015AIncrease alkali concentrationFacilitate dissociationMetallurgical slagDefoaming Agents

The invention provides an all-solid-waste ecological cementing material and relates to the field of building materials. The all-solid-waste ecological cementing material is prepared from raw materialsin parts by mass as follows: 100 parts of solid waste, 1-5 parts of a chemical activator, 0.5-1 part of a water reducing agent and 0.5-1 part of a defoaming agent, wherein the solid waste is preparedfrom 50%-70% by mass of ferro-nickel residues, 10%-30% of slag, 5%-10% of fly ash, 0-10% of gypsum and 5%-10% of steel slag. According to the all-solid-waste ecological cementing material, the ferro-nickel residues, the slag and the steel slag are taken as raw materials, utilized as a clinker source of the cementing material and supplemented with industrial solid waste such as industrial byproducts gypsum and fly ash, and one low-hydration-heat ecological cementing material capable of partially replacing Portland cement is prepared by mechanical excitation and chemical excitation. Efficient recycling of the industrial metallurgical slag such as the ferro-nickel residues, the slag and the steel slag is realized, and usage amount of Portland cement clinker is effectively reduced. Compared with the Portland cement, the all-solid-waste ecological cementing material has the characteristics of low hydration heat and good sulfate corrosion resistance.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD

Method for preparing multiphase ozonation solid catalyst for water treatment by using rare earth molecular sieve waste residues

InactiveCN103962149AImprove environmental pollutionSave land resourcesMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationActive agentMolecular sieve

The invention discloses a method for preparing a multiphase ozonation solid catalyst for water treatment by using rare earth molecular sieve waste residues. According to the method, metallic oxide and rare-earth oxide in the waste residues are sufficiently utilized as active agents for ozonation. The solid catalyst is suitable for various wastewater treatment, purposes of treating waste by waste and turning harm into good are achieved, the defects that the environment is polluted and the land is occupied by the waste residues are overcome, and remarkable economic benefits and environmental benefits are provided.

Owner:张振慧 +2

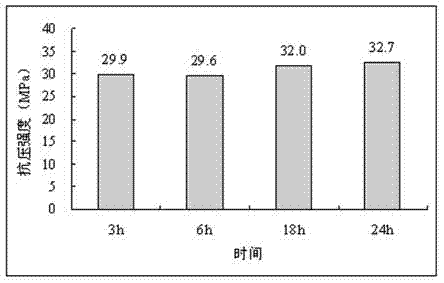

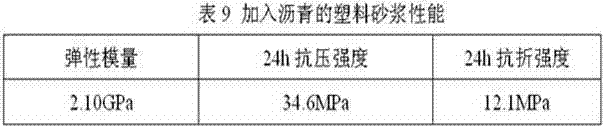

Method for recycling PET (polyethylene terephthalate) plastics, early-strength plastic mortar and method for preparing mortar

InactiveCN102311244AWide range of applicationsImprove environmental pollutionPolyethylene terephthalatePolyethylene terephthalate glycol

The invention discloses a method for recycling PET (polyethylene terephthalate) plastics. In the recycling method, waste PET plastics are cut into pieces to be used as a binder of mortar. The invention also discloses an early-strength plastic mortar prepared from PET and a preparation method thereof. Sand and mineral powder are used as aggregates of the mortar, and waste PET plastics are taken as a binder, and the mass ratio of the aggregates to the binder is (2.8-3.2):1. According to the invention, a new approach is provided for recycling the waste PET plastics, and the environmental pollution caused by PET plastic bottles can be improved effectively. The mortar made of waste PET plastics is low in cost and simple in manufacturing process, the properties such as compression resistance and flexural resistance and the like of the mortar meet requirements, and the strength of the mortar is increased quickly, therefore, the mortar can be used as a quick repairing material for roads.

Owner:SHANDONG UNIV

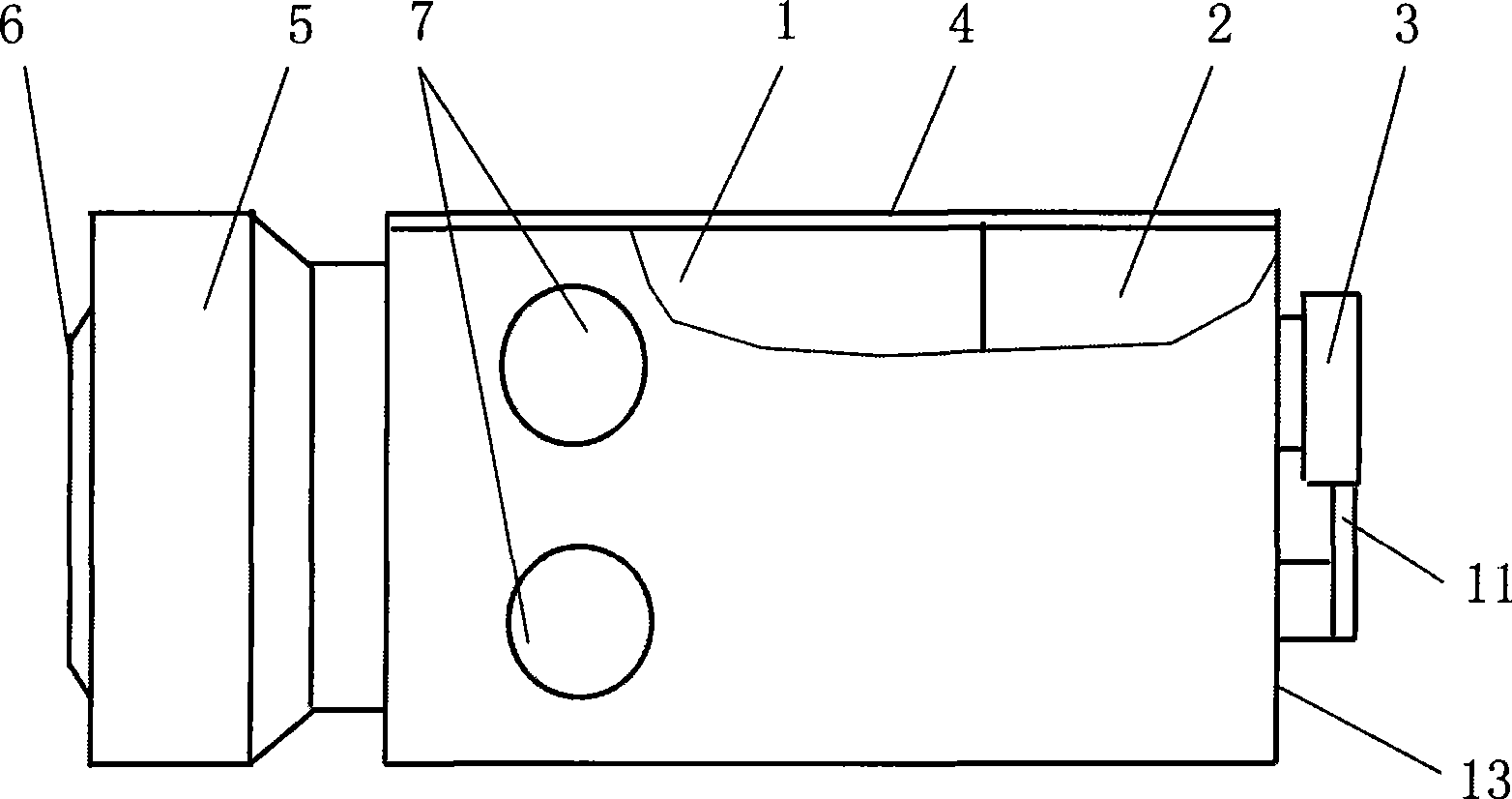

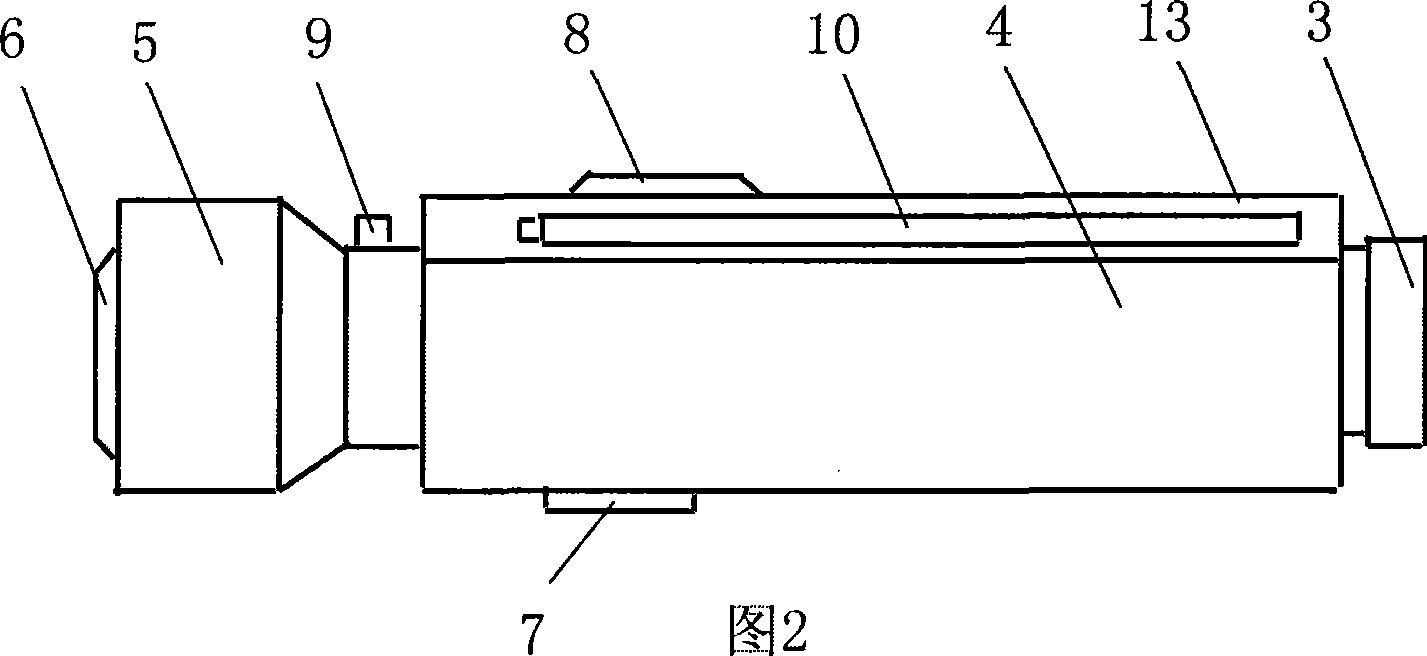

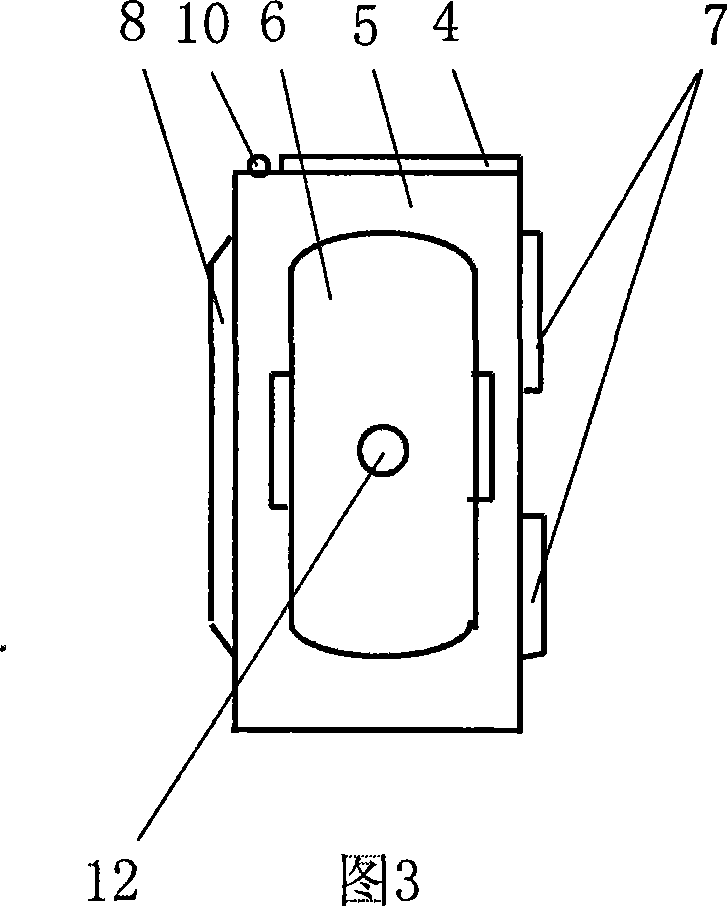

Multifunctional lighting lamps

InactiveCN101435535AConvenient travelImprove environmental pollutionLighting elementsWith electric batteriesElectrical batteryMicro power generator

The invention relates to a lighting tool, in particular to a multi-functional lighting tool which doubles as a radio and is suitable to be used during field operation, travel and emergency call. The multi-functional lighting tool comprises a shell, a microgenerator and a control circuit thereof, batteries and a solar panel, wherein a sound receiving part and a power generation part are arranged in the shell of the multi-functional lighting tool; one end of the power generation part is connected with a charging handle arranged outside the shell; a lighting part is arranged outside the shell far away from one end of the charging handle; and the outer surface of the shell is provided with the solar panel, and the outer surface of the shell is also movably locked with an emergency call lampshade. The multi-functional lighting tool also adopts a structure which doubles as the radio, provides electrical power for lighting and sound receiving through various forms, brings great convenience to work and trips of people, also greatly improves the problem of environmental pollution caused by frequent replacement of the batteries, and also saves the cost for the frequent replacement of the batteries simultaneously. The multi-functional lighting tool has the advantages of simple, reasonable, safe and reliable structure and low cost, and is the multi-functional lighting tool integrated with various functions and environmental protection.

