High-alkalinity pellets for blast furnace ironmaking and production method thereof

A blast furnace ironmaking and production method technology, applied in the field of iron and steel metallurgy, can solve problems such as pollution, inability to meet production requirements, energy consumption environment of pre-iron system, etc., to reduce pollution, improve energy consumption and environmental pollution, and low S content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

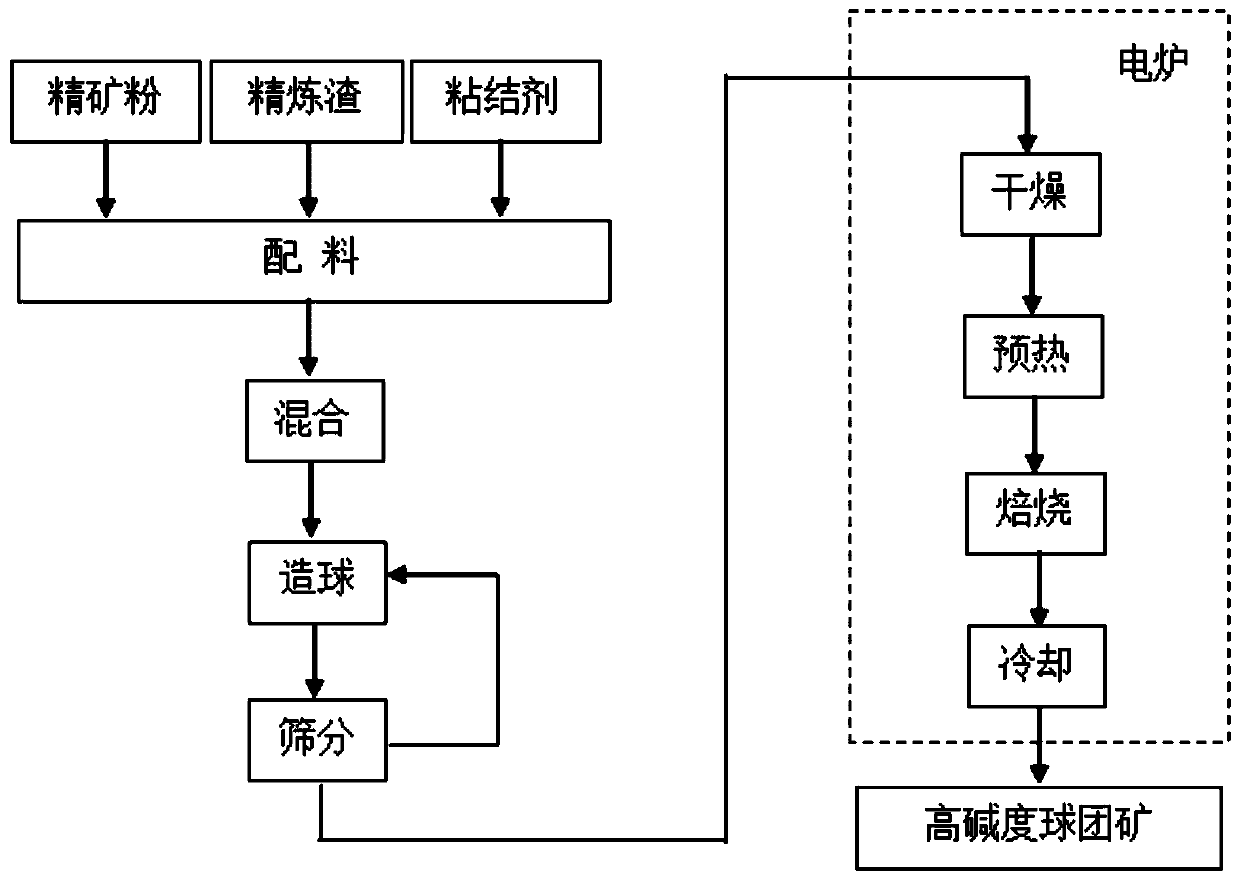

[0040] A kind of production method of high-basicity pellets for blast furnace ironmaking of the present embodiment, its technological process diagram is as follows figure 1 As shown, the specific steps are:

