Preparation method of halogen-free low-smoke flame-retardant crosslinked polyethylene composite material

A cross-linked polyethylene, low-smoke flame-retardant technology, applied in the field of polymer materials, can solve the problems of biomass waste without good application prospects, soil, water and air pollution, and achieve excellent flame-retardant and mechanical properties , Improve the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

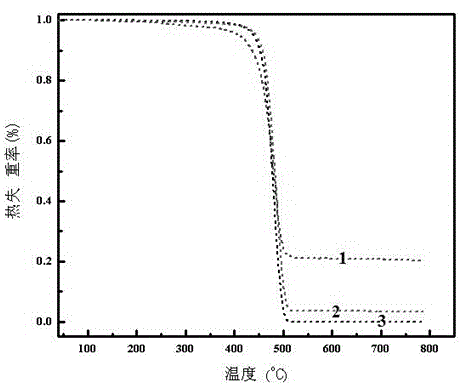

Image

Examples

Embodiment 1

[0020] Weigh 100 kg of low-density polyethylene, 20 kg of flame retardant (12.5 kg of activated carbon sludge from potato residue, 6.25 kg of dimethyl methylphosphonate, and 1.25 kg of palygorskite clay), vinyl trimethoxyl crosslinking agent Silane 1 kg, antioxidant dicumyl peroxide 500 g, lubricant dibutyltin dilaurate 250 g, high-speed stirring (stirring speed 650 rpm) and kneading for 20-40 minutes, then twin-screw extrusion at 140-170 ° C Composite granules are obtained by machine extrusion, and then the composite granules are cross-linked in water at 50-80°C for 0.5-1 hour, and the obtained product is air-dried.

[0021] Product performance: the oxygen index is 29; the smoke density is 102 under flameless conditions, the tensile strength is 15.3MPa, and the elongation at break is 702%. Specifications for mechanical properties.

Embodiment 2

[0023] Weigh 100 kg of low-density polyethylene, 45 kg of flame retardant (15 kg of potato waste activated carbon sludge, 15 kg of dimethyl methylphosphonate, and 15 kg of palygorskite clay), cross-linking agent vinyltrimethoxysilane 4.5 kg, antioxidant dicumyl peroxide 2.5 kg, lubricant dibutyltin dilaurate 2kg, high-speed stirring (stirring speed 1200 rpm) after kneading for 20-40 minutes, extruded by twin-screw extruder at 140-170°C Composite particles are obtained, and then the composite particles are cross-linked in water at 50-80° C. for 0.5-1 hour, and the obtained product is air-dried.

[0024] Product performance: the oxygen index is 38; the smoke density is 75 under flameless conditions, the tensile strength is 14.2 MPa, and the elongation at break is 688%. All properties meet the industry standard YD / T 1113-2001 on the mechanical properties of wire and cable sheathing materials Provisions.

Embodiment 3

[0026] Weigh 100 kg of low-density polyethylene, 27 kg of flame retardant (15 kg of activated carbon sludge from potato residue, 9 kg of dimethyl methylphosphonate, and 3 kg of palygorskite clay), cross-linking agent vinyl trimethoxy Silane 3 kg, antioxidant dicumyl peroxide 2 kg, lubricant dibutyltin dilaurate 1.5 kg, high-speed stirring (stirring speed 1000 rpm) after kneading for 20-40 minutes, twin-screw extrusion at 140-170 ° C Composite granules are obtained by machine extrusion, and then the composite granules are cross-linked in water at 50-80°C for 0.5-1 hour, and the obtained product is air-dried.

[0027] Product performance: the oxygen index is 32; the smoke density is 98 under flameless conditions, the tensile strength is 15.0 MPa, and the elongation at break is 691%. All properties meet the industry standard YD / T 1113-2001 on the mechanical properties of wire and cable sheathing materials Provisions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com