Owner:孙偲豪

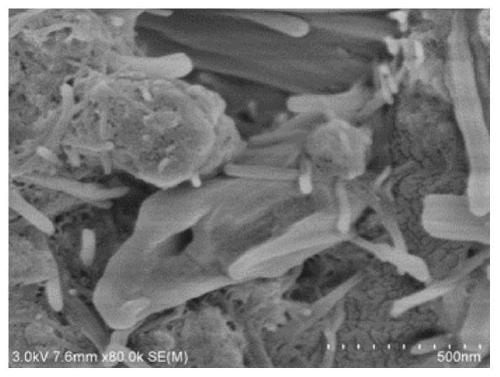

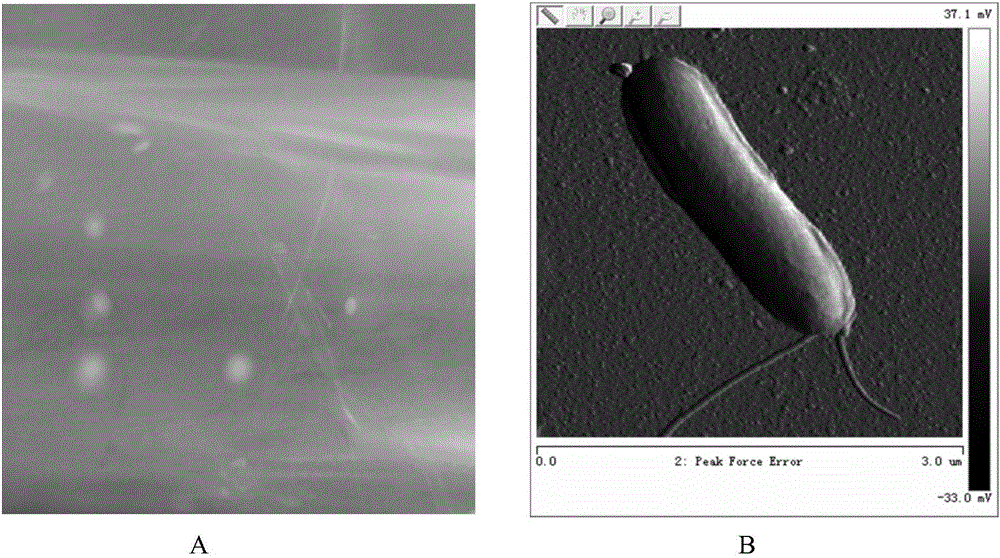

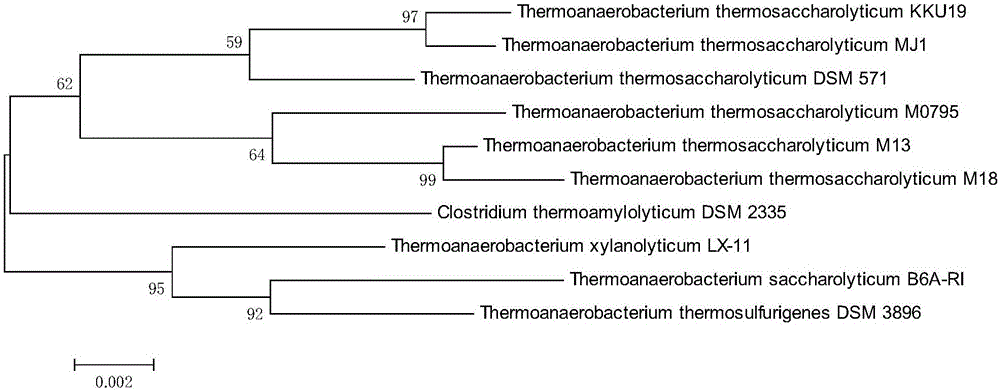

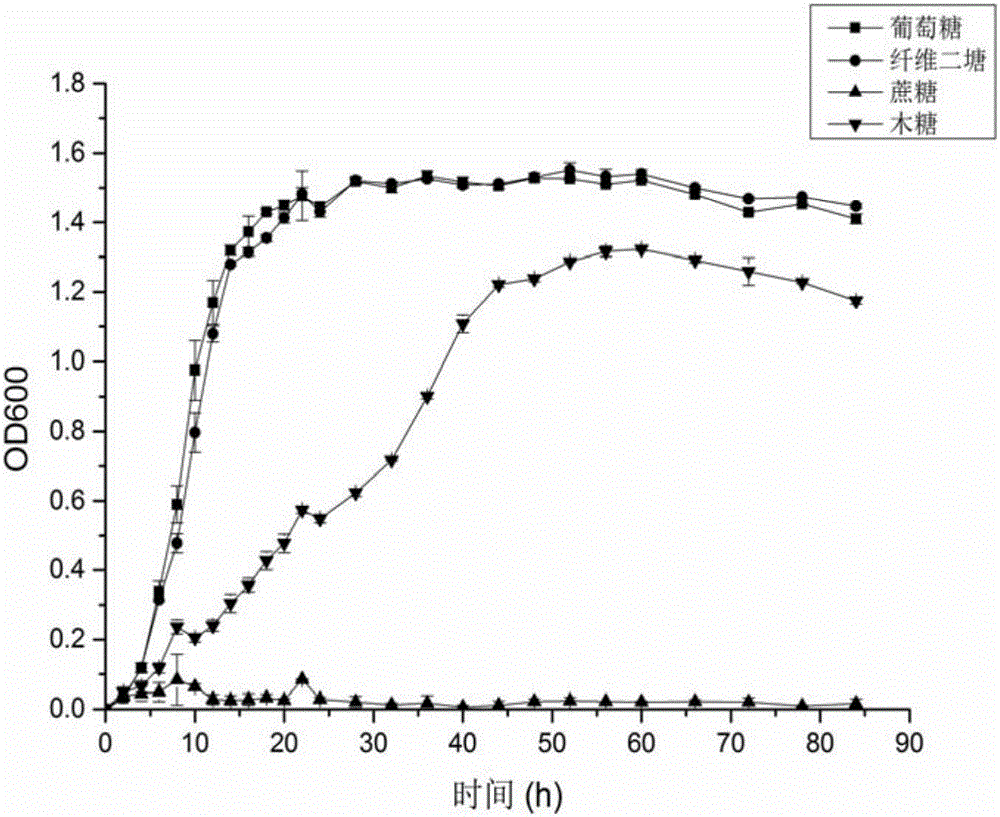

Thermoanaerobacterium thermosaccharolyticum and application thereof to biological hydrogen production

ActiveCN106635887AIncrease productivityBroad prospects for application and promotionBacteriaMicroorganism based processesHydrogen yieldChemistry

The invention discloses thermoanaerobacterium thermosaccharolyticum and application thereof to biological hydrogen production. The name of the thermoanaerobacterium thermosaccharolyticum is thermoanaerobacterium thermosaccharolyticum MJI, and the thermoanaerobacterium thermosaccharolyticum with the preservation number of CGMCC No:60096 is preserved at the Microbial Strain Collection Center of Guangdong, Guangdong Institute of Microbiology on Floor 5, No. 59, No. 100 Courtyard, Xianlie Middle Road, Guangzhou City, Guangdong Province, the People's Republic of China on Oct. 31, 2016. The thermoanaerobacterium thermosaccharolyticum has the following advantages that pentose and hexose can be directly utilized, xylose in acid pretreatment liquid can be directly utilized, and an additional acid pretreatment liquid detoxification process is not required; the hydrogen yield is higher; the hydrogen production efficiency is higher. Therefore, the thermoanaerobacterium thermosaccharolyticum has wide application and popularization prospect in the biological hydrogen production.

Owner:SOUTH CHINA UNIV OF TECH

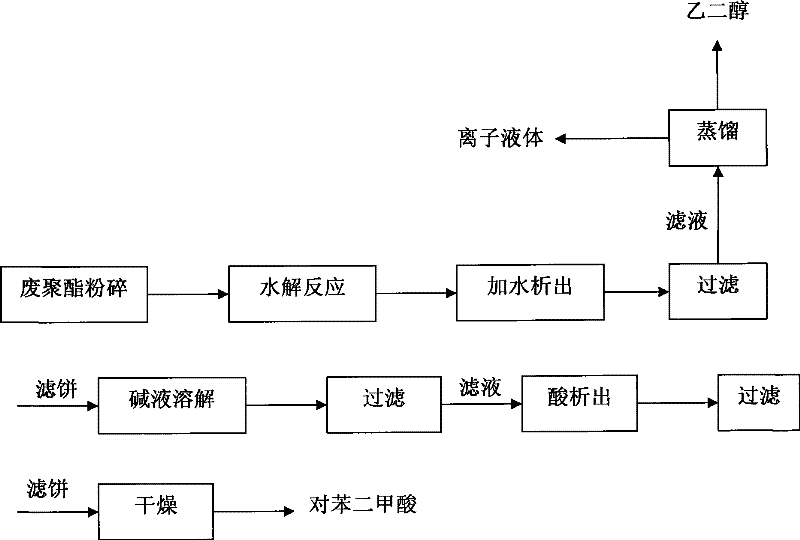

Waste polyester material recovery method with ion liquid as reaction medium and catalyst

InactiveCN101407445BAchieve reuseImprove pollutionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSolubilityHigh concentration

Owner:QINGDAO UNIV OF SCI & TECH

Preparation method of halogen-free low-smoke flame-retardant crosslinked polyethylene composite material

ActiveCN104017264AImprove environmental pollutionExcellent mechanical properties and flame retardant propertiesCross-linked polyethyleneChemistry

The invention relates to a preparation method of a halogen-free low-smoke flame-retardant crosslinked polyethylene composite material. The preparation method comprises the following steps: by taking low-density polyethylene as a base material, a mixture compounded by potato residue activated carbon sludge, dimethyl methylphosphorate and polygorskite clay as a compound flame retardant, vinyl tri-methoxysilane as a crosslinking agent, dicumyl peroxide as an antioxidant, and dibutyltin dilaurate as a lubricant, stirring and kneading at high speed, and extruding through a double-screw extruder to obtain composite granules; then conducting crosslinking to the composite granules in water, and airing to obtain the composite material product. Through determination, the limit oxygen index of the prepared composite material is 29-38, the density of smoke is 75-102 under smokeless conditions, the tensile strength is more than 14.2MPa, the elongation at break is more than 688%, and all performances of the material can meet the regulation of industry standard YD / T1113-2001 on the mechanical properties of cable and cord sheathing materials.

Owner:NORTHWEST NORMAL UNIVERSITY

High-efficiency feed additive

InactiveCN101658240AImprove nutritional qualityIncrease profitAnimal feeding stuffAccessory food factorsWater contentAnimal feed

The invention relates to a high-efficiency feed additive. Diatomite is taken as a raw material, purified, dried and ground into powder of which the particle size range is between 26 and 590 micrometers, wherein the SiO2 content is 30 to 85 percent; the water content is 0.5 to 10 percent; and the pH value is about 7. The high-efficiency feed additive is added to animal feeds, the general consumption is 0.1 to 8 percent of the added total feeding dose, and the addition volume of the high-efficiency feed additive to the feeds is adjusted according to the variety of the fed animals. The high-efficiency feed additive has the characteristics of rich resource, low cost and simple manufacturing, can improve nutritional quality of the feeds, improve the feed utilization rate and nutrient digestionrate, and is particularly suitable for adding to energy feeds to replace a main material corn so as to save feed grains and reduce production cost.