[0041] Step 1. Adding raw materials

[0042] Grind raw pelletizing raw material concentrate powder, refining slag and bentonite to make powder. The self-fluxing pellets in this embodiment are composed of the following components in mass percentage: concentrate powder 71.8%, refining slag 26.2% %, binder bentonite 2%, wherein the composition of concentrate powder, refining slag and bentonite in this embodiment is shown in Table 1-Table 3. The mixture was placed in an oven, dried at 110° C. for 2 hours, and then mixed until fully mixed to obtain the mixture.

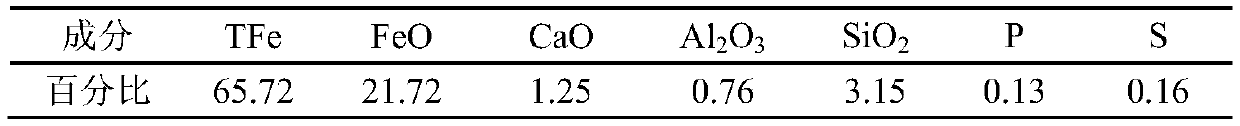

[0043] Table 1 Concentrate powder composition list (%)

[0044]

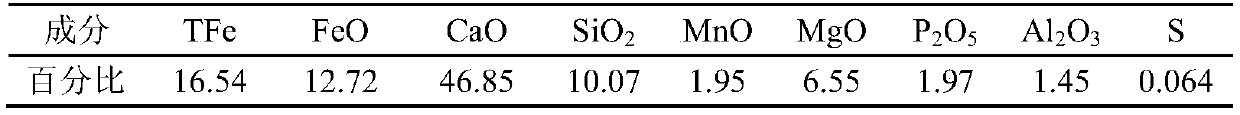

[0045] Table 2 Composition of refining slag (%)

[0046]

[0047] Table 3 Bentonite composition list (%)

[0048]

[0049] Step 2. Green ...

Embodiment 2

[0058] A kind of method of utilizing fine ore powder and refining slag to produce high alkalinity pellets of the present embodiment, its specific steps are:

[0059] Step 1. Adding raw materials

[0060] Grind raw pelletizing raw material concentrate powder, refining slag and bentonite to make powder. The self-fluxing pellets in this embodiment are composed of the following components in mass percentage: concentrate powder 60.5%, refining slag 37.5% %, binder bentonite 2%, the composition of concentrate powder, refining slag and bentonite is the same as embodiment 1 in the present embodiment. The mixture was placed in an oven, dried at 110° C. for 2 hours, and then mixed until fully mixed to obtain the mixture.

[0061] Step 2. Green ball formation

[0062] Pellet the well-mixed mixture on a disc pelletizer with a rotating speed of 7rad / min and a disc inclination of 45° to make green pellets, and screen out the pellets with a particle size of 10-16mm. Qualified pellets, the...

Embodiment 3

[0070] A kind of method of utilizing fine ore powder and refining slag to produce high alkalinity pellets of the present embodiment, its specific steps are:

[0071] Step 1. Adding raw materials

[0072] Grind raw pelletizing raw material concentrate powder, refining slag and bentonite to make powder. The self-fluxing pellets in this embodiment are composed of the following components in mass percentage: concentrate powder 76%, refining slag 22% %, binder 2%, wherein the composition of concentrate powder, refining slag and bentonite is shown in Table 4-Table 6 below. The mixture was placed in an oven, dried at 90° C. for 2 hours, and then mixed until fully mixed to obtain the mixture.

[0073] Table 4 Concentrate powder composition table (%)

[0074]

[0075] Table 5 Composition of refining slag (%)

[0076]

[0077] Table 6 Bentonite composition table (%)

[0078]

[0079] Step 2. Green ball formation

[0080] The well-mixed mixture is pelletized on a disc pelle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com