Straw pulp black liquor concentration process

A straw-pulp black liquor and process technology, which is applied to the regeneration of concentrated waste liquor and lye, can solve the problems of high cost, high activation energy and high energy consumption, and achieve the effects of less energy consumption, wide application and easy treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

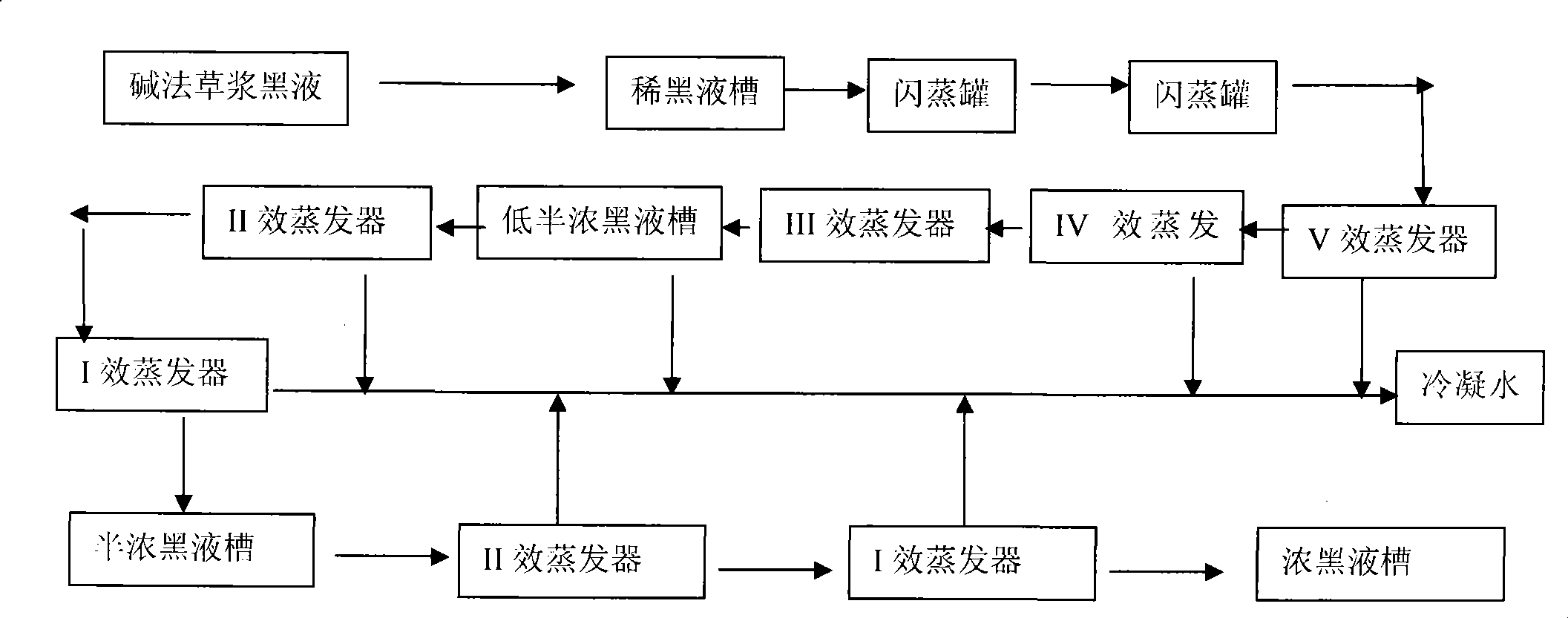

[0048] Alkaline straw pulp black liquor has a fiber content of 200mg / L, a Baume degree of 2, a solid content of 4%, and a pH of 9; the temperature is 60°C, and the straw pulp black liquor is flashed in two steps to obtain flashed straw pulp The black liquor and flash steam are passed into the III-effect and IV-effect evaporators respectively.

[0049] The straw pulp black liquor after flash evaporation is subjected to five-effect evaporation. The five-effect evaporation process is countercurrent multi-effect evaporation. The straw pulp black liquor after flash evaporation flows in from the V effect, and the heating steam flows in from the I effect. After the black liquor is heated and evaporated by the V effect, IV effect and III effect in turn, it becomes a low-semi-concentrated black liquor. The liquid is again heated and evaporated through the II effect and the I effect in turn, and becomes thick black liquor.

[0050] The above-mentioned heating steam has a temperature of...

Embodiment 2

[0058] Alkaline straw pulp black liquor fiber content 100mg / L, Baume degree 9, solid content = 15%, pH = 13