Owner:王志晓

Environment-conservative fuel economizer

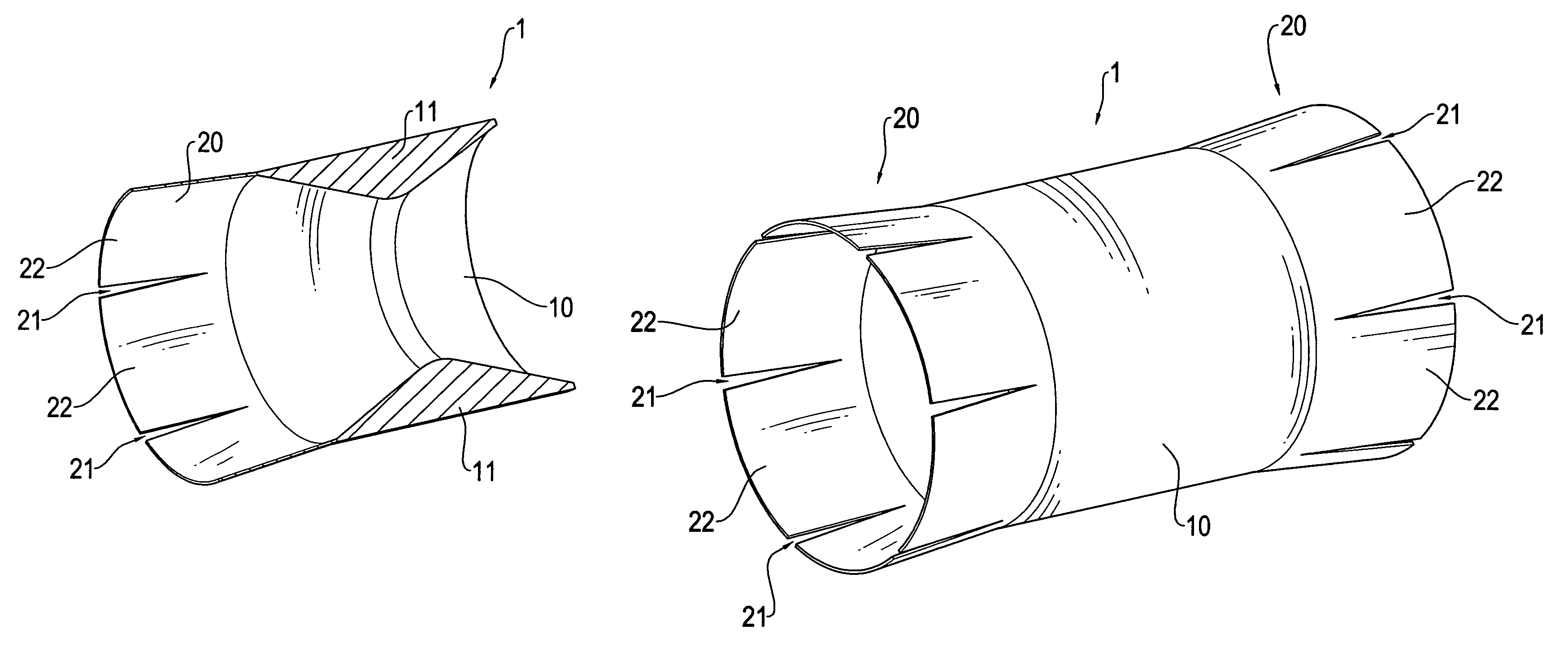

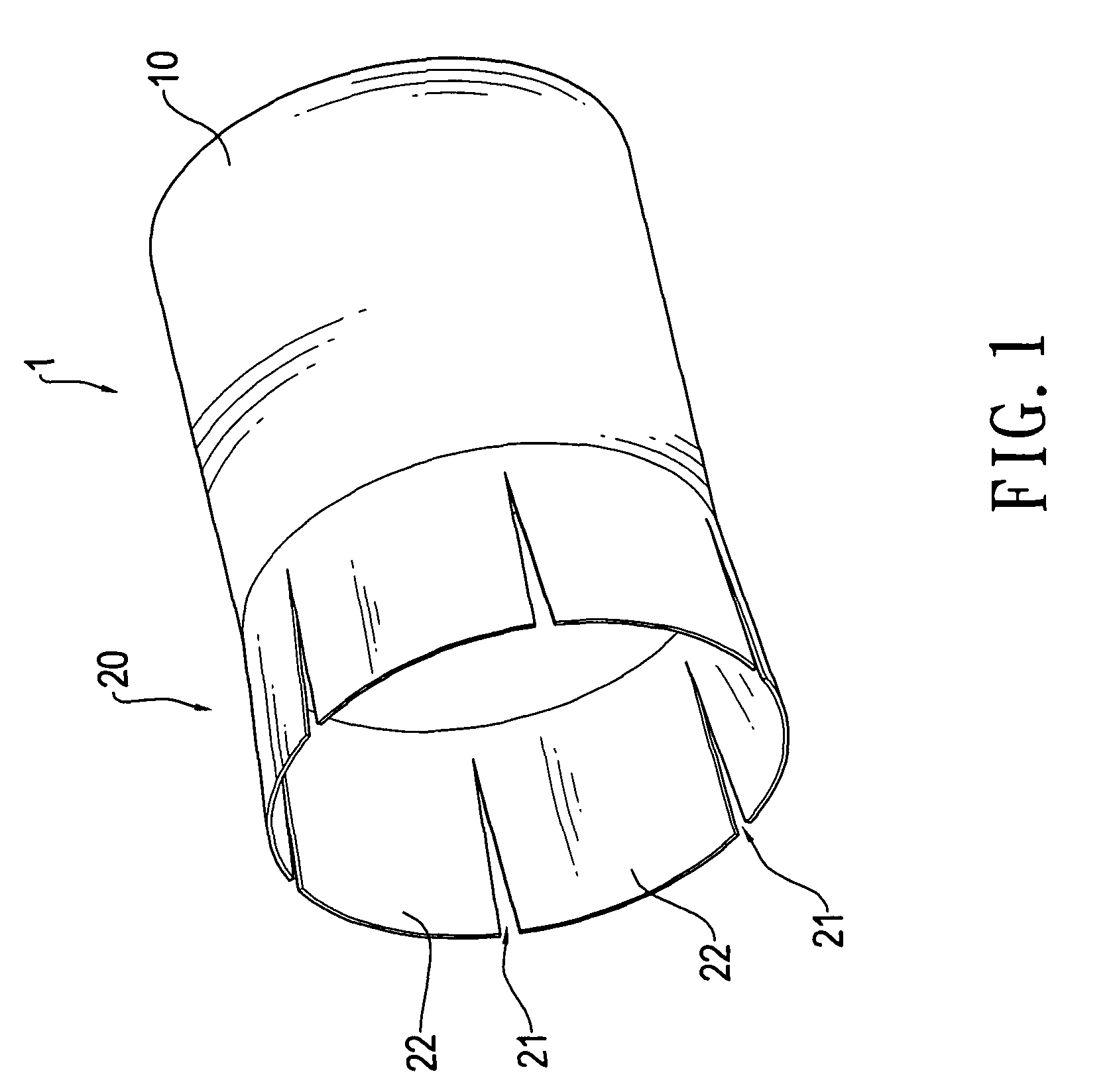

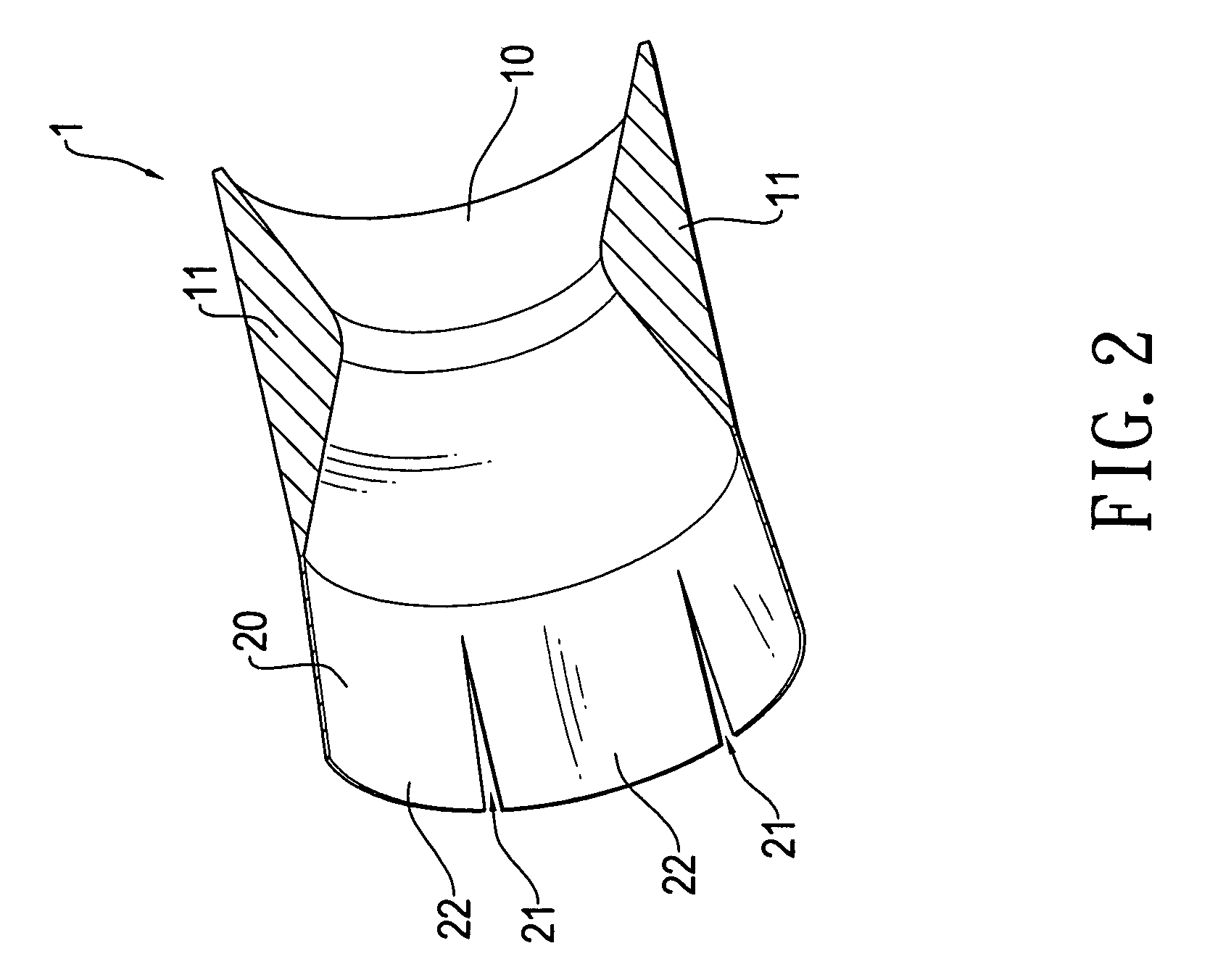

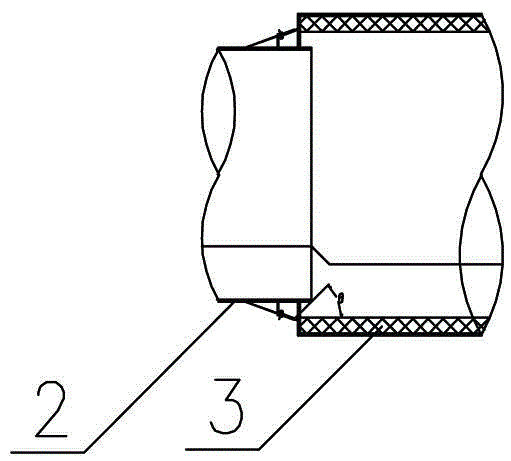

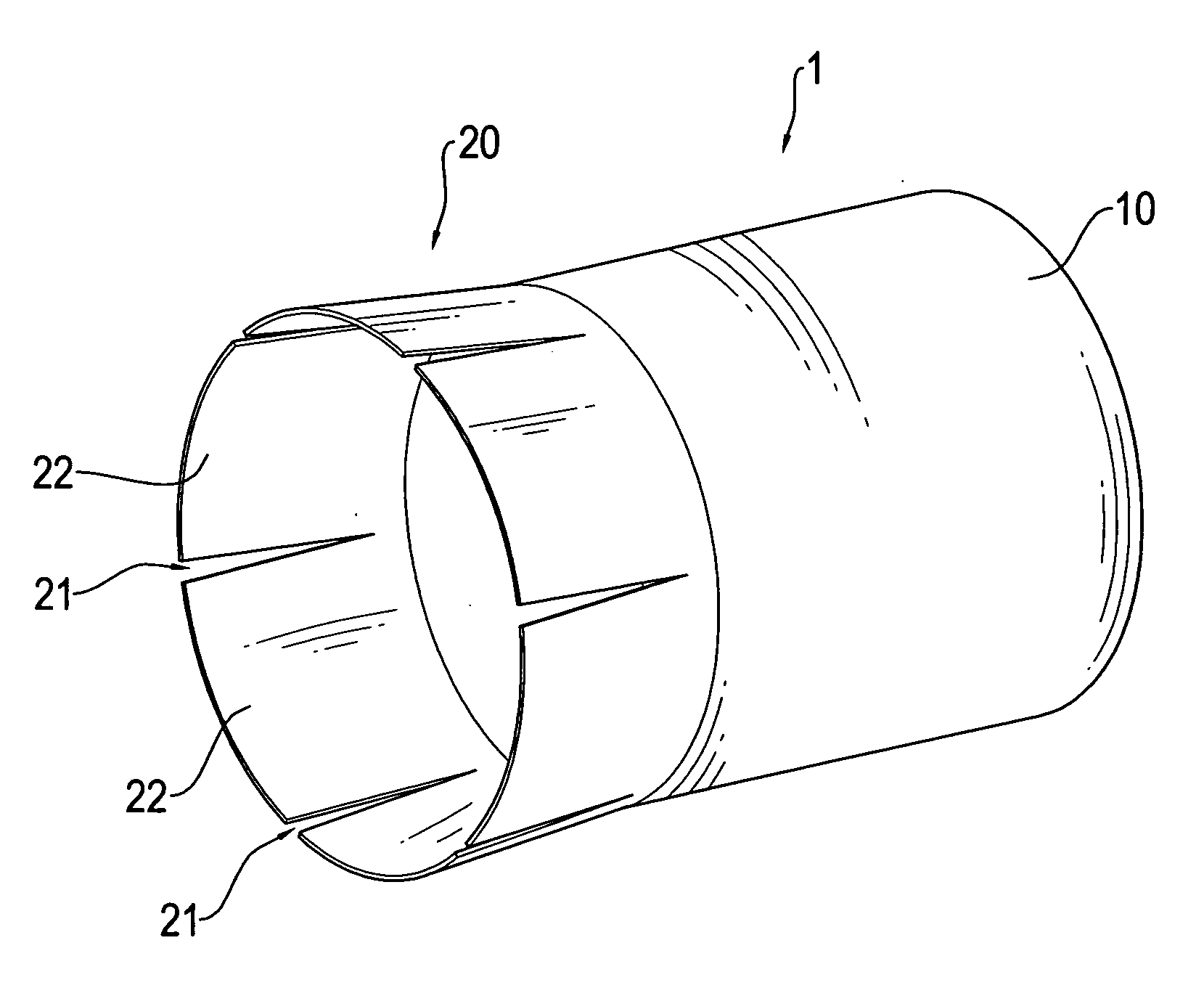

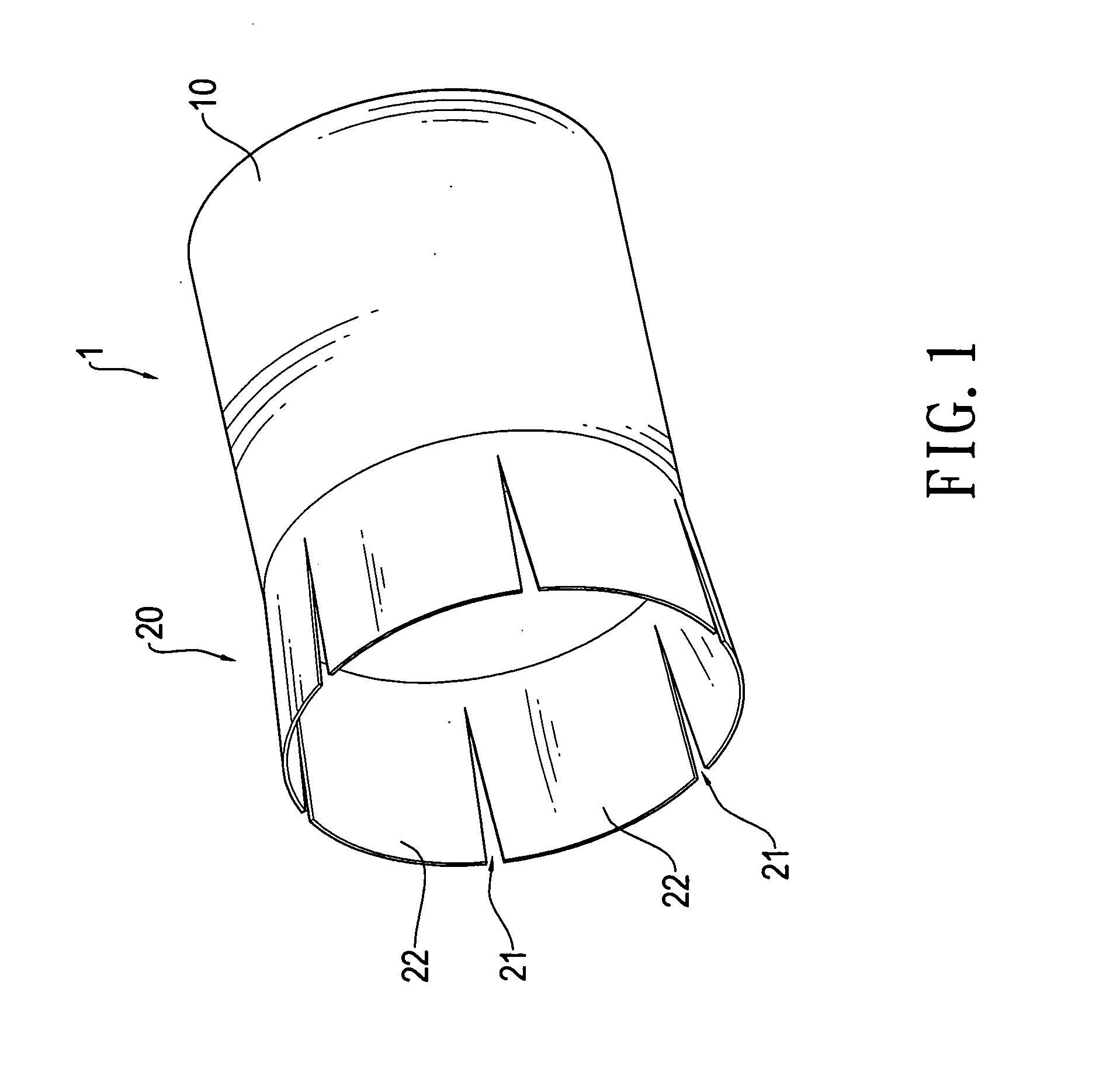

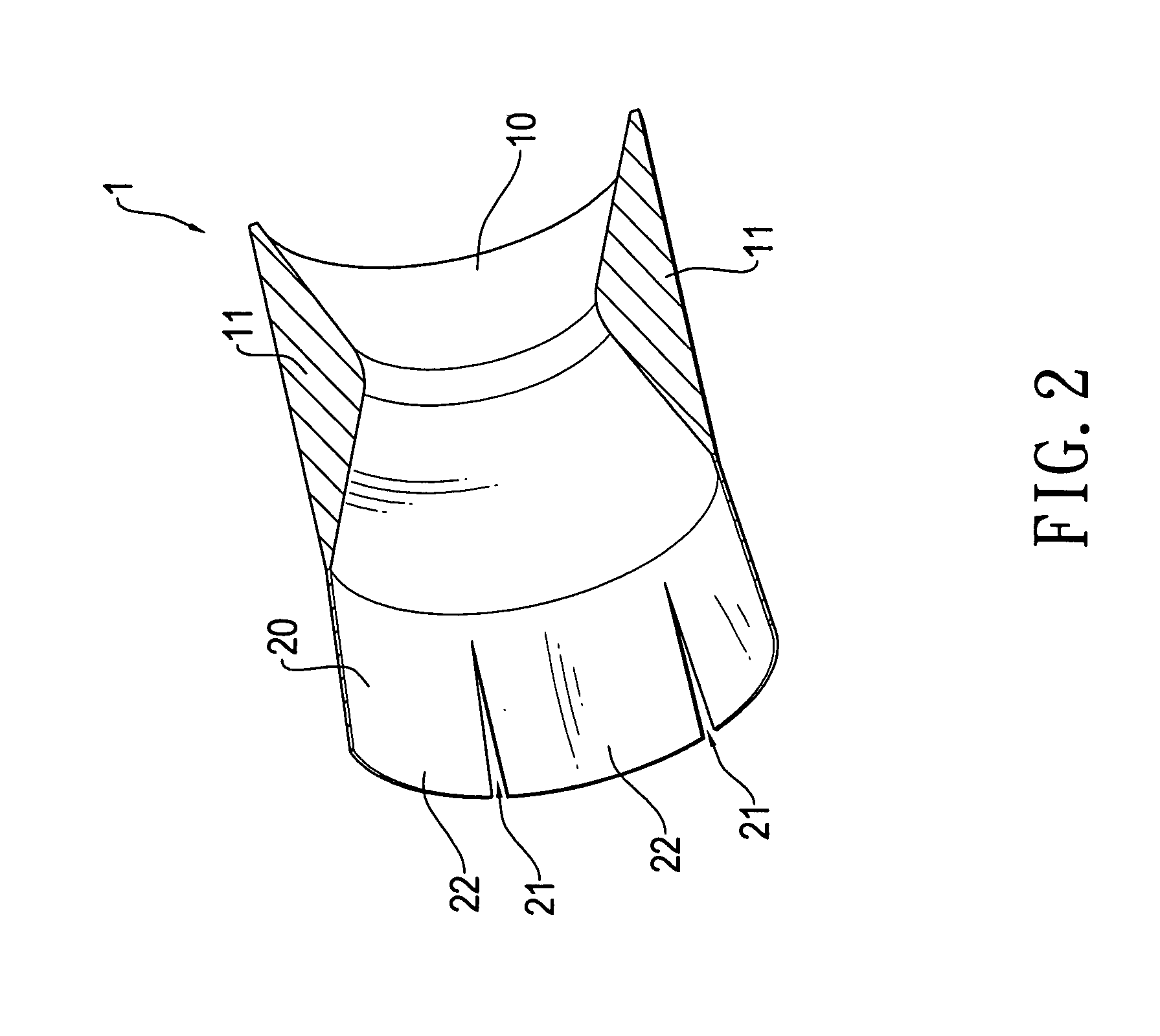

InactiveUS7882699B2Increase output torqueIncrease air velocityCombustion-air/fuel-air treatmentSilencing apparatusCombustionSuction force

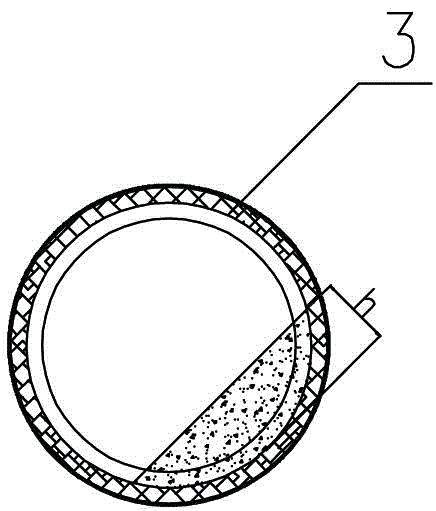

An environment-conservative fuel economizer includes a hollow tubular member and at least one ring member. The tubular member has an internal surface forming a reduced neck section. The ring member is mounted to an end of the tubular member. The ring member forms a plurality of cut-off slits, which defines a plurality of deformable leaves. The neck section of the tubular member forms a flow-accelerating passage, which increases speed of air flow passing therethrough to induce secondary combustion. The leaves are allowed to selectively expand / contract to effect complete combustion and reduce pollution. The fuel economizer is installed between an automobile air filter and engine air-intake tube to use the suction force induce by air intake of cylinder to draw in air so that the mixture density of air and atomized fuel is intensified to effect complete combustion of fuel and enhance instantaneously engine torque and reduce fuel consumption.

Owner:CHENG CHUN HUA

Preparation method for bean curd thin sheets taking soybean protein as raw material

InactiveCN103960375AImprove environmental pollutionImprove color problemsCheese manufactureFood scienceEmulsionEdible oil

The invention provides a preparation method for bean curd thin sheets taking soybean protein as a raw material, belonging to the technical field of food processing. According to the preparation method, the soybean protein, edible oil and non-reduction saccharides are taken as raw materials; after the soybean protein is dissolved and subjected to heat treatment, the edible oil and the saccharides are added and are uniformly mixed and emulsified to form soybean protein emulsion; the bean curd thin sheets are prepared according to a traditional method, namely a product with the mouth feel which is the same as