Multilayer composite negative electrode material, preparation method thereof, negative electrode sheet and lithium battery

A negative electrode material, multi-layer composite technology, applied in the direction of negative electrode, battery electrode, secondary battery, etc., to achieve the effect of improving the first efficiency, improving the cycle performance, and improving the specific capacity of the negative electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

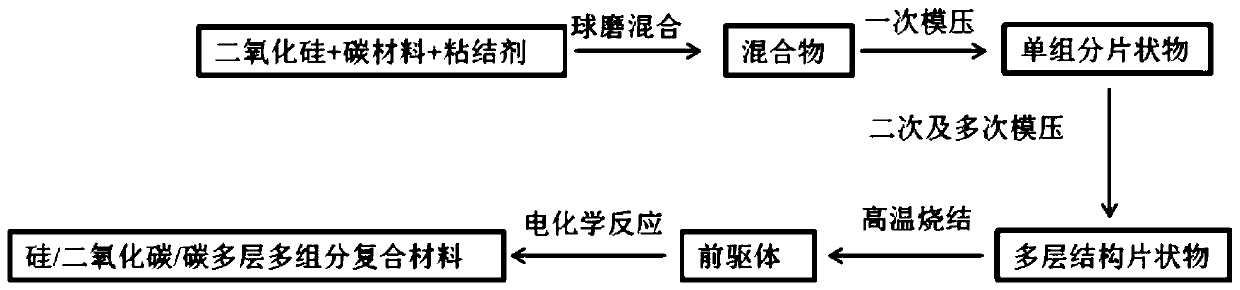

[0030] Such as figure 1 Shown, the steps of the preparation method of silicon / silicon dioxide / carbon multilayer composite material of the present invention are as follows:

[0031] Multi-layer precursor preparation step: using silicon, silicon dioxide, carbon, and carbon as initial raw materials to prepare the first precursor layer, the second precursor layer, and the third precursor layer, wherein the first precursor layer is made of The silicon layer pressed from pure silicon is preferably nanowire silicon, the second precursor layer is a carbon layer pressed from carbon material, preferably nano-carbon material, and the third precursor layer is made of silicon dioxide and carbon material. It is a silicon dioxide / carbon mixed layer formed after mixing the initial raw materials, preferably using nano-polycrystalline silicon dioxide and nano-carbon materials; according to the ratio of the target product, the amount of materials in each layer is added, and an appropriate amount...

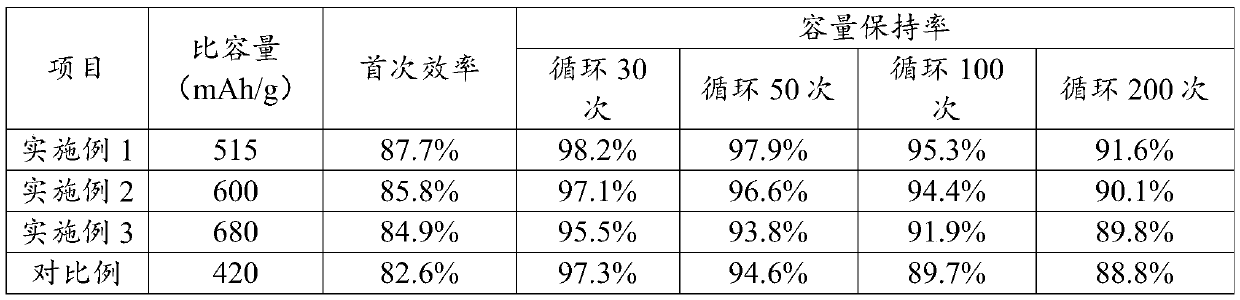

Embodiment 1

[0038]Mix 0.209g of silicon dioxide and 1.800g of artificial graphite, add 0.05g of polyvinyl butyral (binder), and then ball mill evenly, and the obtained uniform powder is used as silicon / silicon dioxide layer precursor powder , the SiO 2 / C mixed powder is pressed into flakes, and 0.200g of pure silicon and 0.900g of pure carbon powder are also pressed into flakes respectively, and then according to Si|SiO 2 / C|C sequentially molded into a multi-layer structure sheet, then put the mixed sheet into a sintering furnace, fill it with argon, heat up to 680°C and sinter for 13 hours to prepare a multi-layer precursor;

