Low-viscosity turpentine-based monoterpene vinyl ester resin monomer and preparation method and application thereof

A technology of vinyl ester resin and monoterpene-based carboxylic acid, which is applied in the field of preparation of bio-based low-viscosity turpentine-based monoterpene vinyl ester resin, can solve the problem of limiting wide application, environmental pollution, yellowing and chalking of cured products and other problems, to achieve the effect of ensuring strength and durability, saving conventional energy, and easing reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

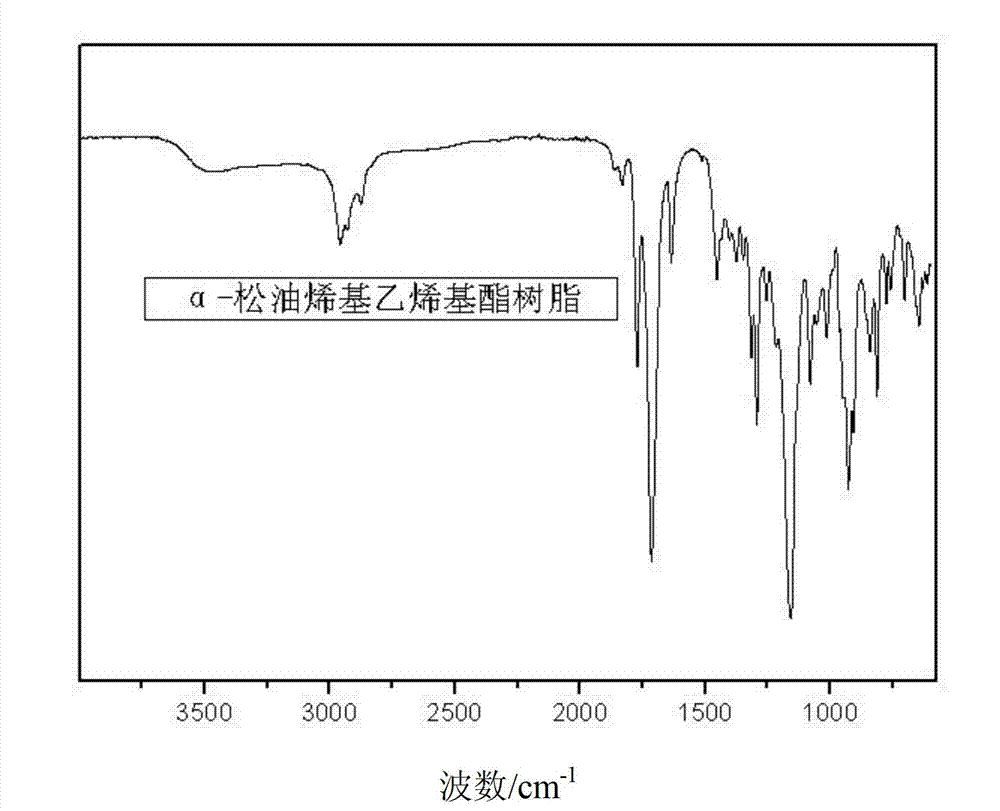

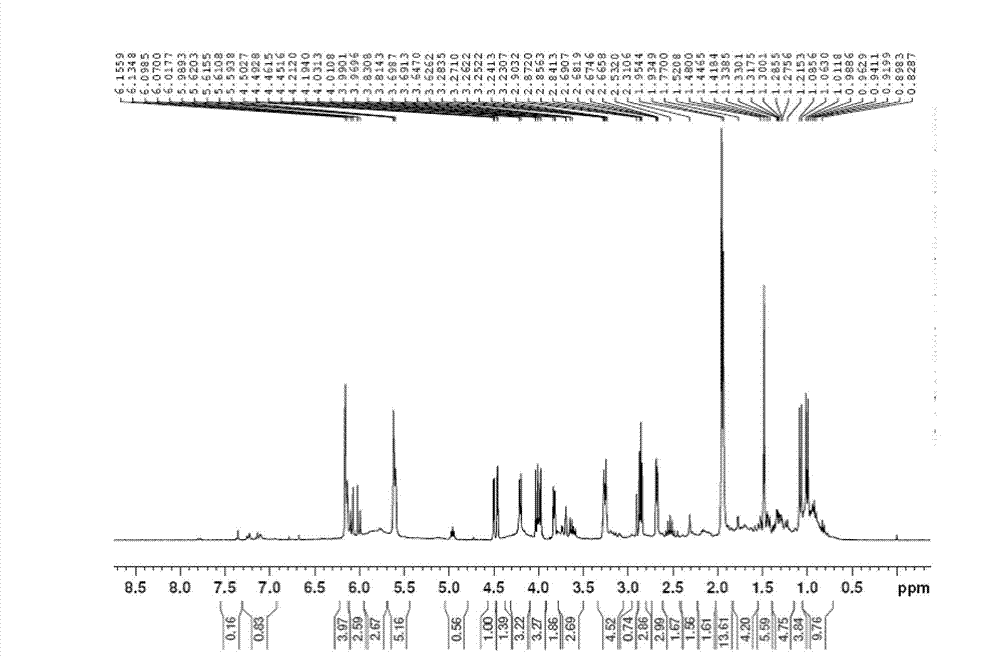

Embodiment 1

[0047] Under a nitrogen atmosphere, put a certain amount of acrylic acid in a reaction flask, stir and heat to control the temperature to 45°C, then add α-phellandrene monomer dropwise at a molar ratio of 1.2:1 to acrylic acid, and then add the total mass 0.25% of the catalyst diaryl prolinol silicon ether, heated to 60 ° C, reacted for 2 hours, and used a rotary evaporator to remove excess unreacted α-phellandrene monomer to obtain monoterpene-based carboxylic acid; under nitrogen atmosphere, Add the solvent benzene with a mass ratio of 1.5:1 to the prepared monoterpene-based carboxylic acid, stir and heat to control the temperature to 60°C, add dropwise methacrylic acid shrinkage at a molar ratio of 1.0:1 to the monoterpene-based carboxylic acid Glycerides; then add 0.10% of total mass of hydroquinone, add 0.50% of total mass of benzyltrimethylammonium chloride, then raise the temperature to 80°C, and reflux for 2 h to obtain the intermediate product monoterpene unsaturated ...

