Fertilizer with matched use of foliage spray and water-washed application ways as well as preparation method and application of fertilizer

A technology of foliar spraying and flushing fertilization, applied in the direction of fertilization method, application, organic fertilizer, etc., can solve the problems of inability to increase crop yield, unreasonable application method, low crop yield, etc., and achieve the improvement of compaction and environmental pollution. Good, fast inhalation effect of crops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

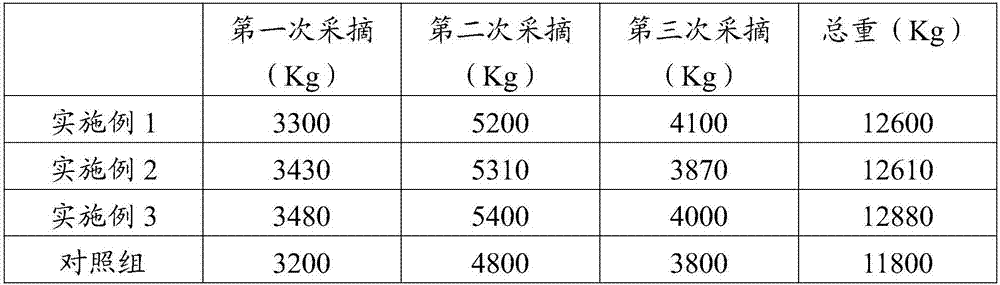

Examples

preparation example Construction

[0040] The preparation method of described root flushing fertilization, comprises the following steps:

[0041] A. mixing urea, monoammonium phosphate, potassium persulfate, potassium nitrate, humic acid and water to obtain a basic raw material mixture;

[0042] B. mixing the basic raw material mixture obtained in step A with methyl cellulose and drought-resistant agent at 25-35°C to obtain root fertilization;

[0043] The preparation method of described foliage spray fertilizer, comprises the following steps:

[0044] 1) mixing animal amino acid with water to obtain animal amino acid wet material;

[0045] 2) Mix the animal amino acid wet material obtained in the step 1) with zinc sulfate, manganese sulfate, boric acid, magnesium sulfate, ferrous sulfate, copper sulfate, citric acid, and ammonium citrate at 60-70°C to obtain the first a mixed material;

[0046] 3) Mix the first mixed material obtained in the step 2) with vitamin B, sodium molybdate, sodium binitrophenolate...

Embodiment 1

[0066] Stir 200Kg urea, 10Kg monoammonium phosphate, 200Kg potassium persulfate, 10Kg potassium nitrate, 200Kg humic acid and 10Kg water at 30r / min for 50min, while stirring, use steam to heat to 35°C to obtain a basic raw material mixture. The obtained basic raw material mixture was mixed with 10Kg of methylcellulose and 200Kg of drought resistance agent at 35° C. and stirred at 30 r / min for 25 minutes to obtain fertilizer for root flushing.

[0067] Soak 1Kg animal amino acid and 24Kg water at 20°C for 100min to obtain animal amino acid wet material. After the obtained animal amino acid wet material is heated to 60°C by steam, it is mixed with 3Kg zinc sulfate, 25Kg manganese sulfate, 1Kg boric acid, 1Kg magnesium sulfate, 3Kg ferrous sulfate, 5Kg copper sulfate, 1Kg citric acid, and 10Kg ammonium citrate at 60 Stir at 40 r / min for 60 min at °C to obtain the first mixed material. The first mixed material obtained with 3Kg vitamin B (vitamin B 1 , B 6 and B 12 The mass ra...

Embodiment 2

[0069] Stir 10Kg urea, 200Kg monoammonium phosphate, 10Kg potassium persulfate, 200Kg potassium nitrate, 10Kg humic acid and 200Kg water at 40r / min for 30min, while stirring, use steam to heat to 25°C to obtain a basic raw material mixture. The obtained basic raw material mixture was mixed with 200Kg methylcellulose and 10Kg drought-resistance agent at 25° C. and stirred at 40 r / min for 15 minutes to obtain root flushing fertilizer.

[0070] Soak 30Kg animal amino acid and 210Kg water at 30°C for 30 minutes to obtain animal amino acid wet material. After the obtained animal amino acid wet material is heated to 70°C by steam, it is mixed with 30Kg zinc sulfate, 1Kg manganese sulfate, 8Kg boric acid, 10Kg magnesium sulfate, 20Kg ferrous sulfate, 1Kg copper sulfate and 3Kg citric acid, 3Kg ammonium citrate at 60 Stir at 40 r / min for 60 min at °C to obtain the first mixed material. The first mixed material obtained with 1Kg vitamin B (vitamin B 1 , B 6 and B 12 The mass ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com