Waste polyurethane foam aminolysis recycling method

A foam aminolysis and polyurethane technology, applied in the field of polyurethane, can solve the problems of polyurethane foam pollution and other problems, and achieve the effect of good strength and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: A method for recycling waste polyurethane foam by aminolysis, adding 500 grams of triethanolamine to a 1500 ml three-necked bottle with a stirring, heating and temperature control device, and adding 2.5 grams of tetrabutyl titanate, heating After reaching 150-250°C, cut 500 grams of recycled polyurethane waste (hard polyurethane foam) into small pieces, slowly add it to triethanolamine, and stir while heating. After about 12 hours, all the foam will dissolve, and the vacuum will remove the low After 30 minutes, 940 g of recovered product A was obtained.

Embodiment 2

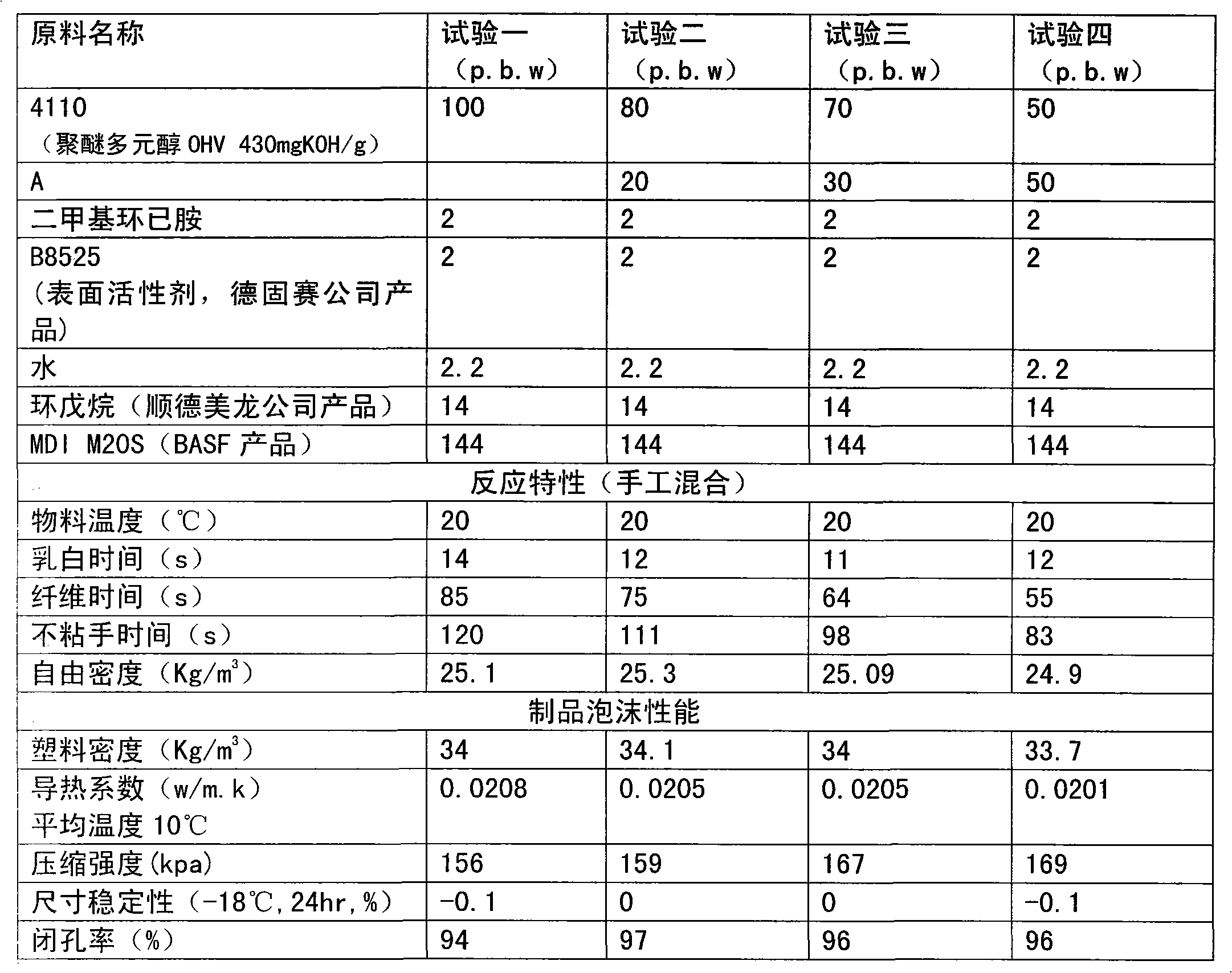

[0020] Example 2: A method for recycling waste polyurethane foam by aminolysis. The recyclate obtained in Example 1 and A obtained above was formulated into a combined polyether for rigid polyurethane foam and a foaming test was carried out. The results are shown in Table 1.

[0021] Table one: embodiment 2 test result

[0022]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com