All-solid-waste ecological cementing material

A technology of ecological glue and solid waste, which is applied in the field of building materials, solid waste treatment and resource utilization, can solve the problems of increasing the water demand of cementitious materials, low activity of nickel-iron slag, high alkali content, etc., and achieve the improvement of high consumption Energy and environmental pollution problems, improve early mechanical strength, promote dissociation and hydration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

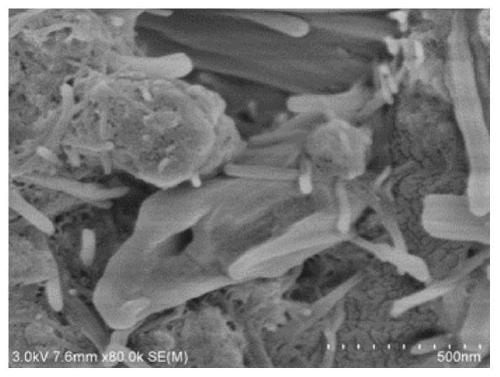

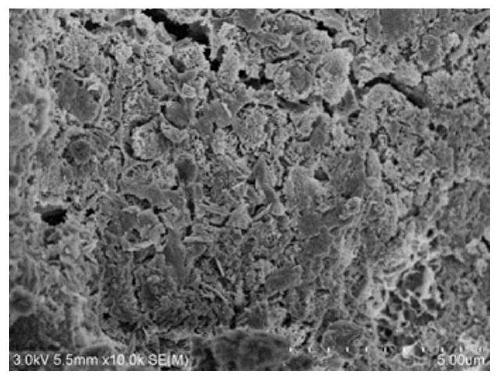

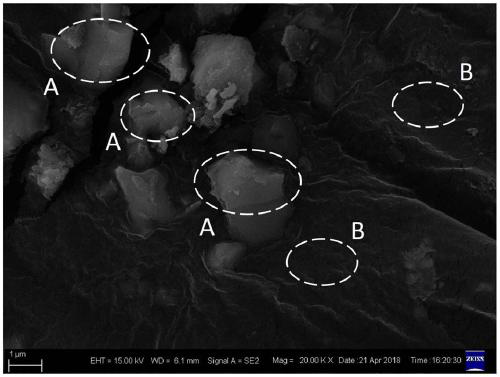

[0032] An all-solid waste ecological gelling material, including the raw materials in parts by mass as shown in the following table, wherein the gypsum is desulfurized gypsum, and the mass ratio of the chemical activator is 50% slaked lime and 50% limestone. The preparation method of the all-solid waste ecological gelling material is as follows: ball mill each solid waste and chemical activator until the specific surface area is greater than or equal to 400m 2 / kg, weigh the abrasive according to the ratio in Table 1 and mix it thoroughly for 30 minutes, dissolve the mixed water reducer and defoamer in a certain amount of water and add it to the mixture and stir for 30 minutes at a speed of 300r / min, stirring evenly Obtain clean slurry and maintain at room temperature for 28 days.

[0033] Table 1

[0034]

[0035]

[0036] The physical performance parameters determined in accordance with GB / T175 above are shown in Table 2. The curing time has a great influence on the ...

Embodiment 2

[0040]A kind of all-solid waste ecological cementitious material, comprises the raw material of mass parts as shown in table 3: 50 parts of ferronickel slag, 30 parts of slag, 10 parts of fly ash, 10 parts of steel slag, 5 parts of desulfurization gypsum, chemical activator 2.5 parts, 1 part of lignosulfonate water reducer, 1 part of defoamer, 24 parts of water and chemical activator, the mass ratio of chemical activator is shown in the following table, the preparation of all solid waste ecological gelling material The method is the same as above.

[0041] table 3

[0042]

[0043] The physical performance parameters determined in accordance with GB / T175 above are shown in Table 4. The addition of chemical activators can shorten the setting time to a certain extent and improve the compressive strength of the product. The ratio analysis of different chemical activators shows that limestone plays a leading role in the chemical activators. The larger the mass ratio of limest...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com