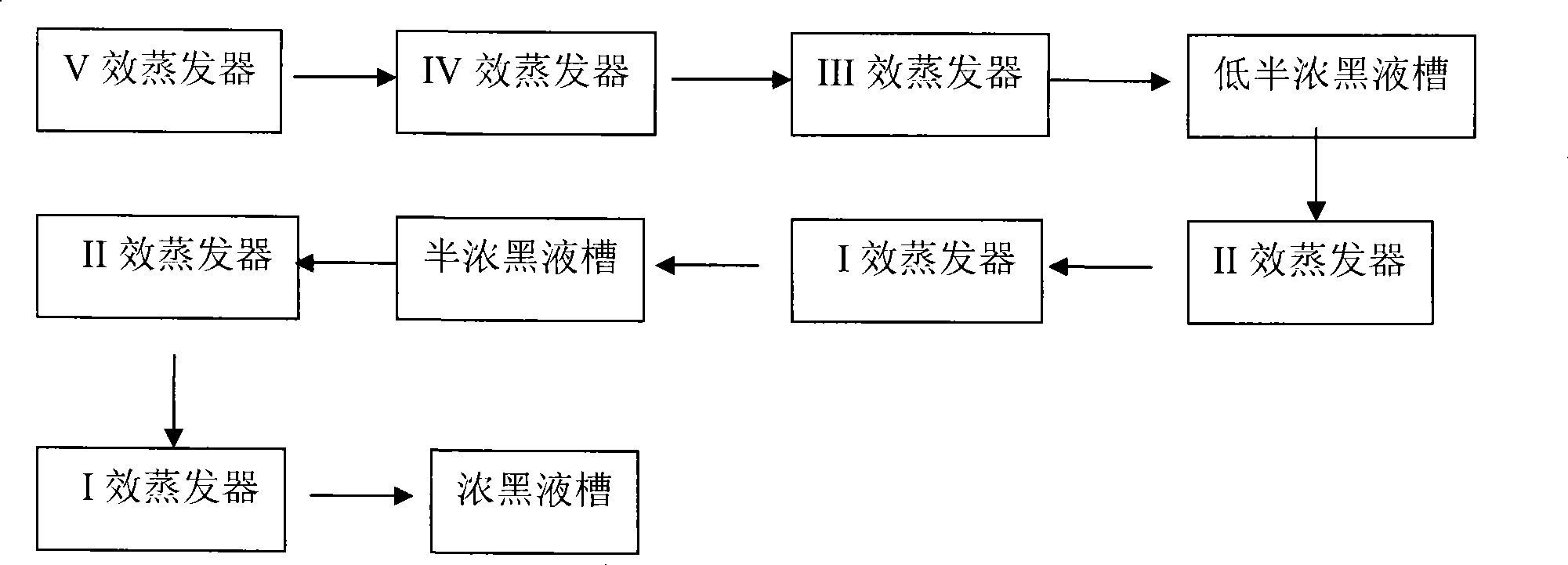

[0059] The soda-process straw pulp black liquor is directly subjected to five-effect evaporation. The five-effect evaporation process is countercurrent multi-effect evaporation. The straw pulp black liquor flows in from the V effect, and the heating steam flows in from the I effect. The straw pulp black liquor passes through the V effect and the IV effect in turn. , After heating and evaporating in effect III, it becomes low-semi-concentrated black liquor, and after heating and evaporating through effect II and I, the low-semi-concentrated black liquor turns into semi-concentrated black liquor, and the semi-concentrated black liquor passes through effect II and I again Efficient heating and evaporation, turning into thick black liquor. .

[0060] The above-mentioned heating steam has a temperature of 200°C and a pressure of 0.4MPa. After flowing in from the I effect, ...

Embodiment 3

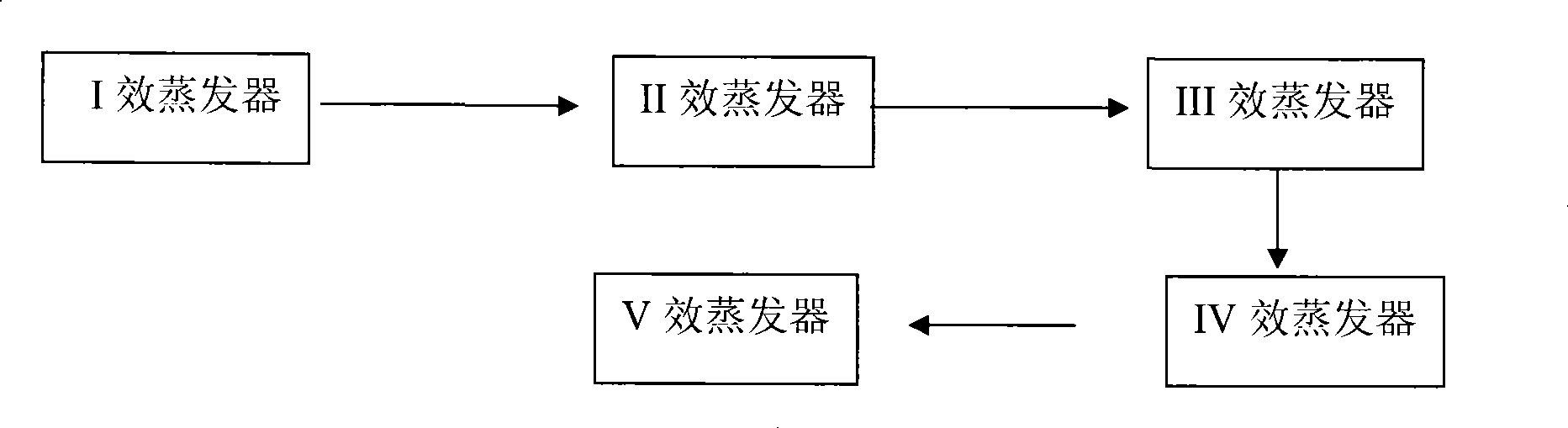

[0068] Alkaline straw pulp black liquor has a fiber content of 50mg / L, a Baume degree of 6, a solid content of 10%, and a pH of 10; at a temperature of 70°C, the straw pulp black liquor is subjected to one-step flash evaporation to obtain the straw pulp black liquor after flash evaporation. liquid. The flashed steam is passed into the III effect evaporator.

[0069] The straw pulp black liquor after flash evaporation is subjected to five-effect evaporation. The five-effect evaporation process is countercurrent multi-effect evaporation. The straw pulp black liquor after flash evaporation flows in from the V effect, and the heating steam flows in from the I effect. After the black liquor is heated and evaporated by the V effect, IV effect and III effect in turn, it becomes a low-semi-concentrated black liquor. The liquid is again heated and evaporated through the II effect and the I effect in turn, and becomes thick black liquor.

[0070] The above-mentioned heating steam has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com