Embodiment 2

[0049] Under a nitrogen atmosphere, put a certain amount of maleic anhydride in a reaction flask, stir and heat to control the temperature to 60°C, and then add α-pine oil dropwise at a molar ratio of 1.2:1 to maleic anhydride Then add 2.5% catalyst triethylamine of the total mass, raise the temperature to 150°C, react for 6h, use rotary evaporator to remove excess unreacted α-phellandrene monomer to obtain monoterpene-based carboxylic anhydride; Under the atmosphere, add the solvent carbon tetrachloride with a mass ratio of 2.5:1 to the prepared monoterpene-based carboxylic anhydride, stir and heat to control the temperature to 80°C, and the molar ratio to the monoterpene-based carboxylic anhydride is 2.2:1 Add glycidyl methacrylate dropwise; then add 0.25% of the total mass inhibitor 2,5-di-tert-butylhydroquinone, add 2.5% of the total mass catalyst N,N-dimethylbenzylamine, Then raise the temperature to 120°C and reflux for 4 hours to obtain the intermediate product monoterp...

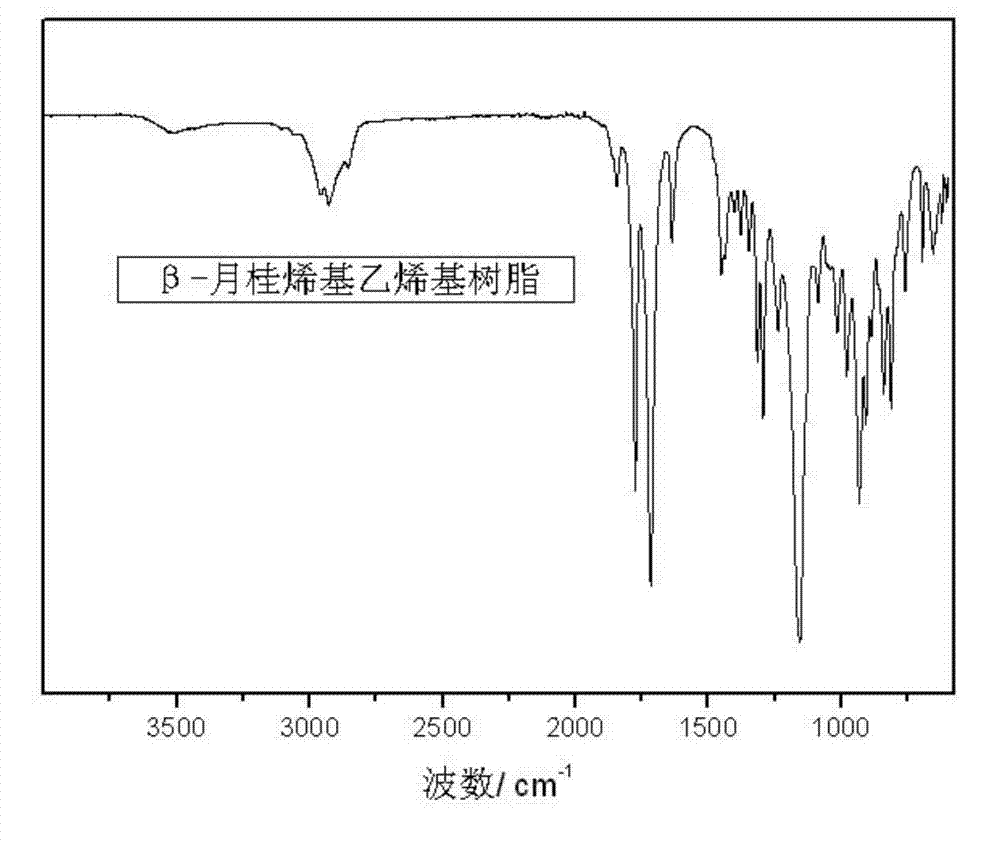

Embodiment 3

[0051] Under a nitrogen atmosphere, put a certain amount of cinnamic acid in a reaction flask, stir and heat to control the temperature to 50°C, then add β-phellandrene monomer dropwise at a molar ratio of 1.05:1 to cinnamic acid, and then add The catalyst titanium tetrachloride with a total mass of 0.5% was heated up to 75° C., reacted for 2 hours, and the excess unreacted β-phellandrene monomer was removed by a rotary evaporator to obtain a monoterpene-based carboxylic acid; under a nitrogen atmosphere, the prepared Add solvent dichloromethane with a mass ratio of 2:1 to the obtained monoterpene-based carboxylic acid, stir, heat and control the temperature to 70°C, and add methyl Glycidyl acrylate; Then add 0.15% of total mass inhibitor 2-tert-butylhydroquinone, add 0.75% of total mass catalyst triethylbenzyl ammonium chloride, then be warming up to 100°C, backflow for 3 h, the intermediate product monoterpene-based unsaturated diglyceride was obtained; under a nitrogen atmo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com