Patents

Literature

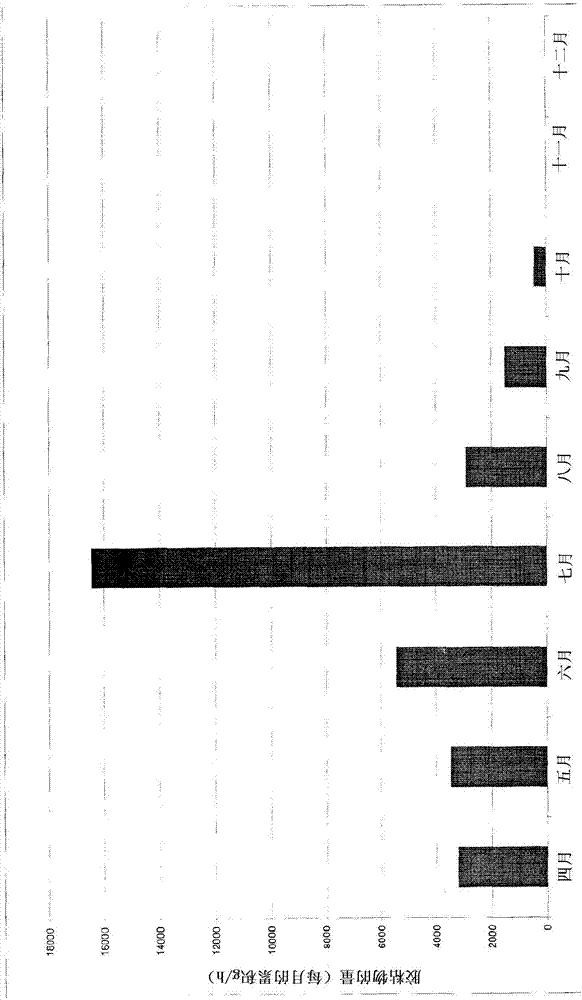

32results about "Pulp deposit formation/corrosion prevention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

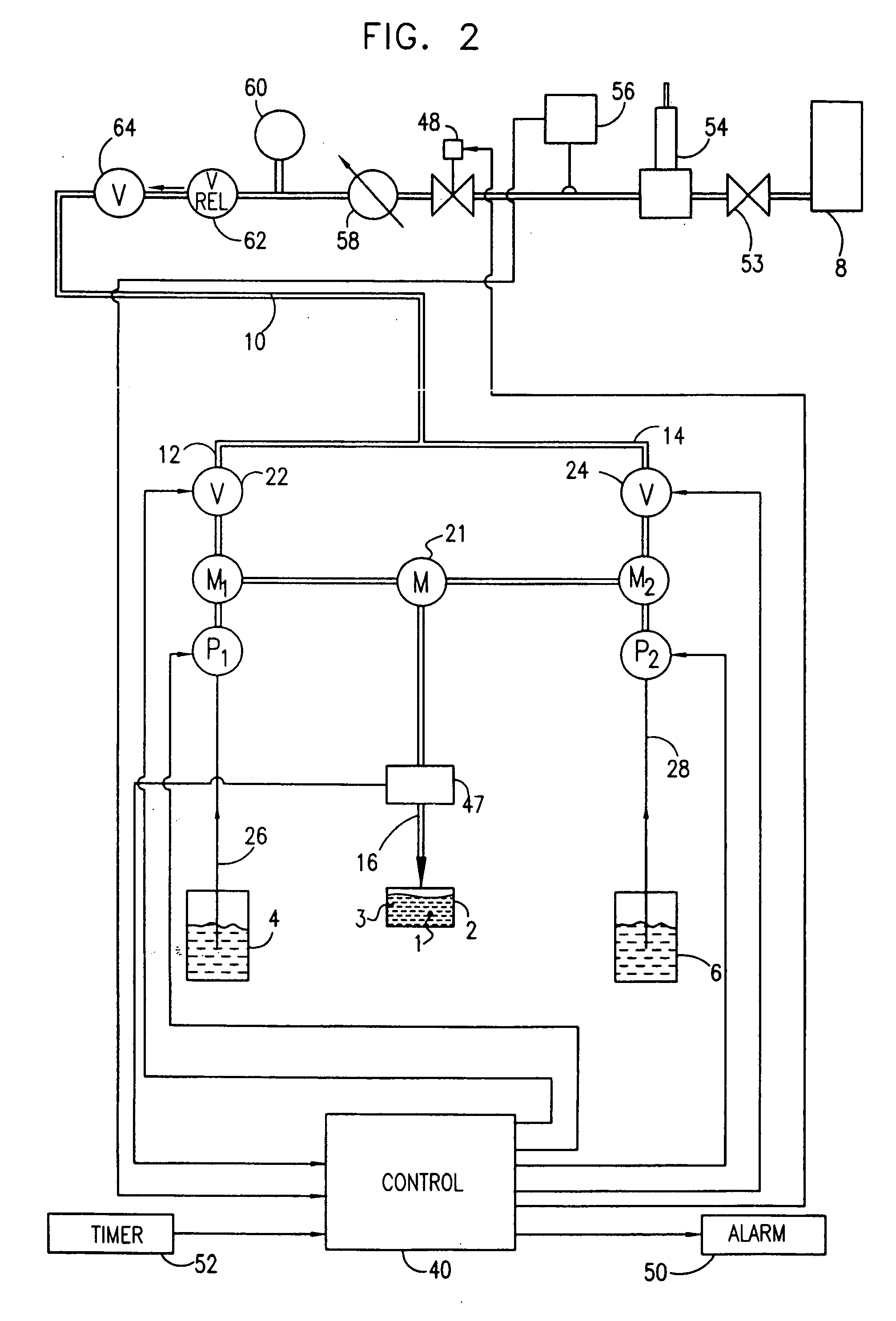

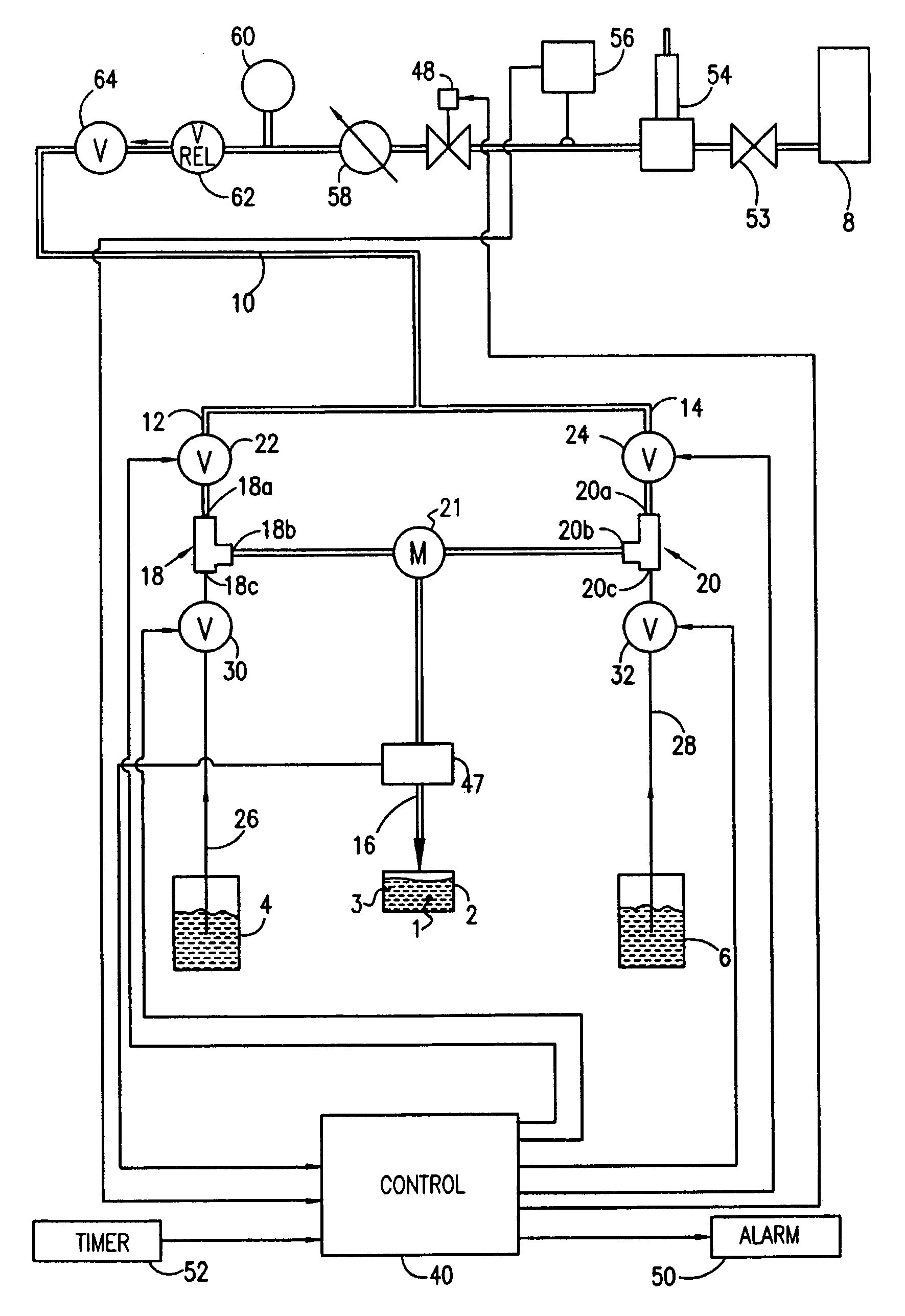

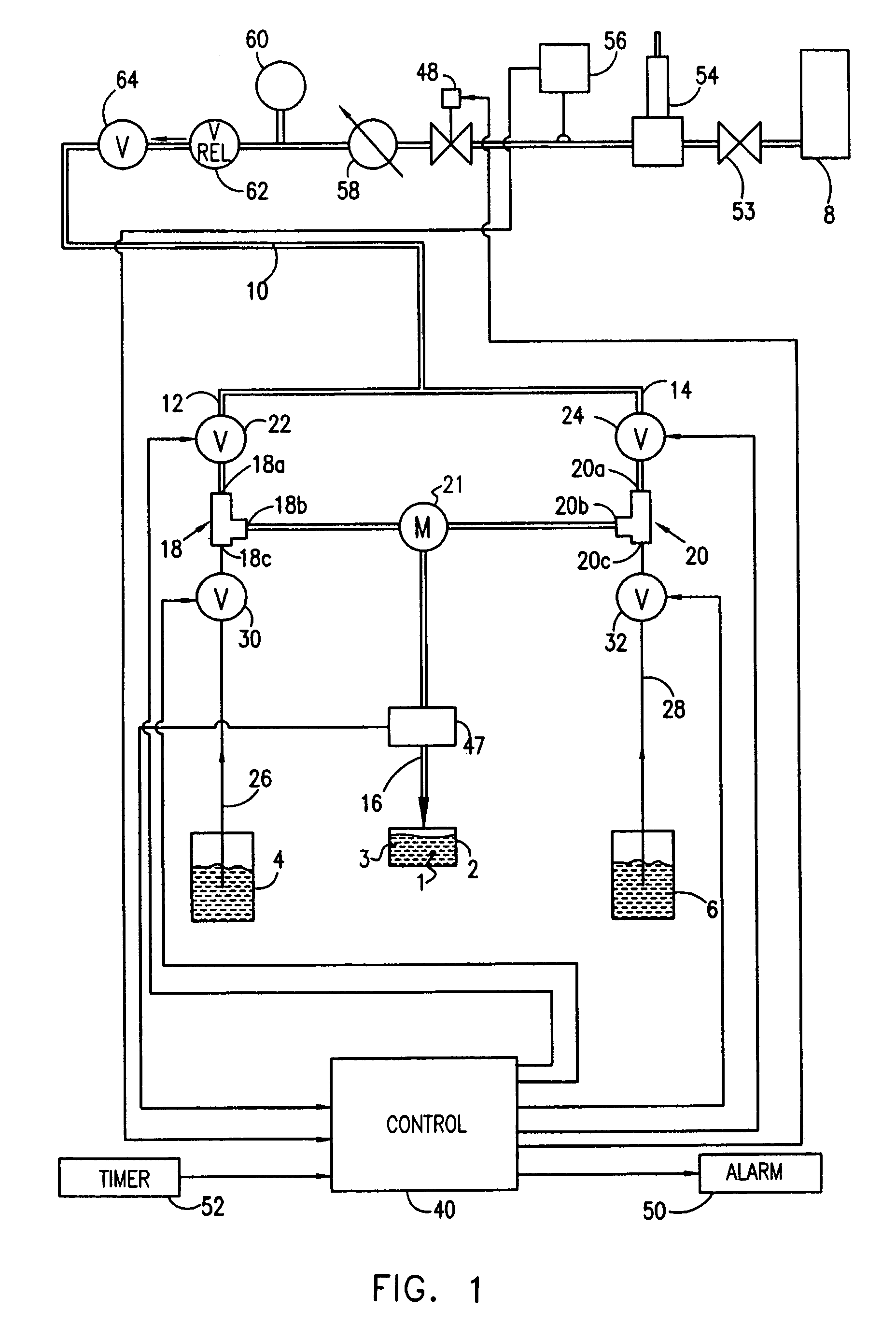

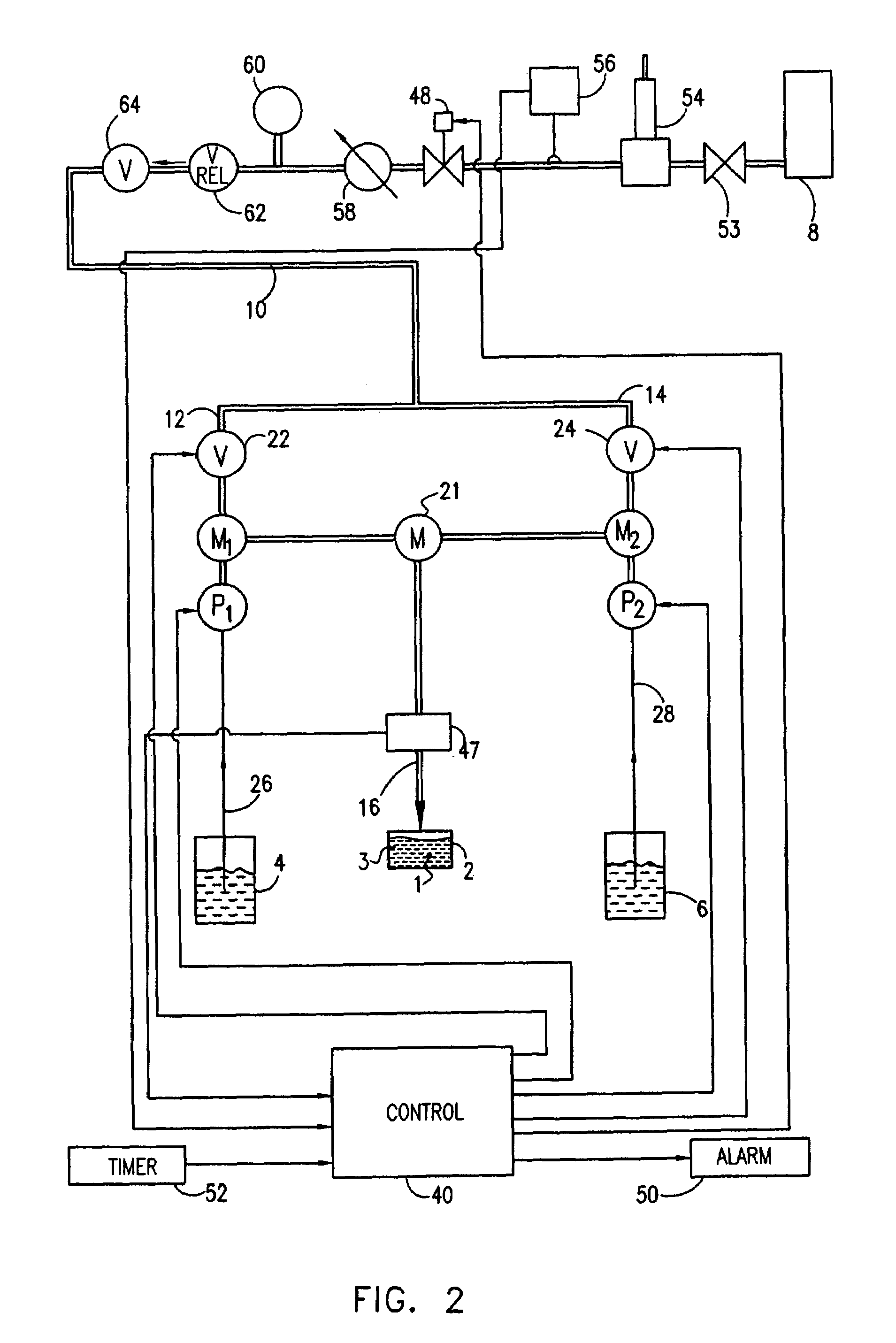

Control of development of biofilms in industrial process water

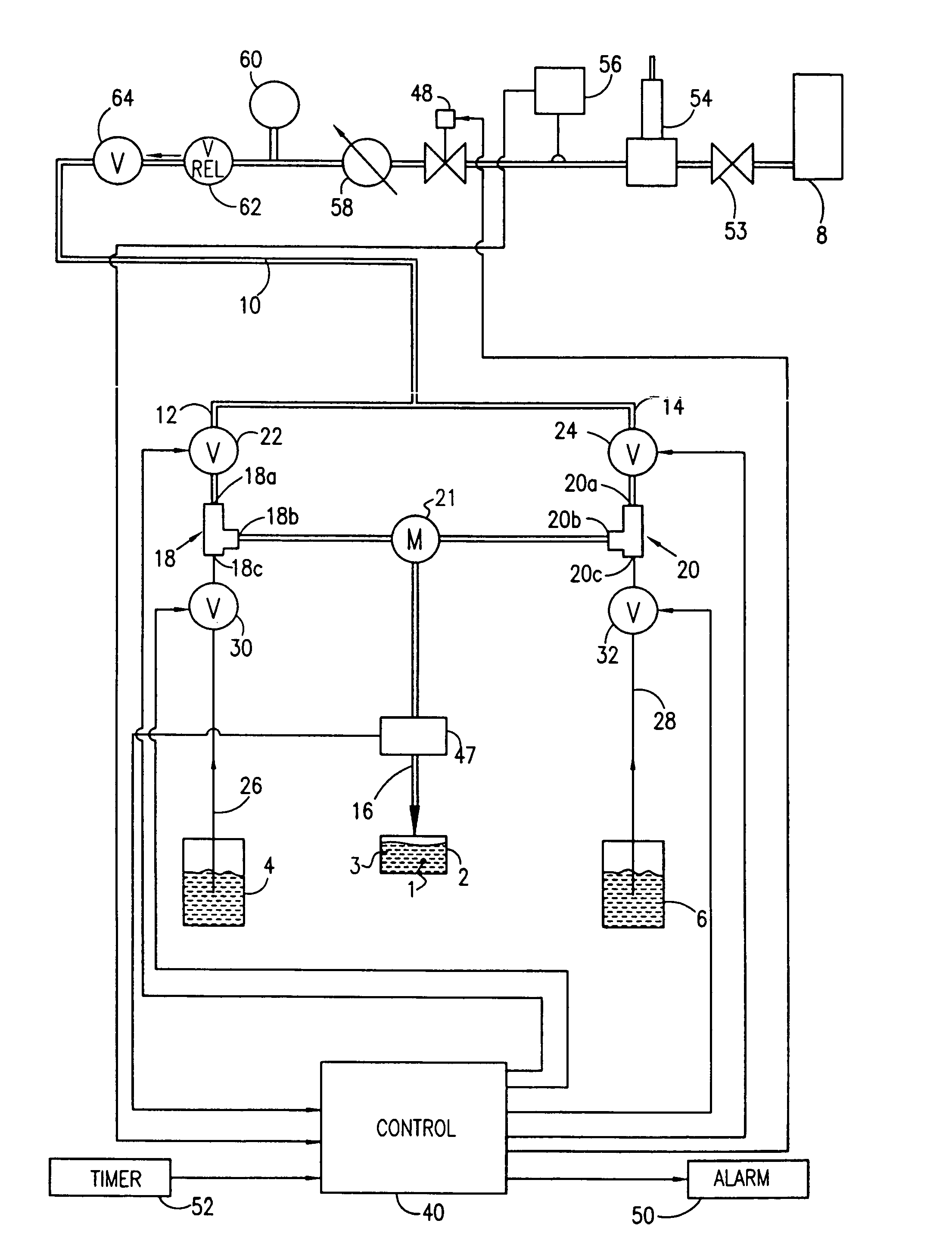

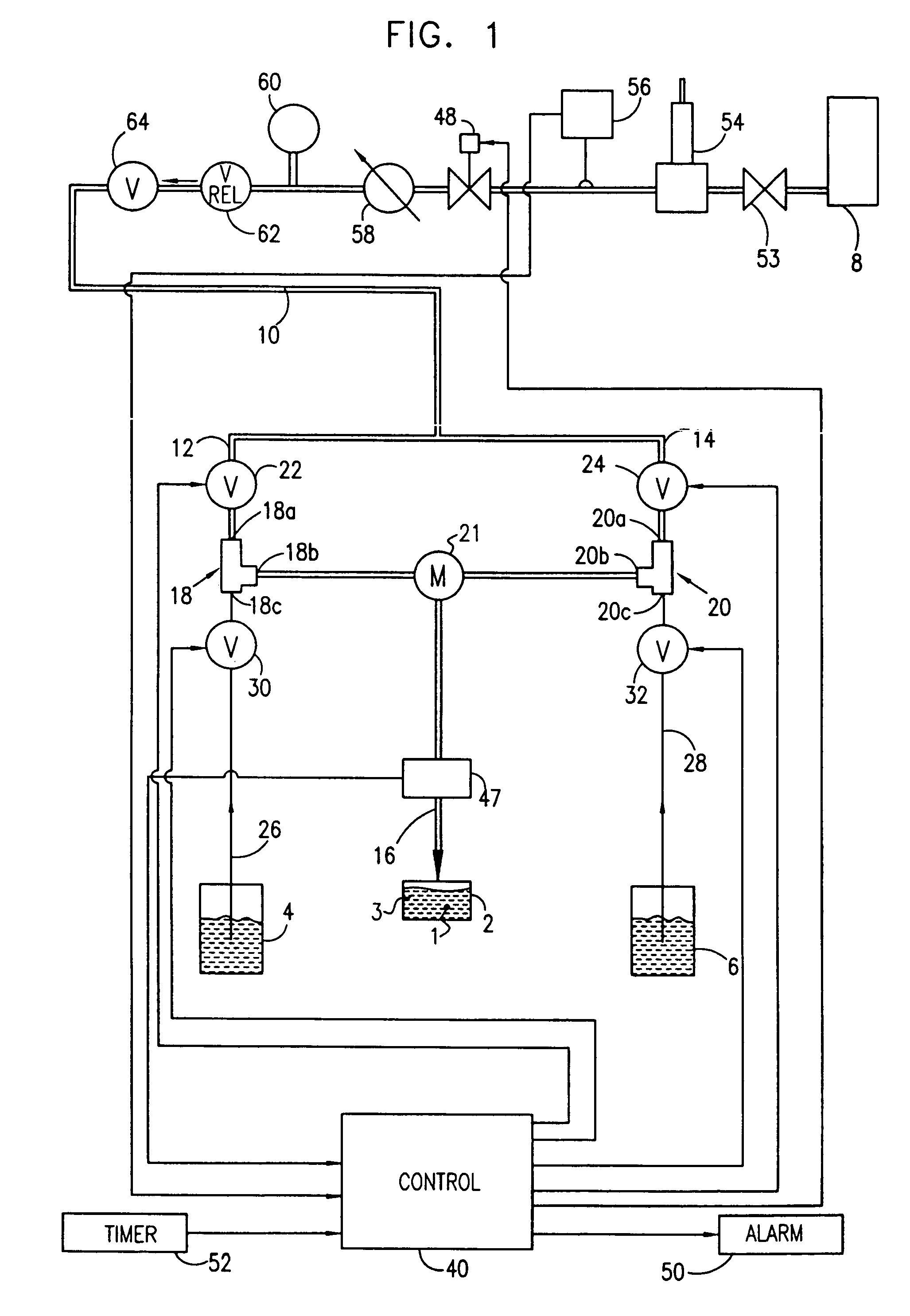

There is provided a method of inhibiting the development of a biofilm adjacent a surface, the method comprising intermittently applying a biofilm inhibiting substance to a collection of microorganisms having biofilm developing potential. There is also provided a method of inhibiting the development of a biofilm adjacent a surface, the method comprising inhibiting the biofilm developing potential of a collection of microorganisms without completely eradicating said collection of microorganisms. Also provided are a system for inhibiting the development of a biofilm, and a method and system for inhibiting the production of an enzyme by a collection of microorganisms.

