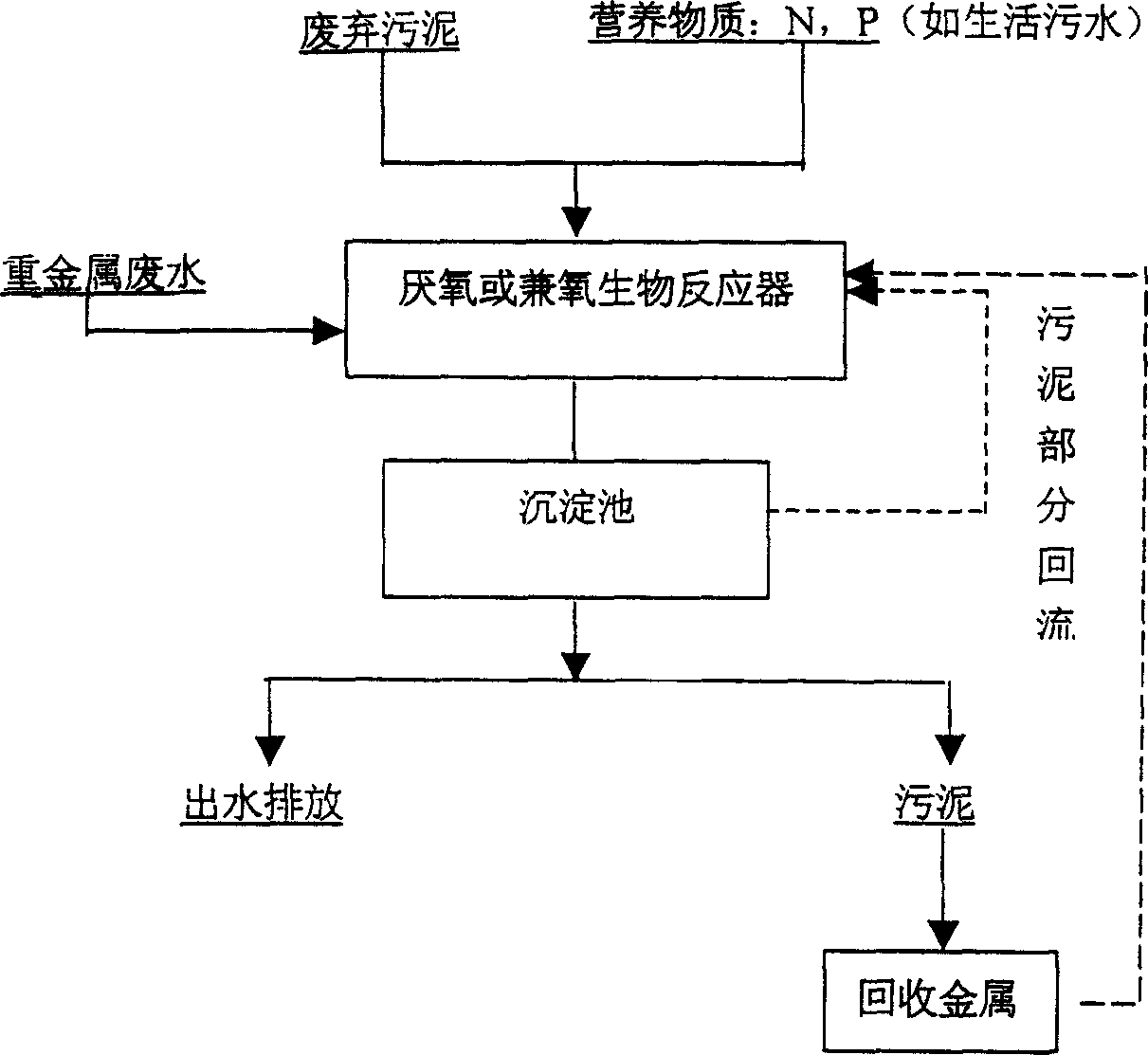

Method of treating waste water containing heavy metal with waste sludge as carrier

A waste sludge and heavy metal technology, applied in water/sludge/sewage treatment, water/sewage treatment, adsorbed water/sewage treatment, etc., can solve problems such as long operation period, harsh operating conditions, and unstable process, and achieve The effect of short operation period, low cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Firstly, the activated sludge from the domestic sewage plant and a very small amount of culture solution containing inducing factors are added to the anaerobic bioreactor, and the directional activation culture of the activated sludge is carried out at 28-35°C. After the activity of the sludge is activated, the bacterial flora After growth and reproduction, heavy metal wastewater with a pH value of 3 and a concentration of 435.95 mg / L from a smelting enterprise is discharged into the reactor and fully mixed with the activated sludge. After 1 to 2 hours of treatment, the main Heavy metal ions Zn 2+ From the initial 413.36mg / L to 4.1mg / L, other heavy metal ions cannot be detected, and the physical and chemical indicators of the wastewater after treatment meet the national discharge standards. The treatment effect of heavy metal wastewater is shown in Table 1.

[0028] Physical and chemical indicators of wastewater

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com