that of the bean curd thin sheets prepared by a traditional process can be obtained. The preparation method is used for preparing the bean curd thin sheets; processes of immersing soybeans, grinding, boiling, filtering and the like in a traditional technology are saved so that the pollution caused by wastewater and waste dreg is reduced obviously; furthermore, the soybean protein, the edible oil and the non-reduction saccharides, which are industrially prepared in a large scale are used as the raw materials so that the process is simple and the stability is good; a Maillard reaction is reduced so that the color of the product is better than that of the bean curd thin sheets prepared by a traditional method.

Owner:JIANGNAN UNIV

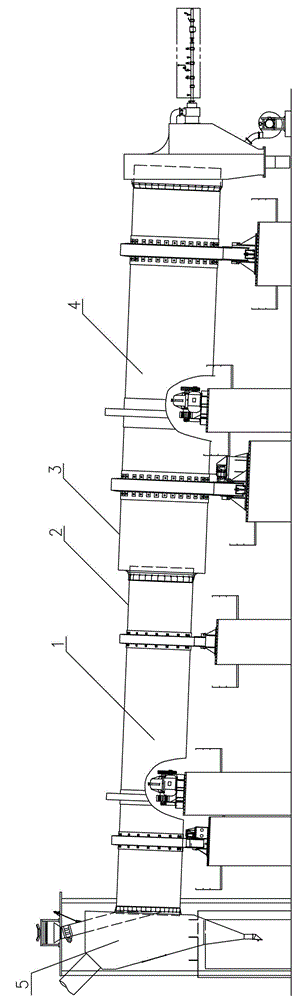

Environment-friendly tandem type drying and calcining kiln

ActiveCN103557691APrevent leakageImprove environmental pollutionRotary drum furnacesDrying machines with non-progressive movementsEngineeringKiln

The invention relates to an improved technology of industrial raising plate drying and calcining equipment, and provides an environment-friendly tandem type drying and calcining kiln. The environment-friendly tandem type drying and claiming kiln comprises a rotary dryer and a rotary calcining kiln, wherein both of the rotary dryer and the rotary calcining kiln are provided with cylinder bodies; the cylinder bodies are butted with each other; the diameter of the cylinder body of the dryer is relatively small; the abutting section of the cylinder body of the dryer is arranged in the cylinder body of the calcining kiln. The environment-friendly tandem type drying and calcining kiln is characterized in that a plurality of material pushing plates are inserted in a circular ring on the abutting end surface of the cylinder body of the dryer, are arranged in a forward material pushing manner in the axial direction, and are tilted to the end surface of the cylinder body of the dryer. The environment-friendly tandem type drying and calcining kiln solves the problem that a material leaks easily from the joint of the dryer and the calcining kiln of the conventional tandem type drying and calcining kiln, so as to avoid dust pollution, and be widely applied to building materials, chemical engineering and the metallurgical industry.