Owner:A Y LAB

Control of development of biofilms in industrial process water

InactiveUS7189329B2Avoid developmentBiocideWater/sewage treatment by substance additionMicroorganismBiochemical engineering

Owner:A Y LAB LTD

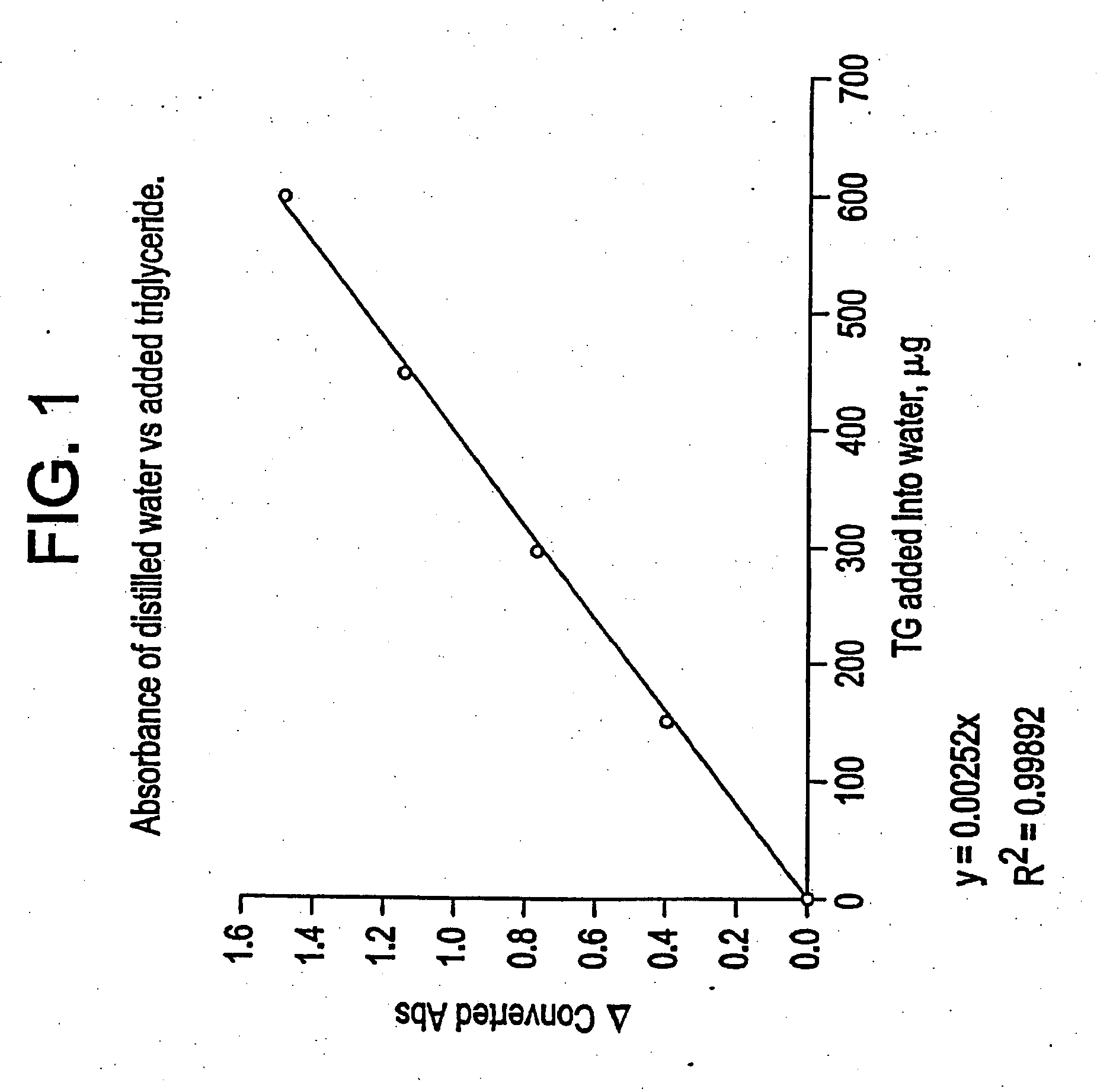

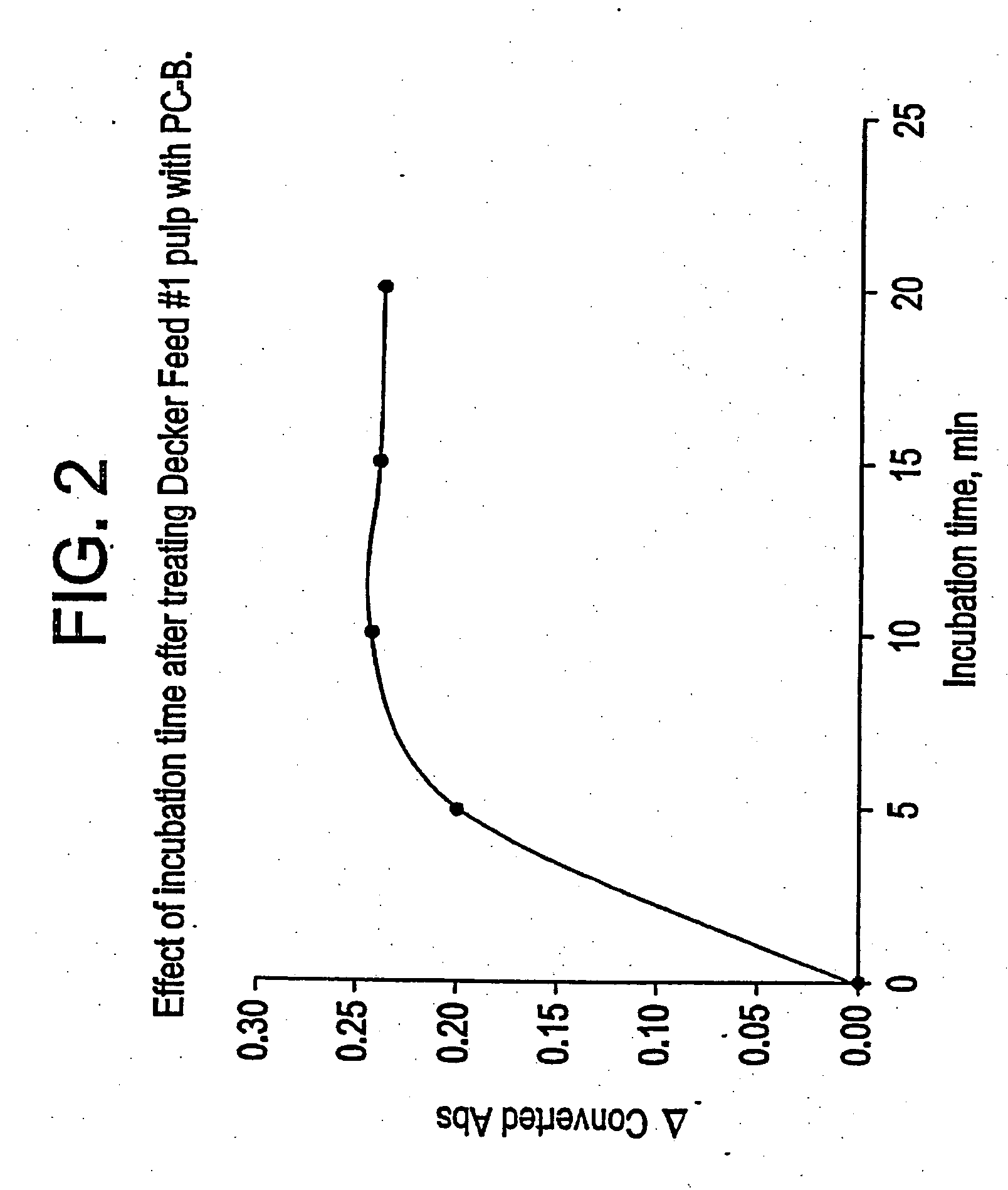

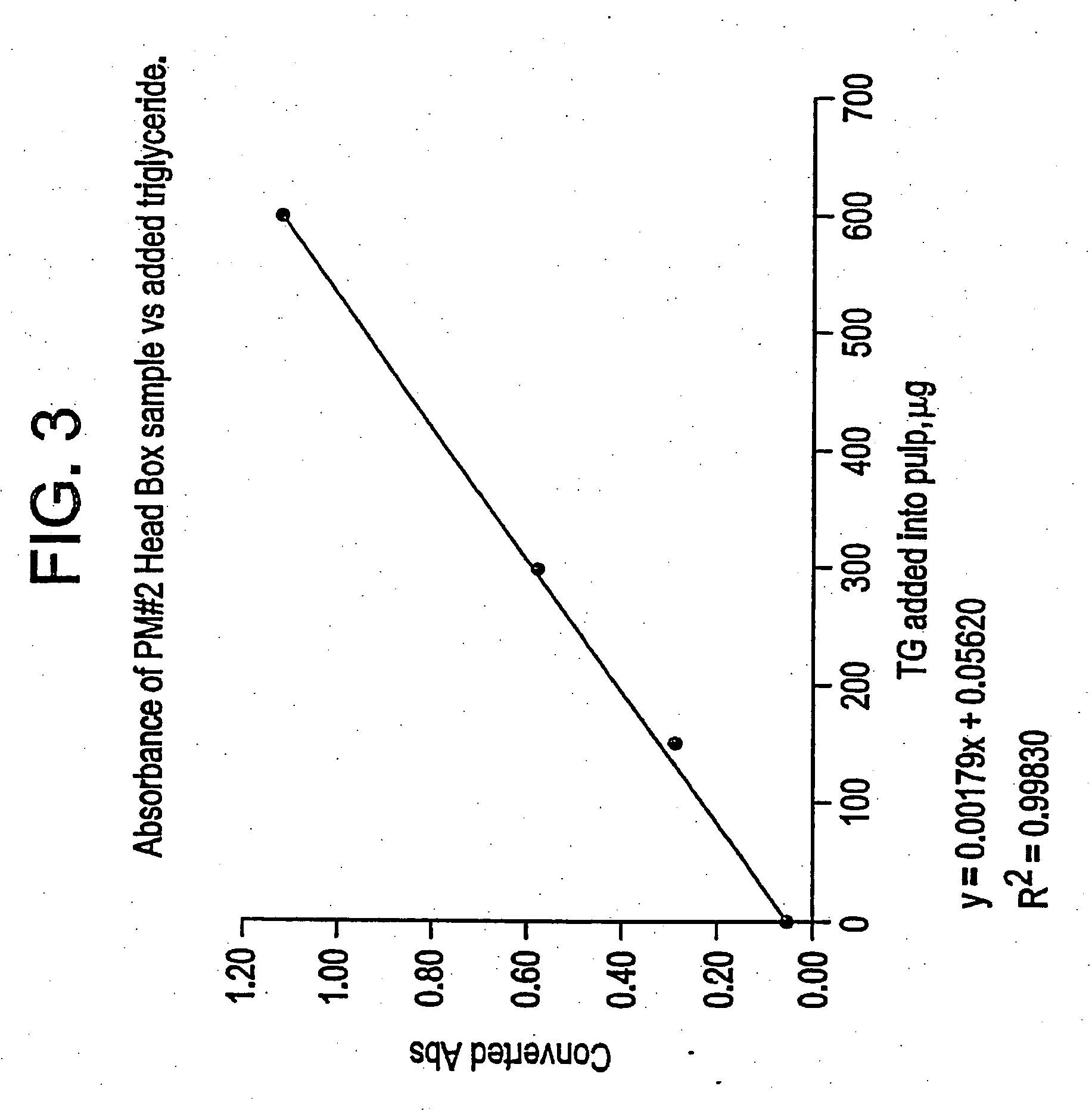

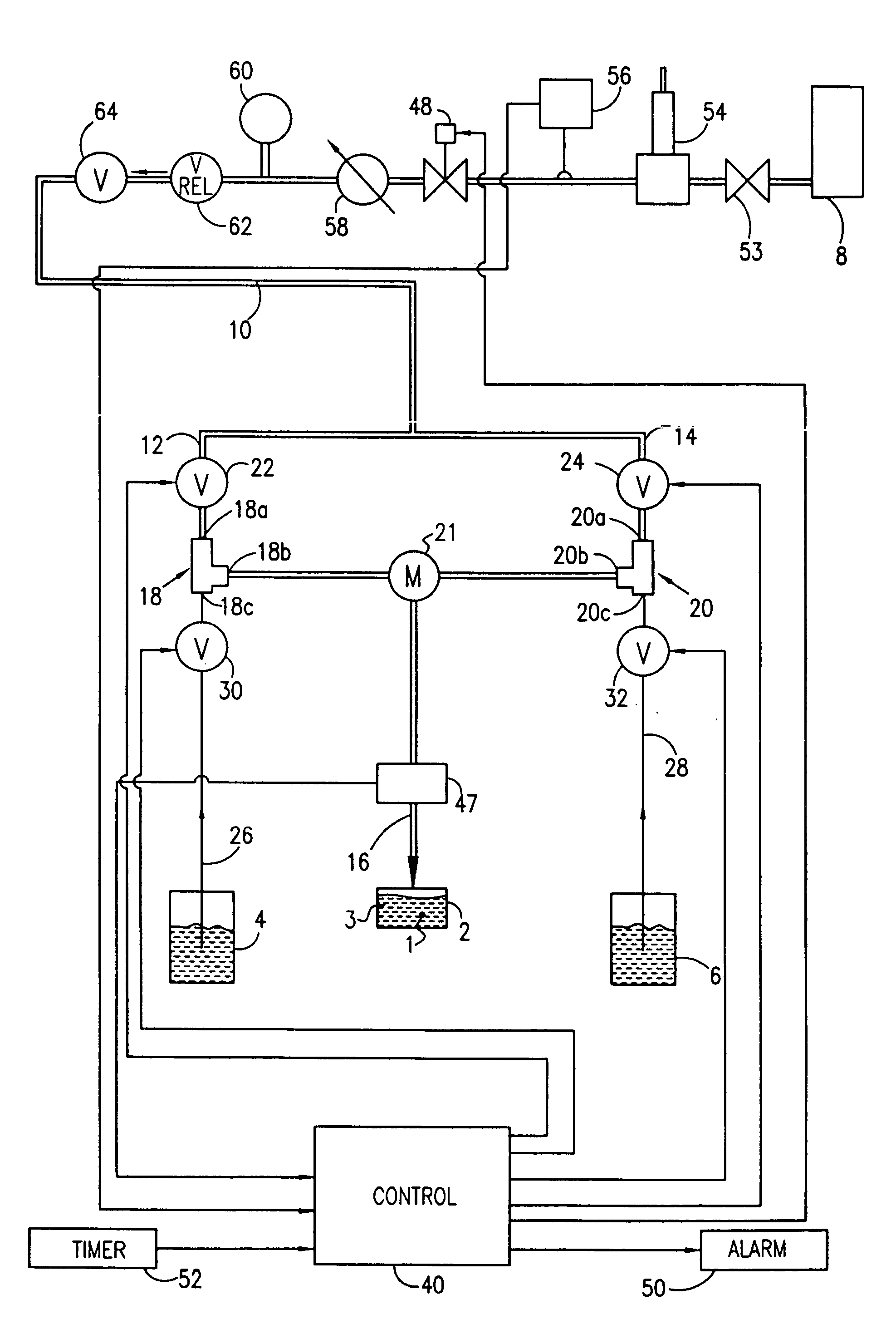

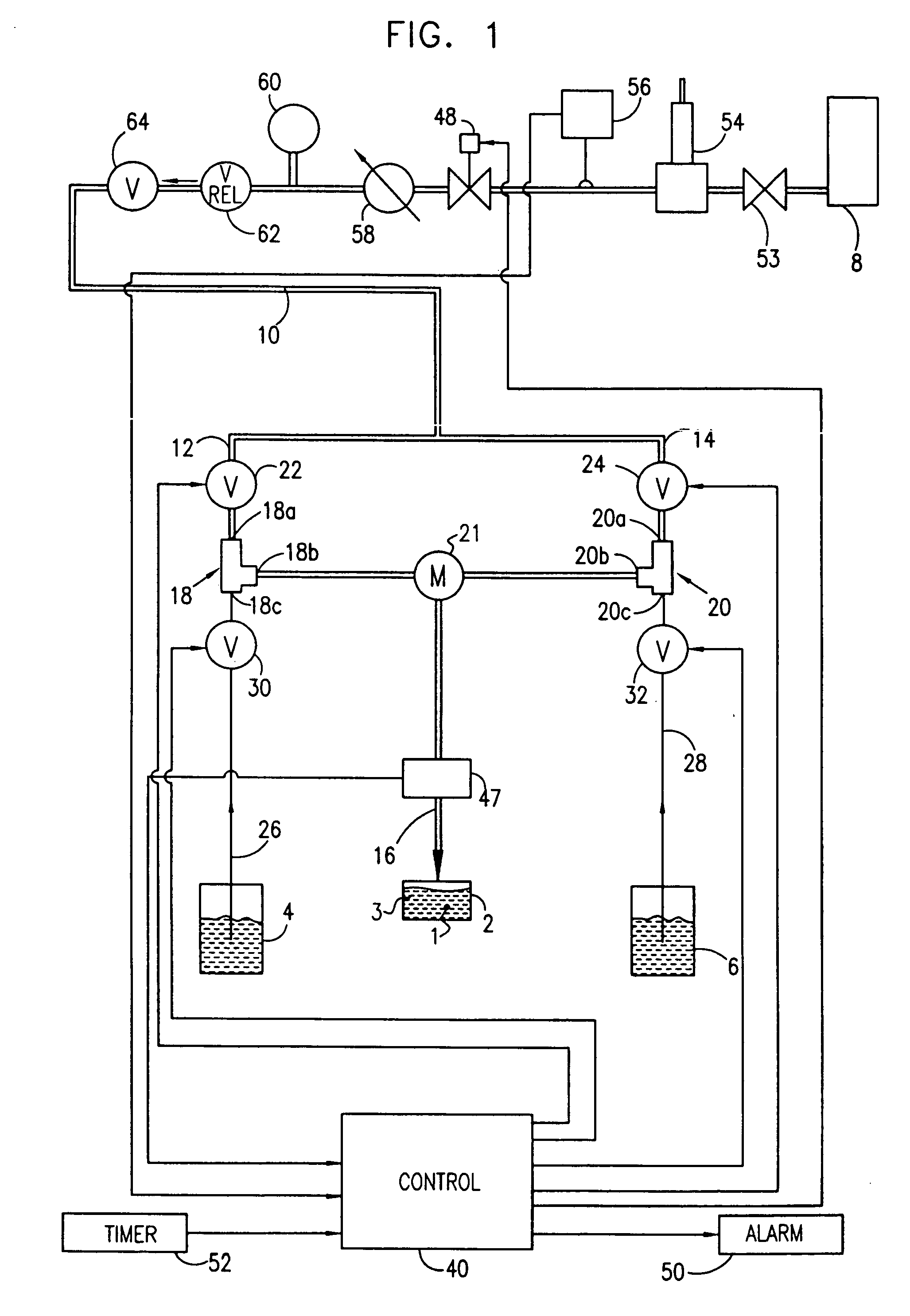

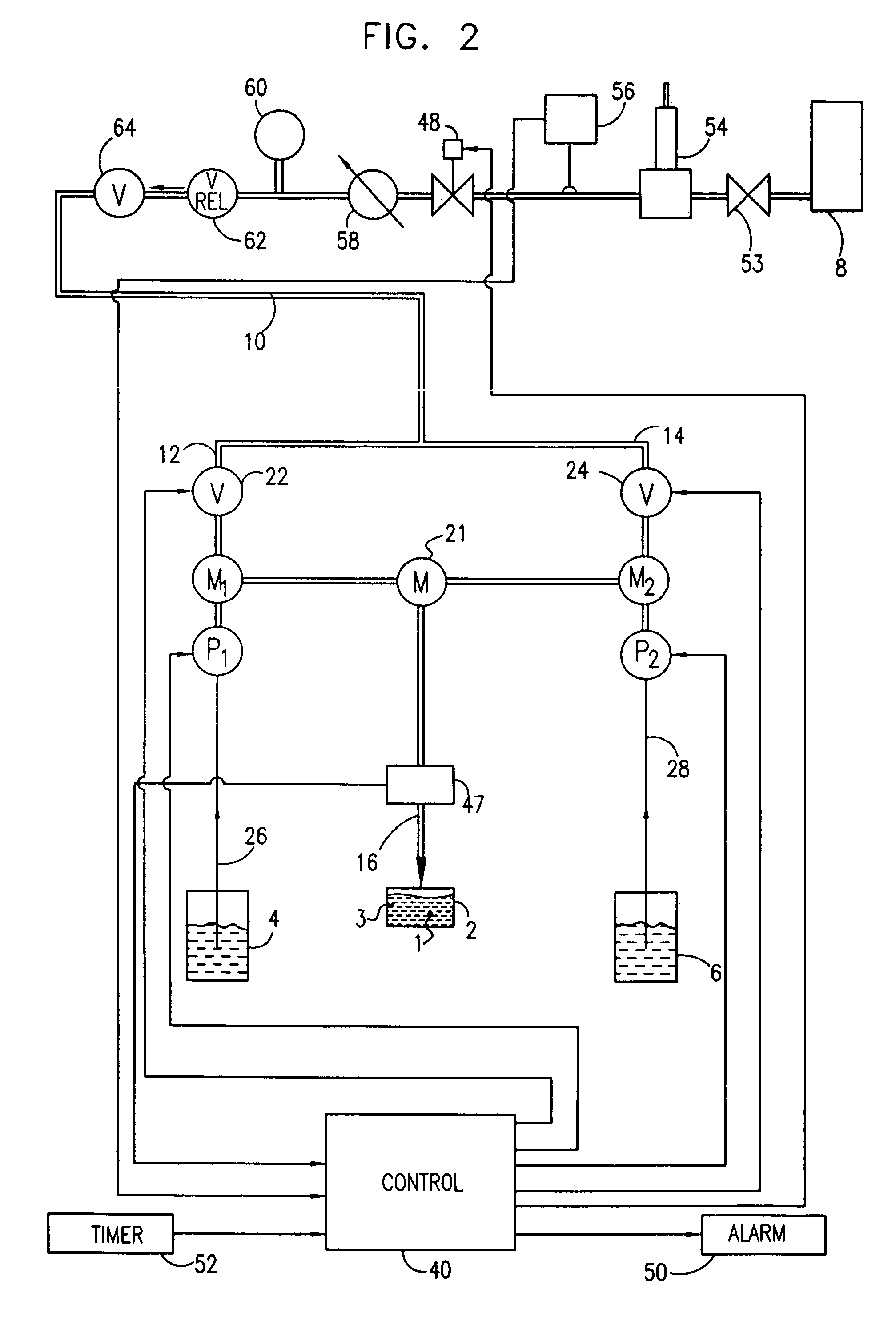

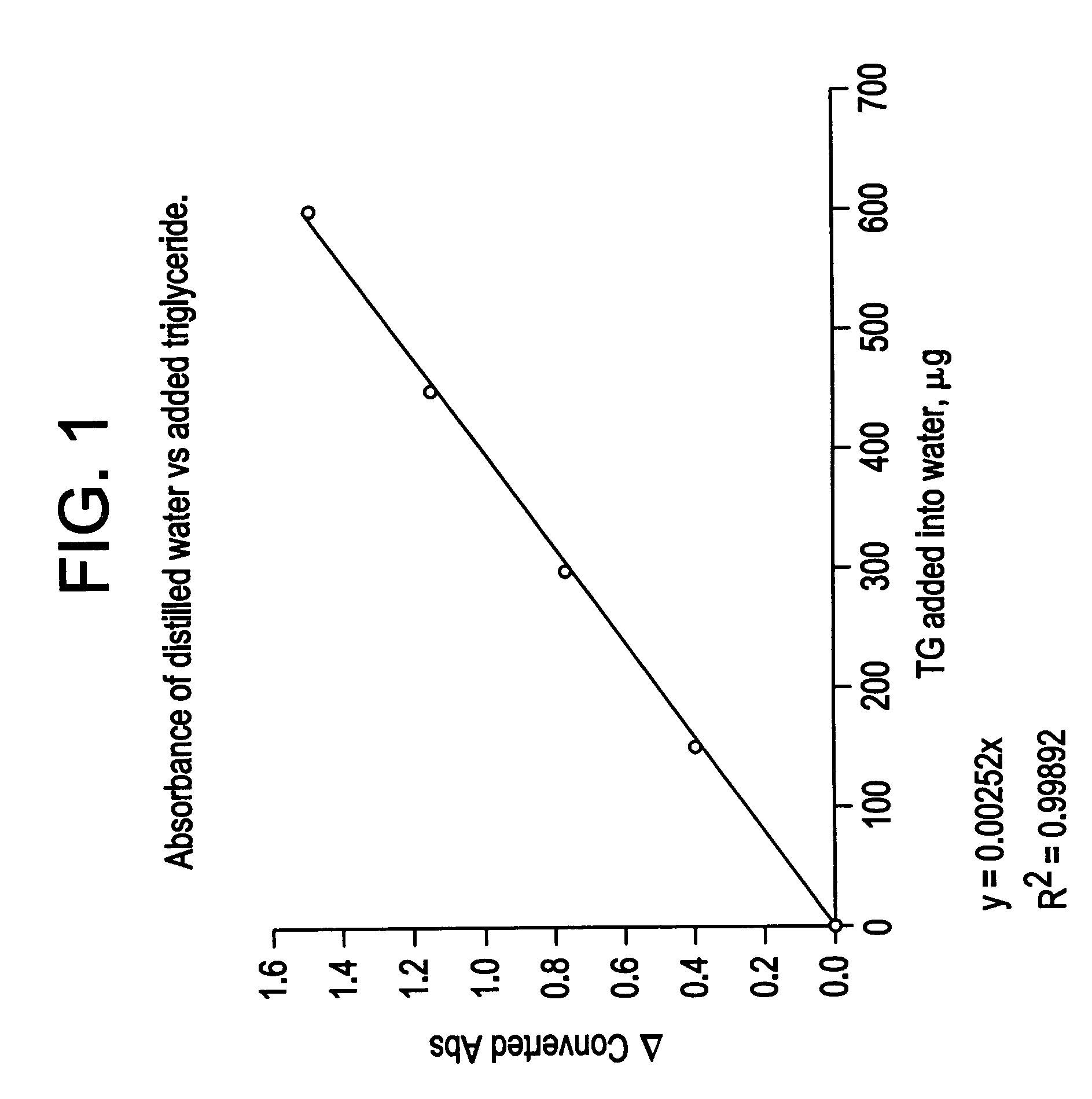

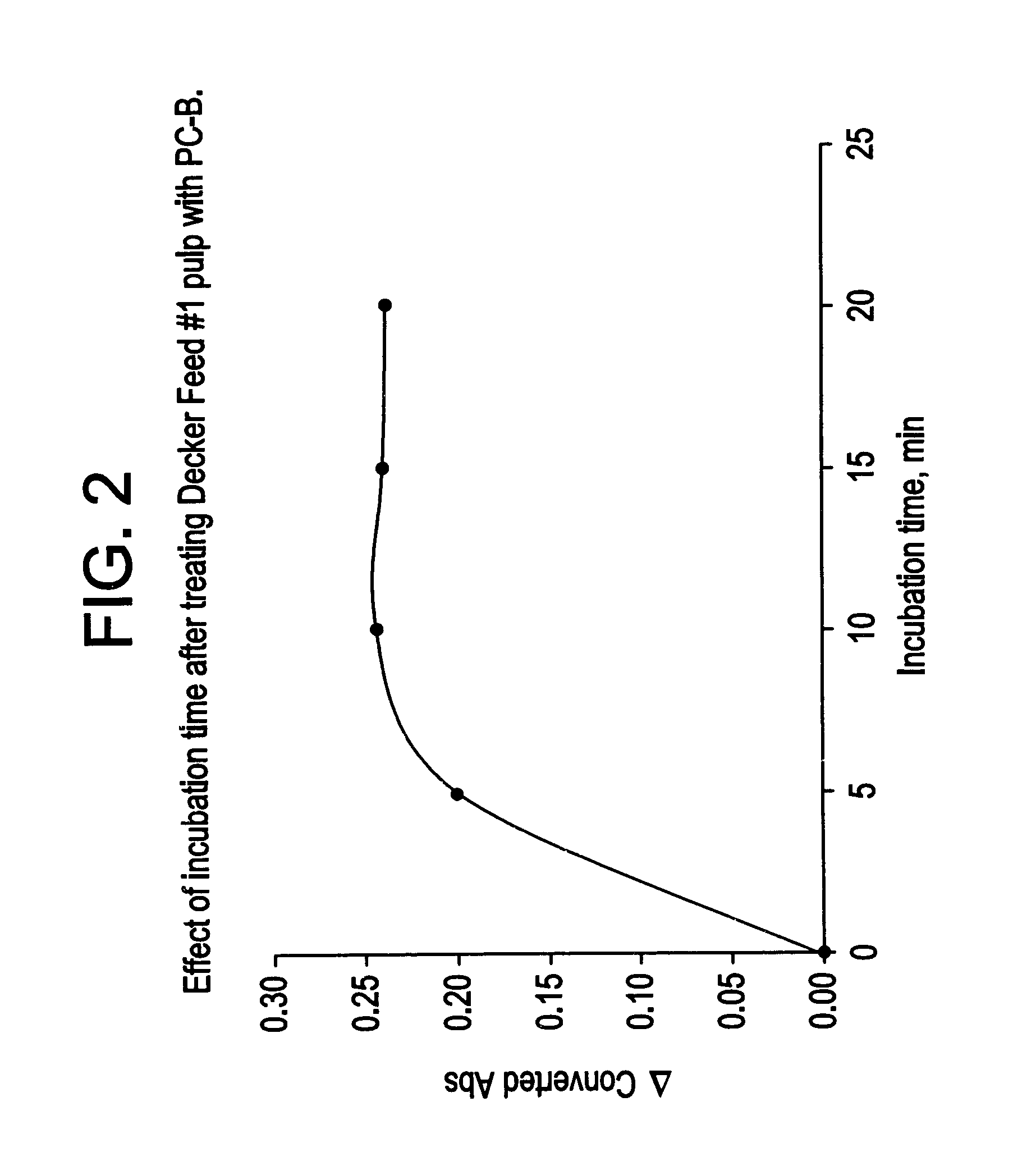

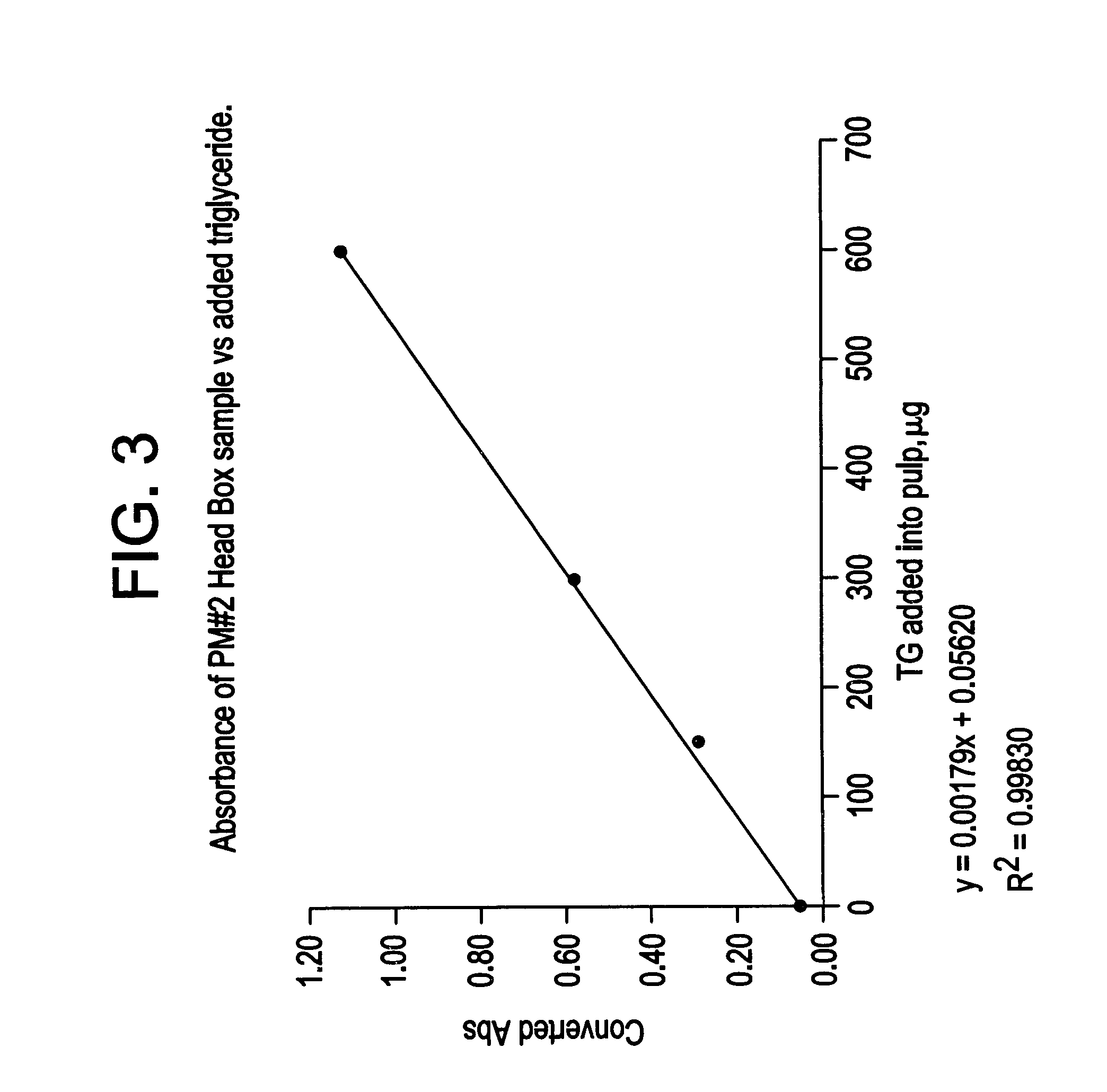

Rapid triglyceride assay for use in pulp pitch control

Enzymatic methods are provided for determining the surface triglycerides content in a sample of wood pulp. The methods preferably comprise reacting triglycerides which are present on the surface of the wood pulp fibers in the sample in the presence of a lipase to form glycerol and fatty acids, and then determining the difference between the amount of free glycerol present in the sample and the amount of glycerol formed from said triglycerides. The method is useful as a quick, portable, accurate, and low cost assay for assessing the amount of triglycerides present at various sample points in pulp and paper mills, which advantageously serves as a diagnostic tool for use in controlling the undesirable deposition of pitch during the papermaking process.

