Kraft pulp mill scale control with end group modified polycarboxylates

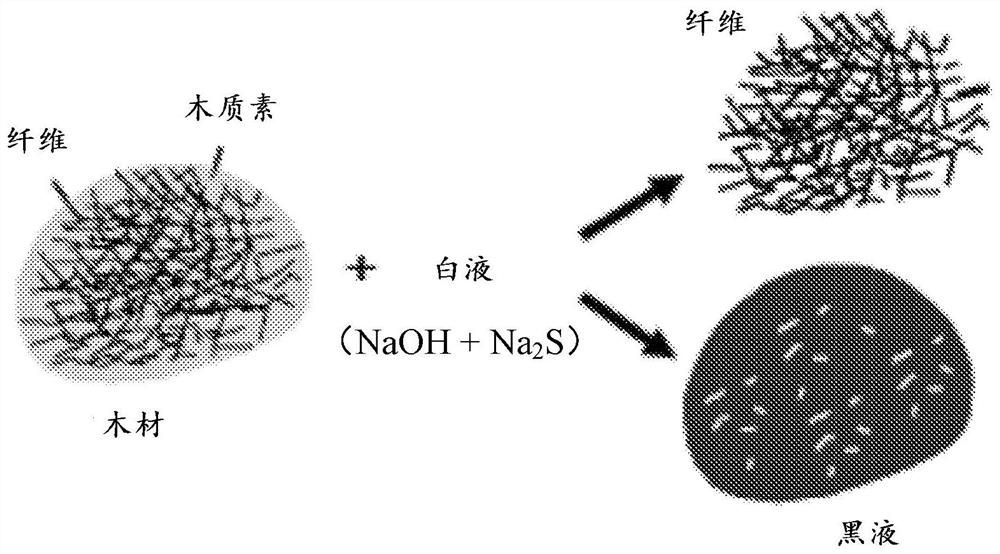

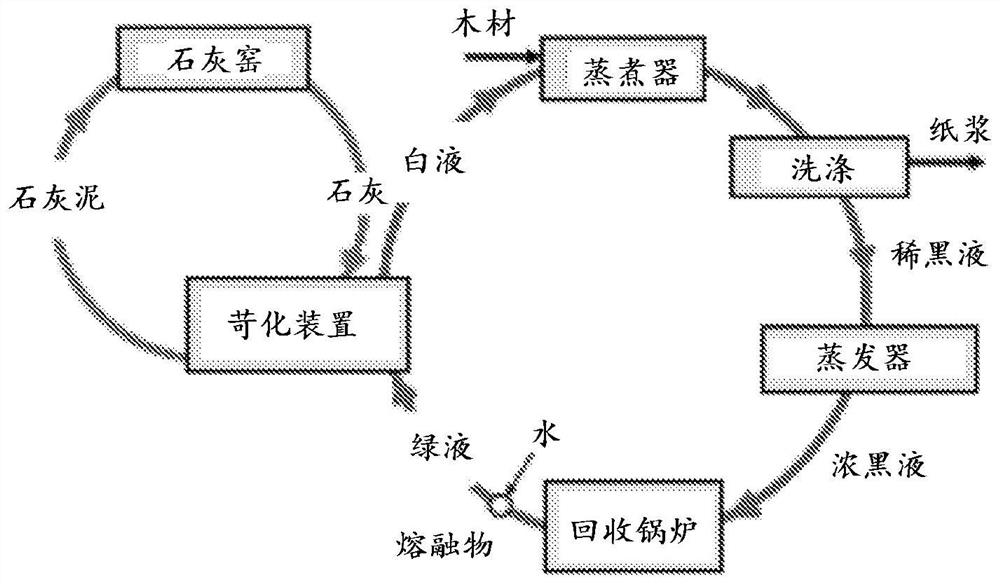

A technology of polycarboxylic acid chains and end groups, which is applied in pulping with inorganic alkali, pulping with organic solvents, papermaking, etc., and can solve the problem of evaporator loss of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

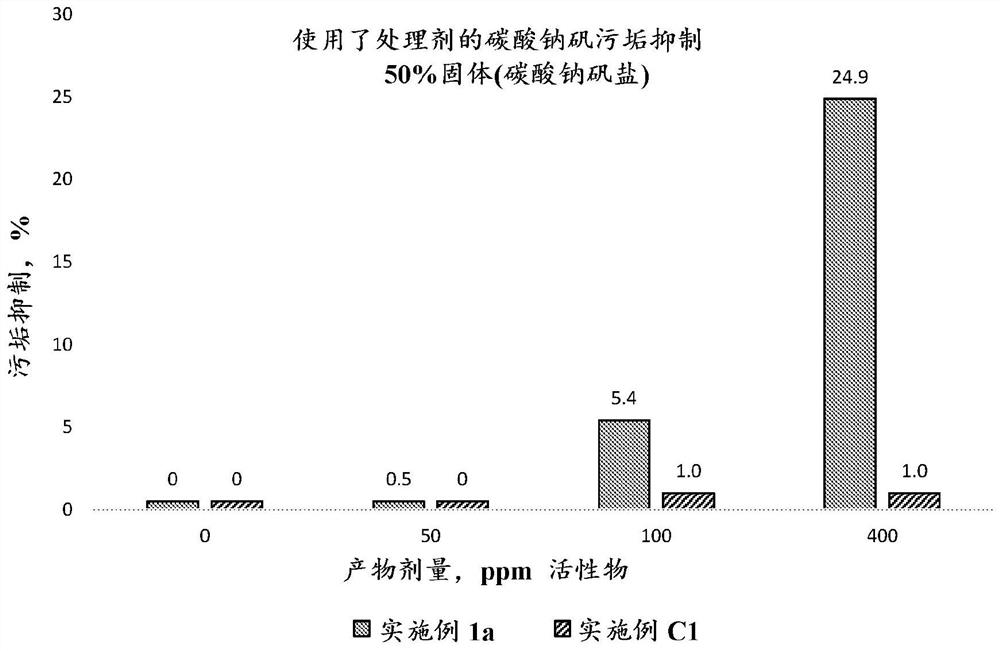

Embodiment C1

[0044] Example C1 - Phosphonate group

[0045] The chelating agent or scale inhibitor in Example C1 is the phosphonate chelating agent DETPMPA, namely diethylenetriaminepenta(methylenephosphonic acid) sodium salt.

Embodiment C2

[0046] Example C2 - Sulfonate group

[0047] The chelating agent of embodiment C2 is polyacrylate prepared using sodium metabisulfite as an initiator. This leaves the sulfonate end groups. Molecular weight is about 2.5 times of the chelating agent molecular weight of embodiment 1a. It is commercially available from Solenis LLC.

Embodiment C3

[0048] Example C3-Hydroxy

[0049] The chelating agent of Example C3 is a polyacrylate prepared using isopropanol as a chain transfer agent, leaving alcohol end groups. The molecular weight is approximately equal to that of the chelating agent of Example 1a. It is commercially available from Lubrizol Corp.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com