Owner:HUBEI JINLU ENERGY SAVING LTD CO

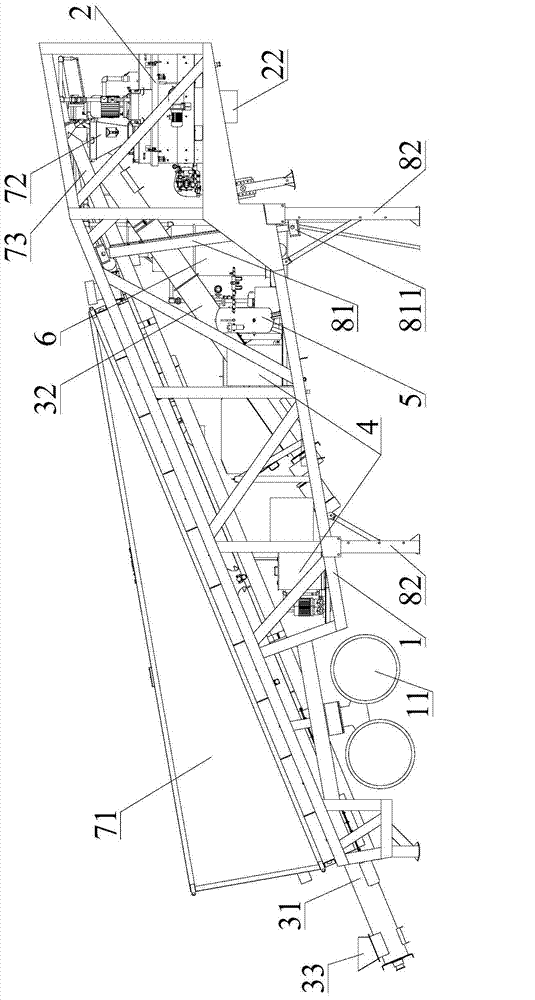

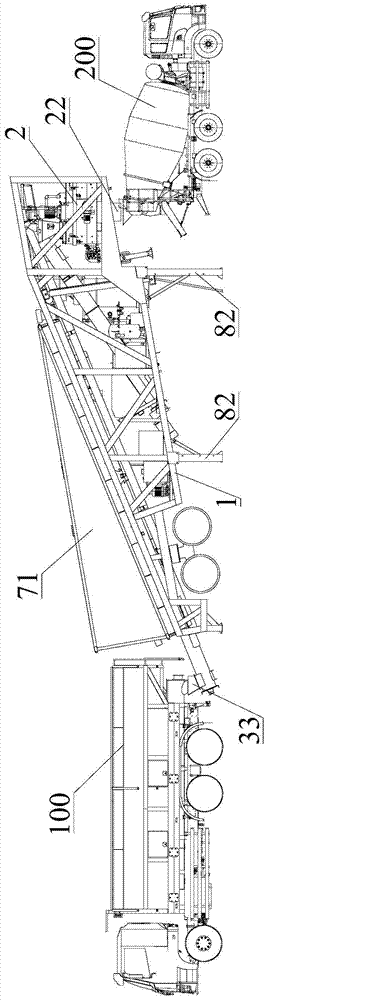

Stirring device

ActiveCN103612332AImprove environmental pollutionEasy to relocateSold ingredients supply apparatusMixing operation plantVehicle frameScrew conveyor

The invention provides a stirring device. The stirring device comprises a vehicle frame, a stirring main machine mounted on the vehicle frame, a first screw conveyor which is used for conveying sand materials and mounted on the vehicle frame, a water tank and waterway system mounted on the vehicle frame, a gas pump and gas way system mounted on the vehicle frame, and a dust collecting device mounted on the vehicle frame, wherein a discharge port of the first screw conveyor is communicated with a stirring cavity of the stirring main machine through a sand material metering device. The stirring device provided by the invention has the advantages of little pollution in working process and easiness in relocation.

Owner:SANY AUTOMOBILE MFG CO LTD

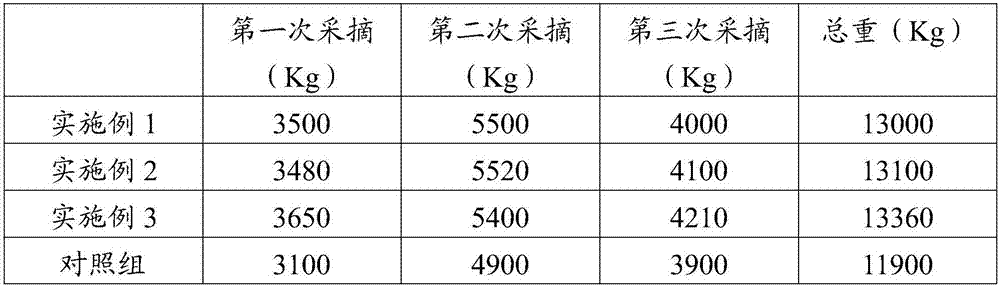

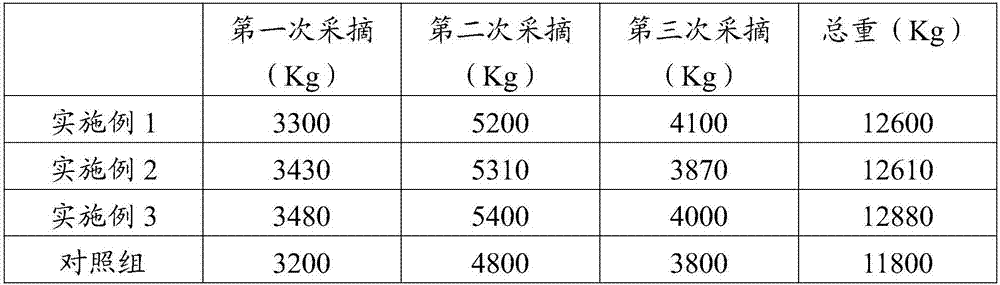

Dual-purpose fertilizer capable of being sprayed onto leaves and washed at roots as well as preparation method and application of fertilizer

InactiveCN107512981AGood use of absorptionIncrease profitMagnesium fertilisersAlkali orthophosphate fertiliserPotassium persulfatePhosphate

The invention provides a dual-purpose fertilizer capable of being sprayed onto leaves and washed at roots as well as a preparation method and application of the fertilizer, belonging to the technical field of fertilizers. The dual-purpose fertilizer comprises 0.1-3 parts of animal amino acid, 1-20 parts of humic acid, 1-20 parts of urea, 1-20 parts of monoammonium phosphate, 1-20 parts of potassium persulfate, 0.3-3 parts of zinc sulfate, 0.1-2.5 parts of manganese sulfate, 0.1-0.8 part of boric acid, 0.1-0.3 part of sodium molybdate, 0.1-1 part of magnesium sulfate, 0.1-0.3 part of compound sodium nitrophenolate, 0.3-20 parts of ferrous sulfate, 0.1-0.5 part of copper sulfate, 0.1-0.3 parts of citric acid, 0.3-3 parts of ammonium citrate, 0.1-0.3 part of vitamin B, 0.1-0.3 part of sodium selenite, 1-20 parts of methylcellulose, 1-20 parts of a drought resistant agent and 1-30 parts of water. By applying the dual-purpose fertilizer provided by the invention for planting tomatoes, the yield is increased by 8.4-12.26% compared with a control group.

Owner:王意强

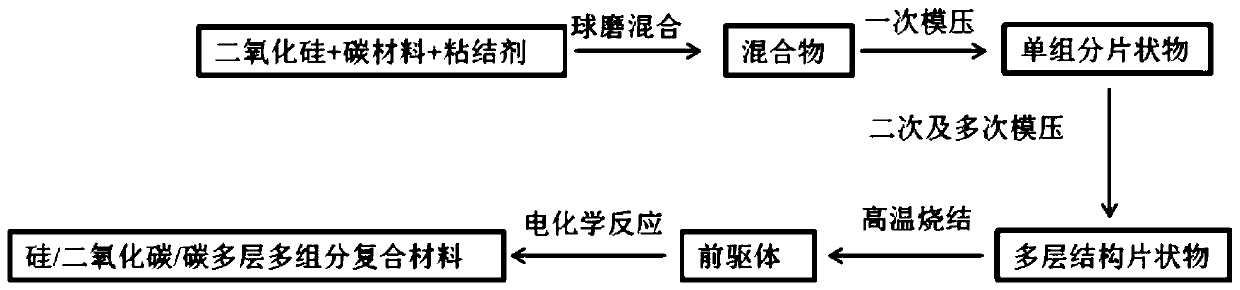

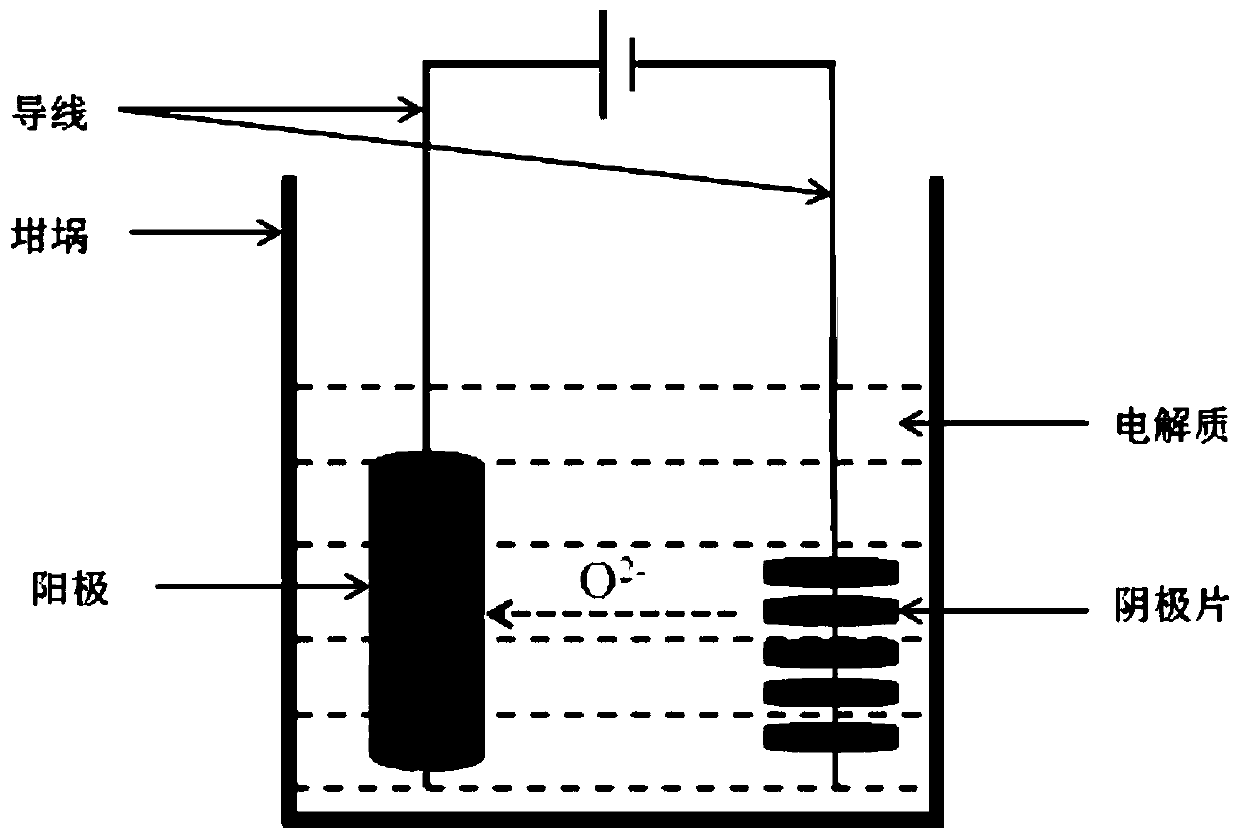

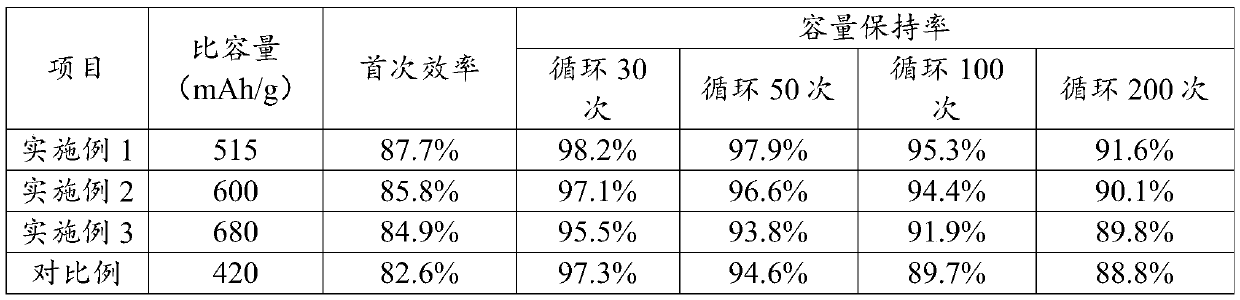

Multilayer composite negative electrode material, preparation method thereof, negative electrode sheet and lithium battery

ActiveCN110112364AImprove efficiencyIncrease the specific capacity of the negative electrodeNegative electrodesSecondary cellsCarbon layerLithium-ion battery

The invention provides a multilayer composite negative electrode material, a preparation method thereof, a negative electrode sheet and a lithium battery. The preparation method of the multilayer composite negative electrode material comprises the steps that silicon, silicon dioxide and carbon are used as raw materials to prepare a multilayer precursor; a silicon material is mixed with a binder toacquire a first precursor layer mixture; silicon dioxide, a carbon material and the binder are mixed to acquire a second precursor layer mixture; the carbon material is mixed with the binder to acquire a third precursor layer mixture; the first, second and third precursor layer mixtures are molded in the order of a silicon layer, a silicon dioxide / carbon mixed layer and a carbon layer, and then are sintered to acquire a multilayer precursor; and silicon dioxide in the multilayer precursor is reduced to monatomic silicon to acquire the multilayer composite negative electrode material. According to the invention, a denser solid electrolyte interface film can be generated during the first charge and discharge process; the volume expansion effect of the silicon material during the charge anddischarge process is suppressed; and the first efficiency of the battery, the specific capacity of the negative electrode and the cycle performance of the battery are improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

Resin based composite

InactiveCN103122153AImprove environmental pollutionIncrease productivityResin-Based CompositeGlass fiber

The invention discloses a resin based composite and belongs to a glass fiber reinforced plastic composite. The resin based composite comprises unsaturated resin and glass powder and also comprises a glass fiber reinforced plastic velvet material, wherein the glass fiber reinforced plastic velvet material, the unsaturated resin and the unsaturated resin are mixed in proportion. The resin based composite product prepared by the invention is high in evenness and beautiful, the resin based composite product can be quickly and effectively prepared, a process is scientific and practical, and cost is low, so that the resin based composite is applicable to popularization and application in the glass fiber reinforced plastic industry.