Owner:ENZYMATIC DEINKING TECH LLC

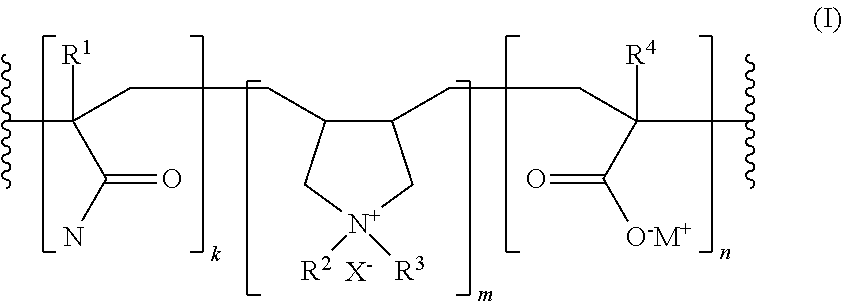

Hydrophobically modifed poly[ethylene glycol] for use in pitch and stickies control in pulp and papermaking processes

ActiveUS20080029231A1Avoid depositionEfficient reductionNon-fibrous pulp additionNatural cellulose pulp/paperPolyethylene glycolPapermaking

Methods for inhibiting the depositions of organic contaminants from pulp in pulp and papermaking systems are disclosed. Hydrophobically modified poly[ethylene glycol] are added to the pulp or applied to deposition-prone surfaces of a papermaking system.

Owner:SOLENIS TECH CAYMAN

Hydrophobically modifed poly[ethylene glycol] for use in pitch and stickies control in pulp and papermaking processes

ActiveUS8388806B2Efficient reductionNon-fibrous pulp additionNatural cellulose pulp/paperPapermakingEthylene glycol

Methods for inhibiting the depositions of organic contaminants from pulp in pulp and papermaking systems are disclosed. Hydrophobically modified poly[ethylene glycol] are added to the pulp or applied to deposition-prone surfaces of a papermaking system.

