PbS nanomaterial characterized by oriented attachment structure and preparation method thereof

A nanomaterial and structural feature technology, applied in the field of biomimetic synthesis and monomolecular membranes, can solve the problems of lack of structurally controllable PbS nanomaterials, insufficient regulation of morphology and structural features, environmental pollution, etc., and achieves simple process and equipment requirements. Low, improve the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

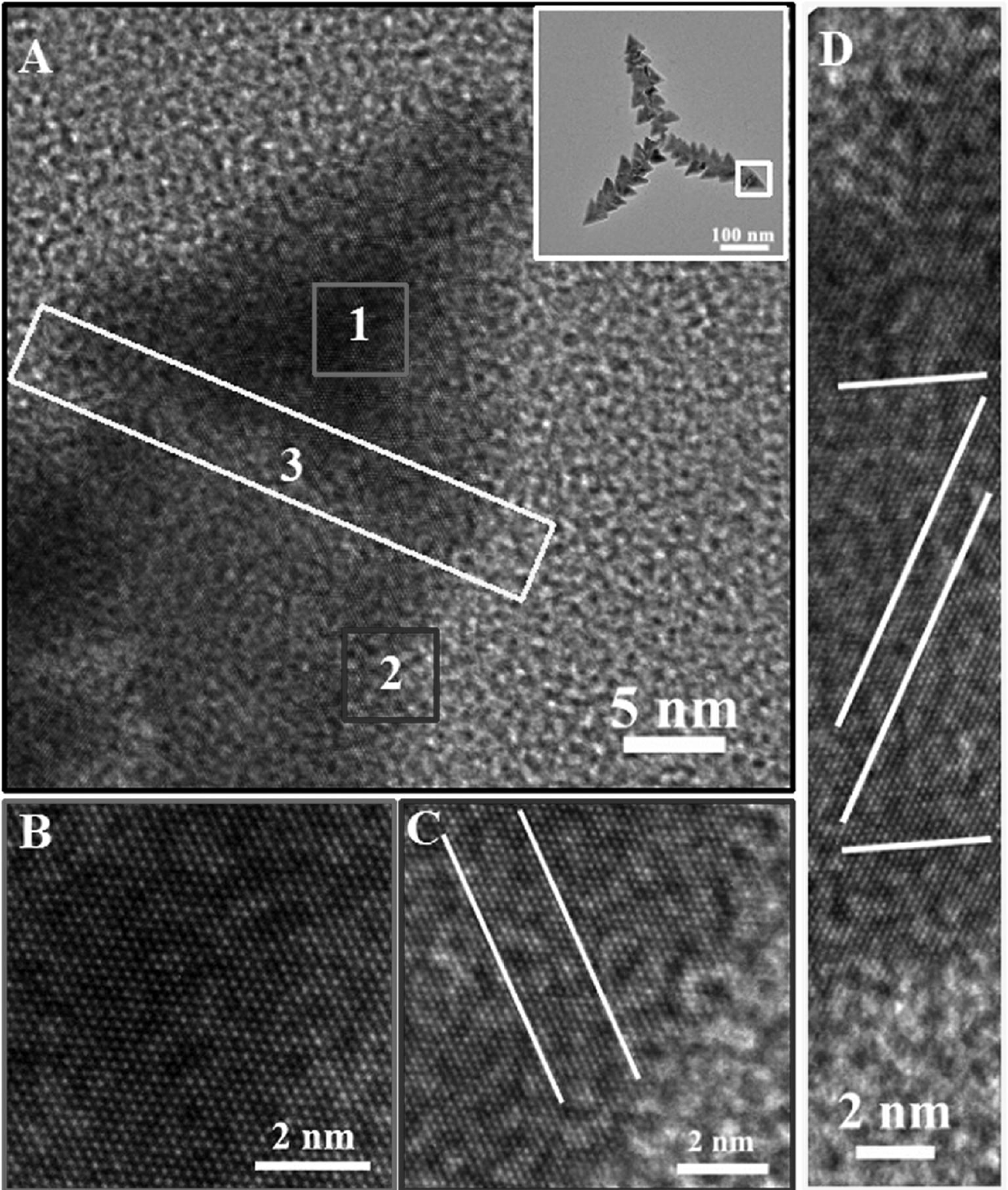

[0021] 1) Add 0.0497 g Pb(NO 3 ) 2 (purity 99%) was dissolved in deionized water to make 0.001 mol / L Pb(NO 3 ) 2 solution; 2) 1.127 g C 2 h 5 NS (purity 99.9%) was dissolved in deionized water to make 0.1 mol / L C 2 h 5 NS solution; 3) Prepare 0.001 mol / L AA chloroform solution; 4) Mix 150 mL each of the solutions prepared in step 1) and step 2) at about 23°C, put them into a small tank of KSV-5000 mini, and then draw them with a needle Clean the membrane several times for possible impurities. Add 80 μL of the AA solution prepared in step 3) to the surface dropwise, let stand for 15 minutes to let the chloroform volatilize, AA fully spreads on the surface of the solution to form a monolayer film, set the target pressure to 2 mN / m, and the moving speed of the baffle to 3 mm / m min. Seal the glass cover of the tank and let it stand for 14 hours. Thioacetamide is hydrolyzed to release sulfur ions and combine with lead ions in the solution to form lead sulfide.

[0022] Fro...

Embodiment 2

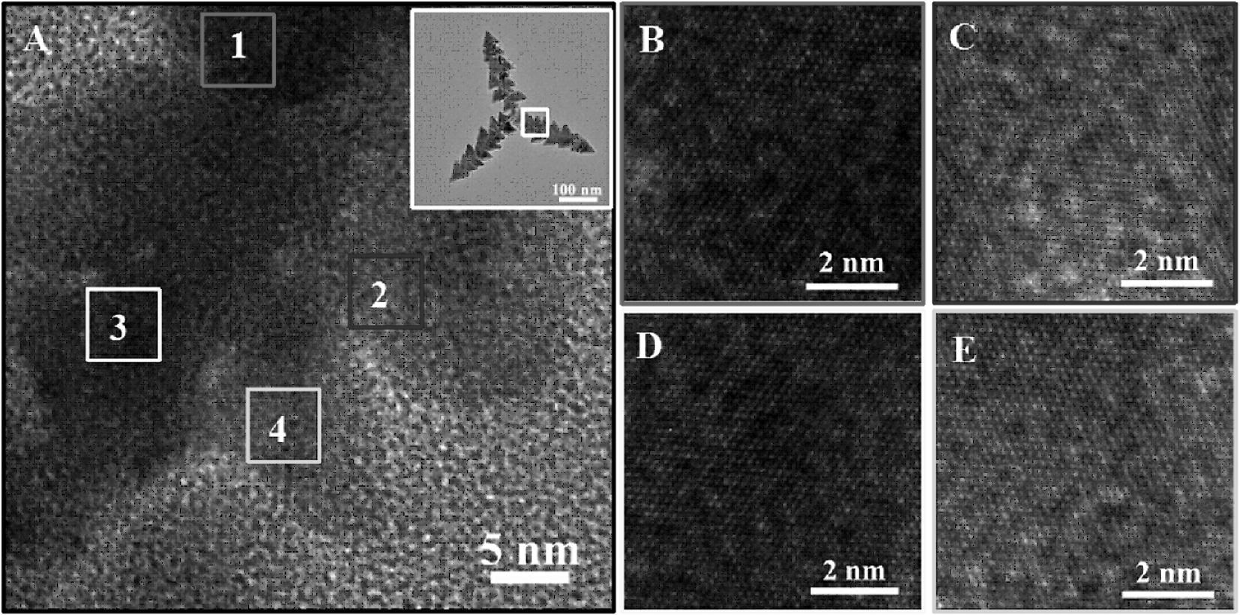

[0024] 1) Add 0.0497 g Pb(NO 3 ) 2 (purity 99%) was dissolved in deionized water to make 0.001 mol / L Pb(NO 3 ) 2 solution; 2) 0.3381 g C 2 h 5 NS (purity 99.9%) was dissolved in deionized water to make 0.03 mol / L C 2 h 5 NS solution; 3) Prepare 0.001 mol / L AA chloroform solution;

[0025] 4) Mix 150 mL each of the solutions prepared in step 1) and step 2) at about 23°C, put it into the small tank of KSV-5000 mini, and then use a needle to suck up the possible impurities to clear the film several times. Add 80 μL of the AA solution prepared in step 3) to the surface dropwise, let stand for 15 minutes to let the chloroform volatilize, AA fully spreads on the surface of the solution to form a monolayer film, set the target pressure to 2 mN / m, and the moving speed of the baffle to 3 mm / m min. Seal the glass cover of the mini tank and let it stand for 14 hours. Thioacetamide is hydrolyzed to release sulfur ions and combine with lead ions in the solution to form lead sulfide...

