Sealing device of wet type ball grinder head section in thermal plant

A technology of wet ball mill and sealing device, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc. It can solve the problems of heavy maintenance workload, leakage, and affecting the stable operation of equipment, so as to improve the waste of working fluid and environmental pollution. The effect of reducing the amount of inspection and maintenance and preventing the phenomenon of slurry leakage at the inlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the technical solutions of the present invention, the embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

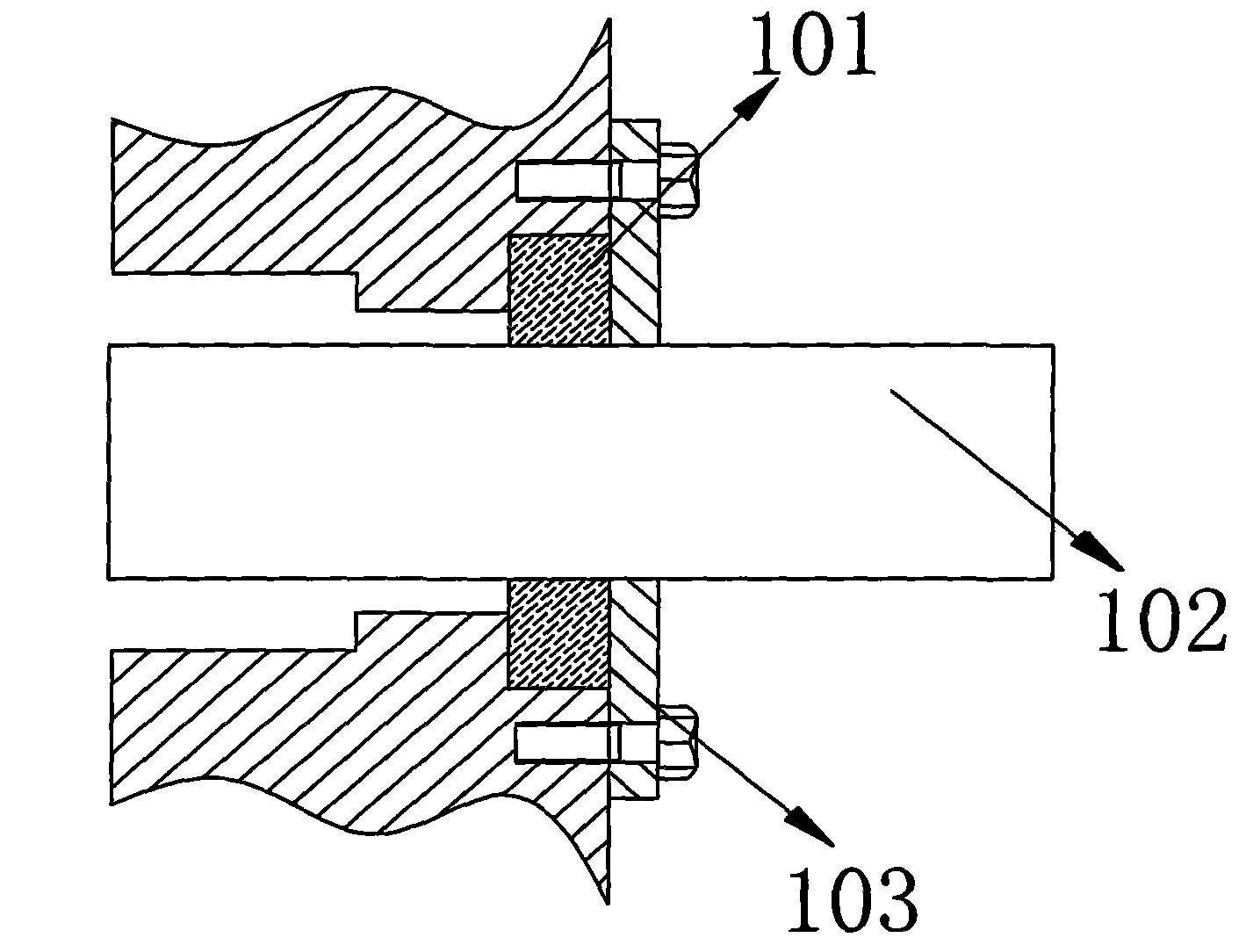

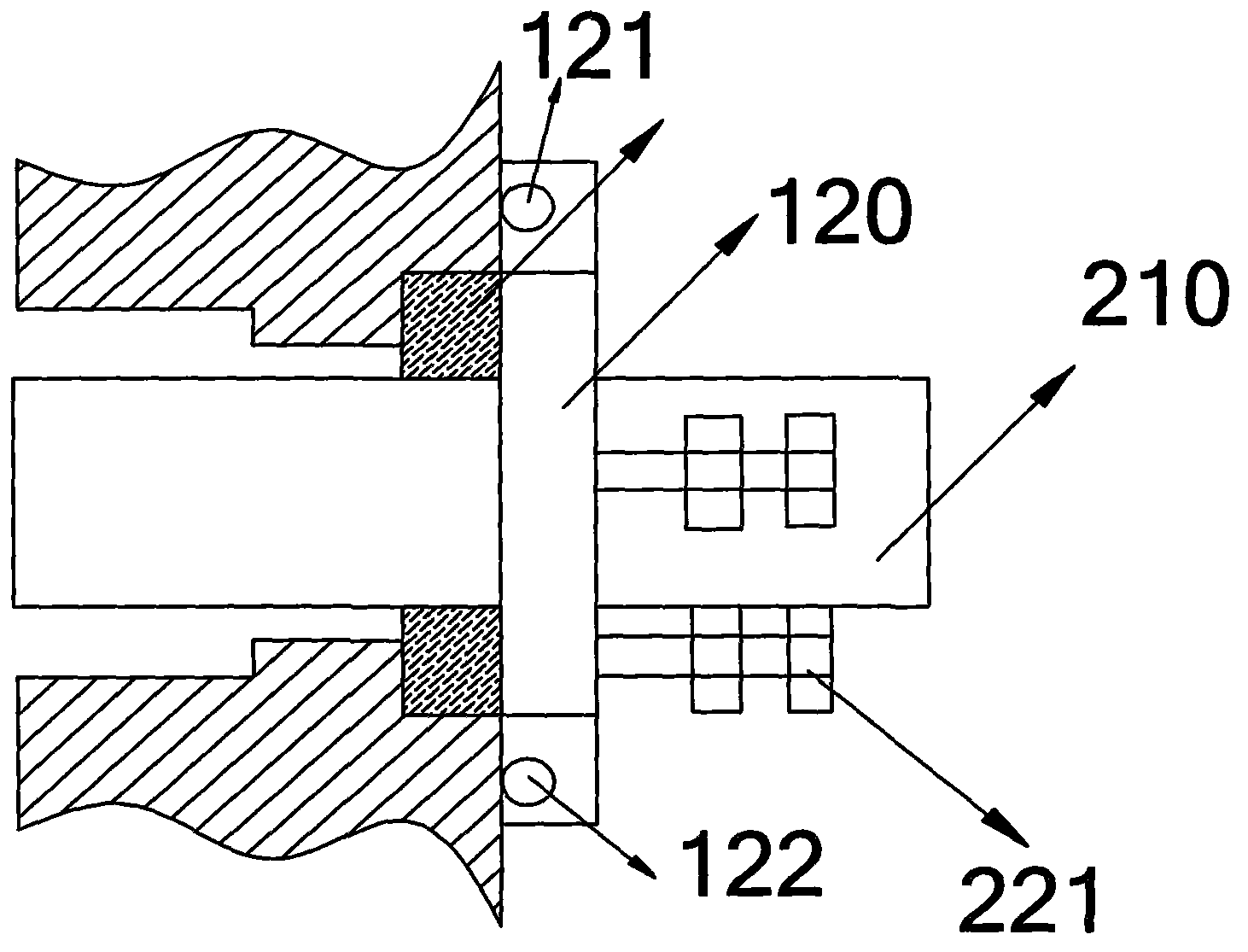

[0021] The invention provides a sealing device for the head of a thermal power plant wet ball mill, such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes: sealing packing 110, fixture 120, radial locking device 130, axial compression device 221, wherein:

[0022] The sealing packing 110 can be made of felt instead of the traditional packing, and fixed at the joint between the mill head and the inlet pipe 210 .