Owner:SOLENIS TECH CAYMAN

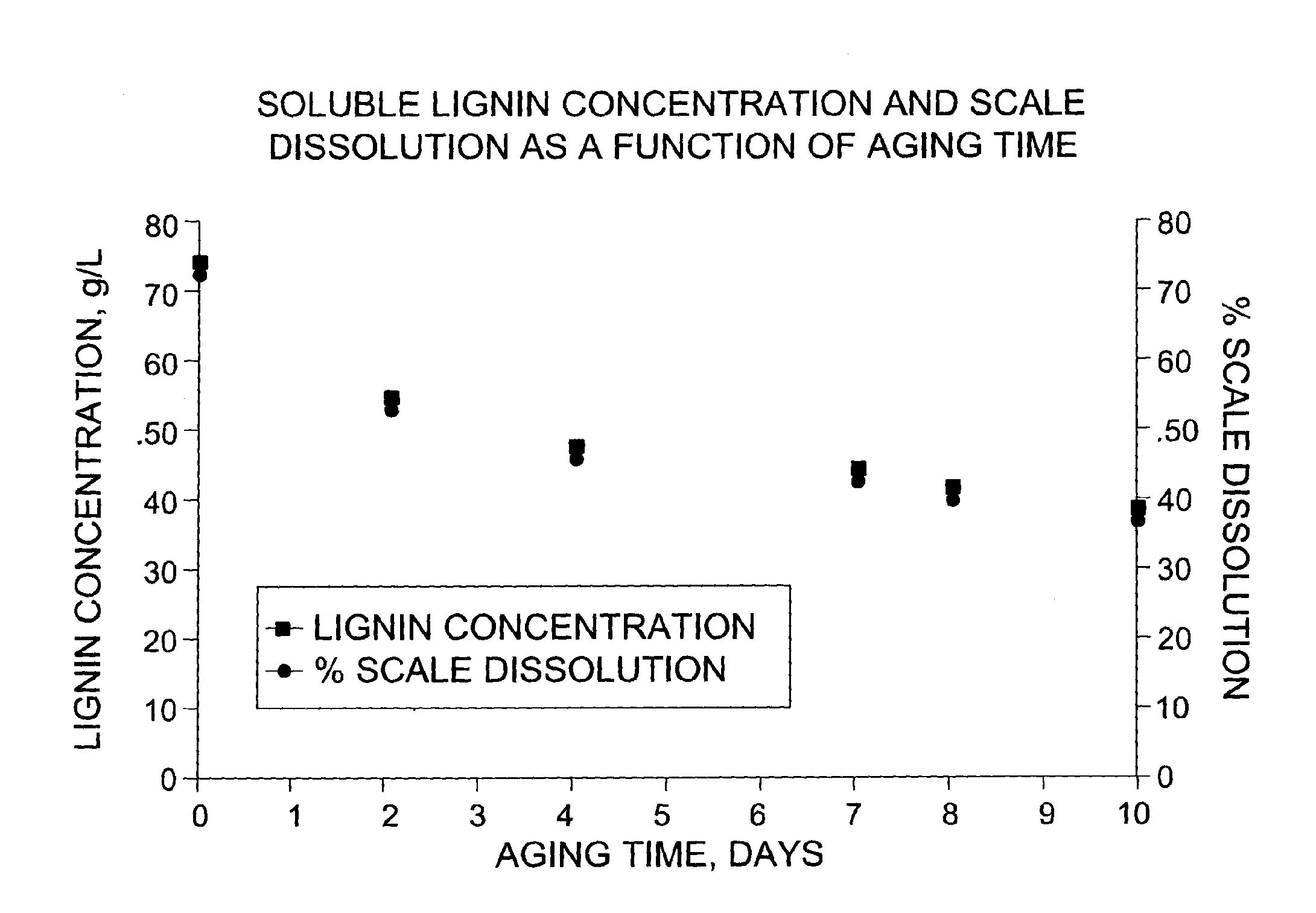

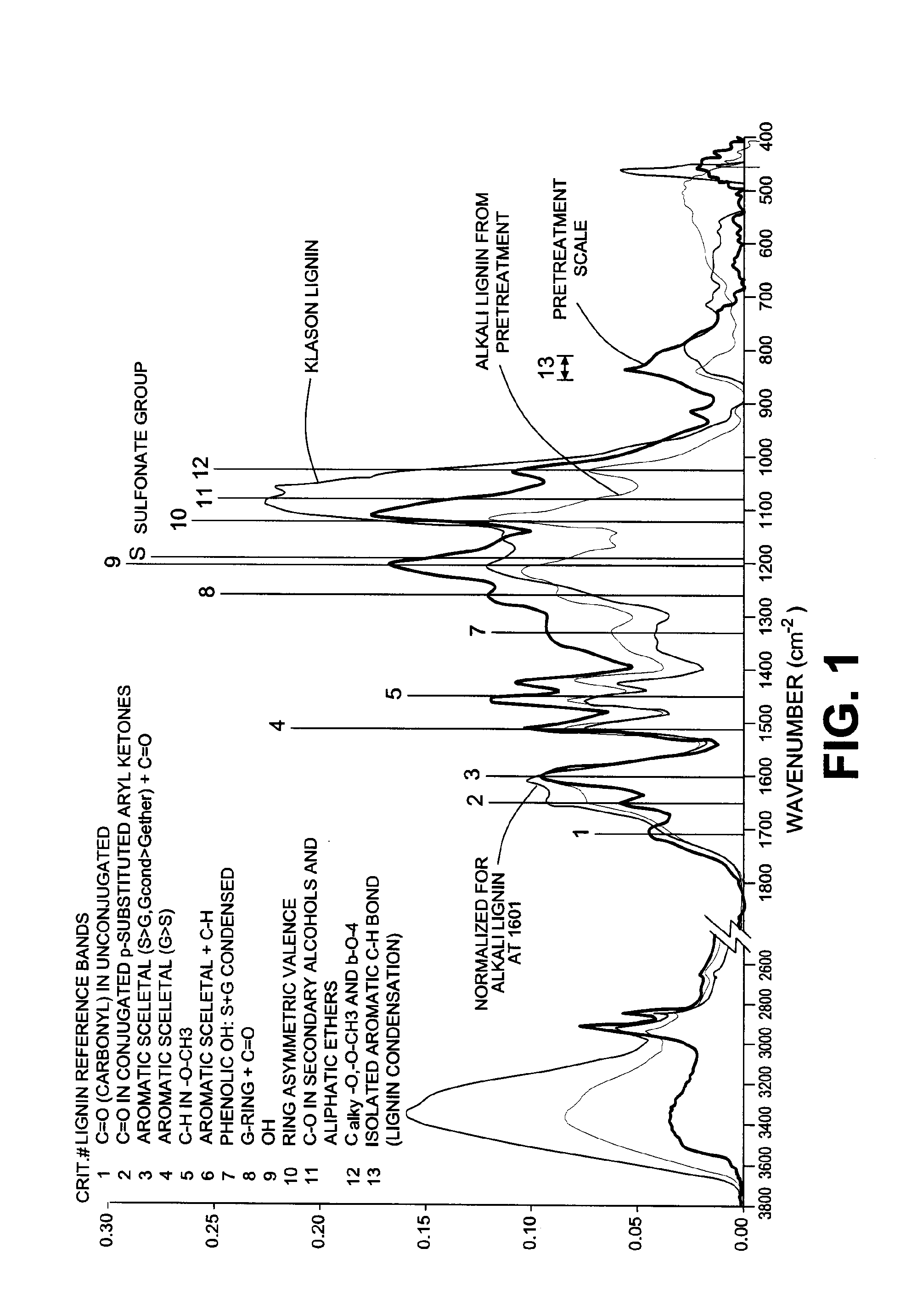

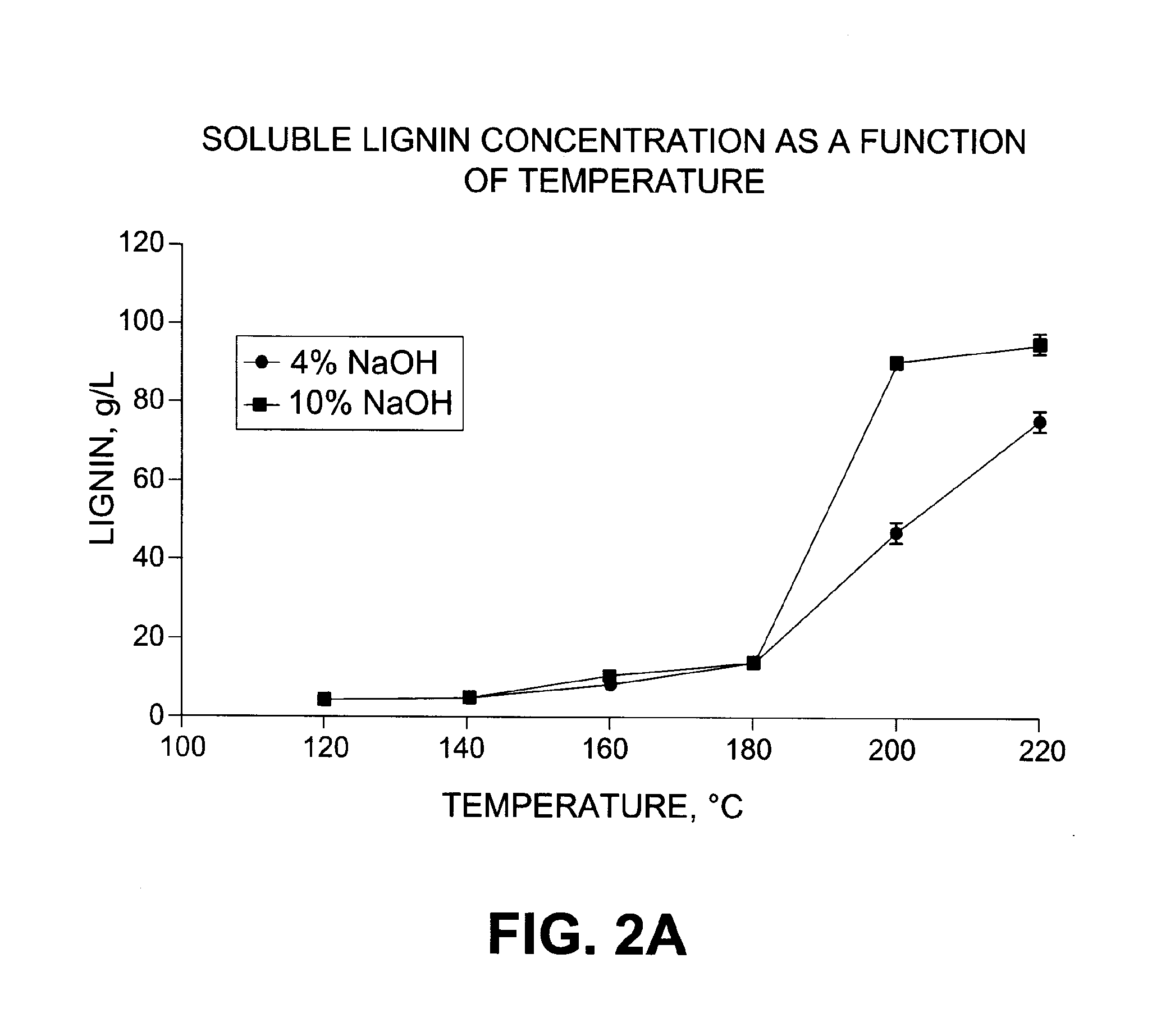

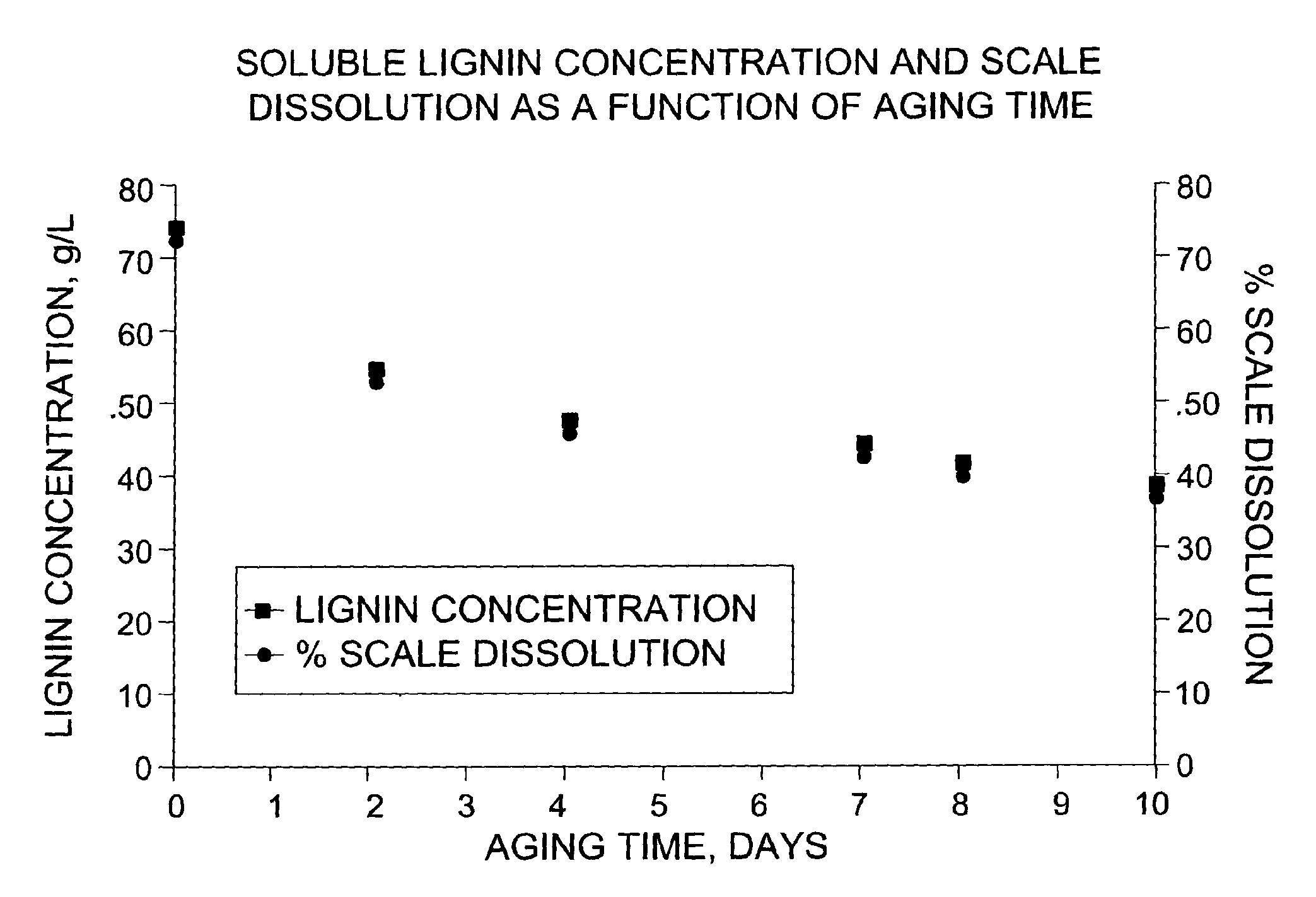

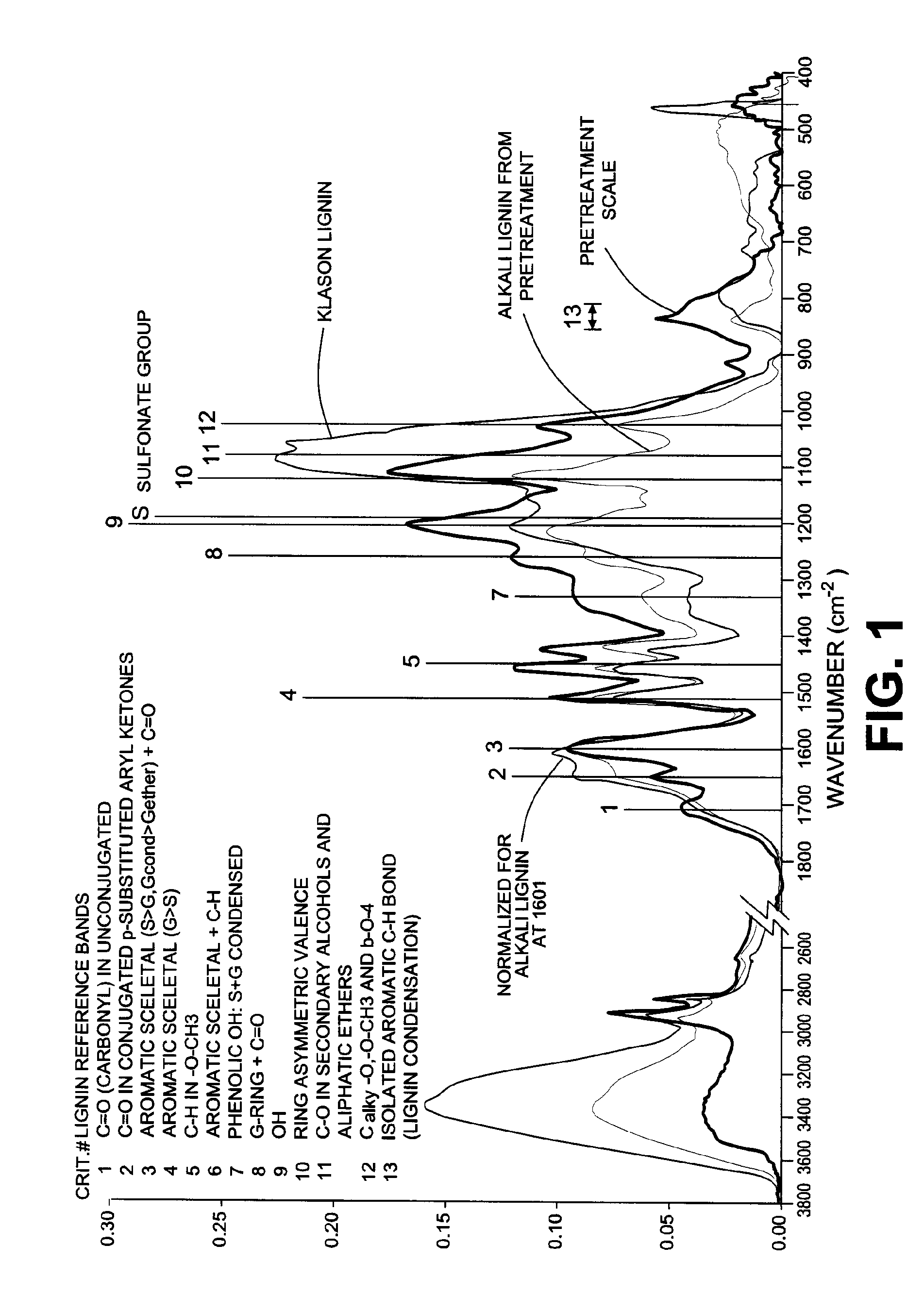

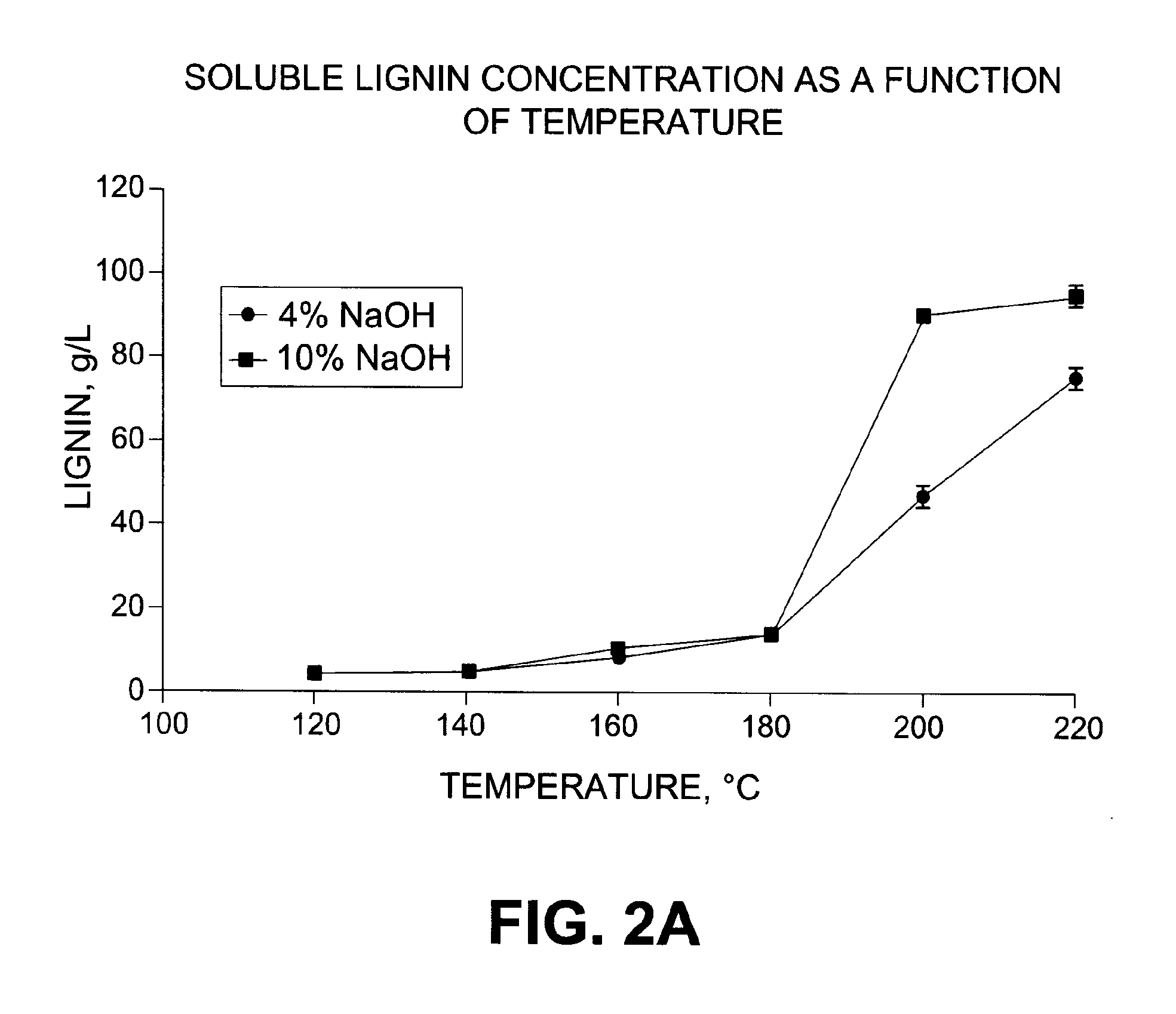

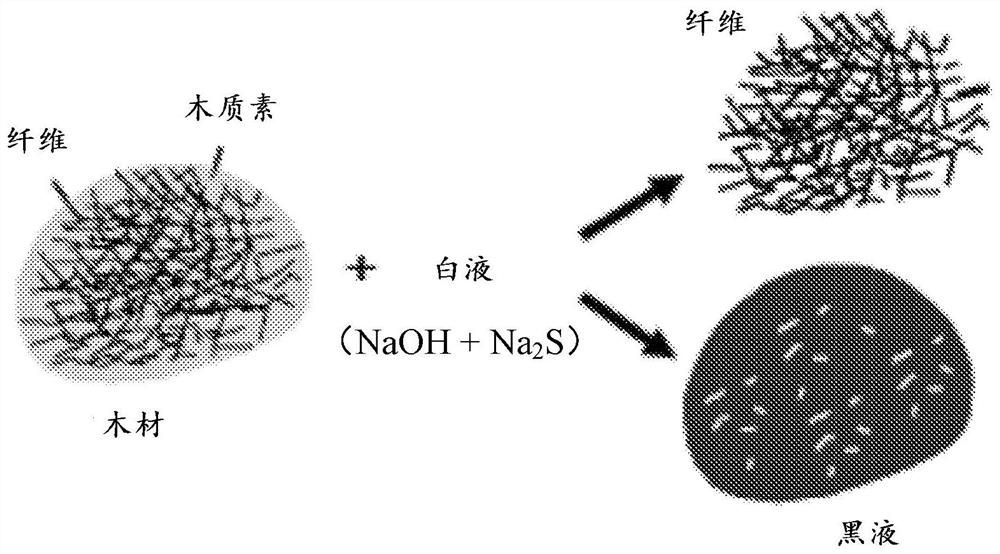

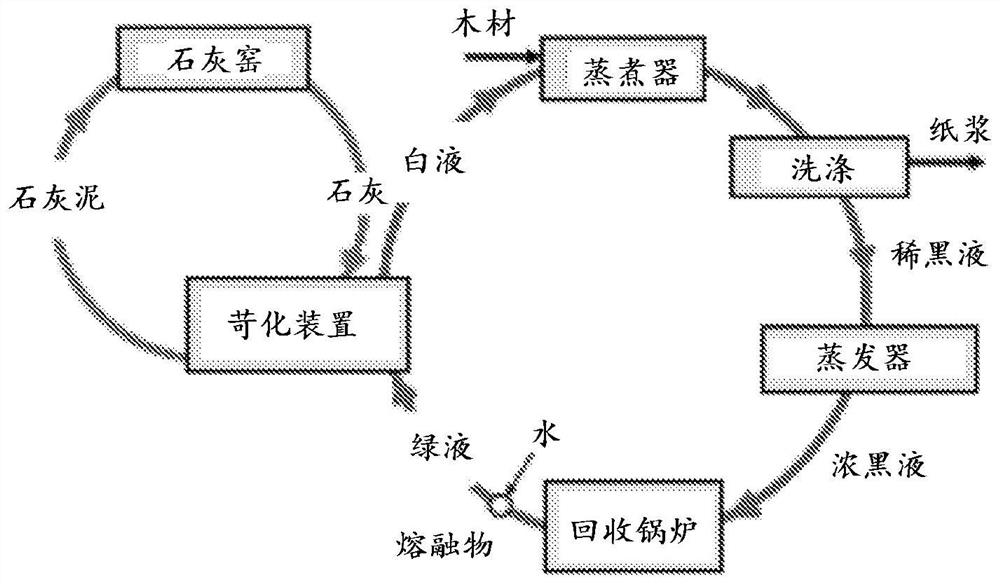

Method for scale removal during a lignocellulosic conversion process

ActiveUS20120325203A1Improve the level ofShort timePulp deposit formation/corrosion preventionBiofuelsProcess equipmentHemicellulose

A method for processing of a lignocellulosic feedstock is provided comprising exposing lignocellulosic feedstock to acid in a reactor to hydrolyze at least hemicellulose present in said lignocellulosic feedstock, wherein during said exposing, a scale deposit comprising lignin forms on the inner surface of said reactor; and treating the scale deposit with an alkali solution at a temperature between about 140° C. and about 250° C. so as to remove scale. Also provided is a method for reducing scale deposit that forms on process equipment during a stage of reacting a lignocellulosic feedstock with acid.

Owner:IOGEN ENERGY CORP

Rapid triglyceride assay for use in pulp pitch control

InactiveUS20060160166A1Low costRapid assessmentPulp deposit formation/corrosion preventionNon-fibrous pulp additionFiberPapermaking

Enzymatic methods are provided for determining the surface triglycerides content in a sample of wood pulp. The methods preferably comprise reacting triglycerides which are present on the surface of the wood pulp fibers in the sample in the presence of a lipase to form glycerol and fatty acids, and then determining the difference between the amount of free glycerol present in the sample and the amount of glycerol formed from said triglycerides. The method is useful as a quick, portable, accurate, and low cost assay for assessing the amount of triglycerides present at various sample points in pulp and paper mills, which advantageously serves as a diagnostic tool for use in controlling the undesirable deposition of pitch during the papermaking process.