Owner:武城县新时代玻璃钢厂

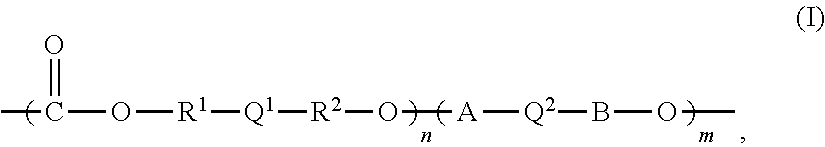

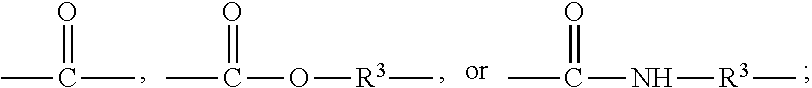

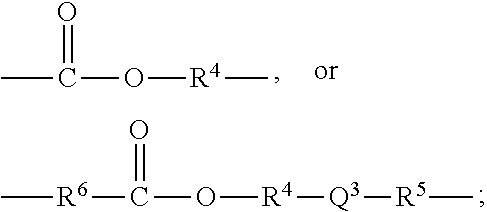

Copolymer based on dimethyl carbonate and method of preparing the same

A copolymer based on dimethyl carbonate and a method of preparing the same are provided. The copolymer based on dimethyl carbonate has a unit from dimethyl carbonate, diols, and a modification monomer. The copolymer based on dimethyl carbonate can be obtained by proceeding transesterification and polycondenastion.

Owner:NAT CHENG KUNG UNIV

Method for preparing animal feed additive from waste diatomite and application of animal feed additive

The invention relates to a method for preparing an animal feed additive from waste diatomite and application of the animal feed additive.The method includes: drying dewatered waste diatomite with solid content higher than wt20% and water content being wt70%-80% at 100-200 DEG C for 20-35h to control the water content below wt5%; using grinding equipment for grinding the dried diatomite into particles smaller than 100-mesh particles; adding according to a ratio of 1%-15% of the weight of feeds for livestock and poultry.Technical simplicity in production, sufficient raw material resources and low product cost are realized; the food safety problems caused by drug residues and drug resistance of pathogenic microorganisms can be effectively avoided, quality and output of livestock and poultry are improved, raising cost is reduced, absorption and appetite of animals can be promoted, and disease-resistant immunity is improved; the problems of environment pollution and residues caused by adoption of chemical insecticides in the breeding industry are effectively improved, and people's life quality is improved.

Owner:HENAN UNIV OF URBAN CONSTR

Feed additive prepared from diatomite

InactiveCN105394323AImprove nutritional qualityIncrease profitAnimal feeding stuffNutritional qualityDigestion

The invention relates to a feed additive prepared from diatomite. Diatomite is taken as a raw material, and after being purified and dried, is pulverized into powder having a particle size range of 20-570 microns. The pulverized powder has a SiO2 content of 35-90%, a water content of 1-15%, and a pH value of about 7. The pulverized powder is added into animal feed and has a general use amount being 0.05%-10% of a total feeding amount. An addition amount of the pulverized powder added into the feed can be adjusted according to the type of a fed animal. The feed additive has characteristics of abundant resources, low cost, and simple manufacture, can improve the nutritional quality of the feed, and can increase the use efficiency and nutrient digestion rate of the feed. The feed additive is particularly suitable for being added into energy feed instead of a main material of corn, so that feed grain is saved, and the production cost is reduced.

Owner:QINGDAO SEIICHI INTPROP SERVICE CO LTD

Method for producing fuel alcohol by fermenting blanched garlic leaf wastes

InactiveCN102732569AHighlight substantive featuresImprove environmental pollutionFermentationChemistryYeast

The invention discloses a method for producing fuel alcohol by fermenting blanched garlic leaf wastes. The method is characterized by comprising the following process steps: treating blanched garlic leaf wastes; heating and condensing; standing for separation and distilling; hydrolyzing; and fermenting and distilling. The method has the following characteristics and progresses: not only can wastes be turned into wealth and environmental pollution be improved, but also the problem that grains are consumed for producing the fuel alcohol at present can be solved; and meanwhile, the factors inhibiting yeast growth are eliminated so as to ensure that fermentation can be carried out smoothly, and costly garlic essential oil is prepared, thus getting a double advantage.

