Preparation method of aluminum alloy resin composite body and aluminum alloy resin composite body

A technology of aluminum alloys and composites, applied in chemical instruments and methods, metal layered products, anodic oxidation, etc., can solve problems such as pollution, achieve good structural strength, and be conducive to industrial production and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

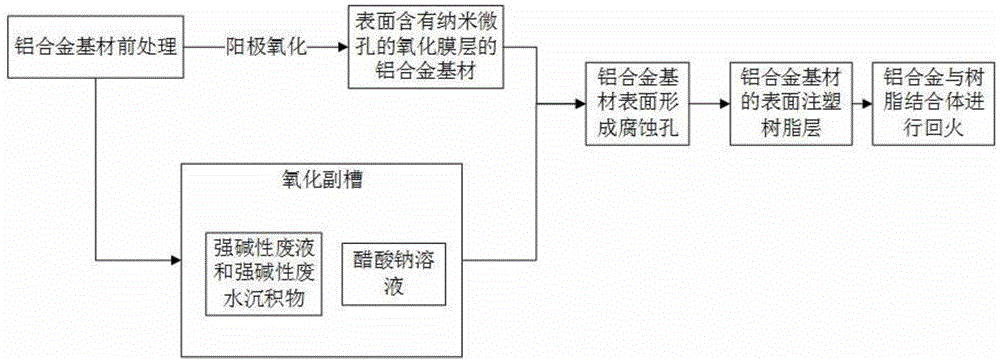

[0027] Examples, see figure 1 , figure 2 , the preparation method of the aluminum alloy resin composite provided in this embodiment is characterized in that it comprises the following steps:

[0028] S1, the aluminum alloy substrate is subjected to the pretreatment of degreasing, water washing, neutralization, water washing, alkali etching, water washing, neutralization, and water washing. The aluminum alloy base material of the film layer; in the pretreatment, the alkali etching is to soak the aluminum alloy base material in the sodium hydroxide solution to obtain the strong alkaline waste water sediment of sodium metaaluminate and the strong alkaline waste water of sodium hydroxide liquid;

[0029] S2, connect the strong alkaline waste liquid and strong alkaline waste water deposits produced in the alkaline etching tank in the pretreatment process of step S1 with the secondary oxidation tank and make the strong alkaline waste liquid and strong alkaline waste water deposit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com