Owner:ENZYMATIC DEINKING TECH LLC

Control of development of biofilms in industrial process water

InactiveUS20060138058A1Improve durabilityPulp deposit formation/corrosion preventionBiocideMicroorganismBiochemical engineering

Owner:A Y LAB LTD

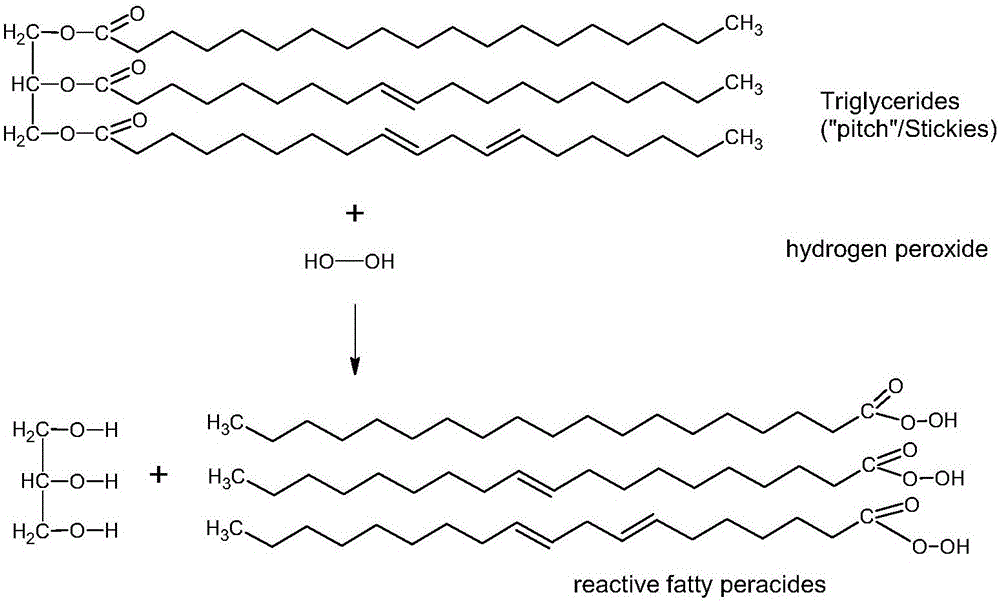

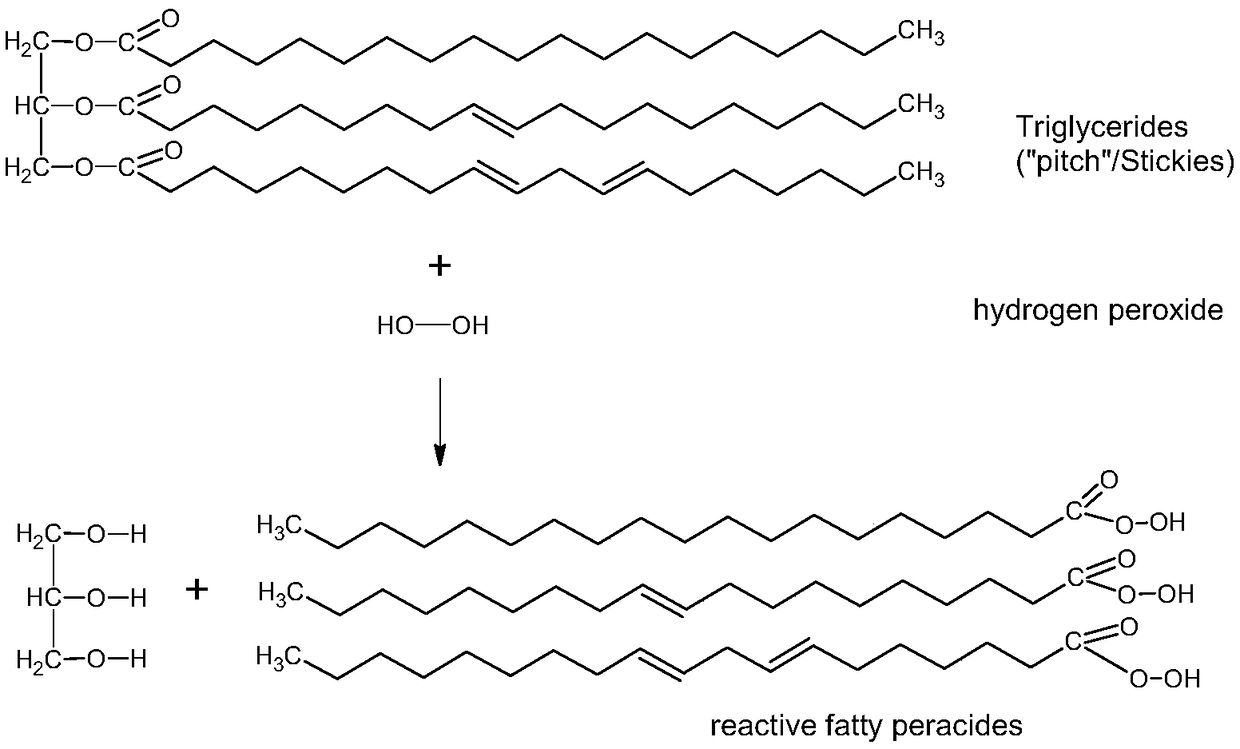

Composition for controlling organic pollutant sedimentation during pulping and papermaking production and papermaking method

ActiveCN106436417AChange physical and chemical propertiesImprove efficiencyPulp deposit formation/corrosion preventionFats/resins/pitch/waxes removal in pulpFiberPapermaking

The invention discloses a composition for controlling organic pollutant sedimentation during pulping and papermaking production and a papermaking method. Effective ingredients of the composition include a bio-enzyme with a peroxide hydrolyzing function and a precursor of hydrogen peroxide and / or a precursor capable of generating hydrogen peroxide, wherein the weight ratio of the bio-enzyme to the precursor in the composition is 1:(0.1-200). The papermaking method comprises the steps that hydrous fiber papermaking pulp is formed; after the composition is added into the fiber papermaking pulp for a reaction, the obtained pulp is conveyed onto a net, water is drained, and paper sheets are formed; the paper sheets are squeezed and dried to obtain paper products. Through the composition, glue and especially sedimentation of viscous matter during pulping and papermaking production can be remarkably controlled, negative effects and harm possibly brought by the glue to papermaking are reduced, papermaking production efficiency and product quality are improved, energy consumption is lowered, production cost is saved for papermaking enterprises, economic profits are increased, and the application range is wide.

Owner:RISINGSTAR BIOTECH GUANGZHOU

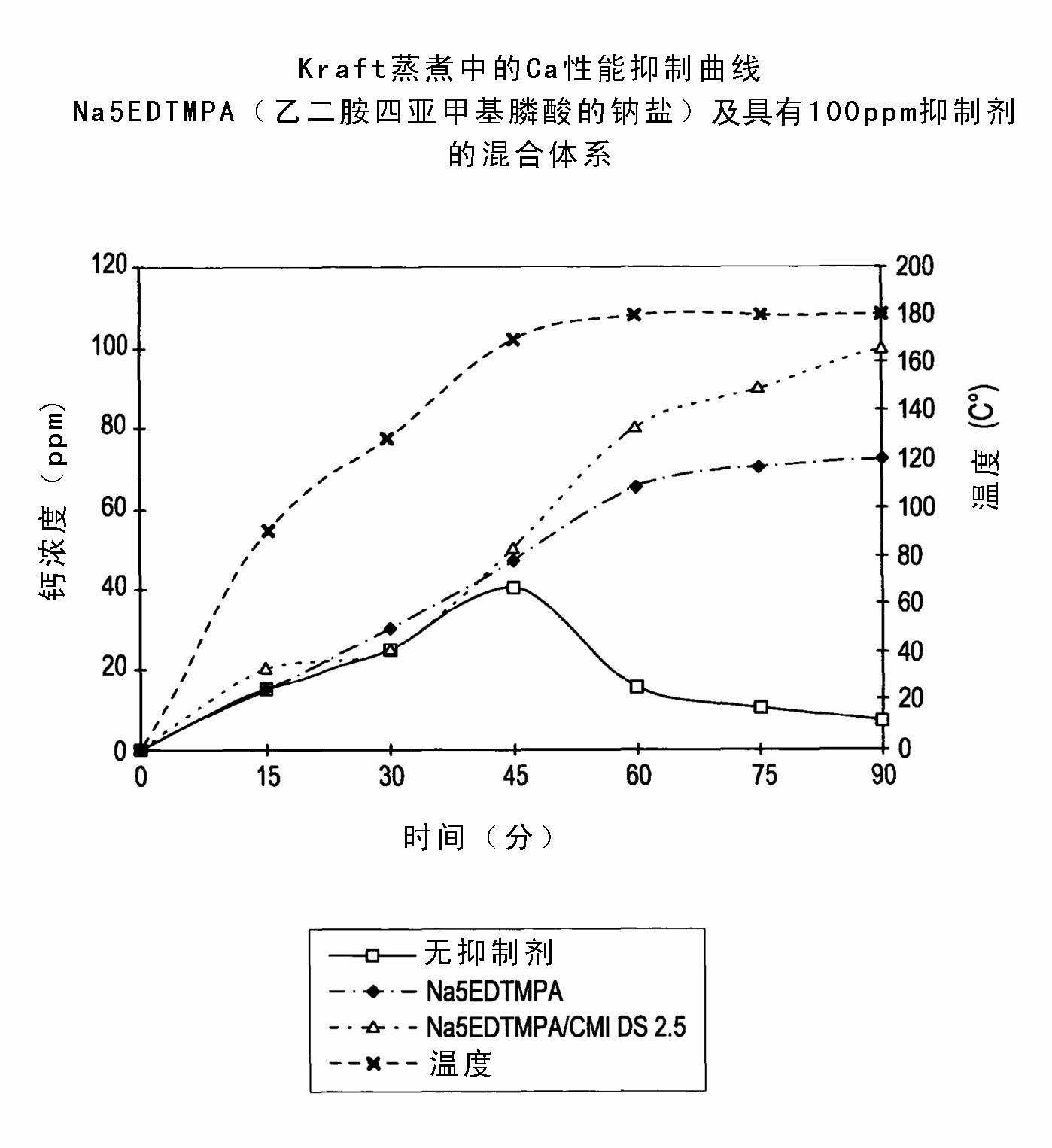

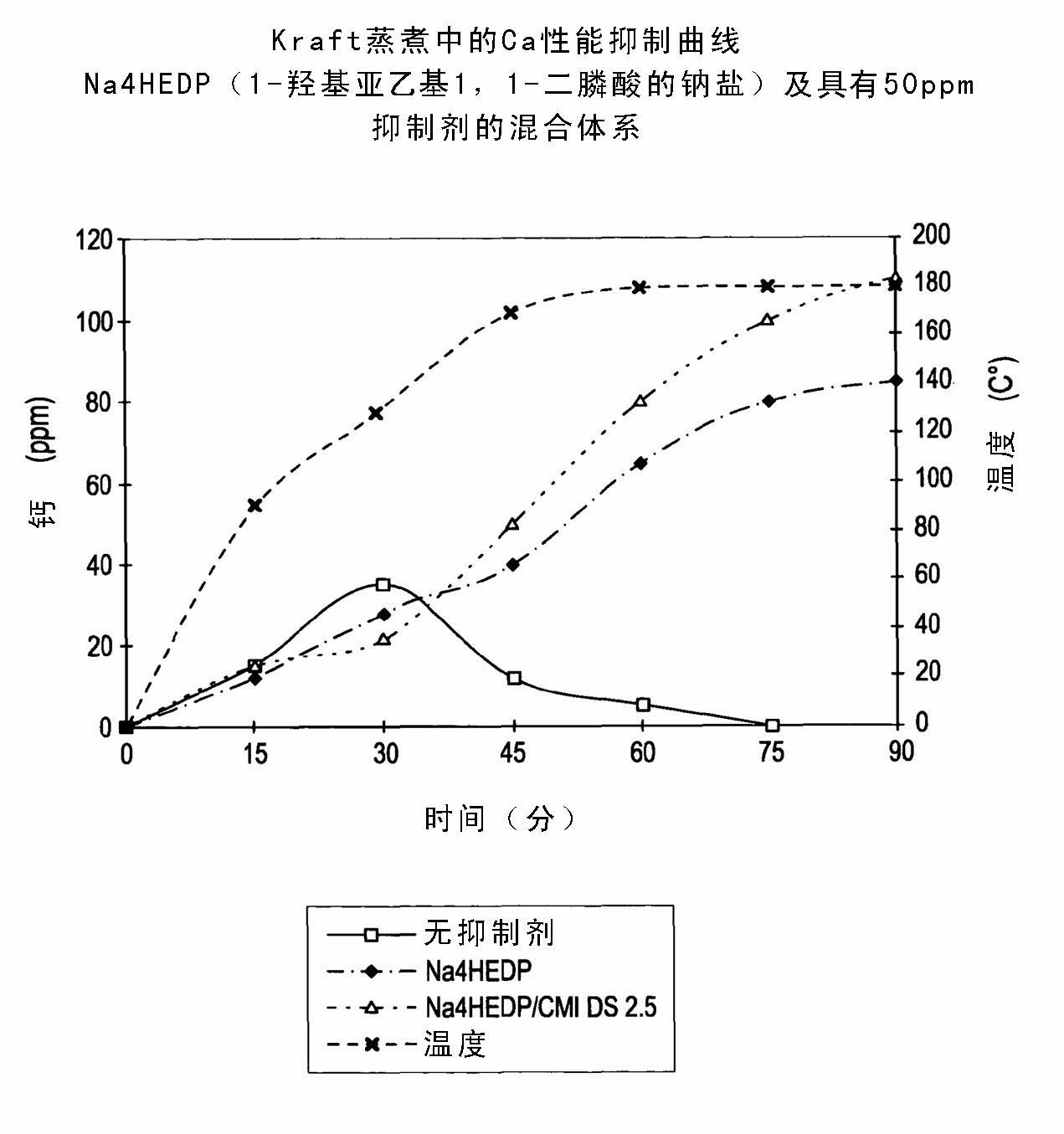

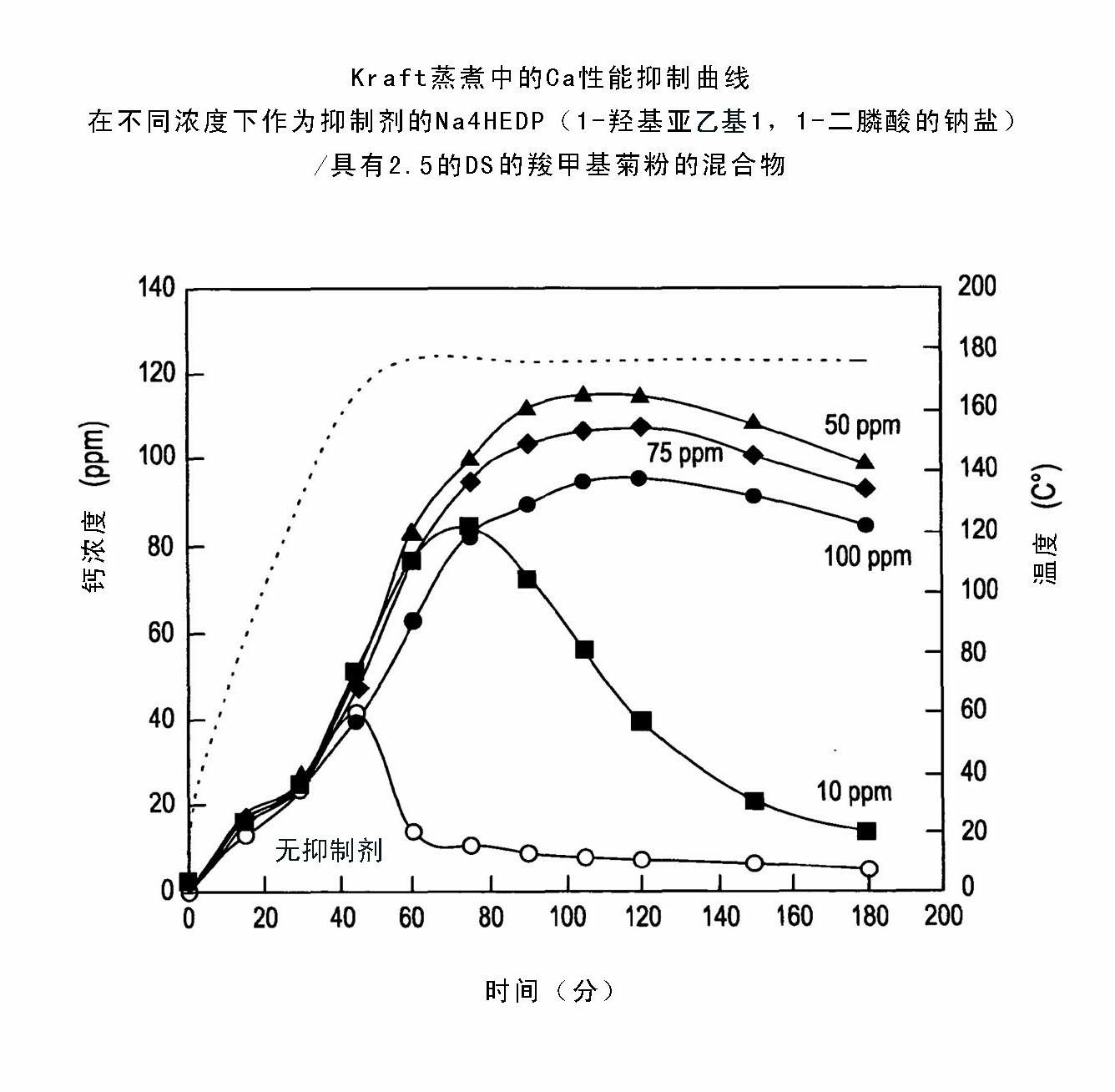

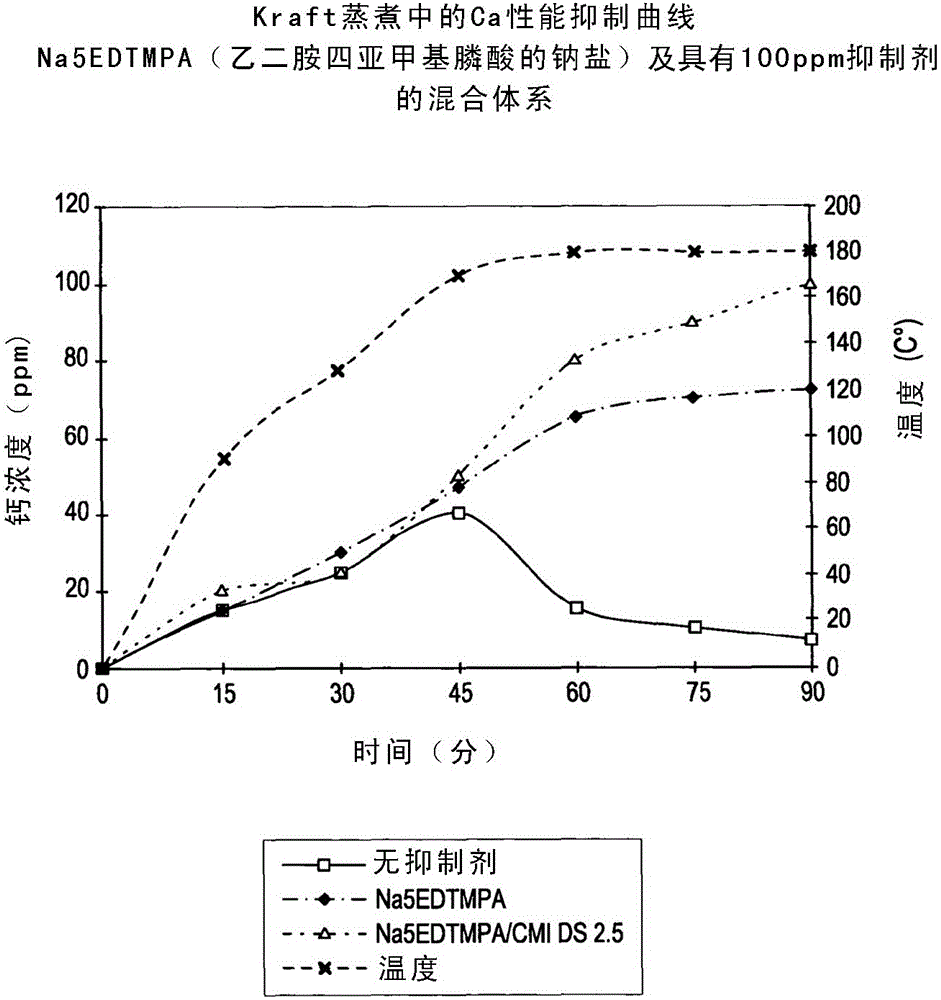

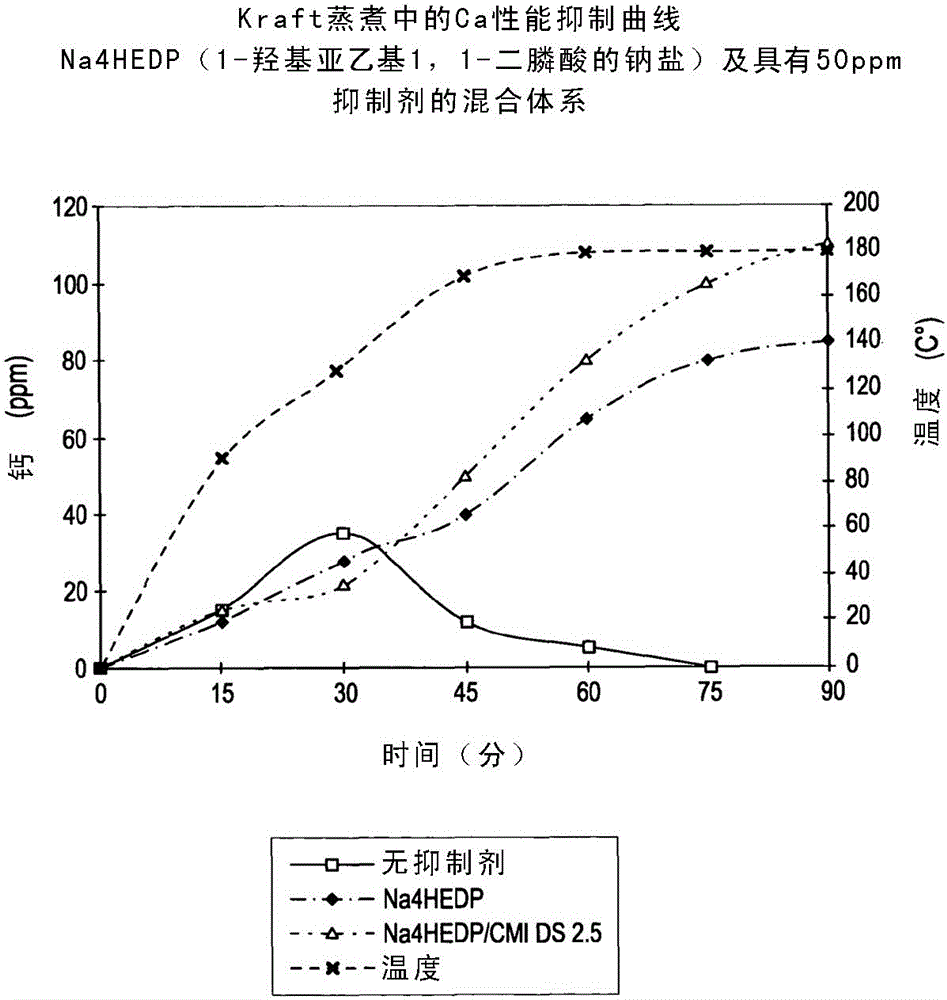

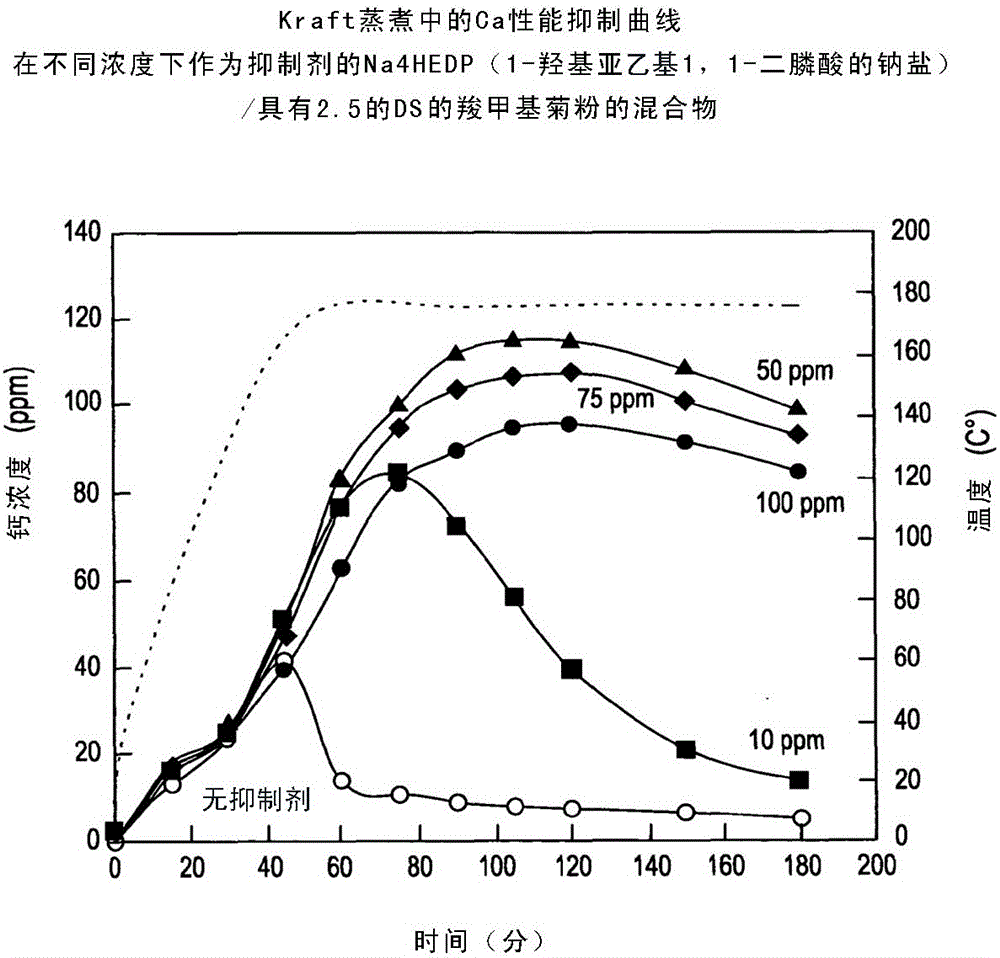

Composition for inhibiting calcium salt scale formation

ActiveCN102428040APulp deposit formation/corrosion preventionFats/resins/pitch/waxes removal in pulpCalcium EDTAMetal