Embodiment 3

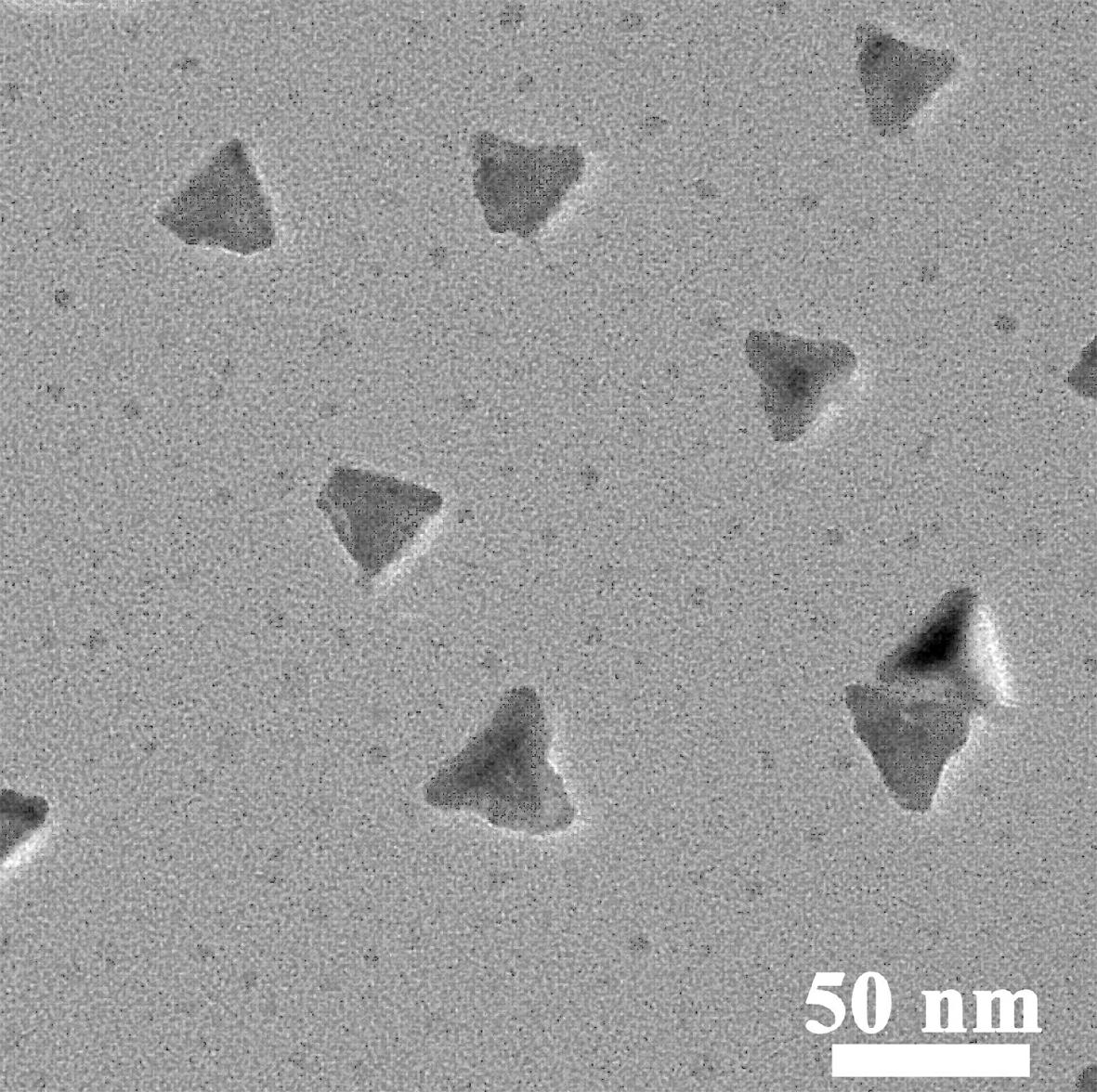

[0028] In step 2), 0.8452 g C 2 h 5 NS (purity 99.9%) was dissolved in deionized water to make 0.075 mol / L C 2 h 5 NS solution, others are with embodiment 1.

[0029] Analytical tests show that, see Figure 5 , the product is a three-legged PbS nanomaterial, and the length of each leg is about 150 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com