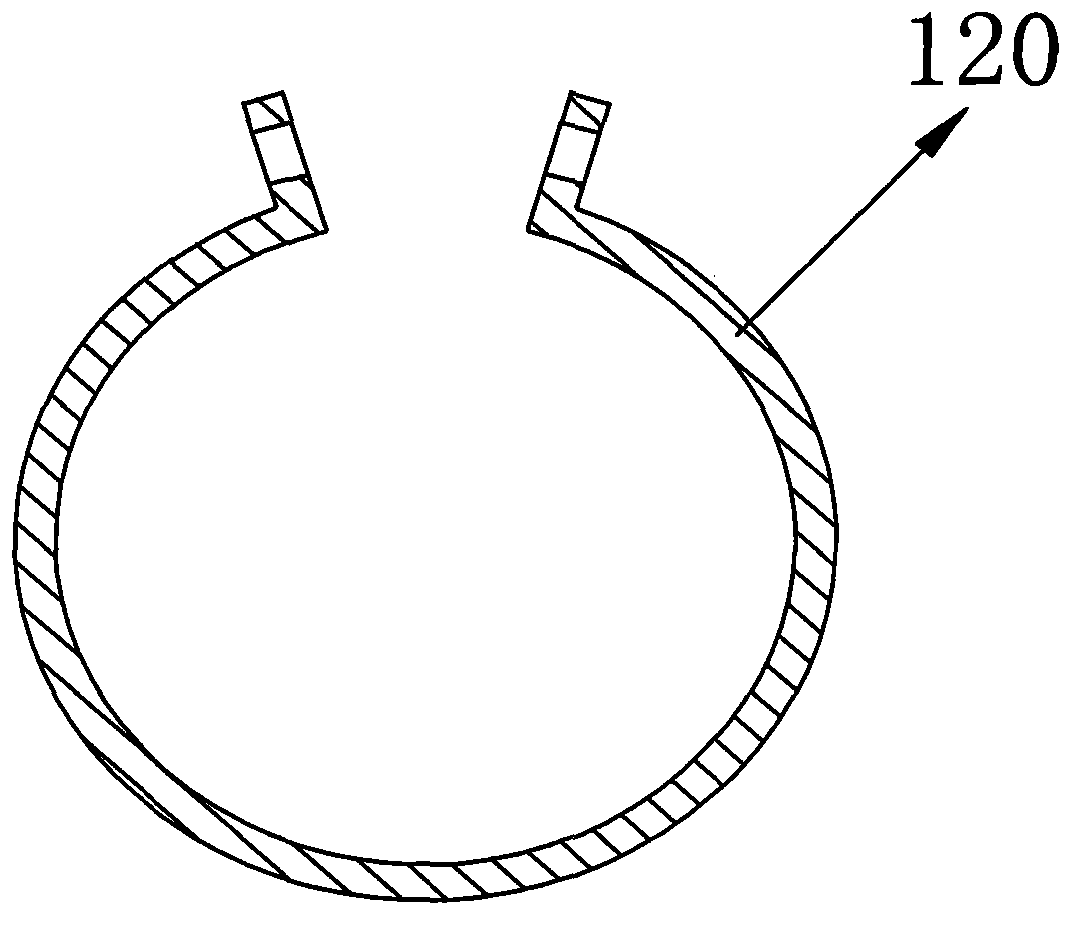

[0023] The clamp 120 is used to fix and compress the sealing packing 110 , and the clamp 120 can insert the sealing packing 110 into its interior during use.

[0024] The radial locking device is used in conjunction with the fixture 120 , and penetrates through the first bolt hole 121 and the second bolt hole 122 of the fixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com