Owner:QINGDAO AGRI UNIV

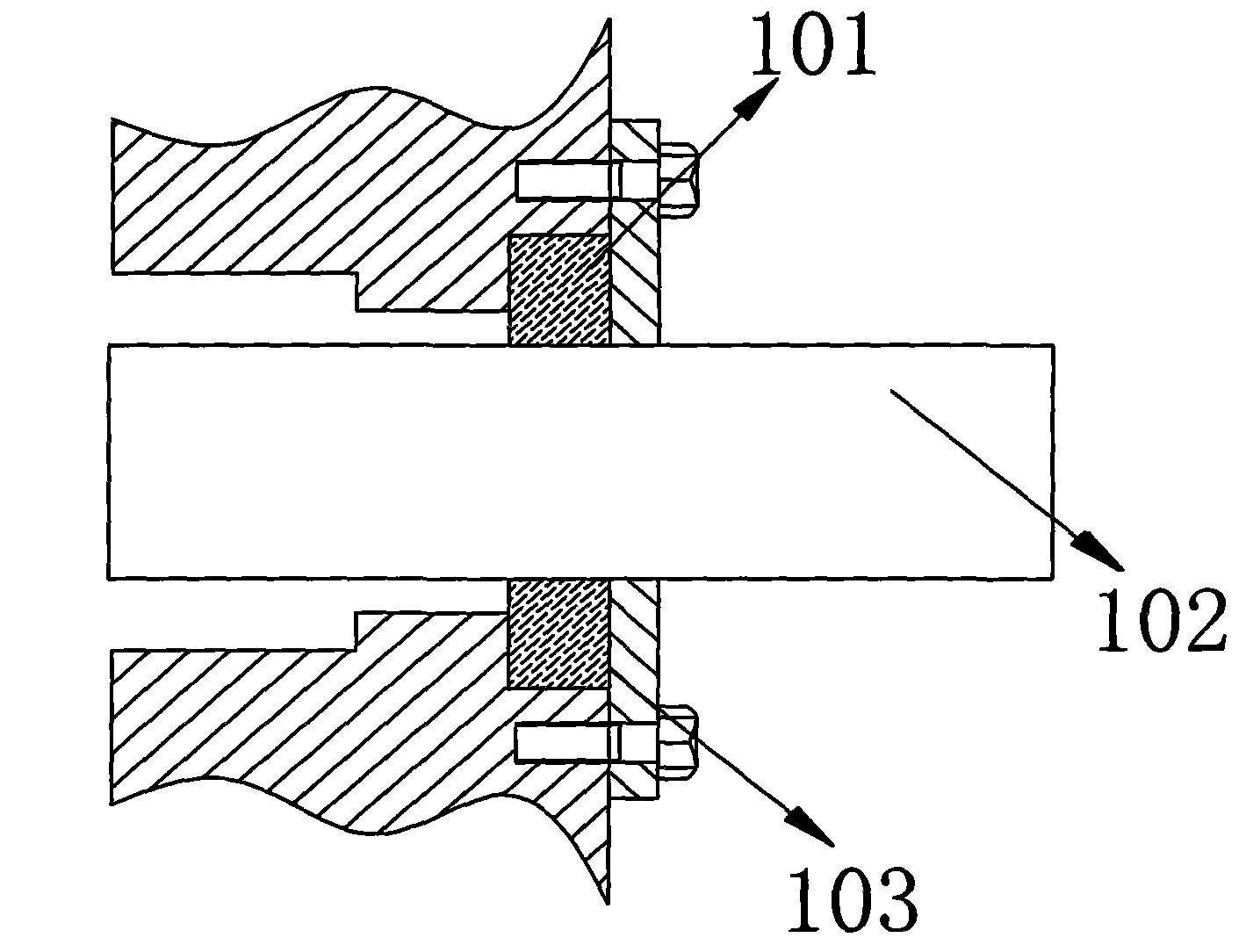

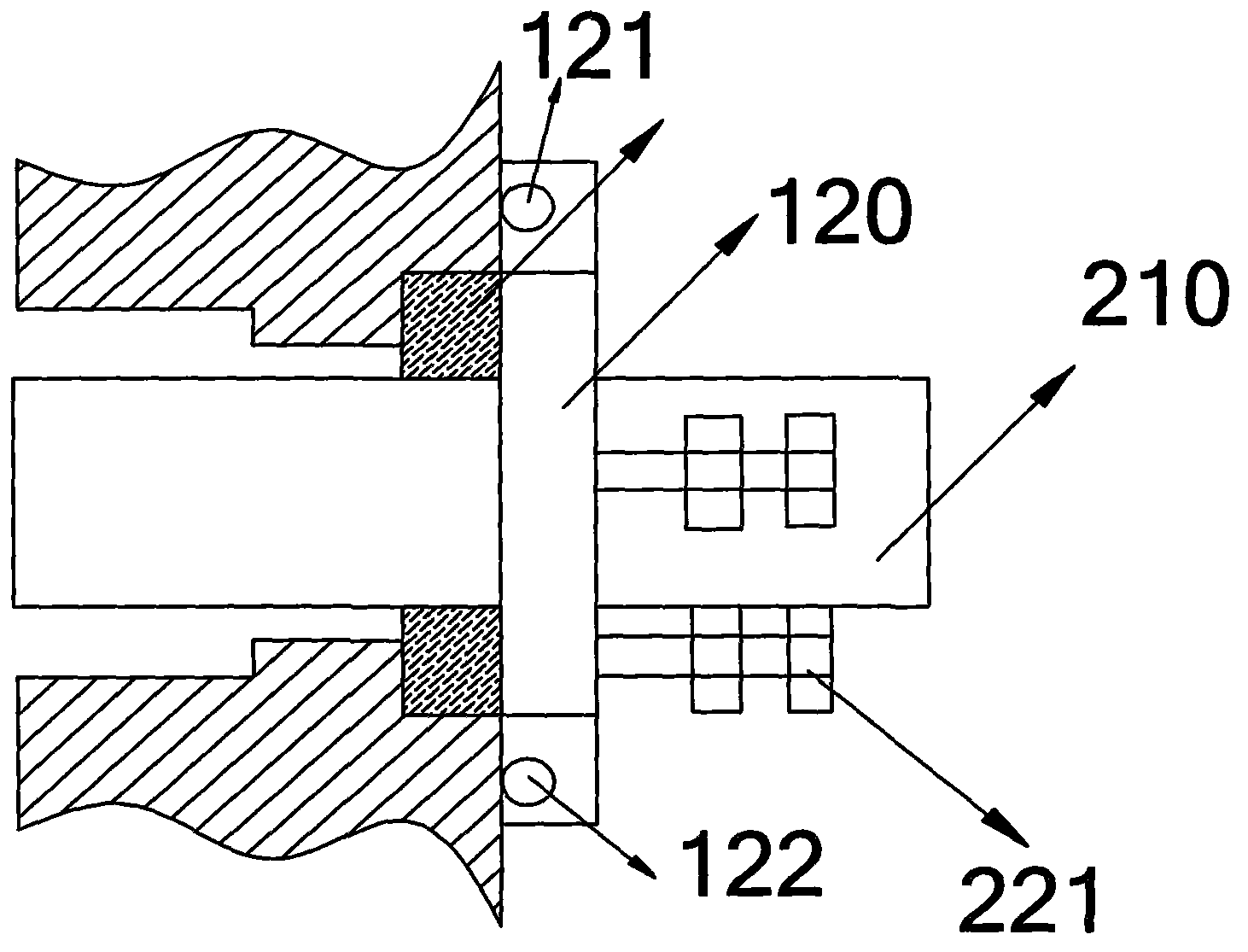

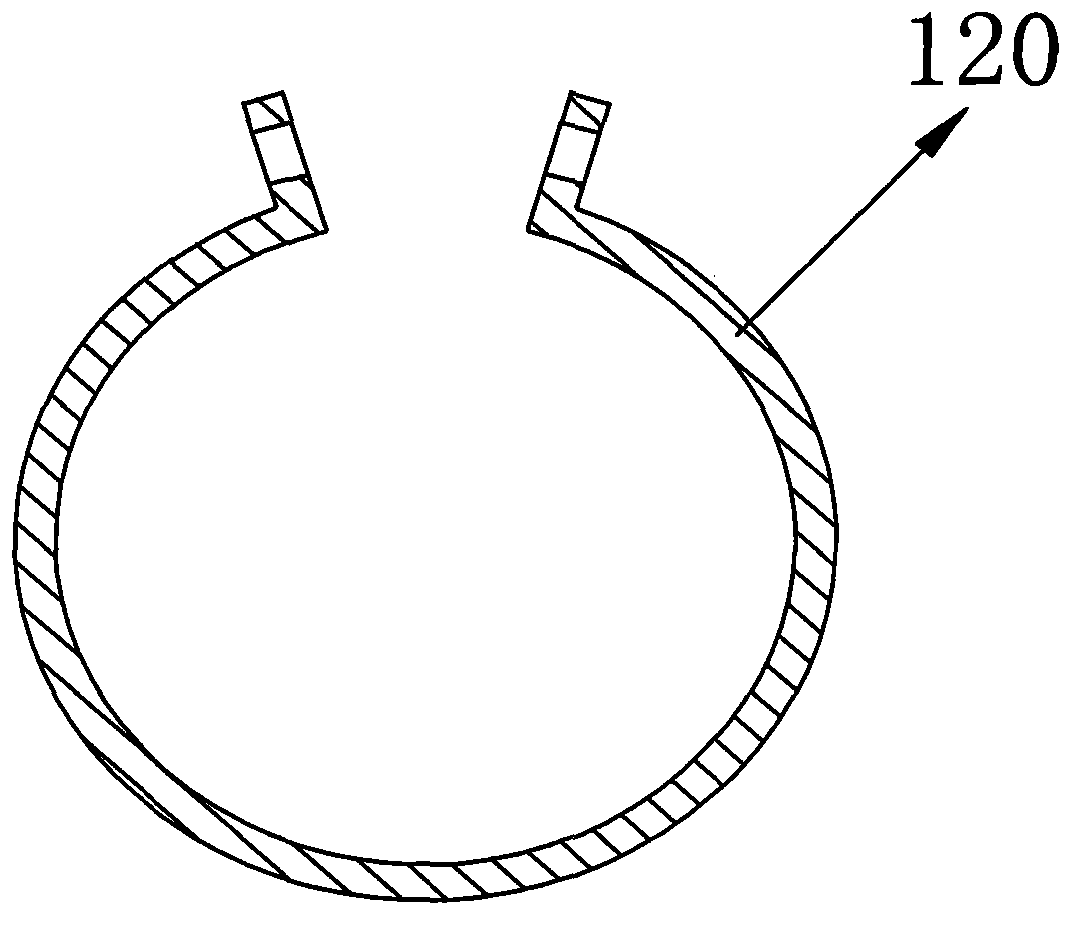

Environment-conservative fuel economizer

InactiveUS20090064671A1Increase output torqueIncrease air velocityCombustion-air/fuel-air treatmentSilencing apparatusSuction forceCombustion

An environment-conservative fuel economizer includes a hollow tubular member and at least one ring member. The tubular member has an internal surface forming a reduced neck section. The ring member is mounted to an end of the tubular member. The ring member forms a plurality of cut-off slits, which defines a plurality of deformable leaves. The neck section of the tubular member forms a flow-accelerating passage, which increases speed of air flow passing therethrough to induce secondary combustion. The leaves are allowed to selectively expand / contract to effect complete combustion and reduce pollution. The fuel economizer is installed between an automobile air filter and engine air-intake tube to use the suction force induce by air intake of cylinder to draw in air so that the mixture density of air and atomized fuel is intensified to effect complete combustion of fuel and enhance instantaneously engine torque and reduce fuel consumption.

Owner:CHENG CHUN HUA

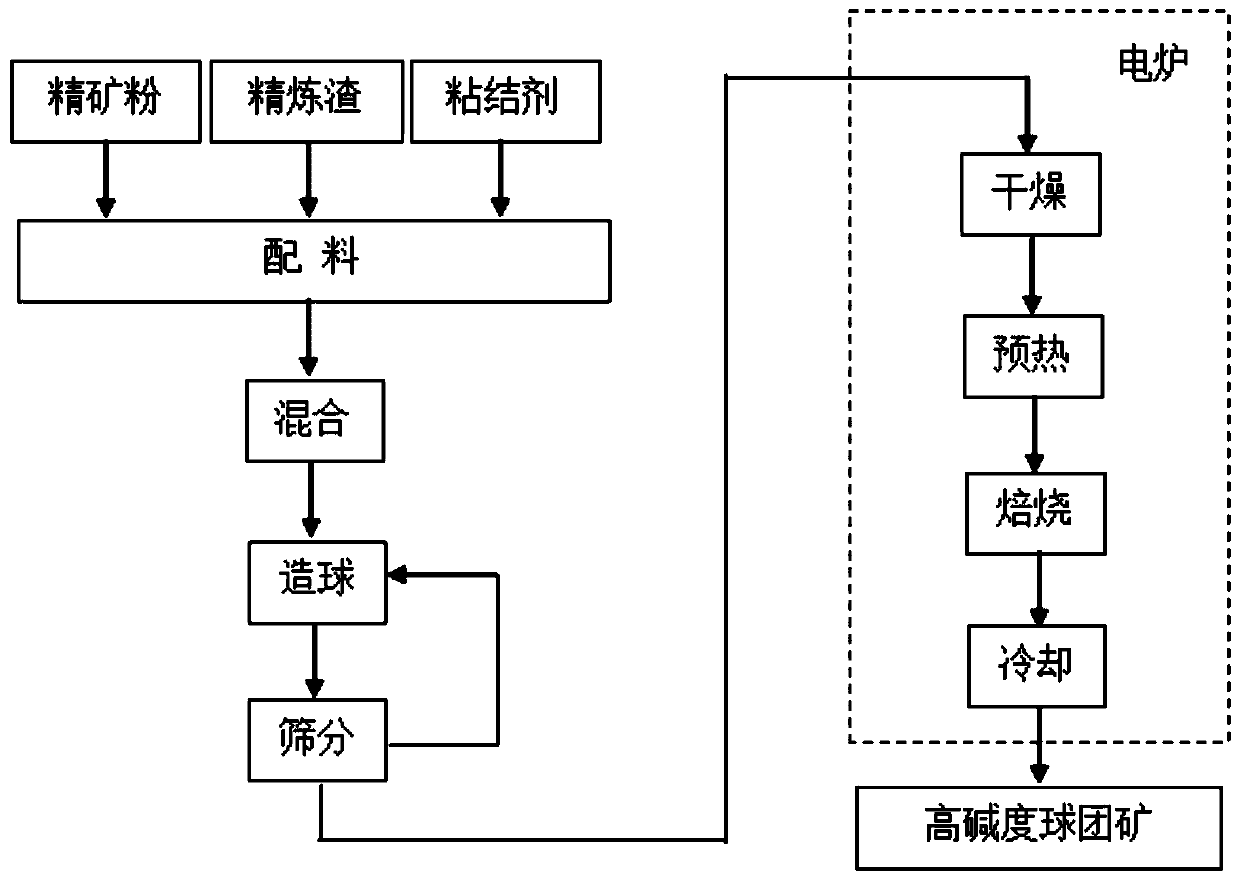

High-alkalinity pellets for blast furnace ironmaking and production method thereof

The invention discloses a high-alkalinity pellet for blast furnace iron making and a production method thereof and belongs to the technical field of ferrous metallurgy. The high-alkalinity pellet for blast furnace iron making is prepared from the following raw materials of concentrate powder, refining slags and bentonite, and specifically from the components in a percent by mass, namely 60-76% of the concentrate powder, 22-38% of the refining slags and 1.5-2.5% of the bentonite. The production method of the high-alkalinity pellet comprises the following steps: preparing the raw materials, forming green pellets, preheating the green pellets, roasting the green pellets and cooling the pellets. By using the concentrate powder and the refining slags as the raw materials, the alkalinity of the qualified pellets which are produced is higher than 2.0, the high-alkalinity pellet can be absolutely used as a main furnace raw material instead of high-alkalinity sintered ore, the inner consumption of the slags is realized, and waste stacking and polluting problems are solved; when pellet production and slag treatment cost is reduced, energy consumption and pollutant emission can be reduced; and the produced pellets are high in compressive strength, low in S content and great in metallurgic performance.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

High compressive strength silica mortar and manufacturing method thereof

InactiveUS7682448B2High compressive strengthMaintain good propertiesSolid waste managementCement productionSlagRoad surface