A method for inhibiting the formation, deposition and adherence of calcium salt scale to metallic and other surfaces in the equipment, vessels and / or piping of a chemical pulp process facility comprising adding an effective scale inhibiting amount of a composition to the alkaline aqueous mixture in the digester of said chemical pulping process. Said composition consists of at least one phosphonate component (I) and at least one component (II) consisting of at least one carboxylated fructan compound.

Owner:伊塔尔麦奇化学股份公司

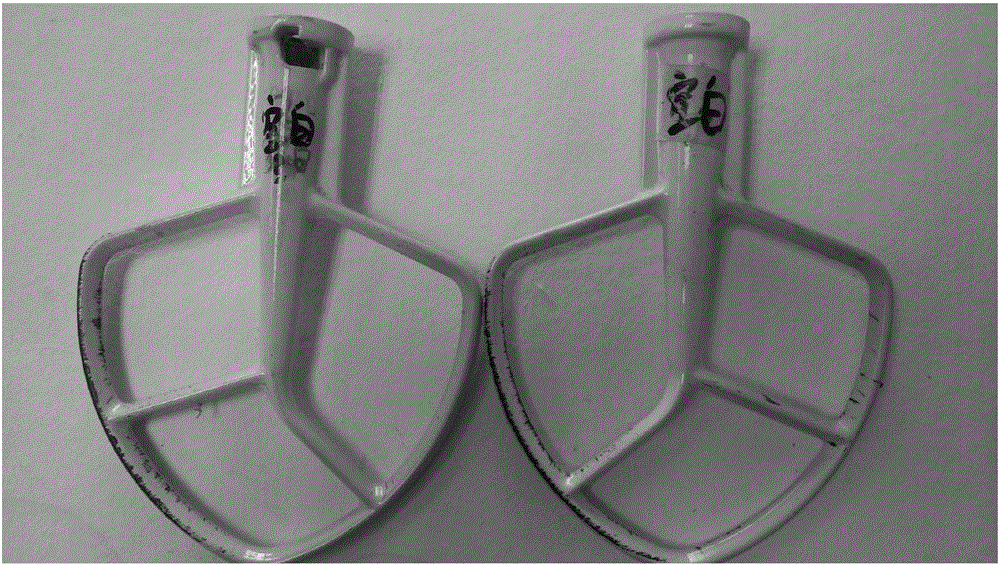

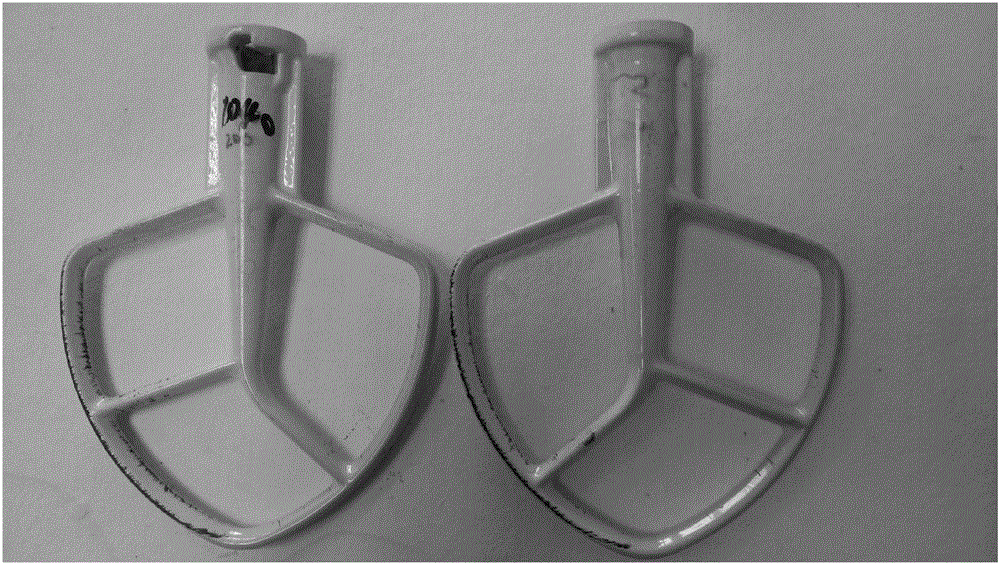

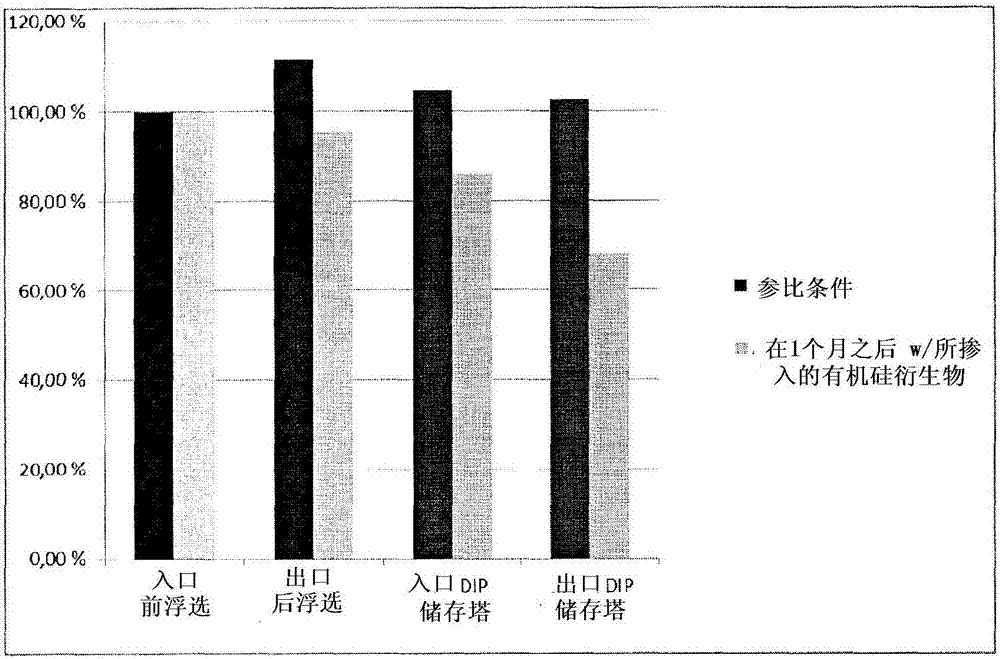

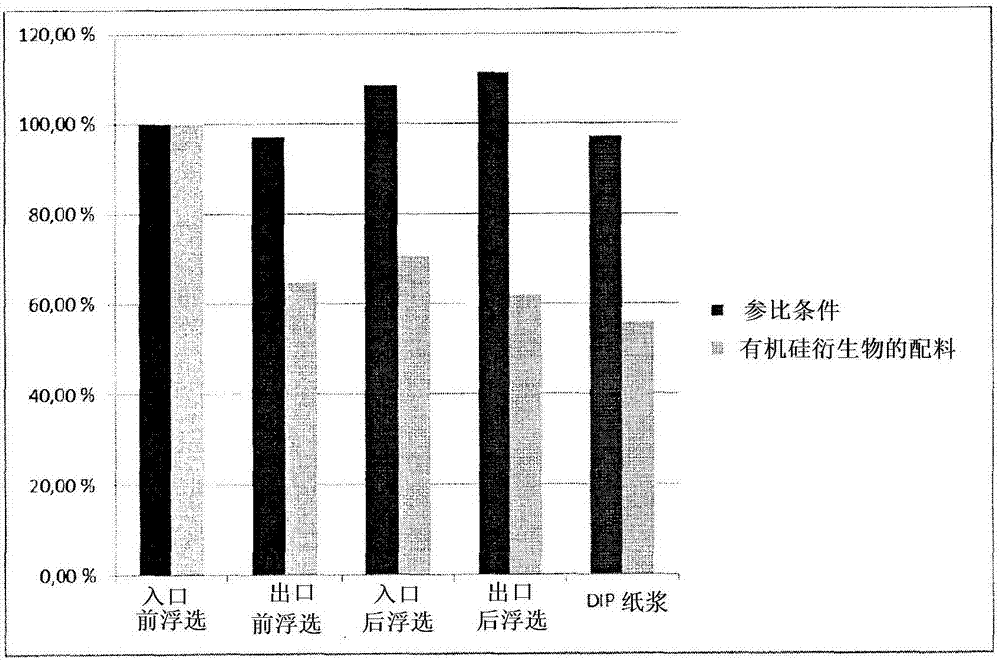

A method for controlling the deposition of stickies in pulping and papermaking processes

A method for controlling the deposition of stickies in pulping and papermaking processes. The method comprises adding to fibre pulp or stock an additive comprising an organo-modified siloxane comprising units of the formula: [R<1>ZSiO<(4-a-b) / 2>]n in which each R<1> is independently selected from a hydrogen atom, an alkyl, aryl, alkenyl, aralkyl, alkaryl, alkoxy, alkanoyloxy, hydroxyl, ester or ether group, and each Z is independently selected from an alkyl group substituted with an amine, amide, carboxyl, ester, or epoxy group, or preferably at least one or more groups -R<2>-(OCpH<2p>)<q>(OC<r>H<2r>)<s>-R<3>, wherein the n is an integer greater than 1; the a and the b are independently 0, 1, 2 or 3; the R<2> is an alkylene group or a direct bond; the R<3> is a group as defined for the R<1> or the Z above; the p and the r are independently an integer from 1 to 6; the q and the s are independently 0 or an integer such that 1 <= q + s <= 400. Each molecule of the organo-modified siloxane contains at least one group Z. The organo-modified siloxane is preferably a hydroxyl- or alkyl- endcapped linear polydimethylsiloxane, in which 5 to 18 mole percents of silicon atoms are substituted by the Z groups of the formula -R<2>-(OCH<2p>)<q>(OC<r>H<2r>)<s>-R<3>, wherein the p is 2, the r is 3, the q and the s are independently 10 to 20, the R<2> is an alkylene group having from 1 to 6 carbon atoms or a direct bond, and the R<3> is a hydrogen atom or a hydroxyl, alkoxy, ester or ether group.

Owner:NOPCO PAPER TECH

Pulping process of high wetting strength napkin paper

ActiveCN110004771AHigh strengthFully absorb water and swellPulp deposit formation/corrosion preventionNatural cellulose pulp/paperProcess optimizationSlurry

The invention relates to the technical field of living paper and particularly relates to a pulping process of high wetting strength napkin paper. The process comprises procedures of long fiber crushing, short fiber crushing, long fiber grinding, short fiber grinding, and slurry blending. Long fibers and short fibers are separately and respectively crushed in the crushing procedures, so that the fiber strength can be improved; in addition, the concentration of the crushed long fiber slurry is controlled as 4.5-6%, the concentration of the crushed short fiber slurry is controlled as 5-6%, and acertain amount of pulping enzymes and liquid caustic soda are used in the process; in the grinding procedures, a conical grinding machine is used, grinding flows, grinding power and pulping concentrations of the long fibers and the short fibers are respectively controlled, the pulping concentration of the long fibers is 28-32 degree SR, the pulping concentration of the short fibers is 32-35 degreeSR, and a resin control agent is put into a pipeline before the long and short fiber slurry is fed into an unloading pump. Due to process optimization and synergetic effects of the procedures, the finally prepared napkin paper has high wetting strength, is excellent in quality, high in paper machine operation efficiency and stable in production operation.

Owner:广东理文卫生用纸有限公司

Methods Of Using Combinations Of A Lipase And An Oxidant For Pitch Control In Paper Making Processes And Products Thereof

ActiveUS20130340959A1Paper quality is reducedQuality improvementPulp deposit formation/corrosion preventionPulp properties modificationFiberPulp and paper industry

A method is provided for controlling deposit-forming contaminants that comprise pitch or other fiber components which can interfere with the processing of the fibers, reduce paper quality, or both in papermaking systems. The method includes contacting fibers with a lipase and at least one peroxide source-free oxidant, and optionally nonionic surfactant, to liberate the organic contaminants from the fibers. Paper products of the method are also provided.

Owner:BUCKMAN LAB INT INC

Preparation method of starch-based fixing agent

InactiveCN109989292AImprove liquidityGood viscosity stabilityPulp deposit formation/corrosion preventionNon-macromolecular organic additionFiberCross-link

Owner:徐扣华

Methods of using combinations of a lipase and an oxidant for pitch control in paper making processes and products thereof

ActiveUS8657996B2Quality improvementReduce surface tensionNatural cellulose pulp/paperPulp liquors combustionFiberPulp and paper industry

A method is provided for controlling deposit-forming contaminants that comprise pitch or other fiber components which can interfere with the processing of the fibers, reduce paper quality, or both in papermaking systems. The method includes contacting fibers with a lipase and at least one peroxide source-free oxidant, and optionally nonionic surfactant, to liberate the organic contaminants from the fibers. Paper products of the method are also provided.

Owner:BUCKMAN LAB INT INC

Composition and method for controlling deposition of organic pollutants in pulp and paper production

ActiveCN106436417BChange physical and chemical propertiesImprove efficiencyPulp deposit formation/corrosion preventionFats/resins/pitch/waxes removal in pulpFiberPaper production

A composition controlling deposition of an organic contaminant during pulp and paper making. Active ingredients thereof comprise: 1) a bio-enzyme having a perhydrolysis function; and ii) hydrogen peroxide and / or a precursor enabling generation of hydrogen peroxide. The part-by-weight ratio of i) to ii) in the composition is 1 : 0.1-200. Also provided is a paper making method in which the composition is added to a paper-making fiber slurry to control deposition of an organic contaminant.

Owner:RISINGSTAR BIOTECH GUANGZHOU

A kind of pulping process of high wet strength napkin

ActiveCN110004771BHigh strengthFully absorb water and swellPulp deposit formation/corrosion preventionNatural cellulose pulp/paperWet strengthTissue paper

Owner:广东理文卫生用纸有限公司

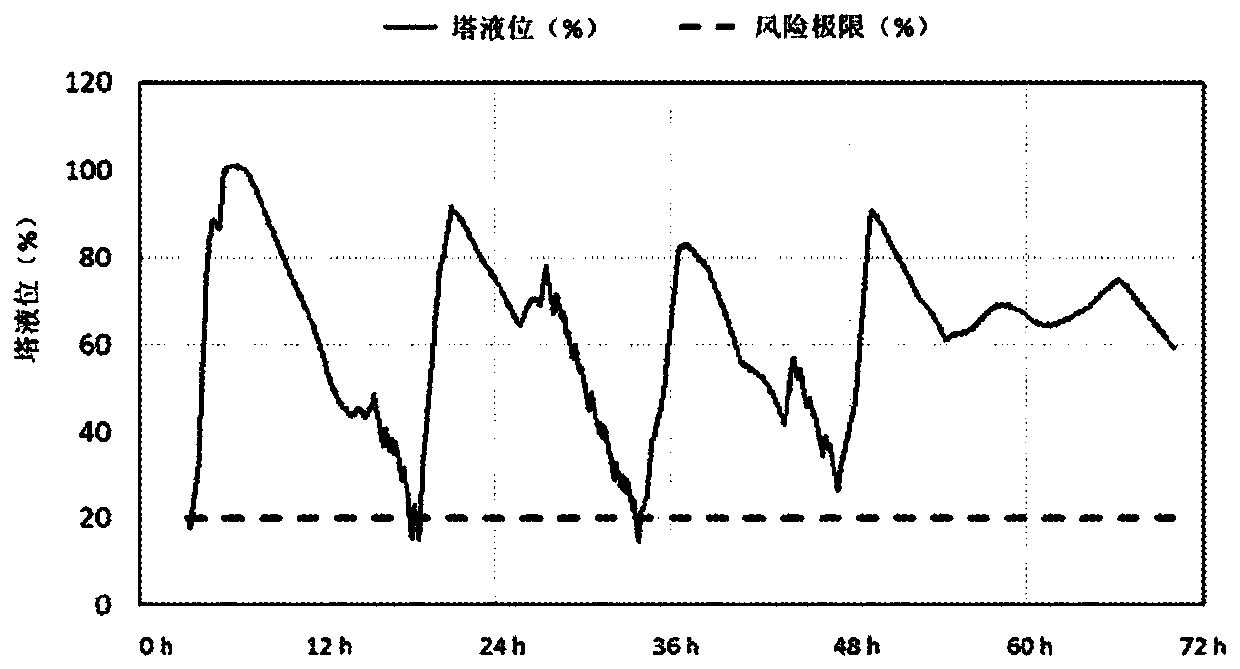

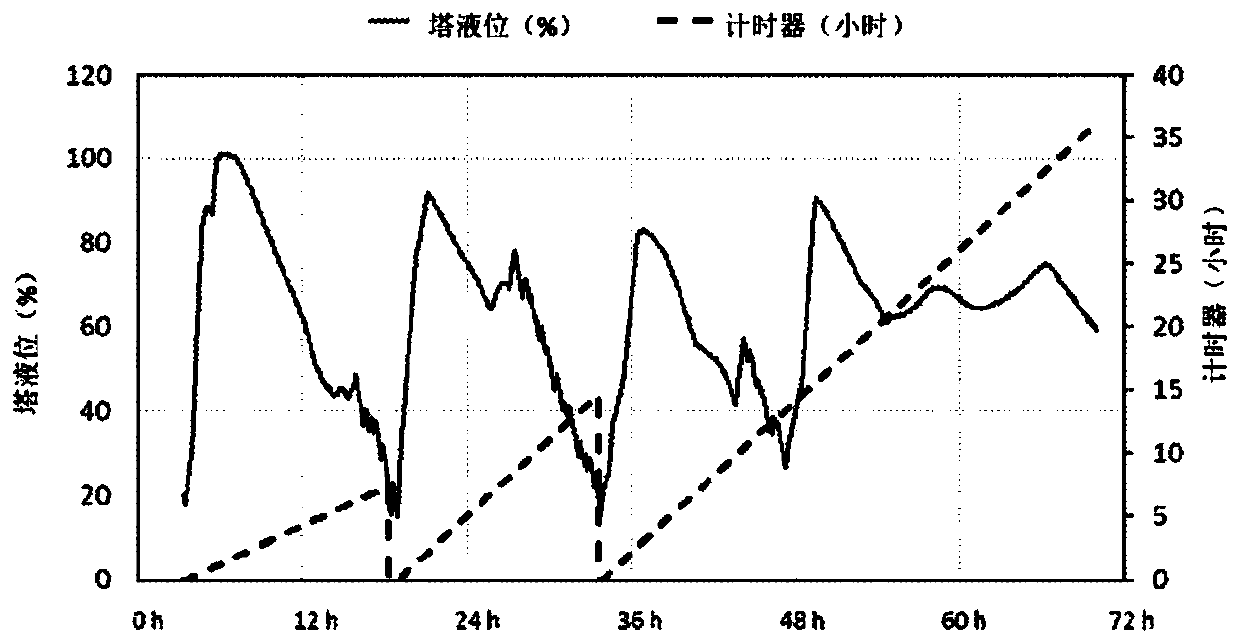

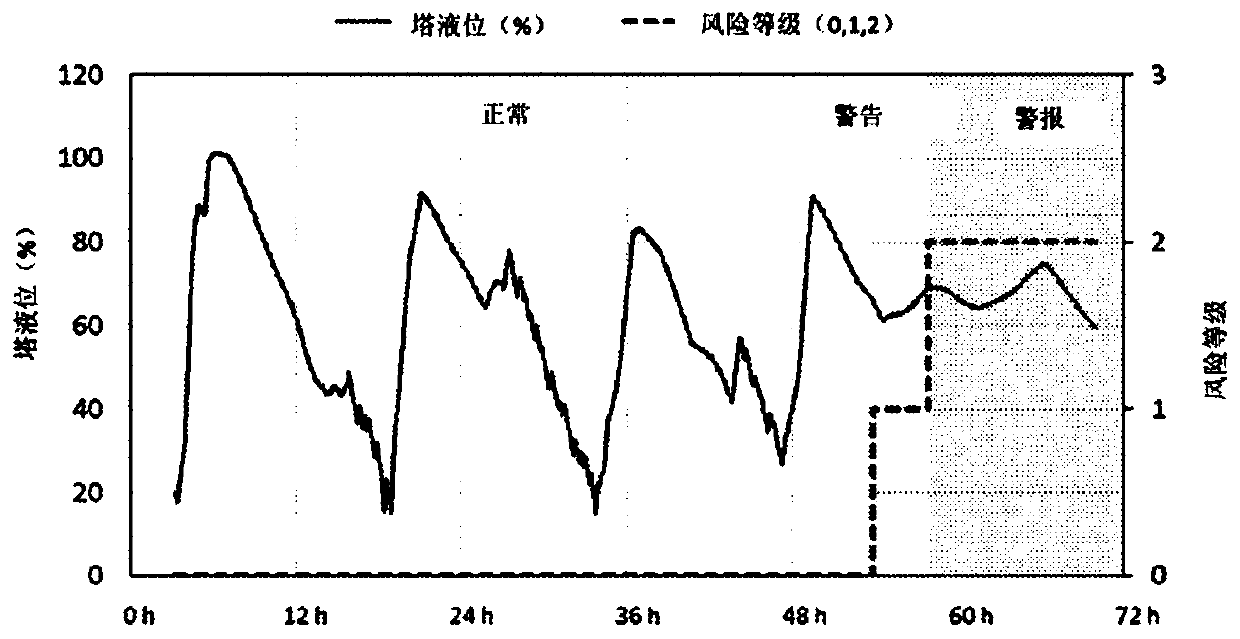

Method for predicting or controlling microbial status of a paper or board making process

ActiveCN111433406APulp deposit formation/corrosion preventionFats/resins/pitch/waxes removal in pulpMicroorganismBiochemical engineering

The present invention relates to a method for predicting the microbial status of a paper or board making process and / or quality of the dry board or paper obtained from said process and to a method forcontrolling microbial status of a paper or board making process or quality of the dry board or paper obtained from said process. Surface level and duration of time in at least one storage tower or pulper are monitored and correlated with respective predetermined values for said tower or pulper in order to predict the risk of microbial activity.

