Hydrocracking method for producing heavy naphtha from high-nitrogen stock

A heavy naphtha, hydrocracking technology, applied in the petroleum industry, hydrotreating process, processing hydrocarbon oil, etc., can solve problems such as the limitation of naphtha yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

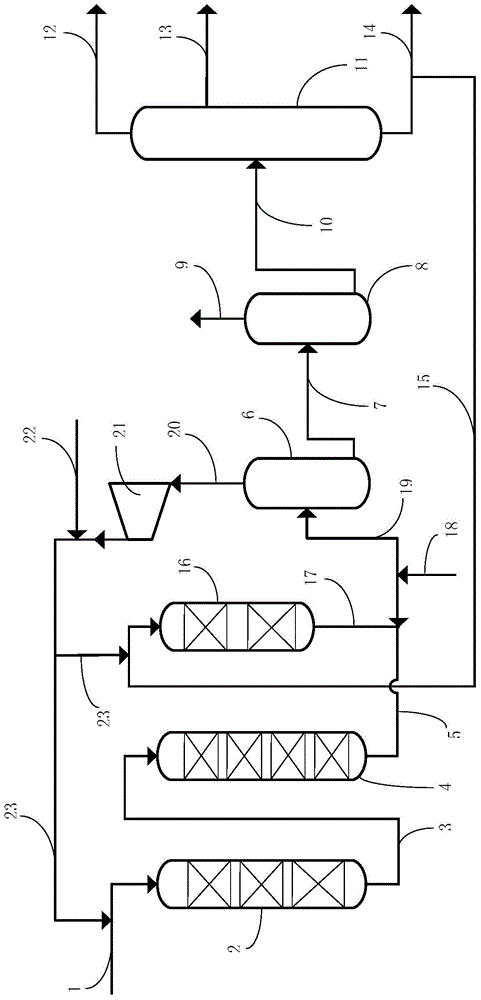

Method used

Image

Examples

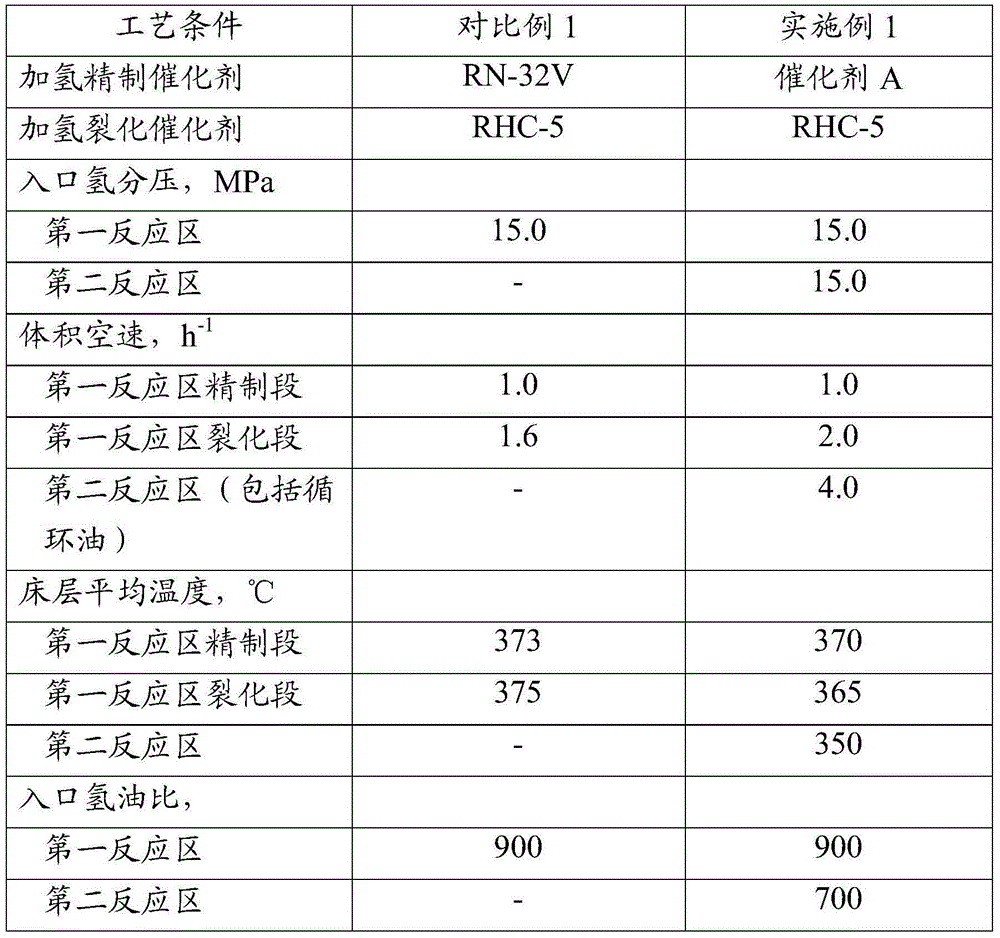

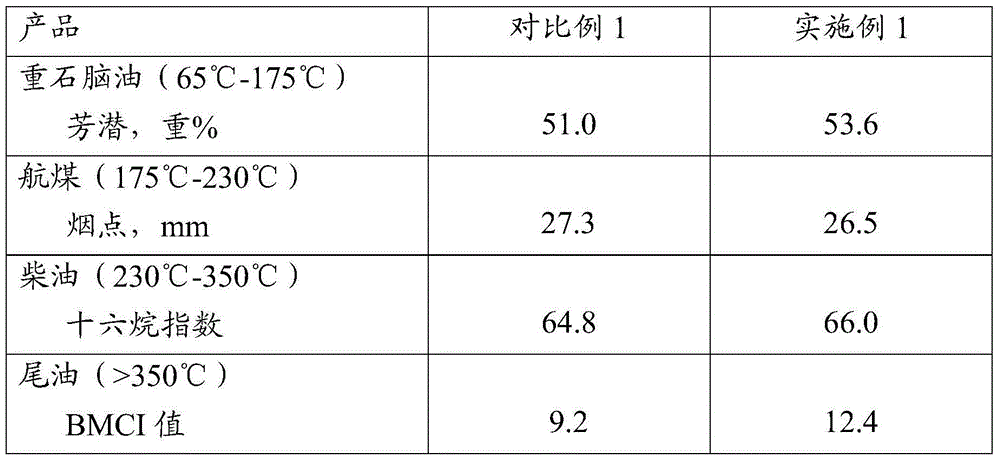

Embodiment 1

[0081] In this example, the same feedstock oil as in Comparative Example 1 was used, and the hydrocracking test was carried out with the hydrotreating catalyst A and the process flow provided by the present invention. The experimental results are listed in Table 2-Table 4.

[0082] As can be seen from the data in the table, under the condition of producing the same amount of heavy naphtha, compared with the one-pass flow process, the method provided by the present invention requires less hydrogen consumption and higher aroma potential of heavy naphtha.

Embodiment 2

[0084] In this example, mixed feed oil B containing VGO and CGO was used to carry out a hydrocracking test with the catalyst and process flow provided by the present invention, and the experimental results are listed in Table 5-Table 7.

[0085] As can be seen from the data in the table, the yield of tail oil can be reduced to the minimum under the condition of hydrogen partial pressure of 13.0MPa by adopting the method provided by the present invention, which is 0; and the maximum production obtains light naphtha and heavy naphtha The oil product has a total yield of more than 89% by weight. It shows that this method can produce the largest amount of naphtha under relatively moderate conditions.

[0086] Table 1. Raw oil properties

[0087] Raw oil name

A

B

Density, g / cm 3

0.921

0.930

S, weight%

2.5

2.7

N, μg / g

1800

2400

Distillation range (D-1160), ℃

initial boiling point

323

3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com