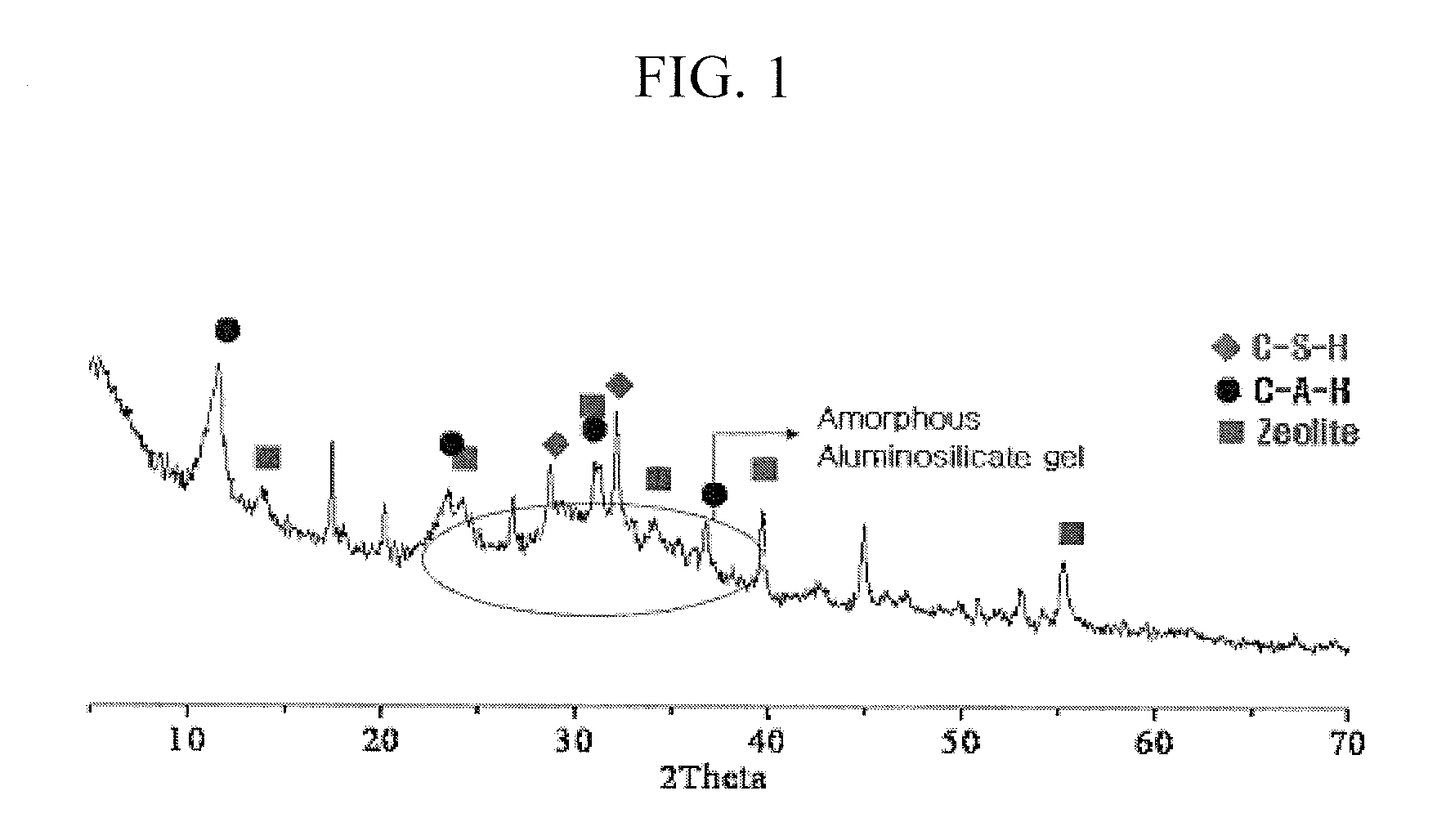

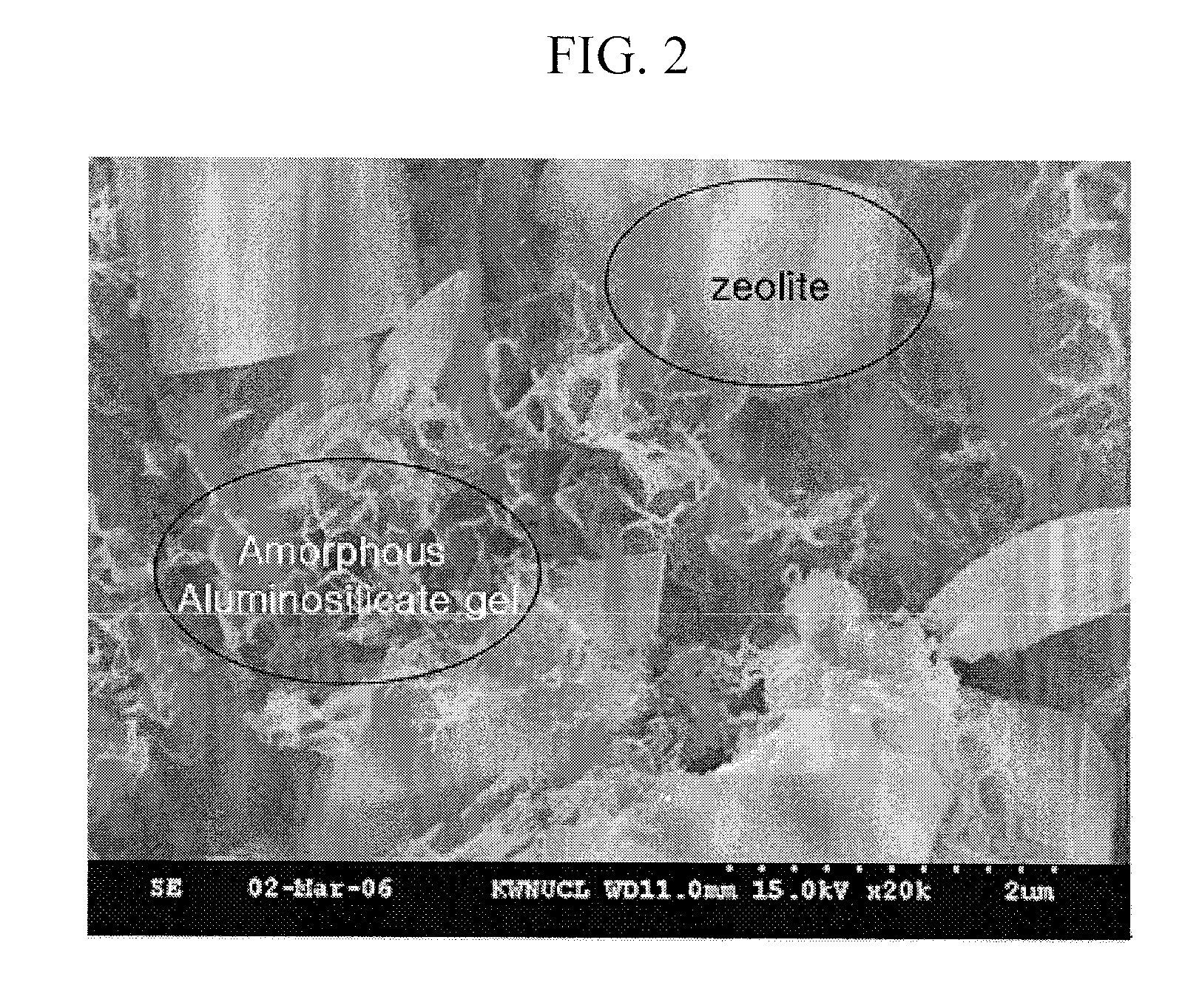

A high compressive strength silica mortar to be used for the installation of constructs such as building inside and outside walls, the road pavement, a slope and planting trees in the roof and manufacturing method thereof are provided. The high compressive strength silica mortar is formed of 30 to 60 wt % of silica, 40 to 70 wt % of blast furnace slag, and the 15 to 35 weight parts of polycondensation regulator for 100 weight parts of dry mortar powder of these silica and blast furnace slag, and is solidified by generating C—S—H, C-A-H, amorphous Geopolymeric Matrix{Al2O3.mSiO2.nM2O.xH2O(M=K,Na,Ca)} and Zeolite in the mortar. In particular, the high compressive strength silica mortar exhibits the compressive strength of 70.0 MPa or more by vibration forming and curing for 12˜48 hours at 25 to 80° C. before removal of form and aging for 28 days, and can save energies because a firing process is not required. Accordingly, the high compressive strength silica mortar has excellent properties compared with conventional cement concretes or polymer cements, and further shows high compressive strength in initial stage, which could not be generated in such products.

Owner:DEPUY SPINE INC (US) +1

Sealing device of wet type ball grinder head section in thermal plant

InactiveCN103230819APrevent inlet slurry leakageReduce the amount of maintenanceEngine sealsGrain treatmentsBall millEngineering

The invention provides a sealing device of a wet type ball grinder head section in a thermal plant. The sealing device comprises sealing packing, a clamping apparatus, a radial locking device and an axial compressing device, wherein the sealing packing is fixed at the joint of the grinder head section and an inlet tube; the clamping apparatus is used for fixing and compressing the outside of the sealing packing; the radial locking device is used for locking the clamping apparatus; and the axial compressing device is used for fixing the inlet tube and compressing the clamping apparatus. According to the sealing device of the wet type ball grinder head section in the thermal plant provided by the invention, the joint face of the sealing packing and the ball grinder can be adjusted regularly, and mortar leakage at the inlet of the ball grinder is effectively prevented, so that the overhaul maintenance quantity is reduced.

Owner:XIAHUAYUAN POWER PLANT OF DATANG INT POWER GENERATION

Multifunctional fuel oil addition agent and preparation method thereof

InactiveCN103160359AReduce environmental pollutionImprove environmental pollutionLiquid carbonaceous fuelsFuel additivesSolventParaffin oils

The invention relates to a multifunctional fuel oil addition agent and a preparation method of the multifunctional fuel oil addition agent. The preparation method comprises the steps of weighing and taking raw materials which comprise, by component and weight, 90-95 parts of normal paraffin, 3-6 parts of isomerism paraffin, 1-2 parts of olefin, 1-2 parts of cyclo-paraffin and 0.2-0.8 part of aromatic hydrocarbon, stirring and mixing the raw materials for 2-3 hours, obtaining a crude product, then, adding oily solvent, enabling the volume ratio of the oily solvent to the crude product to be 1 to 30, mixing the compound for 2-3 hours, and obtaining a yellow liquid product. Compared with the prior art, the multifunctional fuel oil addition agent has the advantages of being small in sulfur content, good in dispersing property and the like.

Owner:SHANGHAI BOHUI CHEM

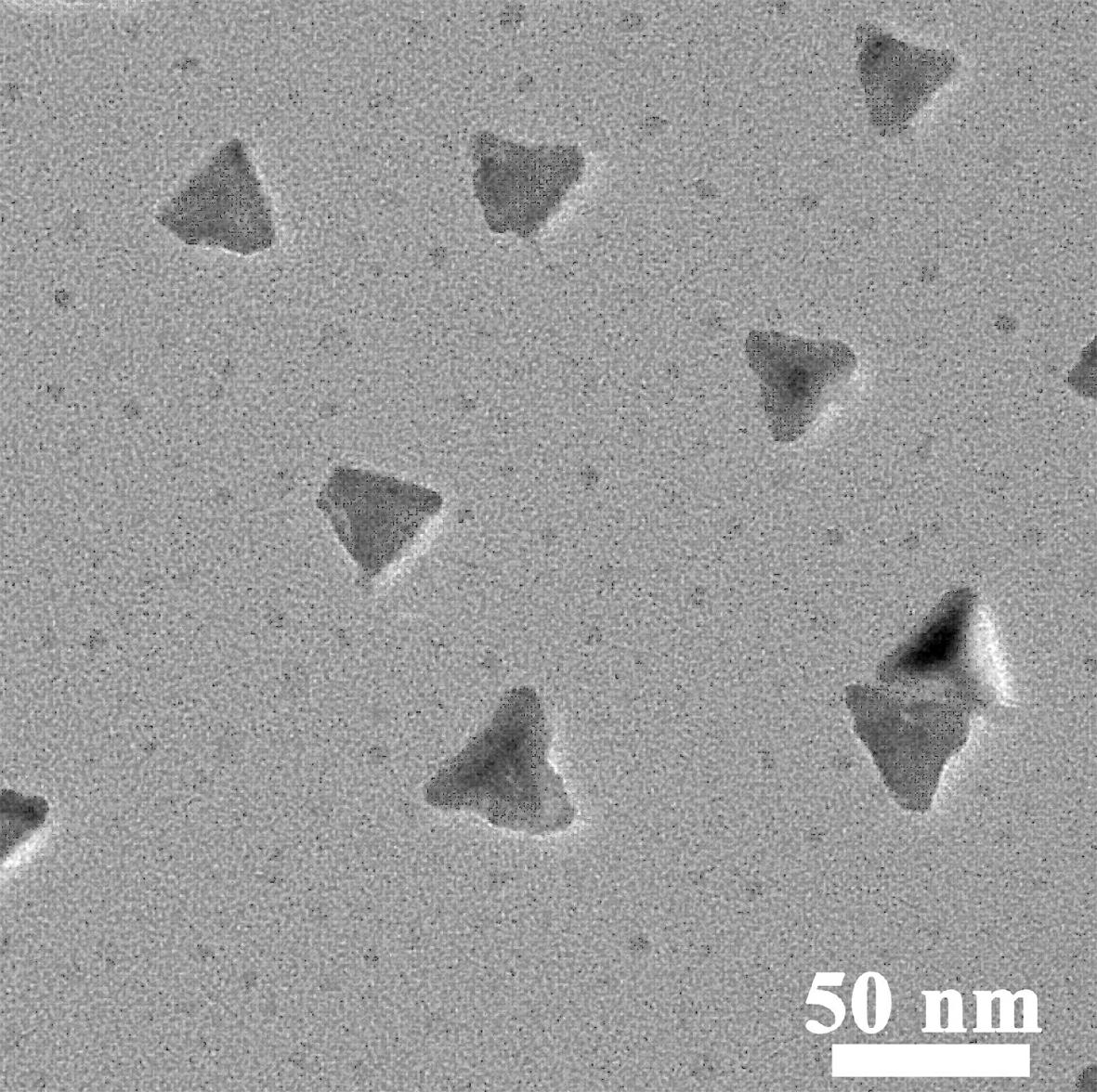

PbS nanomaterial characterized by oriented attachment structure and preparation method thereof

InactiveCN102605428AImprove environmental pollutionSimple processPolycrystalline material growthFrom normal temperature solutionsPhysicsChemistry

The invention belongs to the technical field of biomimetic synthesis and monomolecular films, and particularly relates to a method for preparing a PbS nanomaterial characterized by oriented attachment structure by organic molecular film regulation. The PbS nanomaterial is tri-antennary with each antenna 70-300nm in length and is characterized by the oriented attachment structure. The method is simple in process, has moderate conditions and low equipment requirements, and is low in cost, pollution-free and easy for regulation.

Owner:HENAN UNIVERSITY

Fertilizer with matched use of foliage spray and water-washed application ways as well as preparation method and application of fertilizer

ActiveCN107512961AImprove compaction and environmental pollutionPromote root systemMagnesium fertilisersAlkali orthophosphate fertiliserFertilizerNutrient

The invention provides a fertilizer with matched use of foliage spray and water-washed application ways as well as a preparation method and application of the fertilizer, belonging to the technical field of fertilizer. The fertilizer provided by the invention comprises foliage spray fertilizer and root water-washed fertilizer, elements and ratios thereof in the fertilizer are further limited, the fertilizer is reasonable in the ratio of the elements, nutrient application is balanced, crops can well utilize and absorb nutrients, bottom fertilization and foliage spray are adopted for the crops, balanced fertilization is realized, and comprehensive absorption of the crops is realized, so that the aims of increasing yield and increasing income are achieved; meanwhile, the utilization rate of the fertilizer is increased, and hardening of soil and environmental pollution which are caused by residual fertilizer are alleviated. When tomatoes are fertilized by applying the fertilizer provided by the invention, yield is increased by 6.78-9.15% compared with a control group.

Owner:广西埃索凯循环科技有限公司

Intelligent rainwater/wastewater purification method and system

ActiveCN104843936ARelieve pressureReduce initial investmentClimate change adaptationMultistage water/sewage treatmentPurification methodsWater storage tank

The invention discloses an intelligent rainwater / wastewater purification method and system. The system comprises an intelligent control device and a purification device, wherein the purification device comprises a wastewater sludge sedimentation tank, a wastewater sludge separation tank, a filtering-stone water-purifying tank, an activated-carbon water-purifying tank, a microbial-bacterium water-purifying treatment tank and a purified-water storage tank. The method provided by the invention can reduce the pressure and the initial investment of urban municipal drainage; urban rainwater are collected and stored for comprehensive utilization, diversified application of purified water obtained after intelligent purification and sludge removal as irrigation water for afforestation, washing water for urban roads, fire protection water for living quarters, water for groundwater recharge and the like is realized, so recovery, purification and reclamation of rainwater are accomplished; and the method can effectively reduce urban heat island effect and improve pollution of a water environment for urban residents.

Owner:桂林广泽科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com