Owner:KEMIRA OY

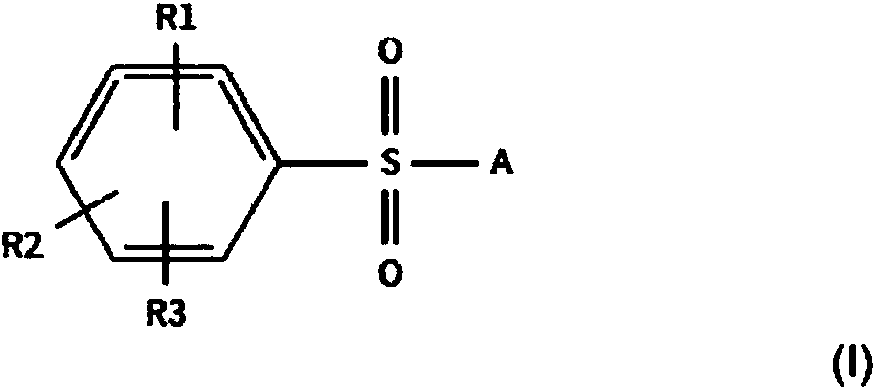

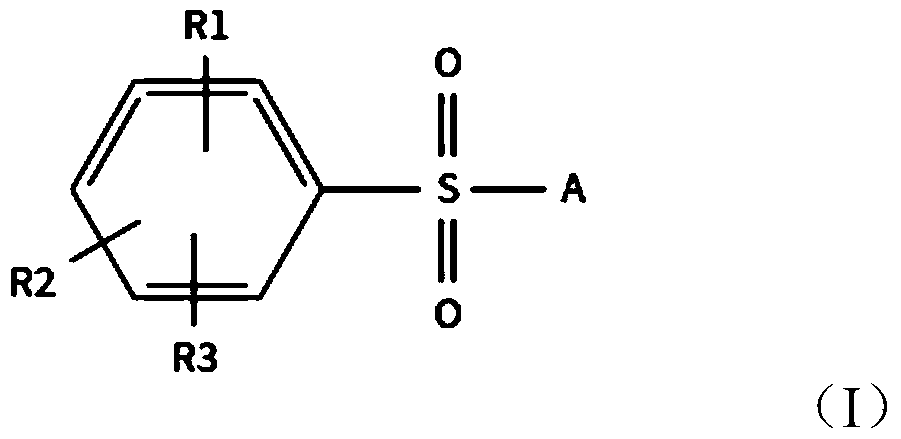

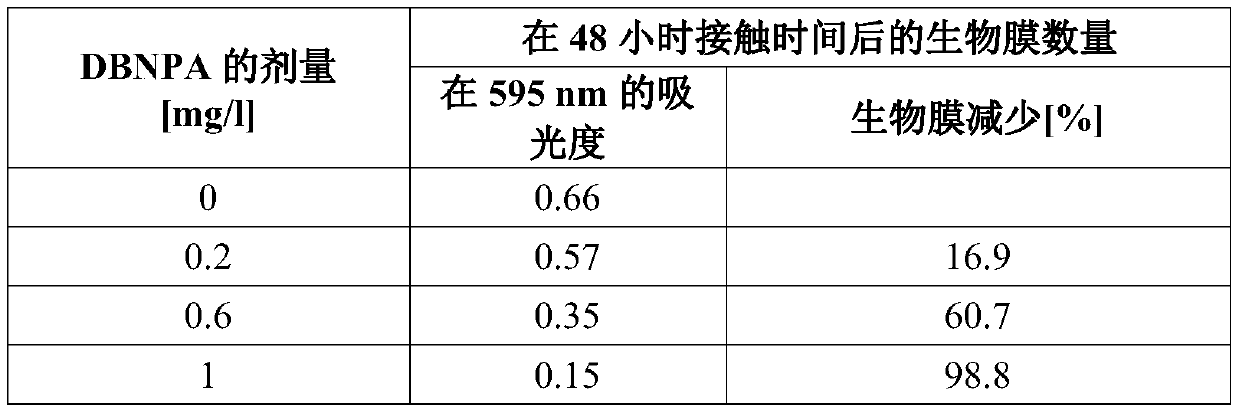

Method for controlling growth of microorganisms and/or biofilms in an industrial process

ActiveCN111051609AEffective controlInhibit growthPulp deposit formation/corrosion preventionNon-macromolecular organic additionBiotechnologyPhenylsulfonamide

The invention relates to a method for controlling of a biofilm, for removing of a formed biofilm and / or for controlling a growth of microorganisms, preferably bacteria, in an aqueous environment of anindustrial manufacturing processcomprising cellulosic fibre material. A compound according to Formula I is administered to the aqueous environment of the process, in which Formula I R1, R2 and R3 independently represent a hydrogen atom; halogen atom; hydroxy group; amino group; alkylamino group, alkyl group, hydroxyalkyl group, haloalkyl group or alkoxy group having 1 to 4 carbon atoms; or an acylamido group having 1 to 10 carbon atoms; and A represents 2-thiazolamine; 2-propenenitrile; 2-propenoic acid; alkyl ester or hydroxyalkyl ester of 2-propenoic acid having 1 to 4 carbon atoms; or -CHCHCONR5R6 group, where R5 and R6 represent independently hydrogen atom, alkyl or hydroxyalkyl having 1 to 4 carbon atoms, with the proviso that the compound according to Formula I is not 3-[(4-methylphenyl)sulphonyl]-2-propenenitrile or 4-amino-N-2-thiazolyl-benzene-sulphonamide.

Owner:KEMIRA OY

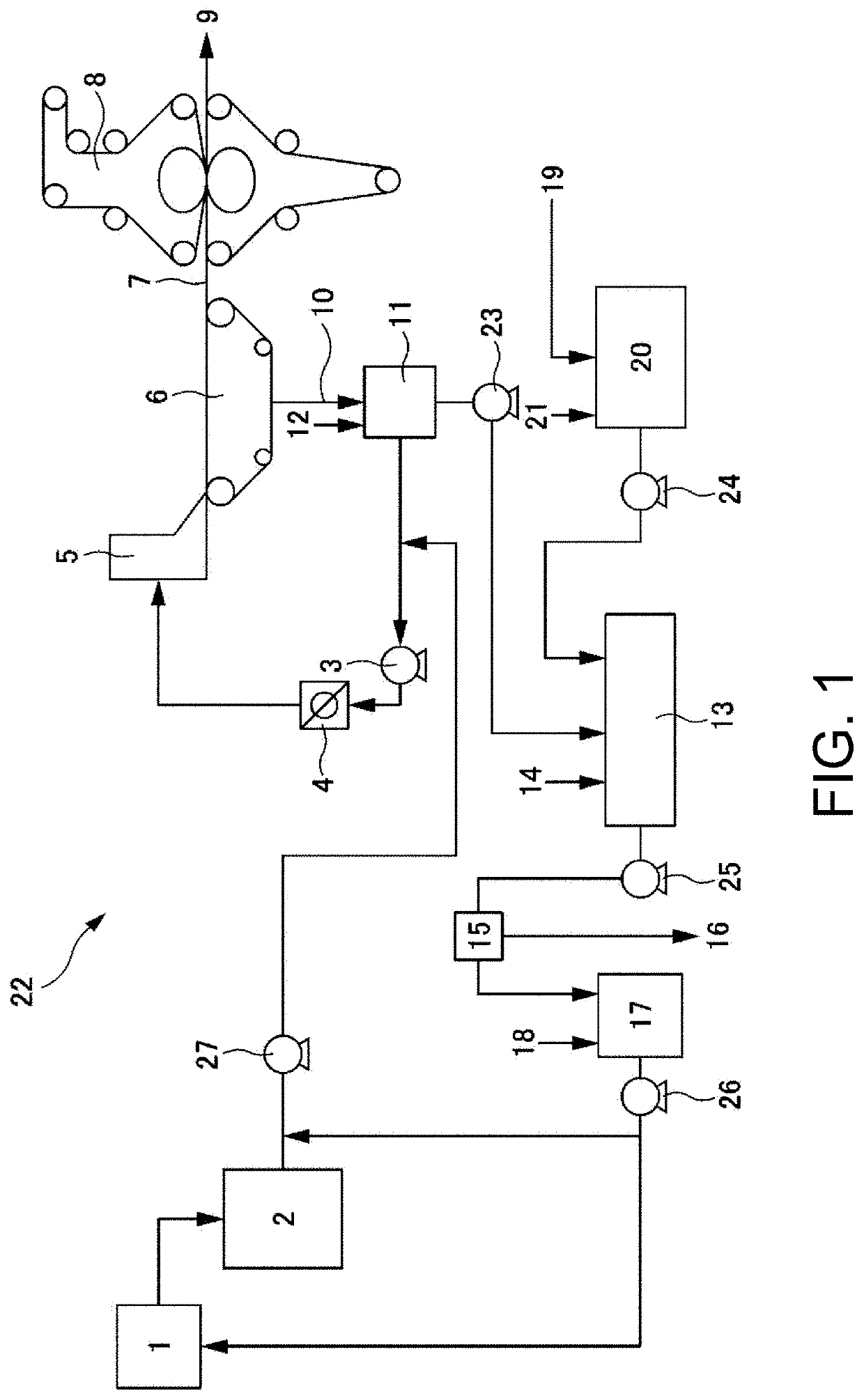

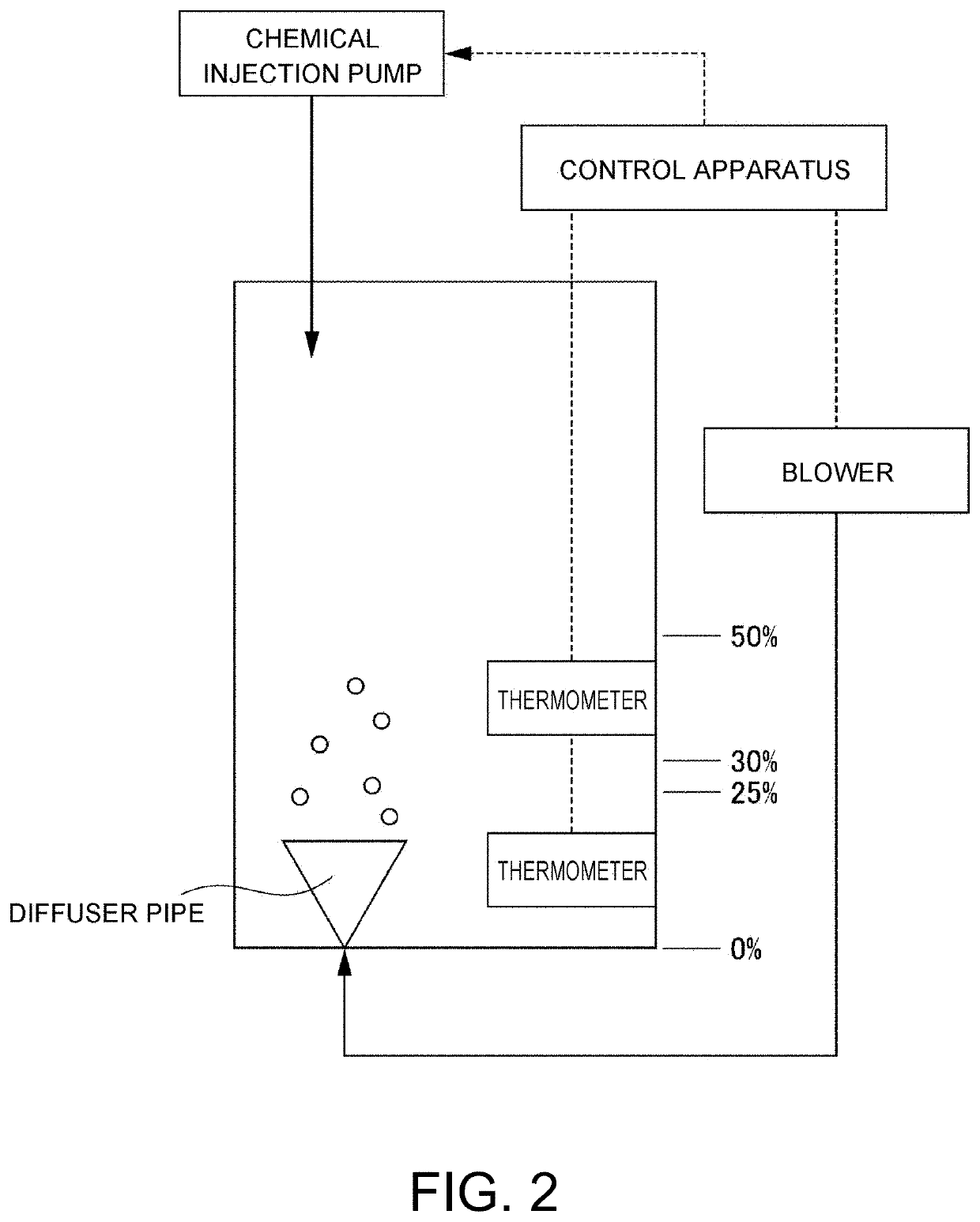

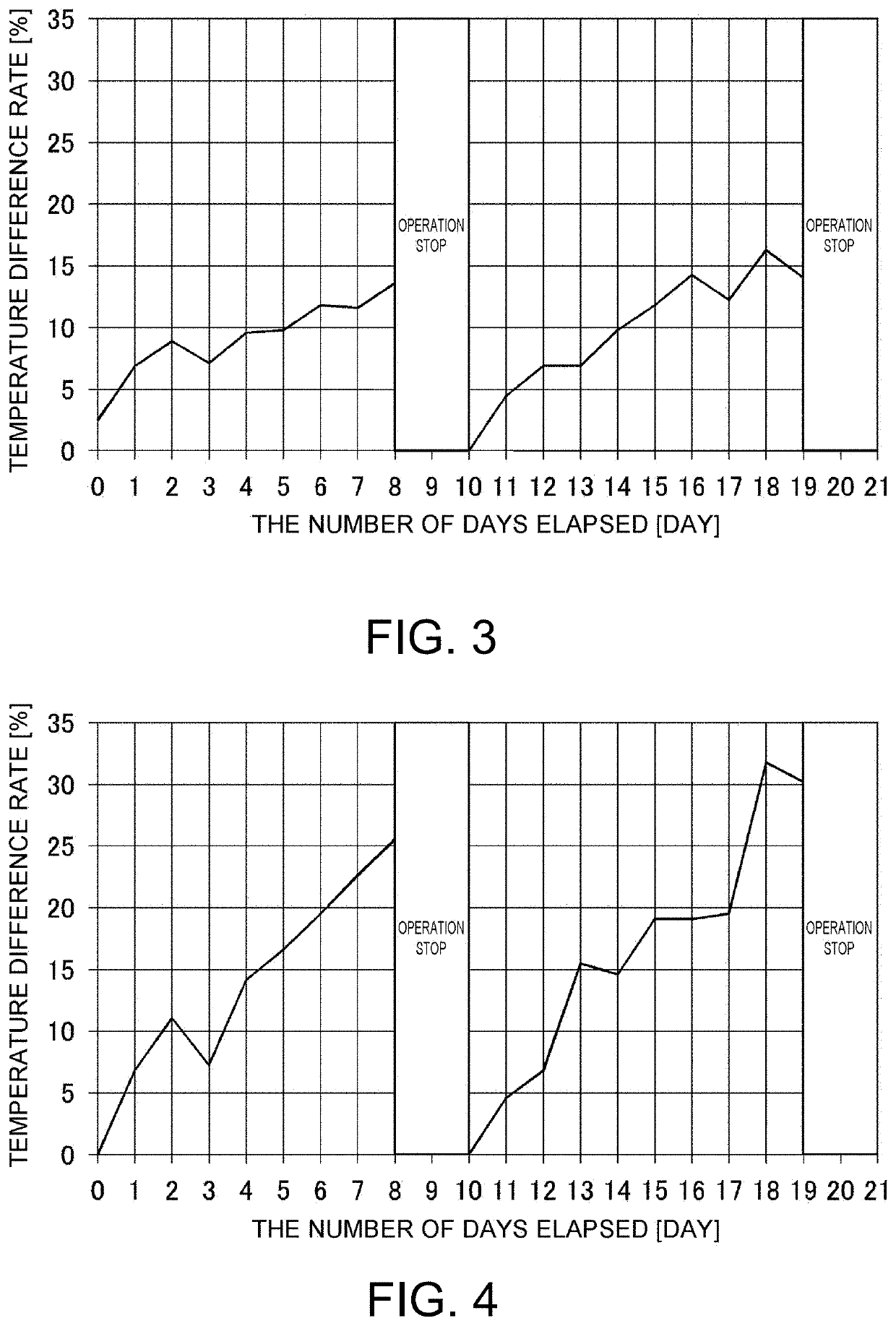

Method for suppressing sedimentation of suspended substance, method for suppressing pitch trouble, and method for detecting sedimentation of suspended substance

PendingUS20220325473A1Reduce productionSuppressing pitch troubleTreatment using aerobic processesBiological treatment regulationEnvironmental engineeringSuspended matter

Owner:KURITA WATER INDUSTRIES LTD

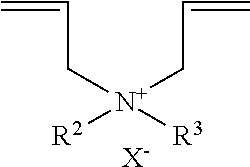

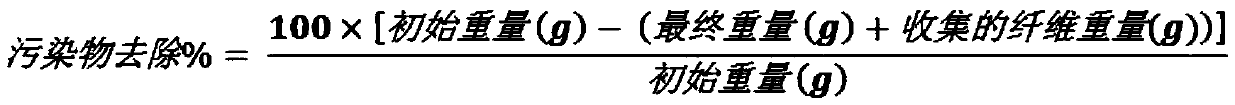

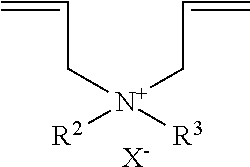

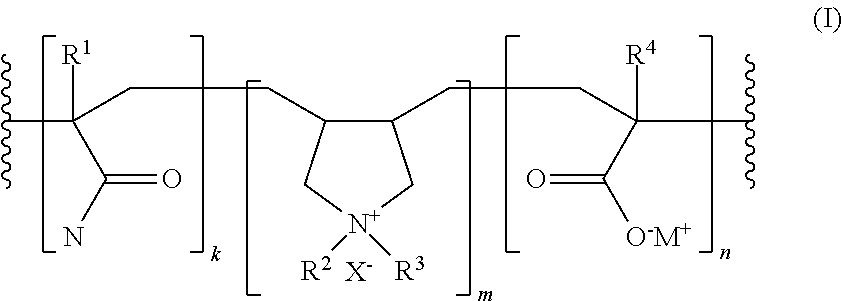

Pitch-controlling agent and pitch-controlling method

ActiveUS10240295B2Improve controllabilityPulp deposit formation/corrosion preventionNon-fibrous pulp additionMeth-Controllability

Disclosed is a pitch control agent including a (meth)acrylamide-based amphoteric polymer. The (meth)acrylamide-based amphoteric polymer contains 50 mol % or more of (meth)acrylamide, 0.5 to 20 mol % of a diallyldialkylammonium salt; and 0.1 to 14 mol % of an anionic monomer, as copolymerizable monomer components. This pitch control agent is less likely to be affected by a change in a surrounding environment, and therefore can exhibit excellent pitch controllability under various environments in paper production process.

