Furnace cover device used for semi-closed submerged arc furnace

A kind of submerged arc furnace, semi-closed technology, applied in the direction of furnace, furnace components, lighting and heating equipment, etc., can solve the problems of high production cost of the furnace cover, difficult to enlarge the diameter, complicated production process, etc., to reduce long-term production, use and maintenance The amount, save the cooling water circulation, reduce the effect of side wall water cooling structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

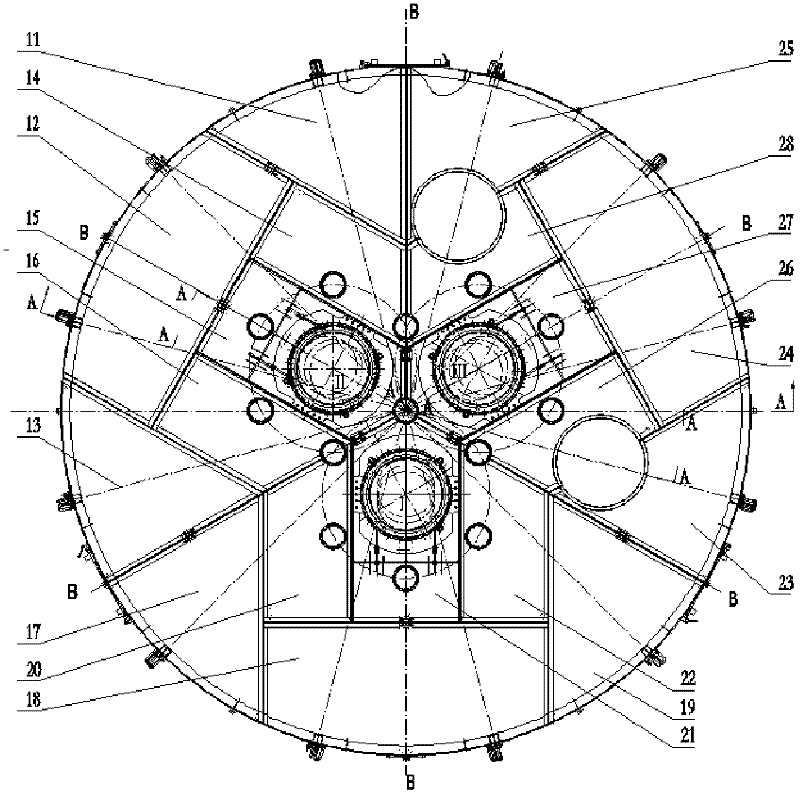

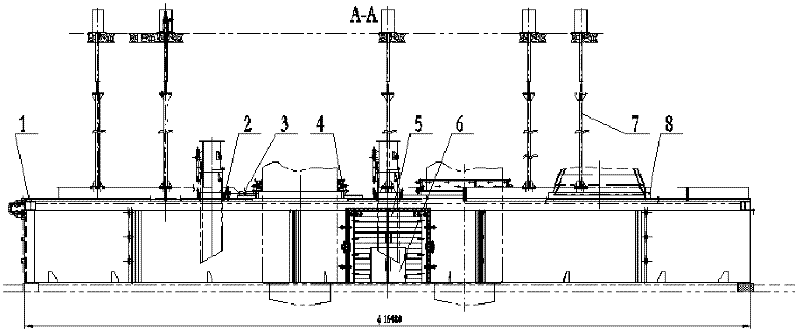

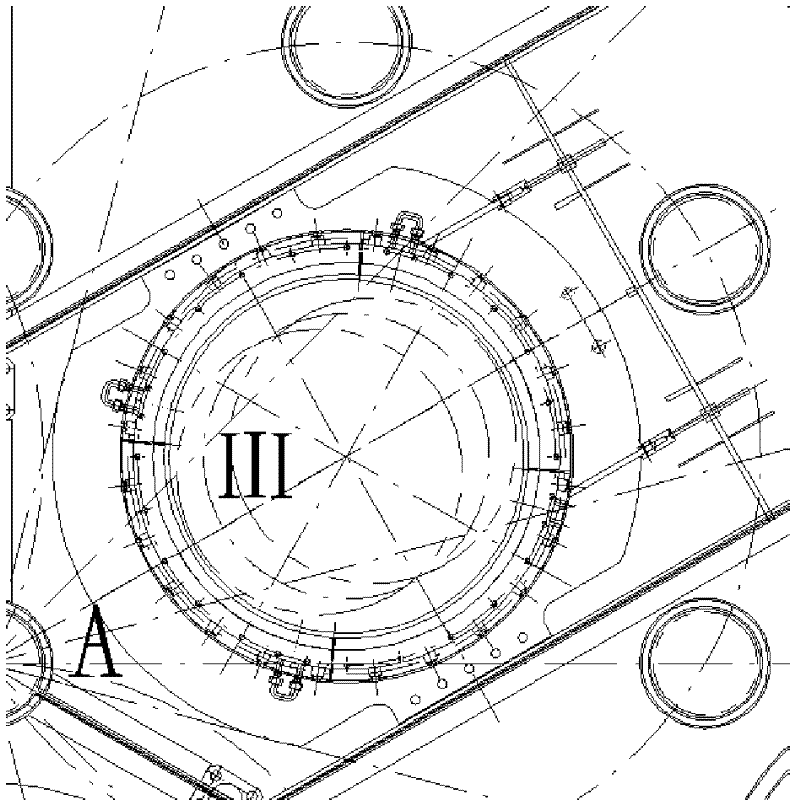

[0031] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-8 As shown, a furnace cover device for a semi-closed submerged arc furnace includes a furnace cover, a large water-cooled ring beam 1, a furnace cover blanking opening 2, an electrode pole center circle diameter adjustable mechanism 3, an electrode water-cooled sealing device 4, a furnace Cover water cooling door 5, furnace cover push door 6, furnace cover hanging device 7 and furnace cover smoke collecting port 8;

[0032] The furnace cover is composed of 18 water-cooled furnace cover flaps. An insulating and sealing structure is provided between the water-cooled furnace cover flaps, and the double-layer high-strength bolts and locknuts are used to tighten and connect the integral furnace cover. One hanging point, fixed on 10 furnace cover hanging devices 7 through flanges and bolts, and hung on the third floor of the civil construction, and the large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com