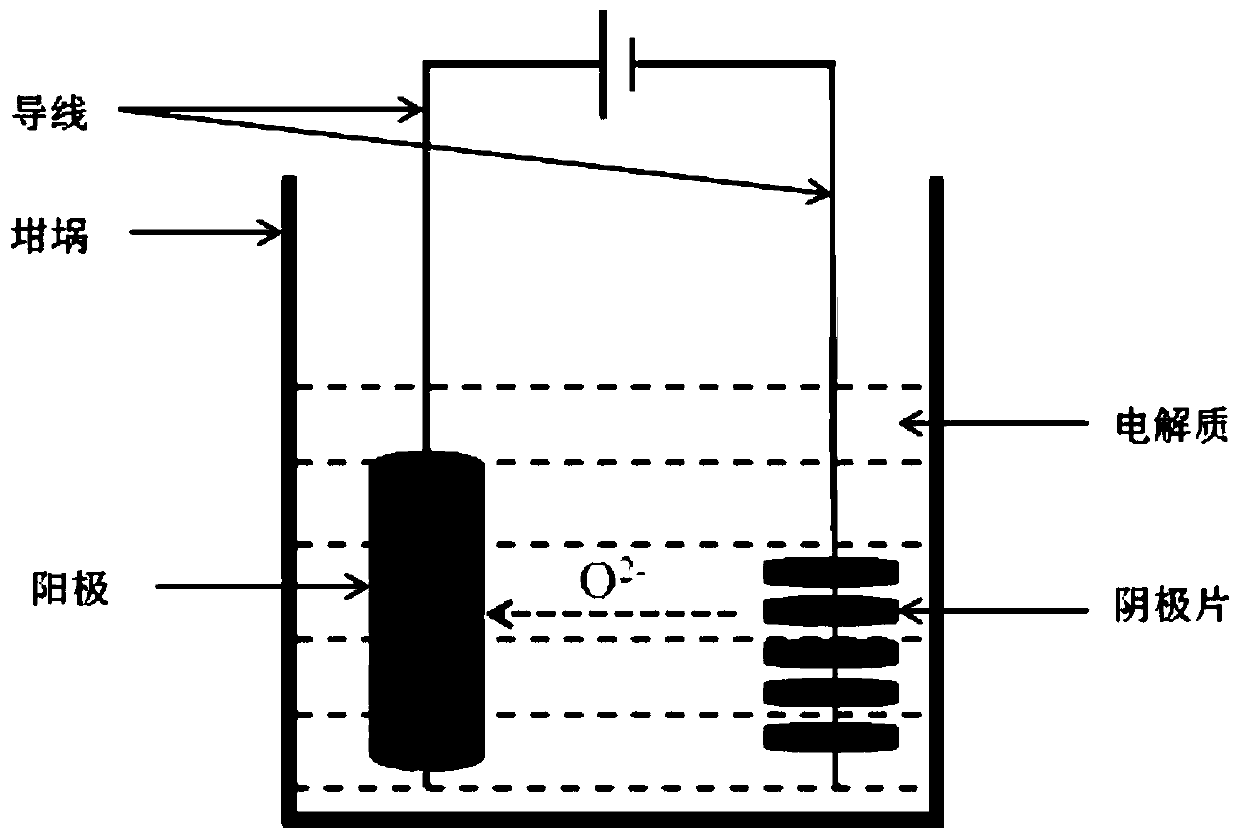

[0039] The multi-layer precursor is connected and drawn out with an electronically conductive material as the cathode, and the high-purity graphite rod is used as the anode. In the electrolytic furnace, the corundum crucible is used as the electrolytic cell, and 380 grams of calcium chloride (molten salt) is weighed and put into the ceramic crucible. Introduce a...

Embodiment 2

[0042] Mix 0.618g of silicon dioxide and 2.600g of artificial graphite, add 0.18g of polyvinyl butyral, and then ball mill evenly. The uniform powder obtained is used as silicon / silicon dioxide layer precursor powder, and SiO 2 / C mixed powder is pressed into flakes, and 0.800g of pure silicon and 0.200g of pure carbon powder are also pressed into flakes respectively, and then according to SiO 2 |SiO 2 / C|C sequentially molded into a sheet with a three-layer structure, then put the mixed sheet into a sintering furnace, fill it with argon, heat up to 850°C and sinter for 8 hours to prepare a multi-layer precursor;

[0043] Connect the multi-layer precursor with an electronically conductive material as the cathode, use the high-purity graphite rod as the anode, and use the stainless steel crucible as the electrolytic cell in the electrolytic furnace, weigh 400 grams of calcium chloride into the stainless steel crucible, and pour it into the crucible resistance furnace Put argon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com