Owner:HARIMA CHEM INC

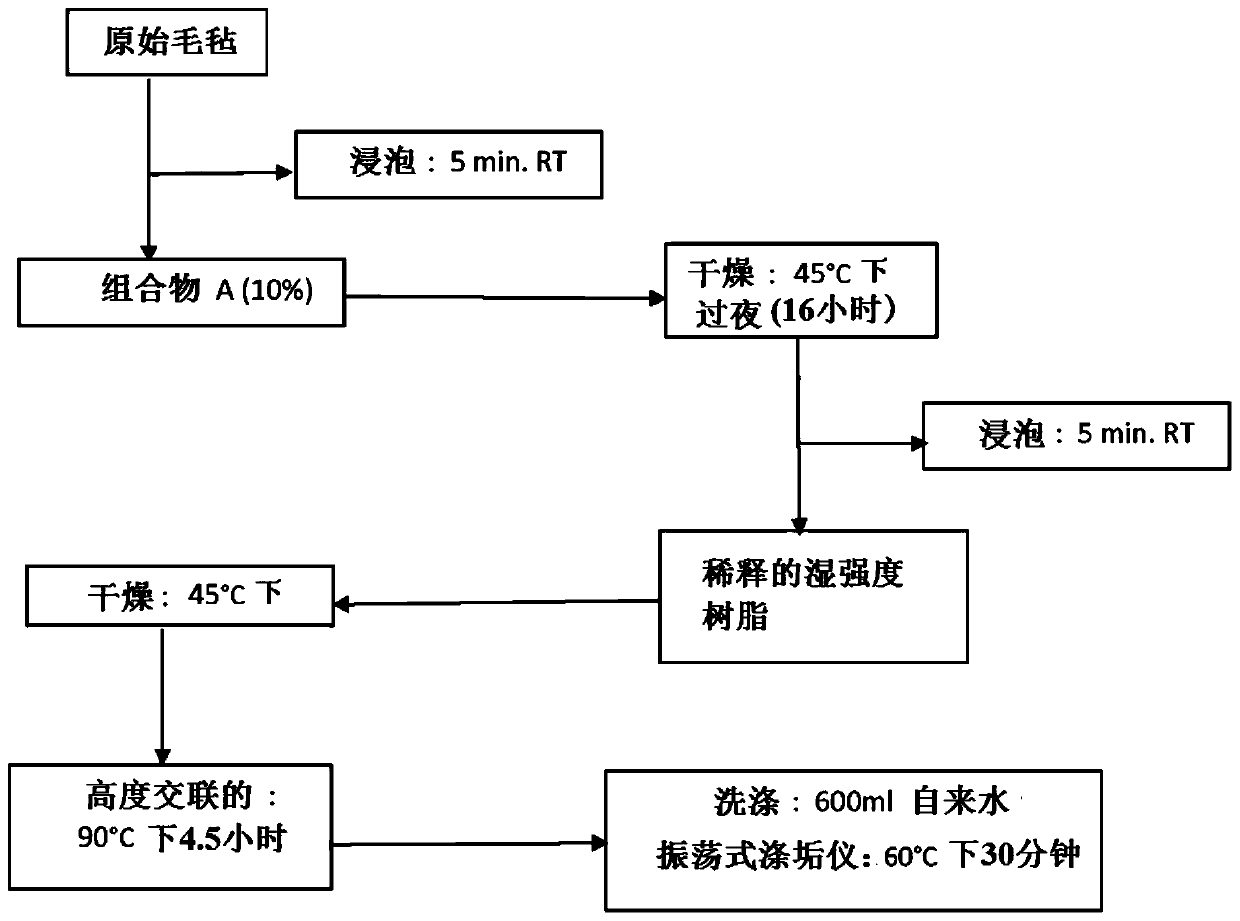

Composition, its use and method for removing and preventing wet strength resins from contaminating papermaking equipment

ActiveCN110785524AImprove cleaning efficiencyEasy to cleanPulp deposit formation/corrosion preventionReinforcing agents additionOrganic acidPtru catalyst

Compositions and methods for cleaning wet strength resin contamination from papermaking equipment and / or for preventing wet strength resins from contaminating papermaking equipment using the compositions are disclosed. The compositions comprise an aqueous solution of a weak organic acid; a surfactant, preferably a nonionic surfactant, a divalent metal ion containing catalyst and optionally a glycol ether containing solvent.

Owner:KEMIRA OY

Methods for controlling the growth of microorganisms and/or biofilms in industrial processes

ActiveCN111051609BEffective controlInhibit growthPulp deposit formation/corrosion preventionNon-macromolecular organic additionPhenylsulfonamideBiofilm growth

The present invention relates to a method for controlling biofilms to remove biofilms formed and / or to control the growth of microorganisms, preferably bacteria, in aqueous environments of industrial production processes comprising cellulosic fibrous material. Applying a compound according to formula I to the aqueous environment of the process, wherein R1, R2 and R3 of formula I independently represent a hydrogen atom; a halogen atom; a hydroxyl group; an amino group; or an amide group having 1 to 10 carbon atoms; and A represents 2-thiazolamine; 2-acrylonitrile; 2-acrylic acid; having 1 to 4 carbon atoms 2-Alkyl or hydroxyalkyl esters of acrylic acid; or -CHCHCONR5R6 groups, wherein R5 and R6 independently represent a hydrogen atom, an alkyl or hydroxyalkyl group having 1 to 4 carbon atoms, provided that a group according to formula I The compound is not 3-[(4-methylphenyl)sulfonyl]-2-acrylonitrile or 4-amino-N-2-thiazolyl-benzene-sulfonamide.

Owner:KEMIRA OY

Compositions for inhibiting calcium salt scaling

ActiveCN102428040BPulp deposit formation/corrosion preventionFats/resins/pitch/waxes removal in pulpPolymer scienceChemical pulp

A method for inhibiting the formation, deposition and adhesion of calcium salt scale on metal surfaces or other surfaces of equipment, vessels and / or pipelines in a chemical pulping plant comprising adding an effective scale inhibiting amount of a composition to the in the alkaline aqueous mixture in the digester of the chemical pulping process described above. Said composition consists of at least one phosphonate component (I) and at least one component (II) consisting of at least one carboxylated fructan compound.

Owner:伊塔尔麦奇化学股份公司

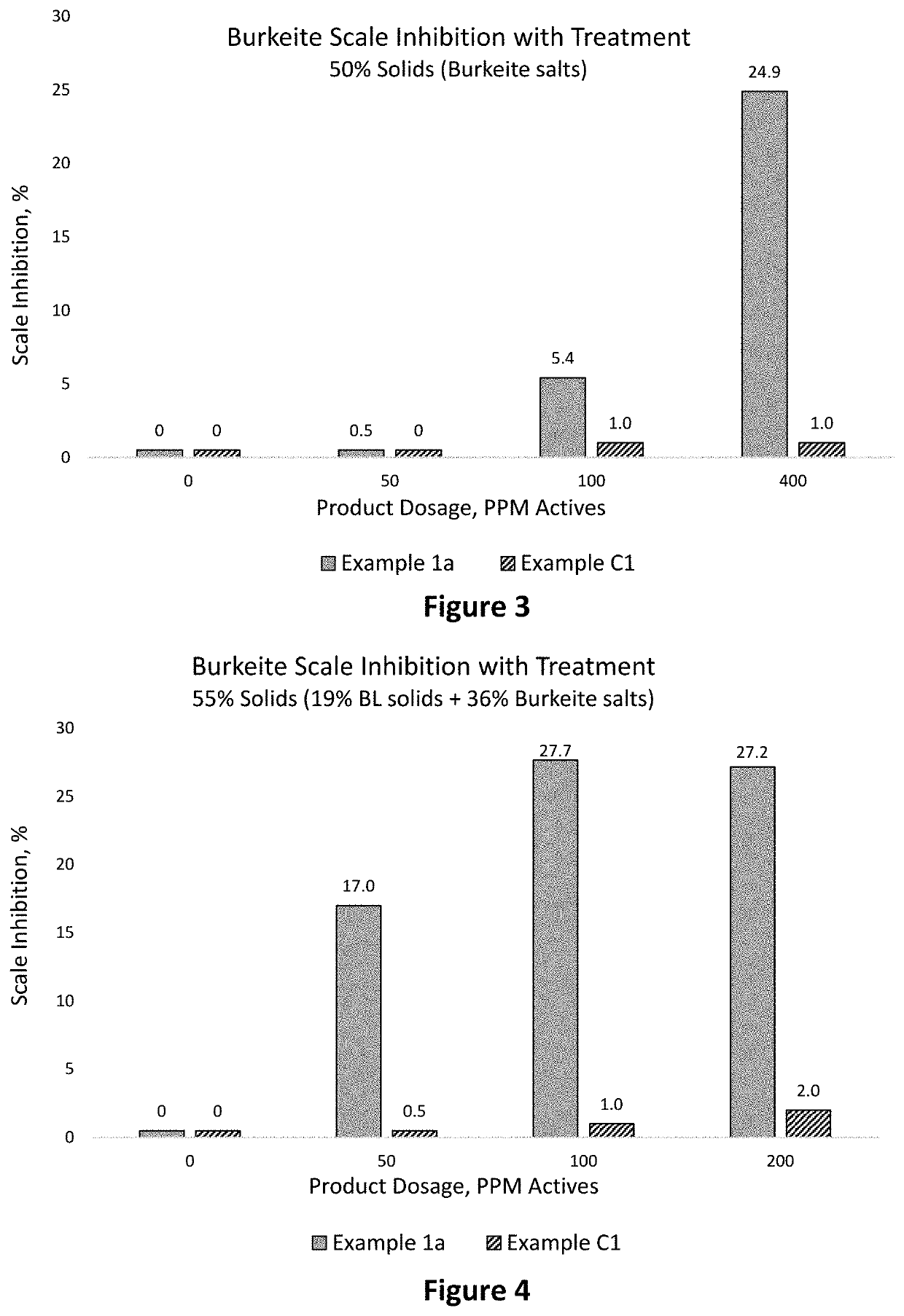

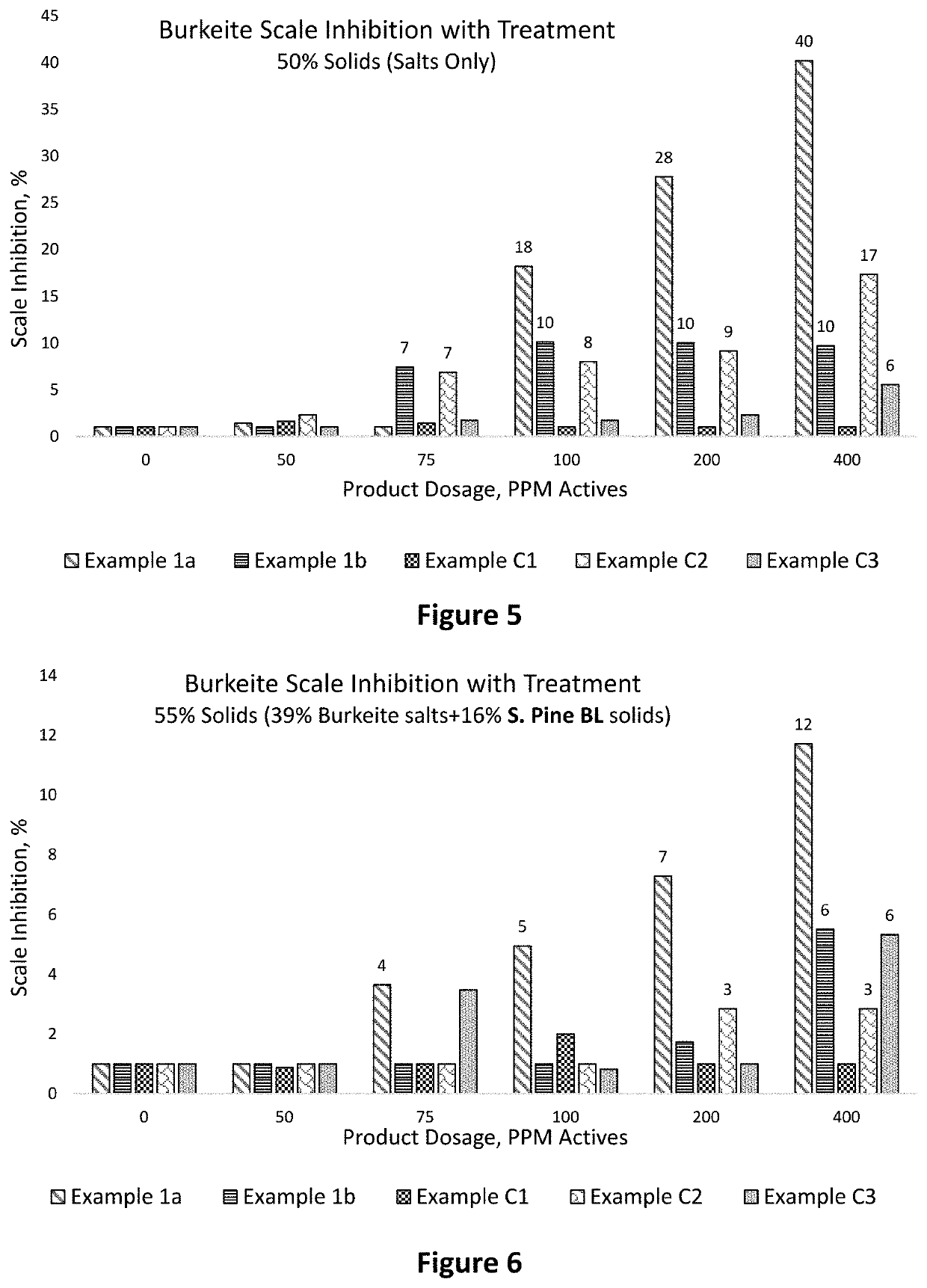

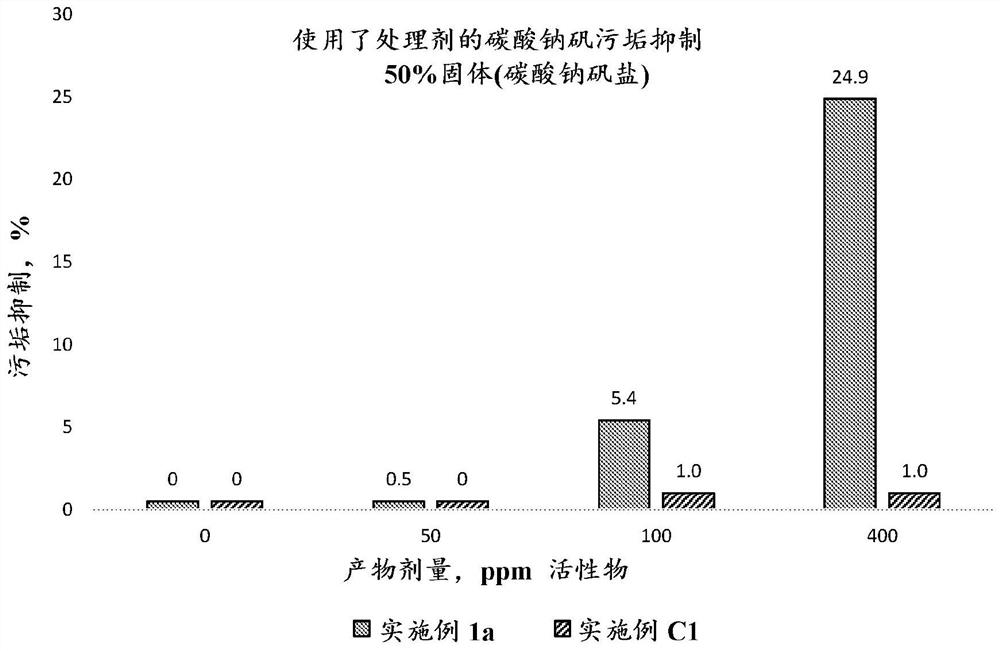

Kraft pulp mill scale control with end group modified polycarboxylates

PendingUS20210002826A1Inhibition formationAvoid concentrationPulp deposit formation/corrosion preventionPulping with inorganic basesPropanoic acidBlack liquor

Scale build-up on metal surfaces of a black liquor evaporator is prevented or mitigated by treating the black liquor with a deposit inhibiting concentration of a water-soluble polymer containing a polycarboxylate chain and a 3-mercaptopropionic acid end group.

Owner:SOLENIS TECH CAYMAN

Pitch-controlling agent and pitch-controlling method

ActiveUS20180230652A1Improve controllabilityPulp deposit formation/corrosion preventionNon-fibrous pulp additionPaper productionControllability

Disclosed is a pitch control agent including a (meth)acrylamide-based amphoteric polymer. The (meth)acrylamide-based amphoteric polymer contains 50 mol % or more of (meth)acrylamide, 0.5 to 20 mol % of a diallyldialkylammonium salt; and 0.1 to 14 mol % of an anionic monomer, as copolymerizable monomer components. This pitch control agent is less likely to be affected by a change in a surrounding environment, and therefore can exhibit excellent pitch controllability under various environments in paper production process.

Owner:HARIMA CHEM INC

Method for controlling growth of microorganisms and/or biofilms in an industrial process

ActiveUS11490621B2Effective controlPrevent and inhibit and reduce biofilm growthPulp deposit formation/corrosion preventionBiocideBiotechnologyPhenylsulfonamide

Disclosed is a method for controlling a biofilm, for removing a formed biofilm and / or for controlling a growth of microorganisms, preferably bacteria, in an aqueous environment of an industrial manufacturing process including cellulosic fibre material. In the method, a composition including a compound selected from a group consisting of 3-[(4-methylphenyl)sulphonyl]-2-propenenitrile and 4-amino-N-2-thiazolyl-benzenesulphonamide is administered to the aqueous environment of the process.

Owner:KEMIRA OY +1

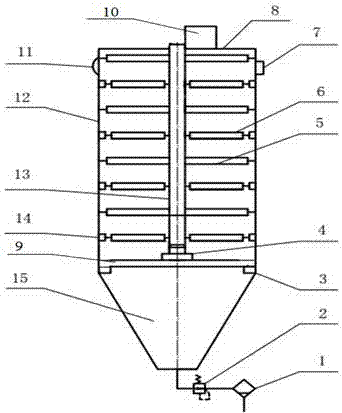

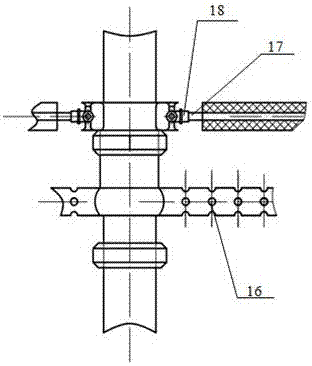

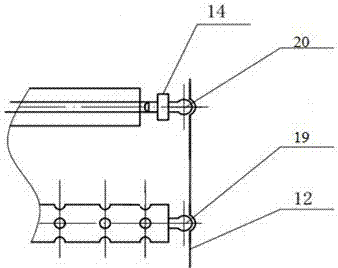

Ozone bleaching device

ActiveCN107489052AShort processReduce energy consumptionPulp deposit formation/corrosion preventionPulp de-wateringPulp and paper industryOperability

The invention discloses an ozone bleaching device. The ozone bleaching device comprises a pulp draining machine, a pressure adjusting valve, an annular bearing table, a motor I, center pipe branch pipes, pulp hanging net films, a liquid level sensor, a constant pressure pump, an infrared moisture meter, a box body, a center pipe, a motor II, a pulp accumulating conical pond, and a universal shaft coupler. The ozone bleaching device disclosed by the invention integrates technologies of pulp hanging, pulp dehydrating, ozone bleaching, pulp washing and the like, so that technological processes are greatly shortened, and the production cost is reduced; the ozone bleaching device is simple in structure, high in operability, and good in bleaching effect; and through the adoption of the ozone bleaching device disclosed by the invention, the pulp with the maximum surface area can be obtained, and the pulp can be in sufficient contact with ozone, so that the bleaching efficiency is improved; and the ozone bleaching device disclosed by the invention is simple, economical, high-efficiency and energy-saving.

Owner:KUNMING UNIV OF SCI & TECH

Method for scale removal during a lignocellulosic conversion process

ActiveUS8882925B2Improve the level ofImprove economyPulp deposit formation/corrosion preventionFats/resins/pitch/waxes removal in pulpProcess equipmentHemicellulose

A method for processing of a lignocellulosic feedstock is provided comprising exposing lignocellulosic feedstock to acid in a reactor to hydrolyze at least hemicellulose present in said lignocellulosic feedstock, wherein during said exposing, a scale deposit comprising lignin forms on the inner surface of said reactor; and treating the scale deposit with an alkali solution at a temperature between about 140° C. and about 250° C. so as to remove scale. Also provided is a method for reducing scale deposit that forms on process equipment during a stage of reacting a lignocellulosic feedstock with acid.

Owner:IOGEN ENERGY CORP

Kraft pulp mill scale control with end group modified polycarboxylates

PendingCN114096712AGraphical fouling inhibitionPulp deposit formation/corrosion preventionPulp liquor regenerationPropanoic acidBlack liquor

Scale build-up on metal surfaces of a black liquor evaporator is prevented or mitigated by treating the black liquor with a deposit inhibiting concentration of a water-soluble polymer containing a polycarboxylate chain and a 3-mercaptopropionic acid end group.

Owner:SOLENIS TECH CAYMAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Hydrophobically modifed poly[ethylene glycol] for use in pitch and stickies control in pulp and papermaking processes Hydrophobically modifed poly[ethylene glycol] for use in pitch and stickies control in pulp and papermaking processes](https://images-eureka.patsnap.com/patent_img/c5d257b6-c3d5-432d-bcef-4aadb8aff200/US20080029231A1-20080207-C00001.png)

![Hydrophobically modifed poly[ethylene glycol] for use in pitch and stickies control in pulp and papermaking processes Hydrophobically modifed poly[ethylene glycol] for use in pitch and stickies control in pulp and papermaking processes](https://images-eureka.patsnap.com/patent_img/c5d257b6-c3d5-432d-bcef-4aadb8aff200/US20080029231A1-20080207-C00002.png)

![Hydrophobically modifed poly[ethylene glycol] for use in pitch and stickies control in pulp and papermaking processes Hydrophobically modifed poly[ethylene glycol] for use in pitch and stickies control in pulp and papermaking processes](https://images-eureka.patsnap.com/patent_img/c5d257b6-c3d5-432d-bcef-4aadb8aff200/US20080029231A1-20080207-C00003.png)

![Hydrophobically modifed poly[ethylene glycol] for use in pitch and stickies control in pulp and papermaking processes Hydrophobically modifed poly[ethylene glycol] for use in pitch and stickies control in pulp and papermaking processes](https://images-eureka.patsnap.com/patent_img/56d2b279-cba9-48b3-a0db-38840c467bae/US08388806-20130305-C00001.png)

![Hydrophobically modifed poly[ethylene glycol] for use in pitch and stickies control in pulp and papermaking processes Hydrophobically modifed poly[ethylene glycol] for use in pitch and stickies control in pulp and papermaking processes](https://images-eureka.patsnap.com/patent_img/56d2b279-cba9-48b3-a0db-38840c467bae/US08388806-20130305-C00002.png)

![Hydrophobically modifed poly[ethylene glycol] for use in pitch and stickies control in pulp and papermaking processes Hydrophobically modifed poly[ethylene glycol] for use in pitch and stickies control in pulp and papermaking processes](https://images-eureka.patsnap.com/patent_img/56d2b279-cba9-48b3-a0db-38840c467bae/US08388806-20130305-C00003.png)